Electric-hydraulic reversing energy recovery device

A technology of energy recovery device and electro-hydraulic reversing valve, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, mechanical equipment, etc. It can solve complex valve control system, small processing capacity, increase system operating pressure, etc. problems, to achieve the effects of simplifying the device control system, high energy recovery efficiency, and smooth and fast commutation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

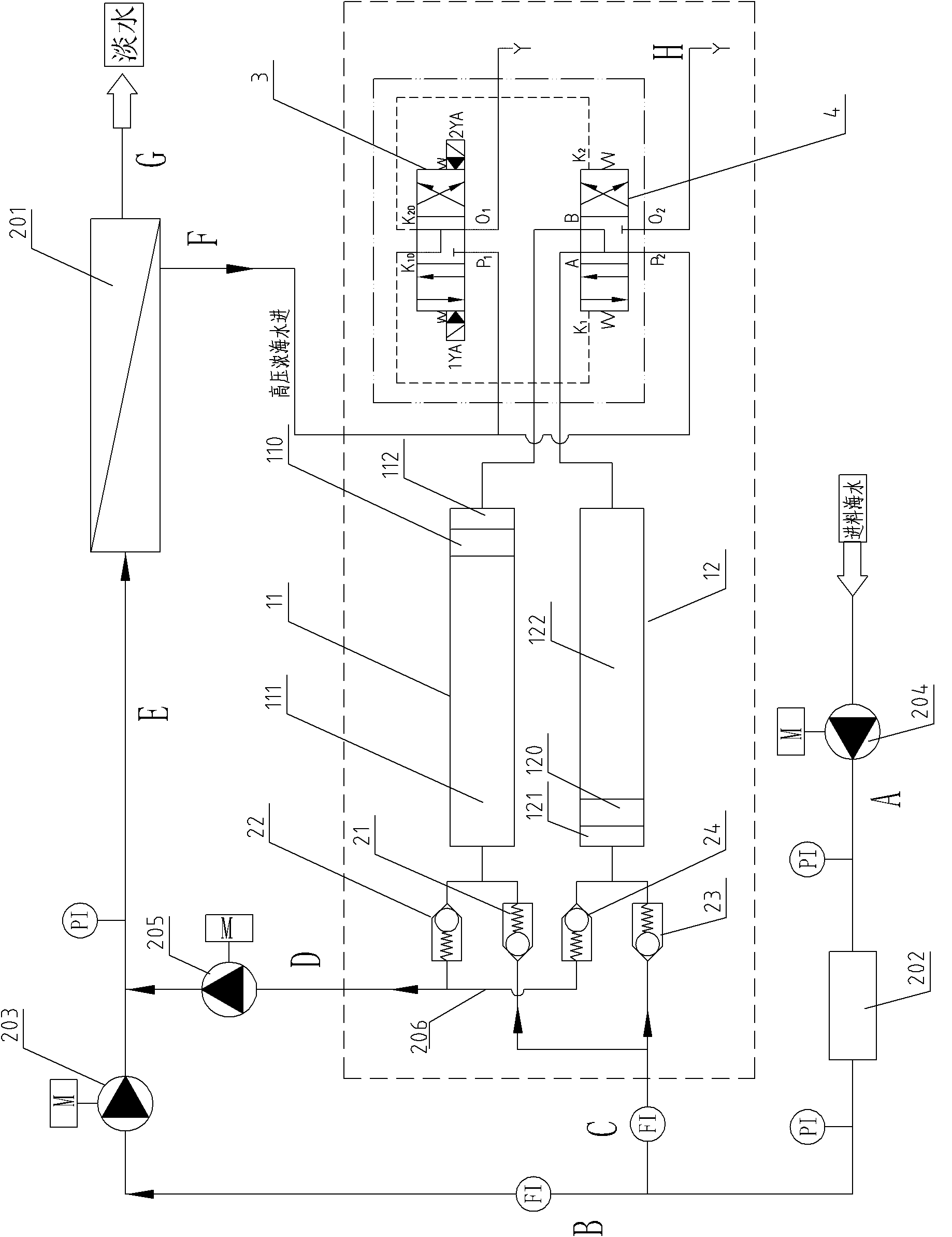

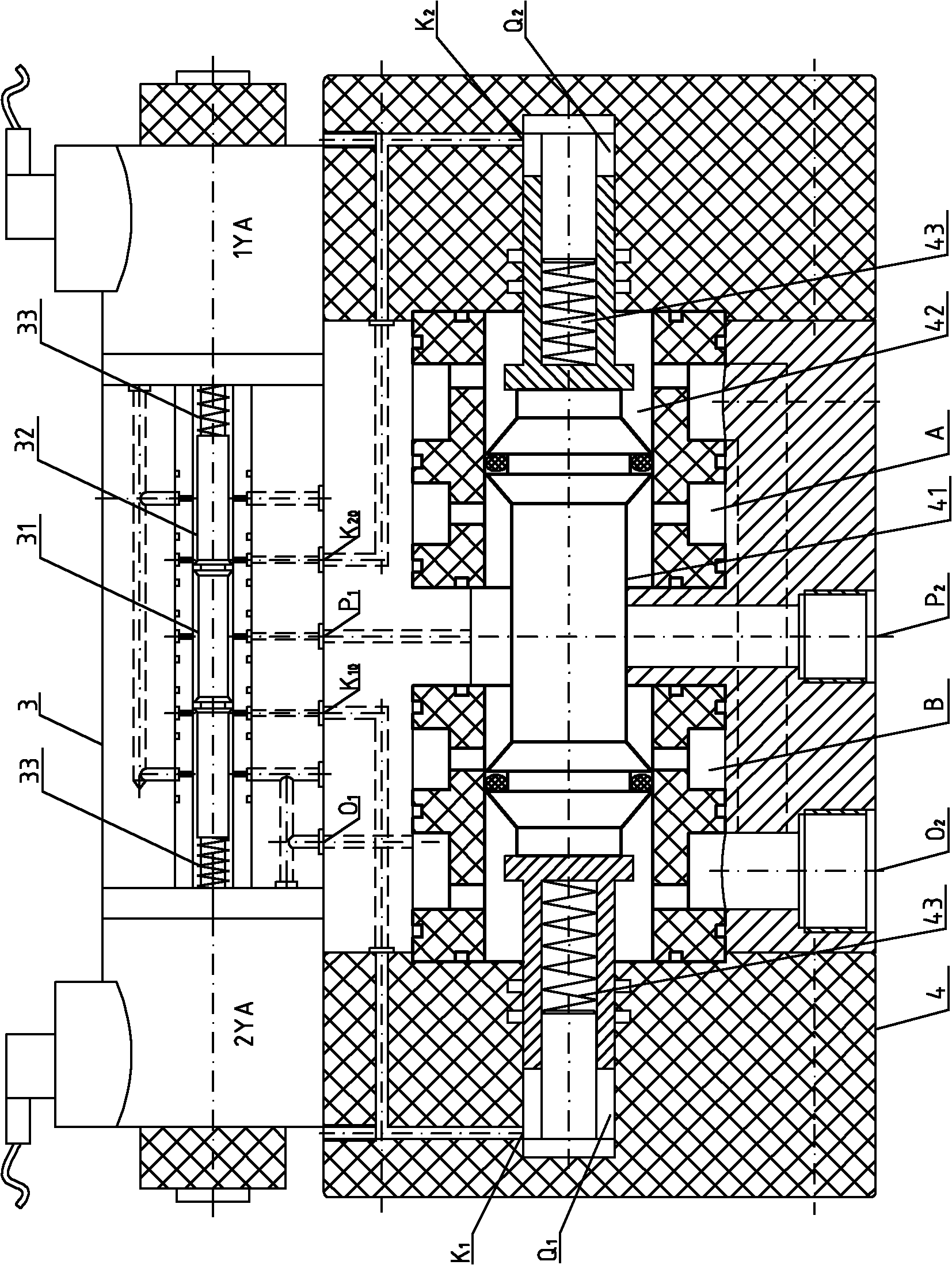

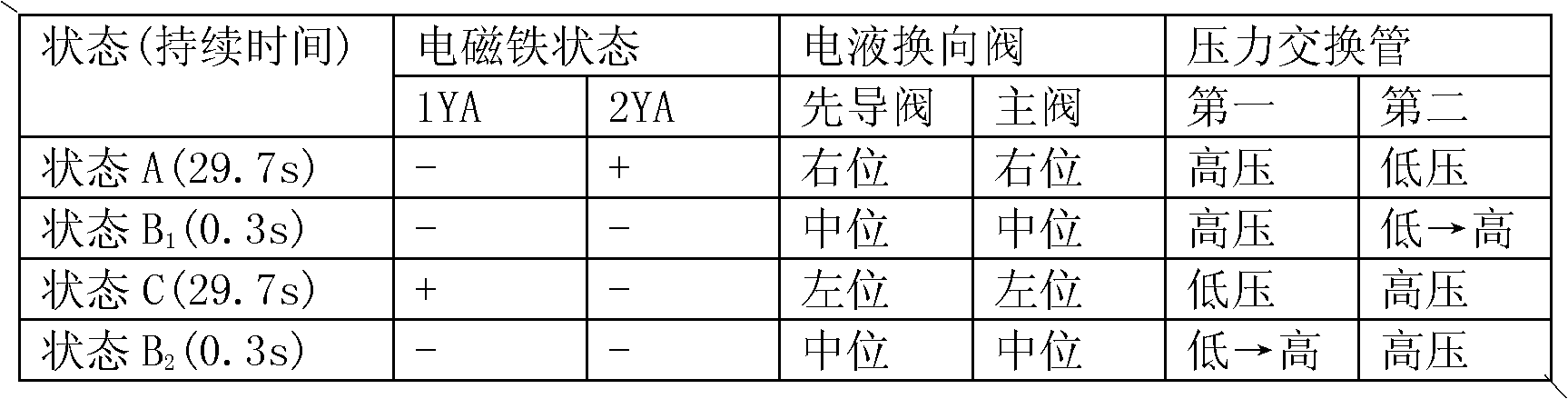

[0024] Refer to attached picture. The present invention includes an electro-hydraulic reversing valve, two pressure exchange pipes 11, 12 and four one-way check valves 21, 22, 23, 24;

[0025] The pressure exchange tube 11 is provided with a free piston 110, which is divided into two working chambers, which are the working chamber 111 of the delivered liquid and the working chamber 112 of the waste liquid; the free piston 120 is provided in the pressure exchange pipe 12, and is divided into Two working chambers, namely the conveyed liquid working chamber 121 and the waste liquid working chamber 122;

[0026] The four one-way check valves are equally divided into two groups. The one-way check valves 21 and 22 form a group that communicates with the delivered liquid working chamber 111 of the pressure exchange pipe 11. The one-way check valve 21 and the one-way check valve The direction of the return valve 22 is opposite, and the one-way check valve 23, 24 is a group that commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com