Patents

Literature

62results about How to "Reduce water hammer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

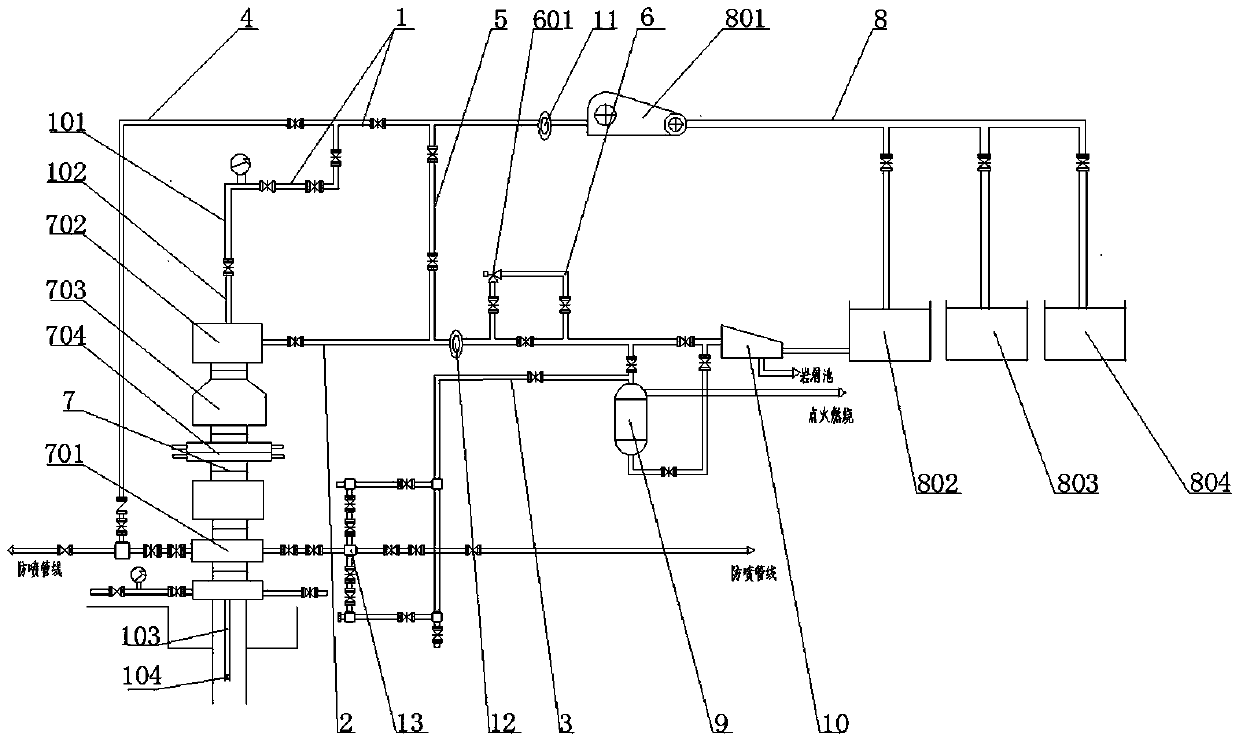

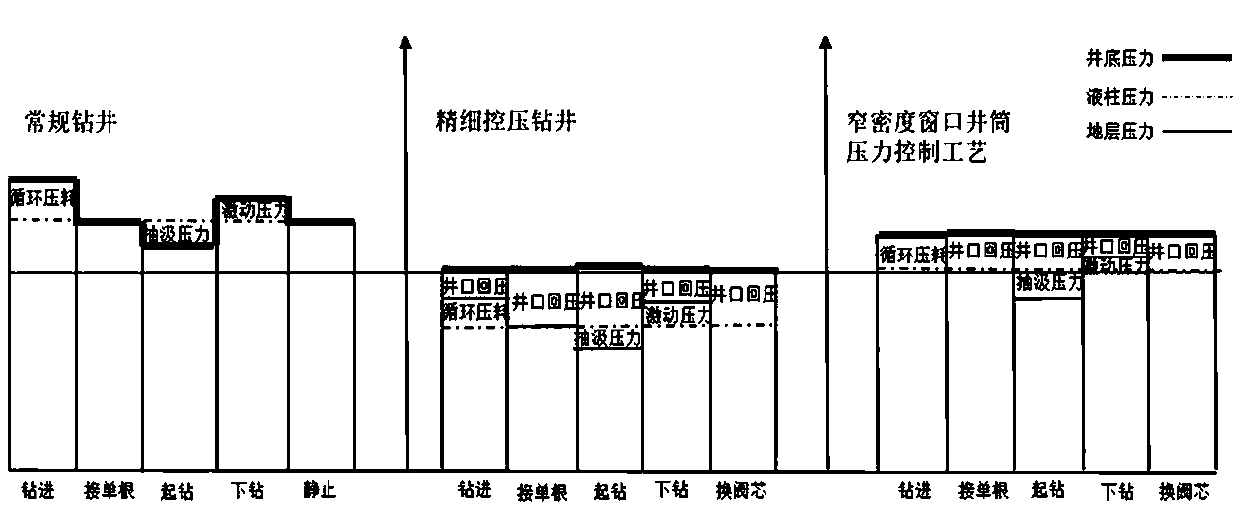

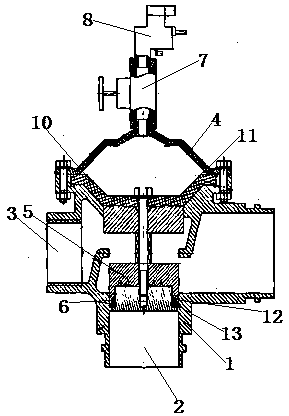

Well drilling pressure control facility and operation method of ultra-deep well

The invention discloses a well drilling pressure control facility and operation method of an ultra-deep well. The well drilling pressure control facility comprises a mud input pipeline, a first mud reversing out pipeline, a second mud reversing out pipeline, a kill line, a back pressure pipeline, a throttle pipeline, and a well control device; the operation method comprises the steps that a normaldrilling mode is conducted, the normal drilling mode is converted to a single root mode, the normal drilling mode is converted to a drilling starting mode, a drilling downward mode and a valve element changing mode; and control equipment eliminates a backpressure pump and other facilities, a throttle pipeline control device is simplified, the facility cost is lowered, the on-site construction process is simplified, and the stress control aspect is safer and more efficient. The well drilling pressure control facility and operation method can decrease the degree of well leakage, the difficultyof plugging is reduced, Chinese oil and gas standards are met, and the safe drilling purpose is achieved.

Owner:SOUTHWEST PETROLEUM UNIV

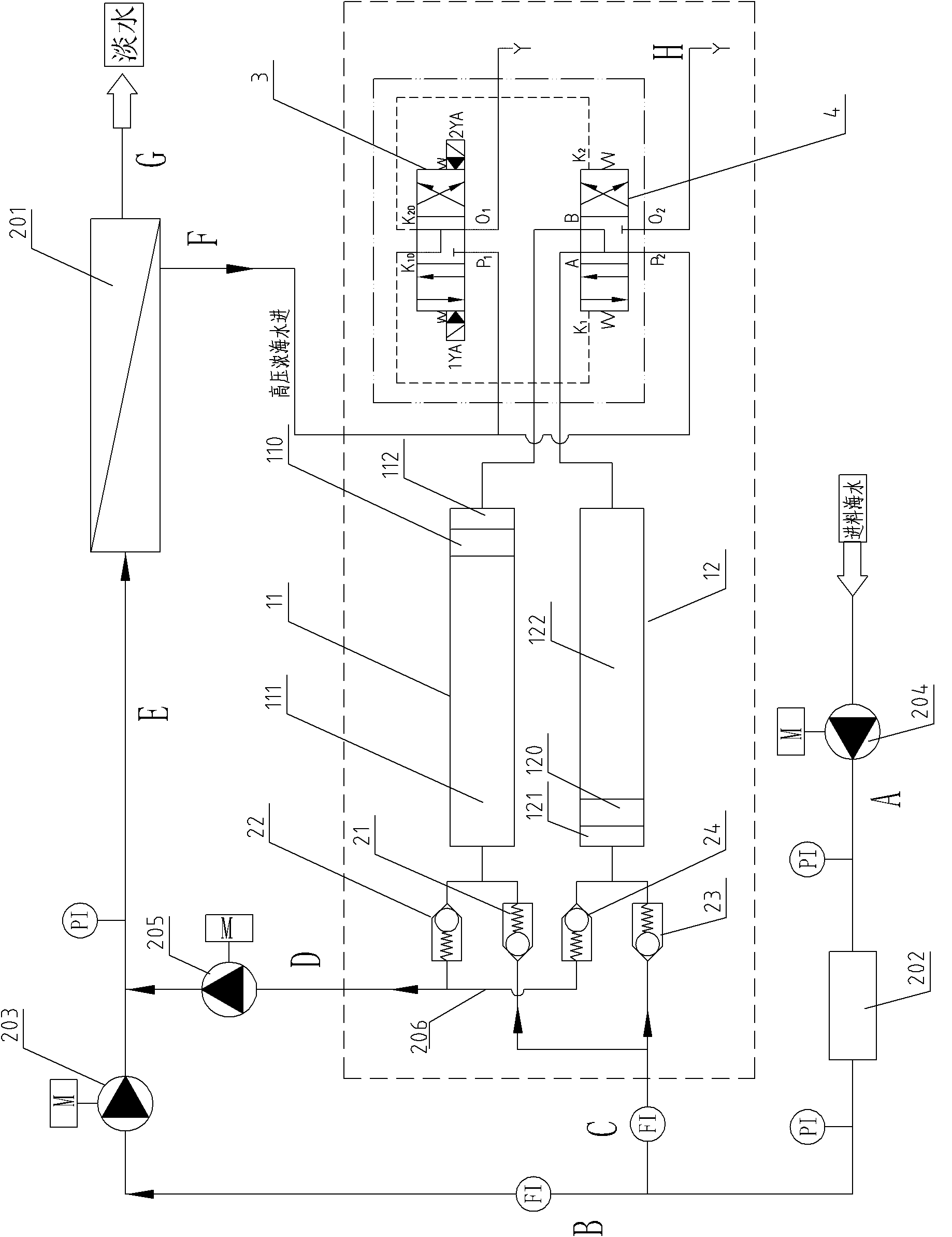

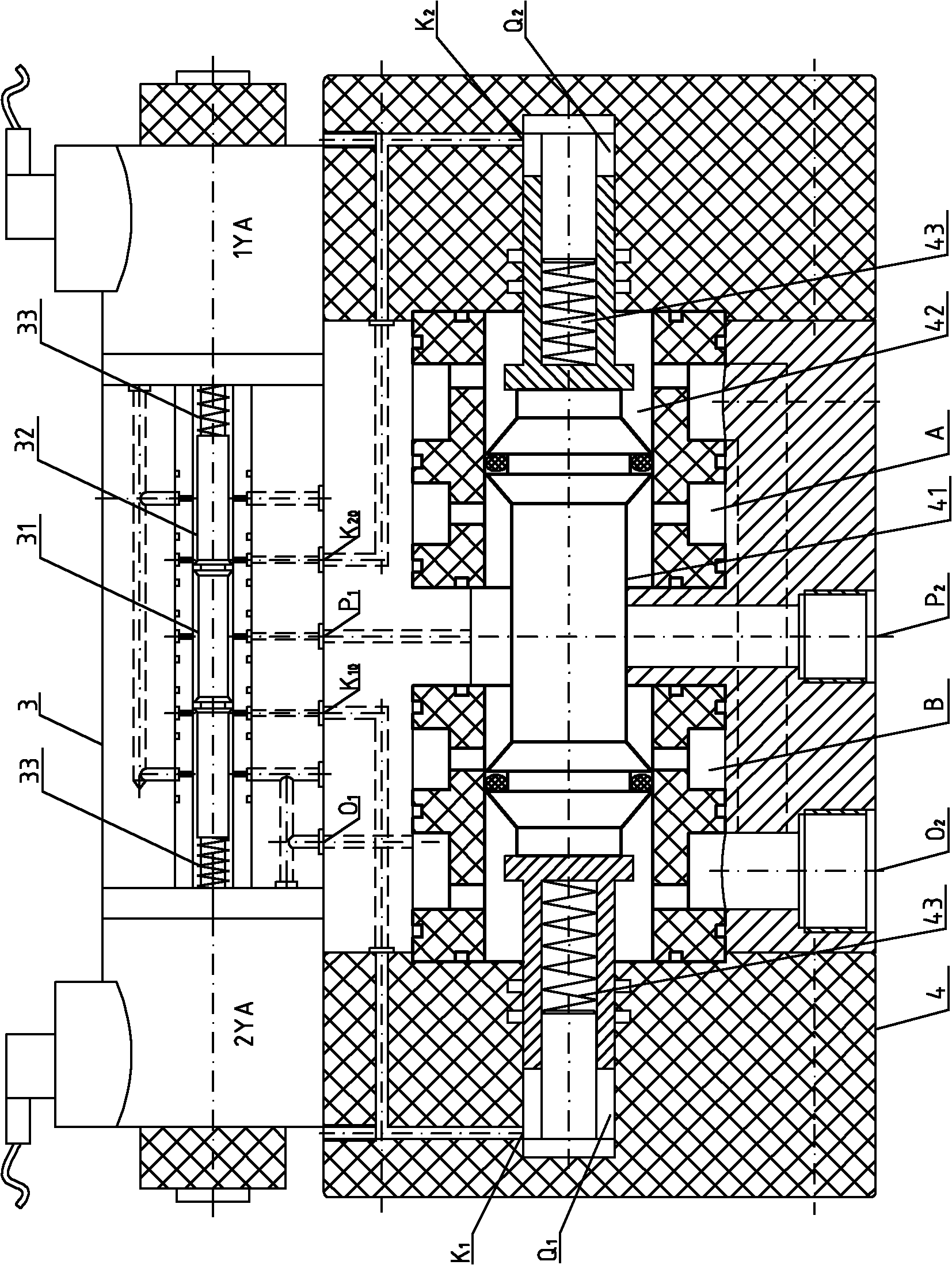

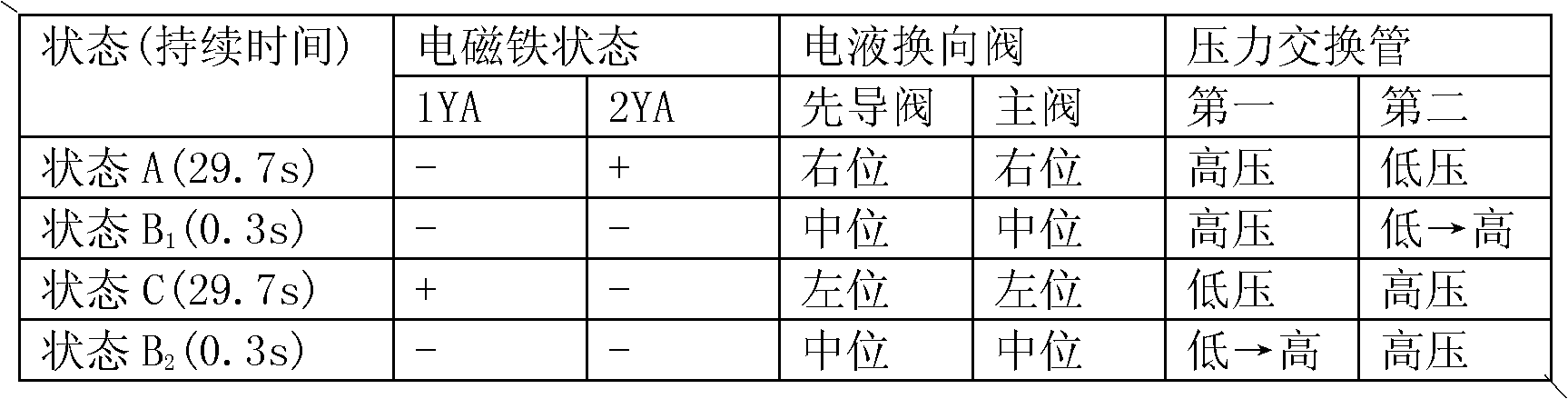

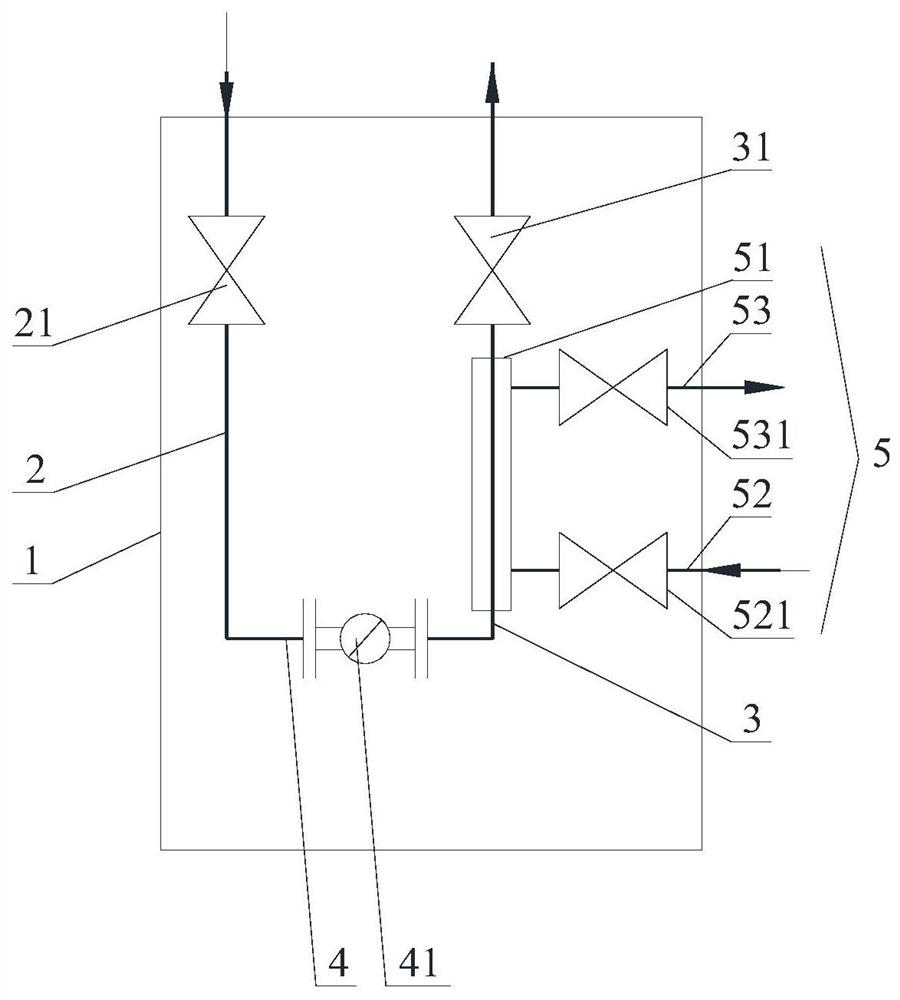

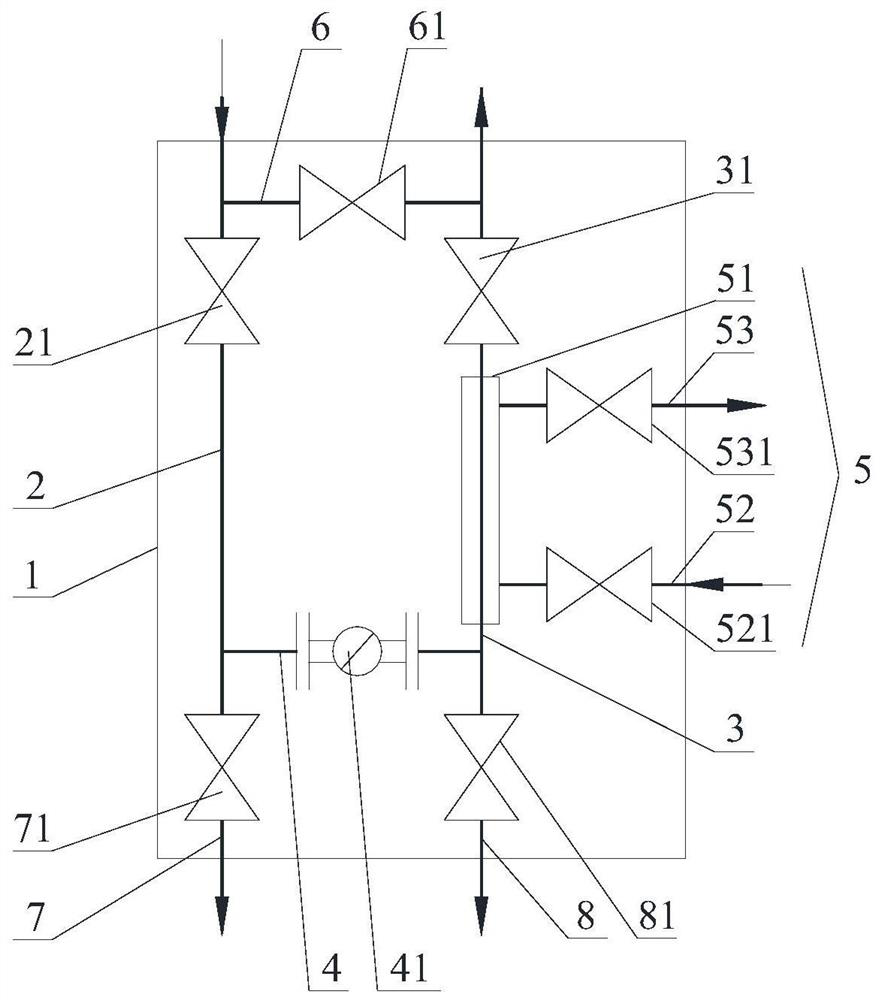

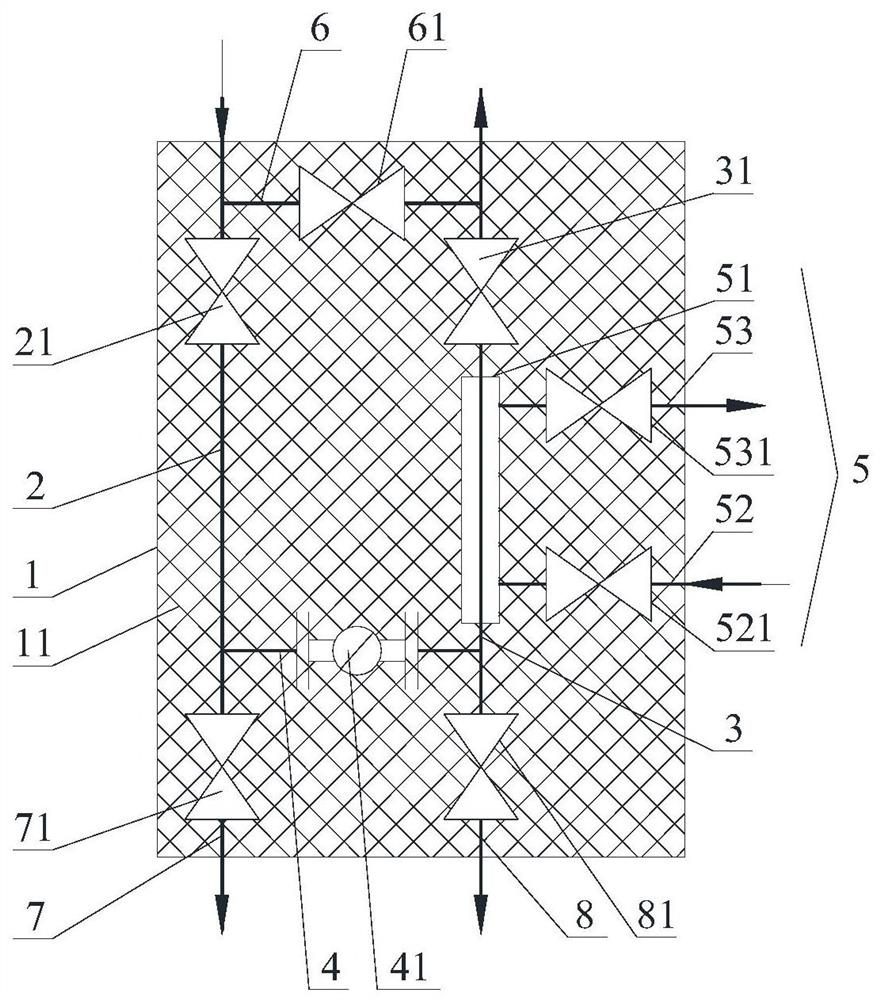

Electric-hydraulic reversing energy recovery device

ActiveCN101985951ALarge thrustEasy to operateFluid-pressure actuator componentsControl systemEngineering

The invention provides an electric-hydraulic reversing energy recovery device, which is simple in control and less in pressure oscillation. The device comprises an electric-hydraulic reversing valve, two pressure exchanging pipes and four unidirectional check valves. A free piston is arranged in each pressure exchanging pipe to divide the pressure exchanging pipe into two working cavities which are a transmitted liquid working cavity and a waste liquid working cavity. The device has the following beneficial effects that because the electric-hydraulic reversing valve is piloted by using a magnetic pilot valve, and the main valve is pushed by the high pressure waste liquid which is manipulated and controlled by the magnetic pilot valve in the system pipeline, the pushing power can be very large, the operation is simple, and the reversing is stable and fast. The electric-hydraulic reversing energy recovery device is suitable for a reverse osmosis desalination system with high pressure and large flow rate.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

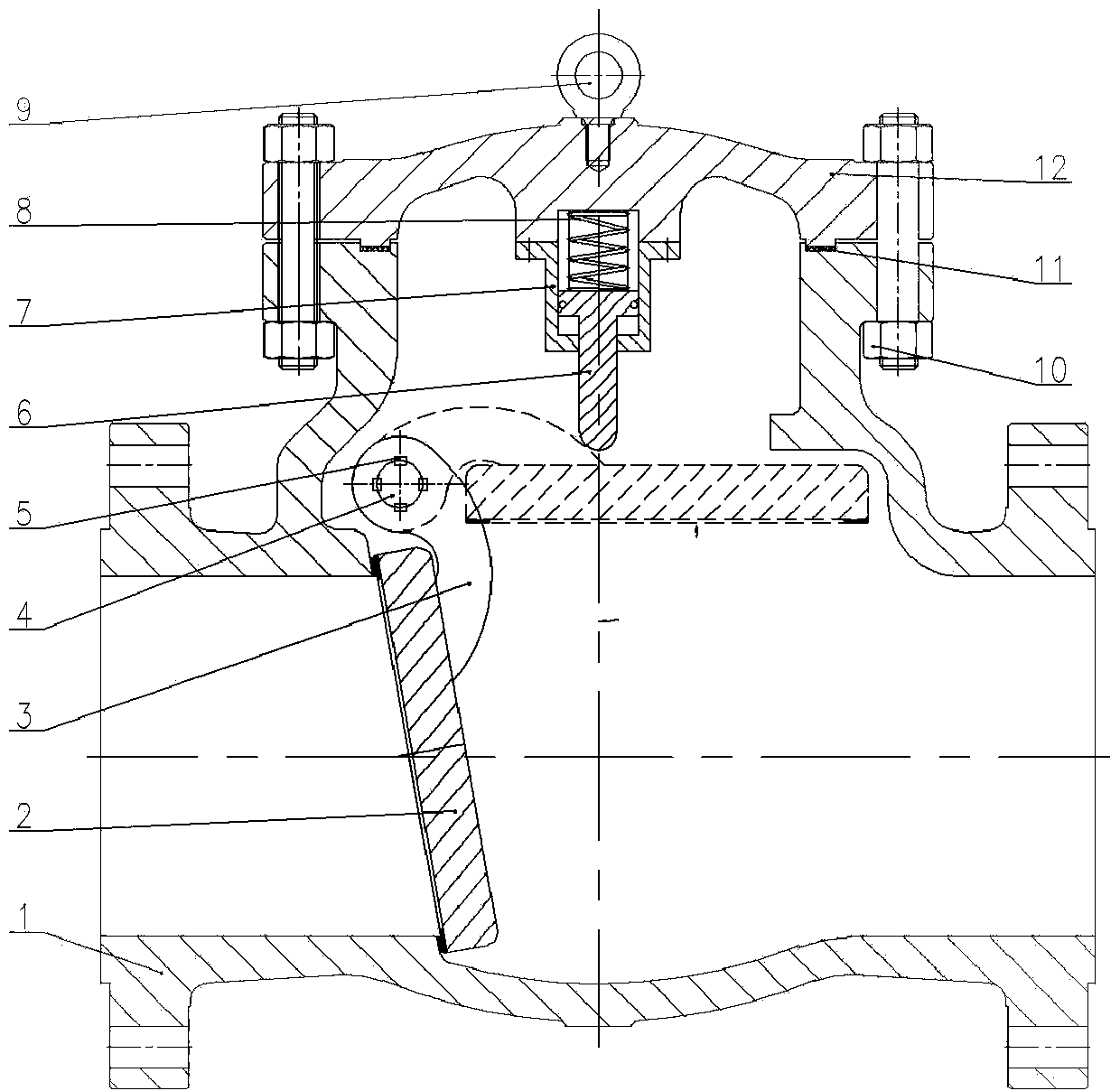

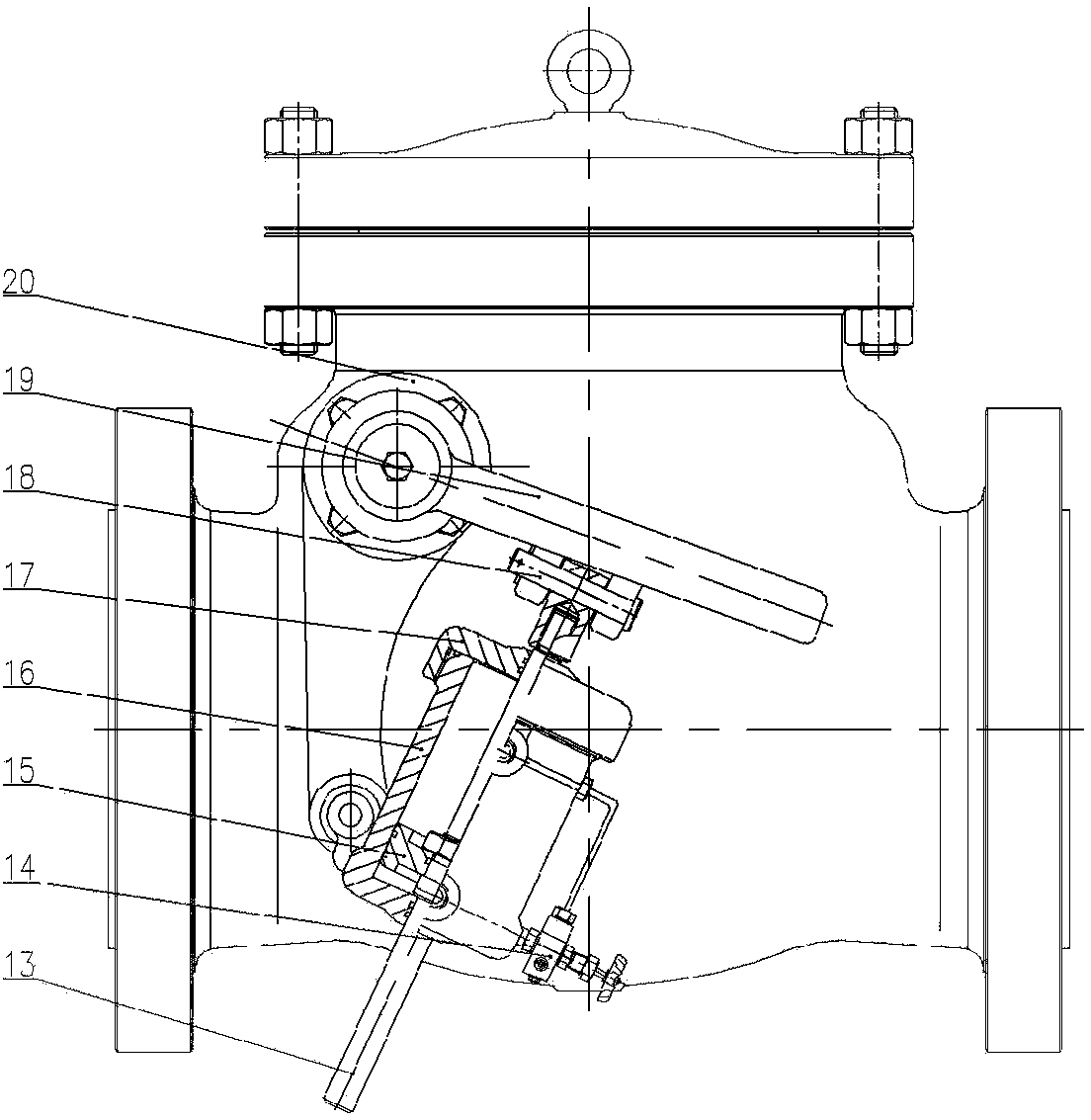

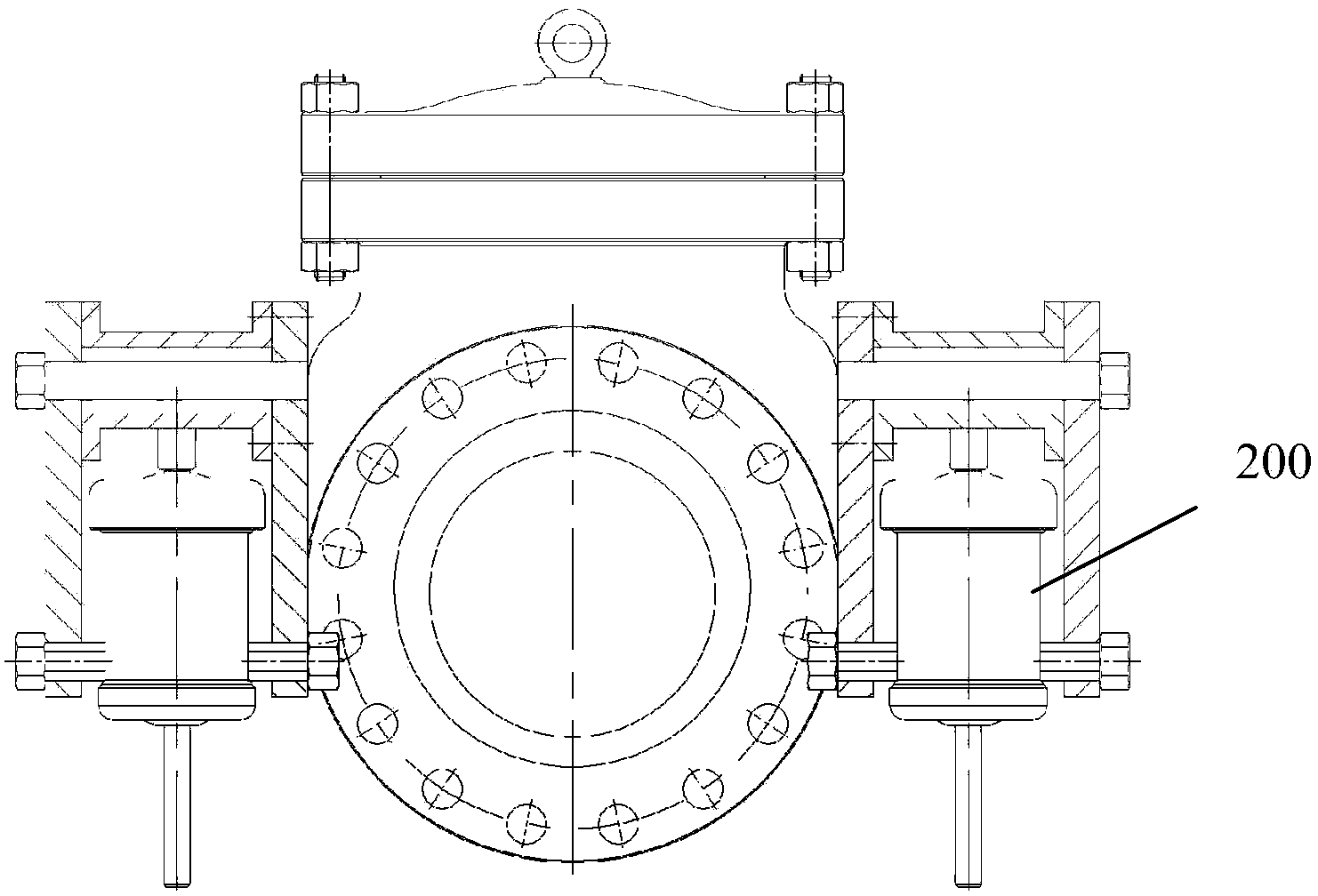

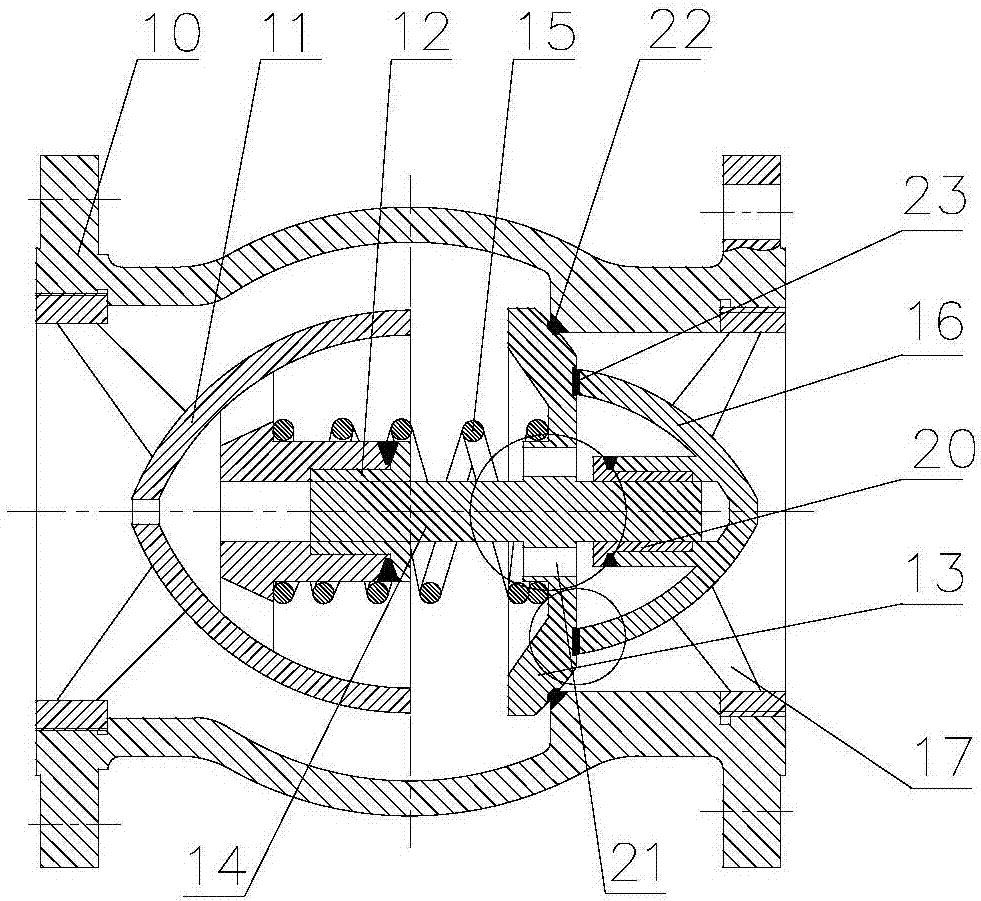

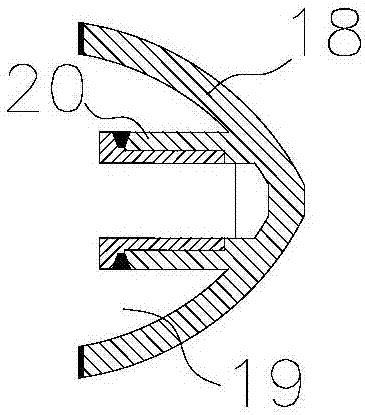

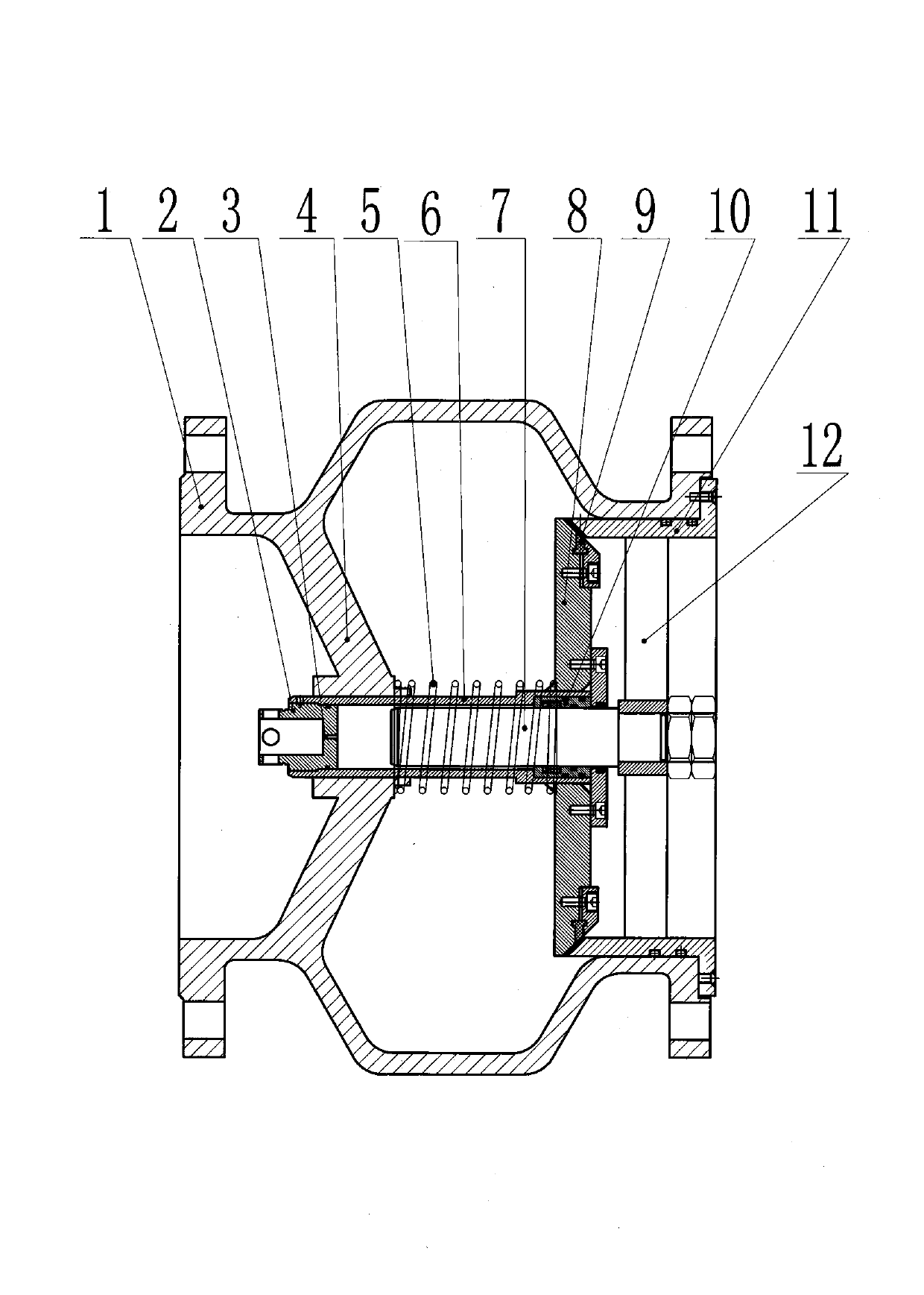

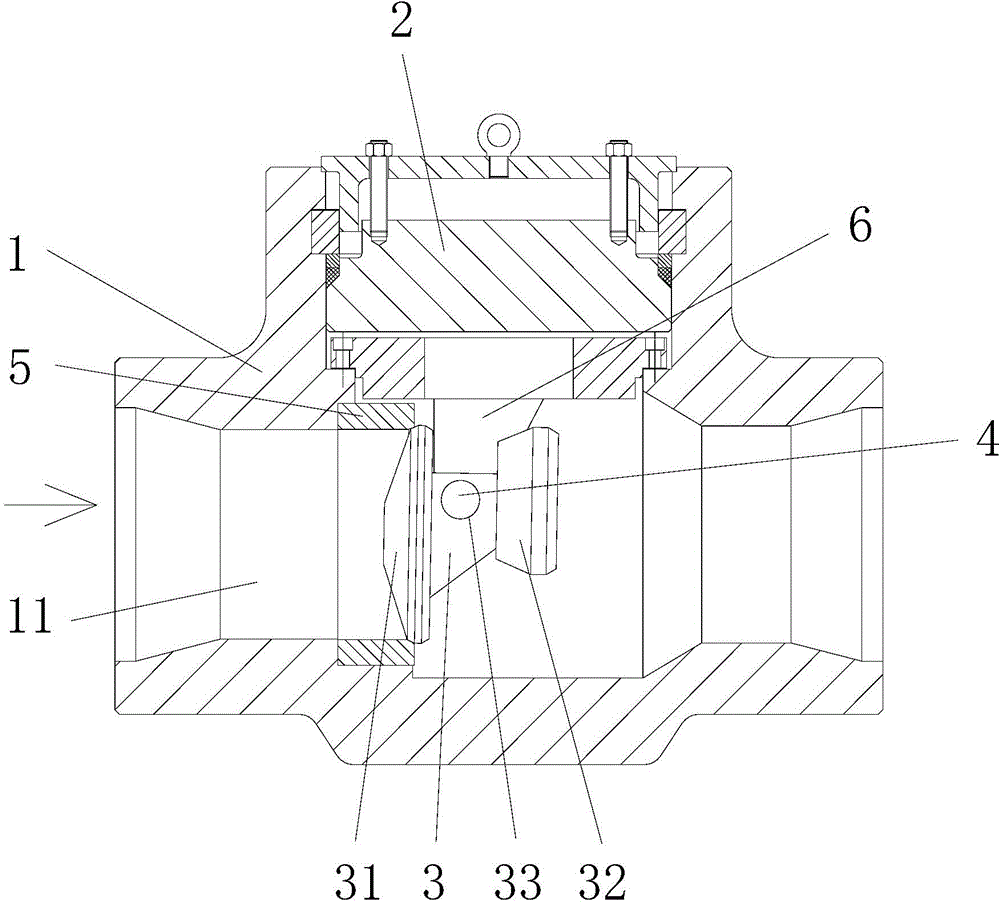

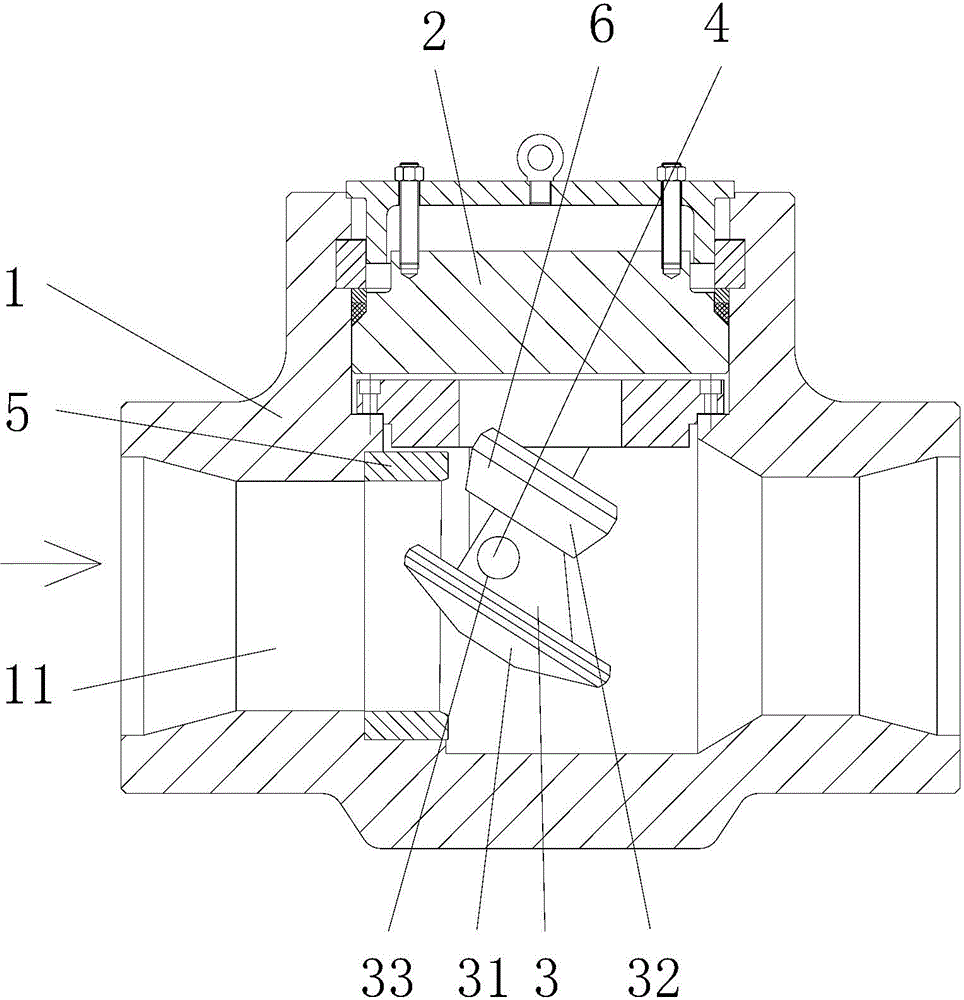

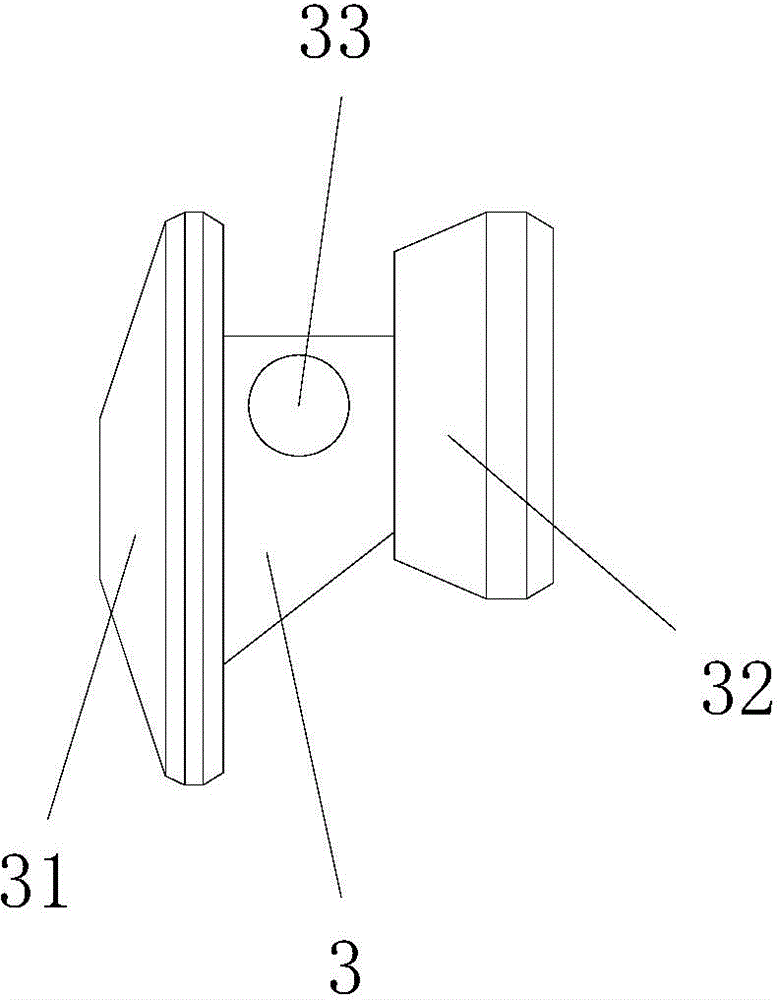

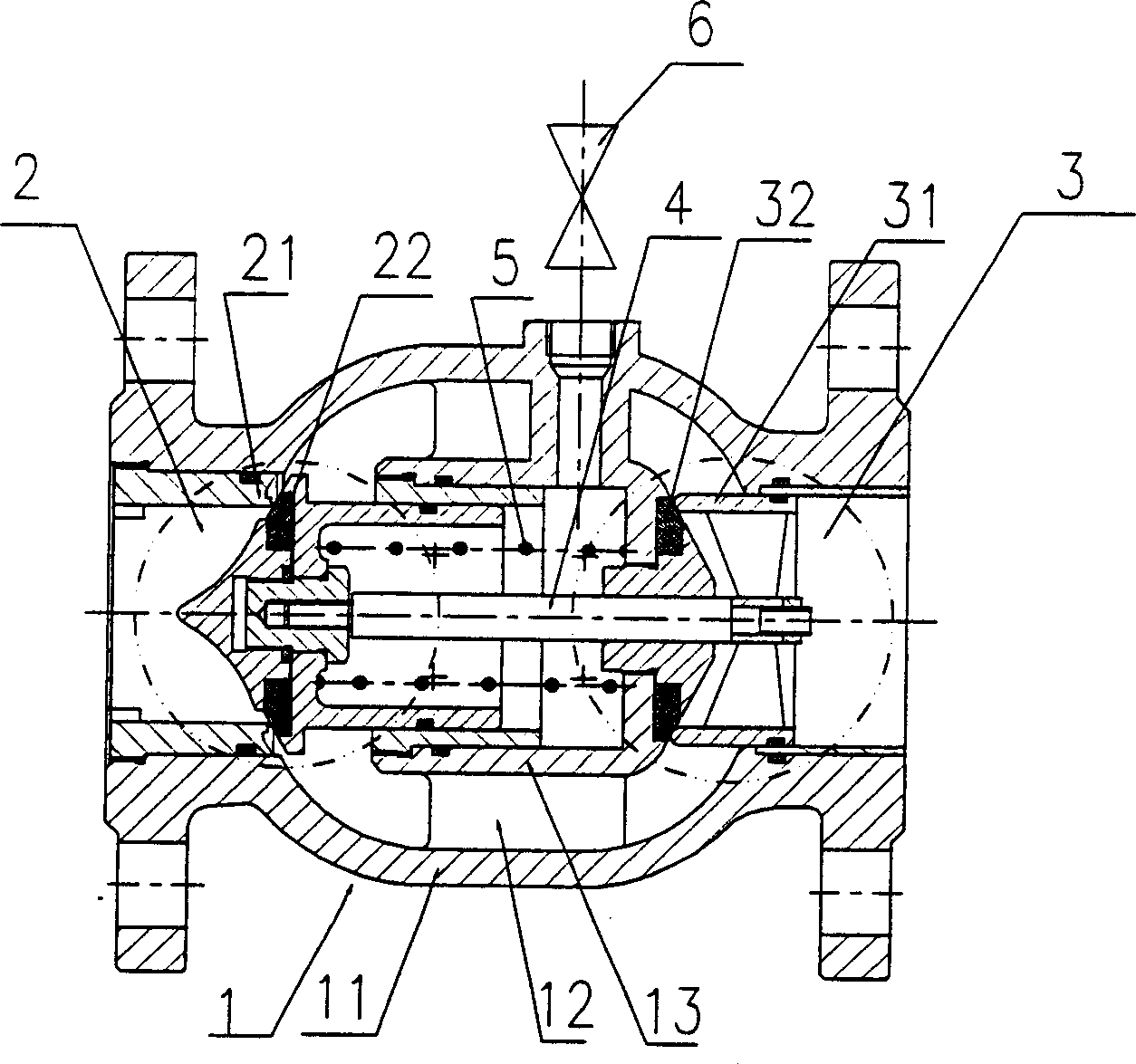

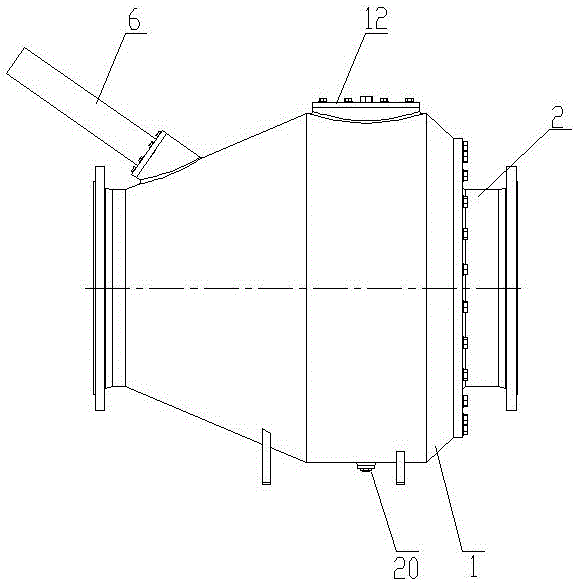

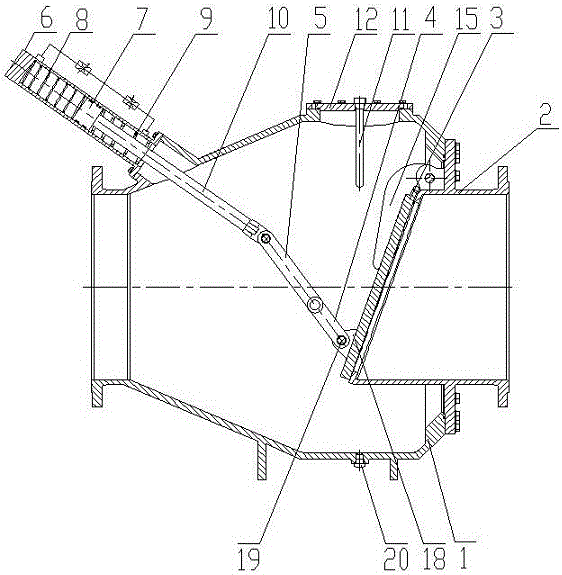

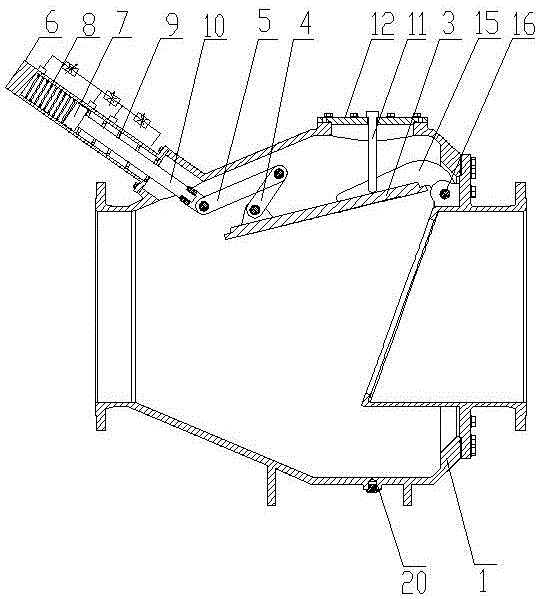

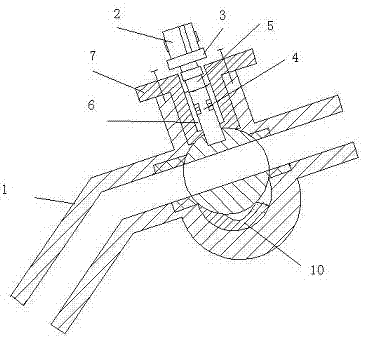

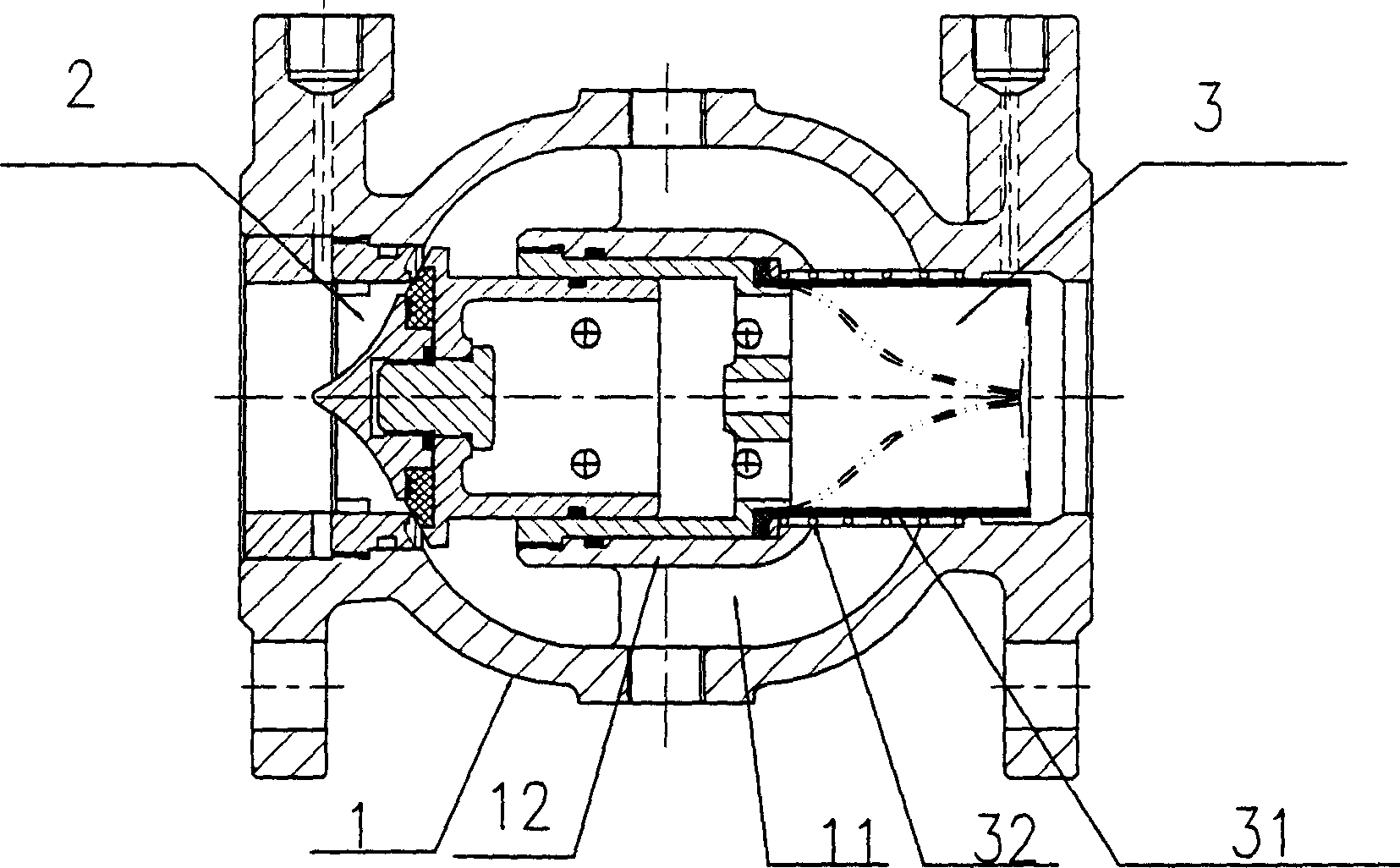

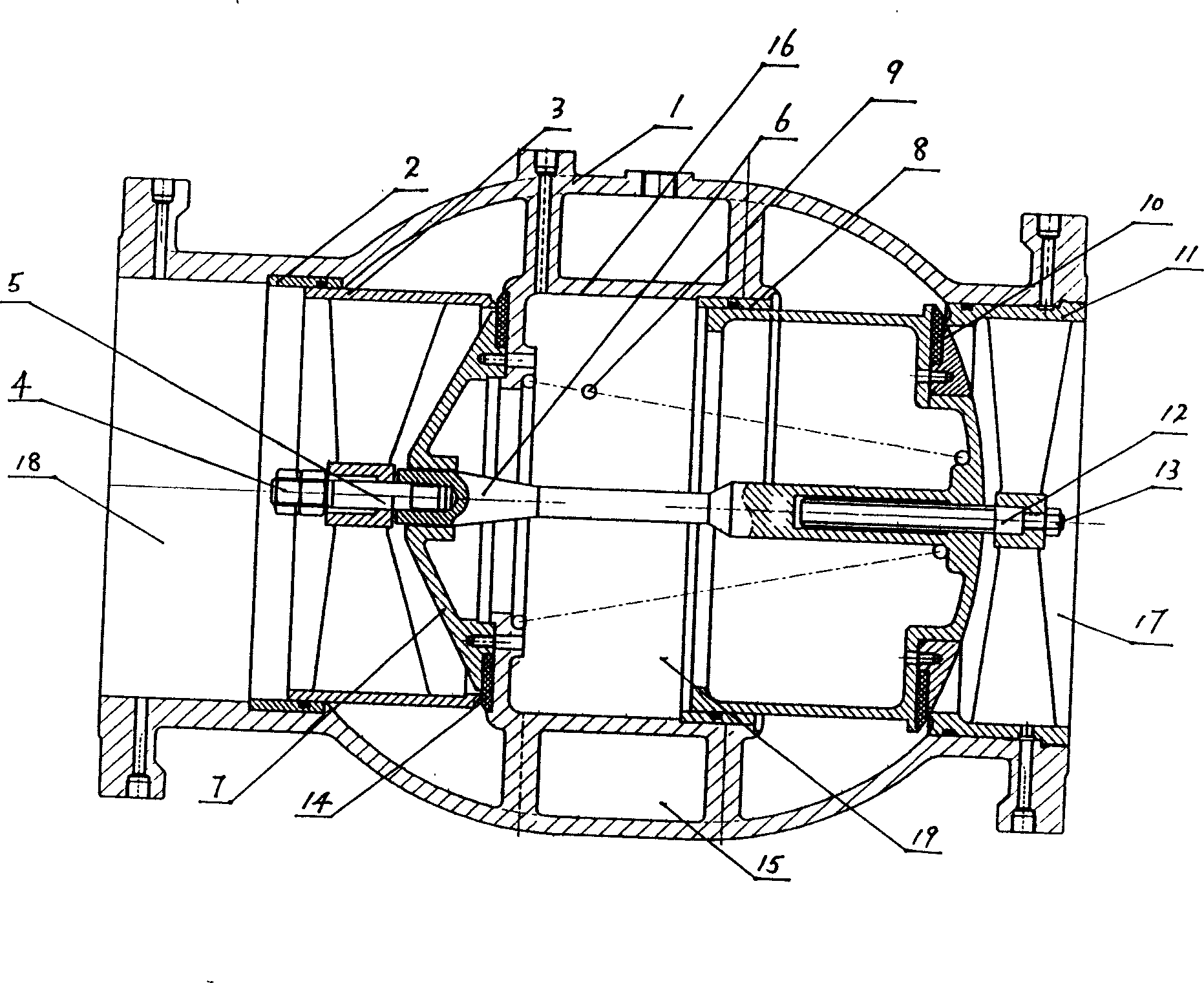

Energy-saving resistance-free check valve

ActiveCN103925395AReduce water hammerReduce damagePositive displacement pump componentsCheck valvesEngineeringCheck valve

An energy-saving resistance-free check valve comprises a valve body, a valve clack and a valve deck. A valve rod is arranged in the valve body. The axial direction of the valve rod is perpendicular to the axial direction of a medium inlet. The valve rod penetrates through the upper portion of a valve cavity. The two ends of the valve rod extend out of the front side and the rear side of the valve body respectively. A rotating pair is arranged between the valve rod and the valve body. A rocker is connected to one side of the valve clack. The upper end of the rocker is connected with the valve rod. A limiting device is connected to the bottom side of the valve deck. The front side and the rear side of the valve body are respectively provided with a hydraulic slow-closing device. According to the energy-saving resistance-free check valve, gravity and buoyancy enable a medium to pass through the valve body fully without resistance when the valve clack is fully opened, so that the work efficiency of a water pump is improved, power consumption is lowered, and the energy-saving effect is achieved; since the valve body is in a streamline form, the medium cannot deposit in the valve cavity, and the energy-saving resistance-free check valve is suitable for conveying media with particles prone to deposition; in the closing process, water hammer can be effectively reduced, and damage of the water hammer to a pipeline and valve equipment is lowered; under the condition that the pressure of return water is very low, sealing can be guaranteed, and therefore the conveying medium can be effectively prevented from flowing back in the quick-closing process.

Owner:上海东方威尔阀门有限公司

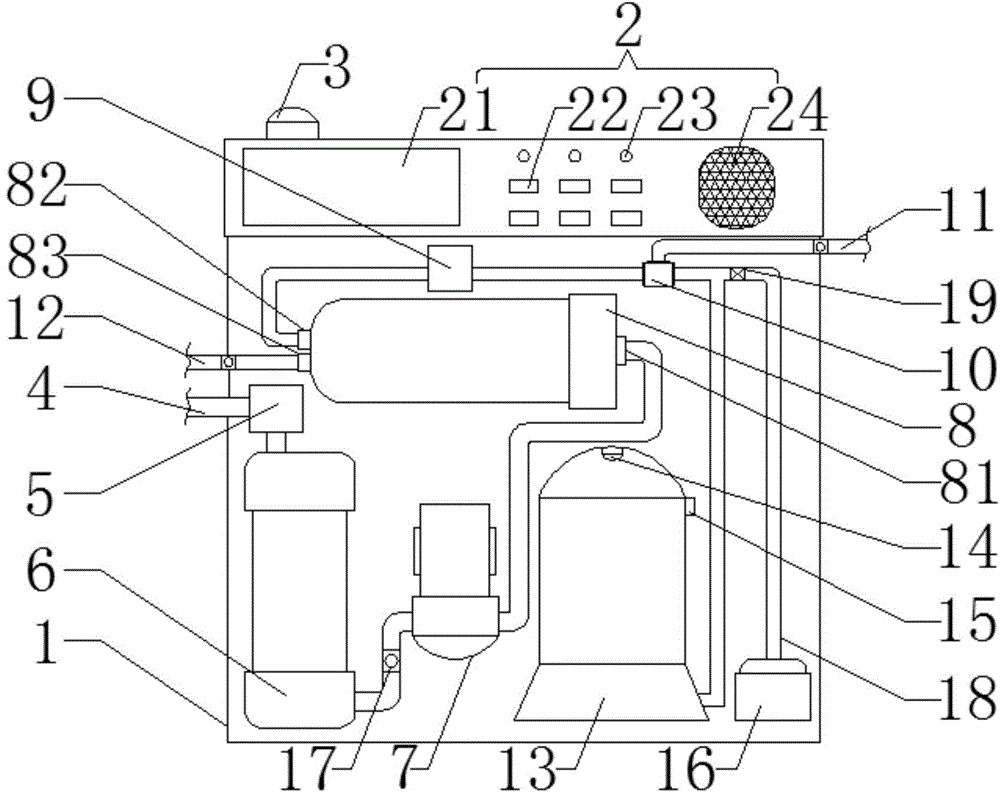

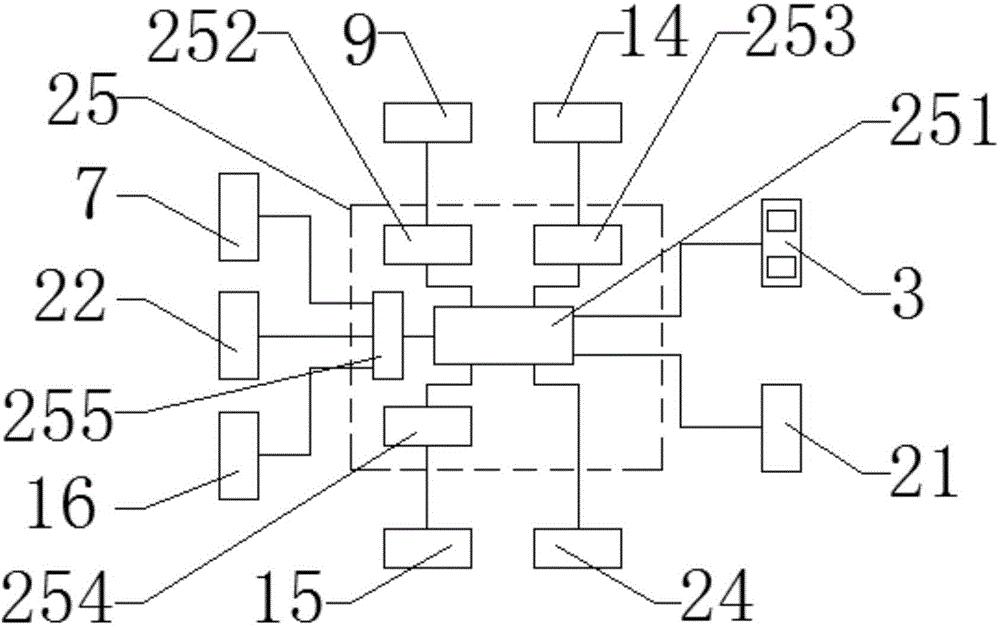

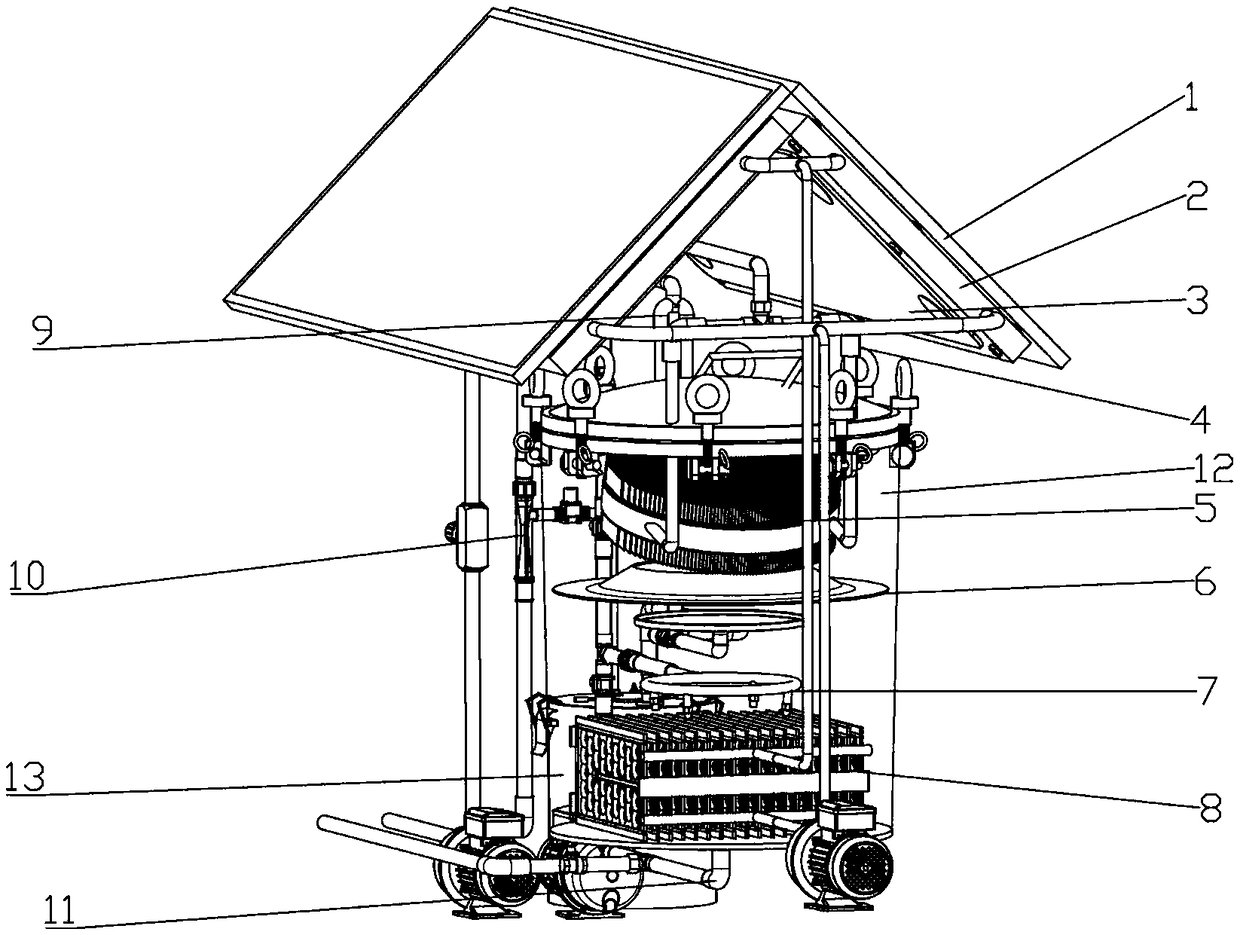

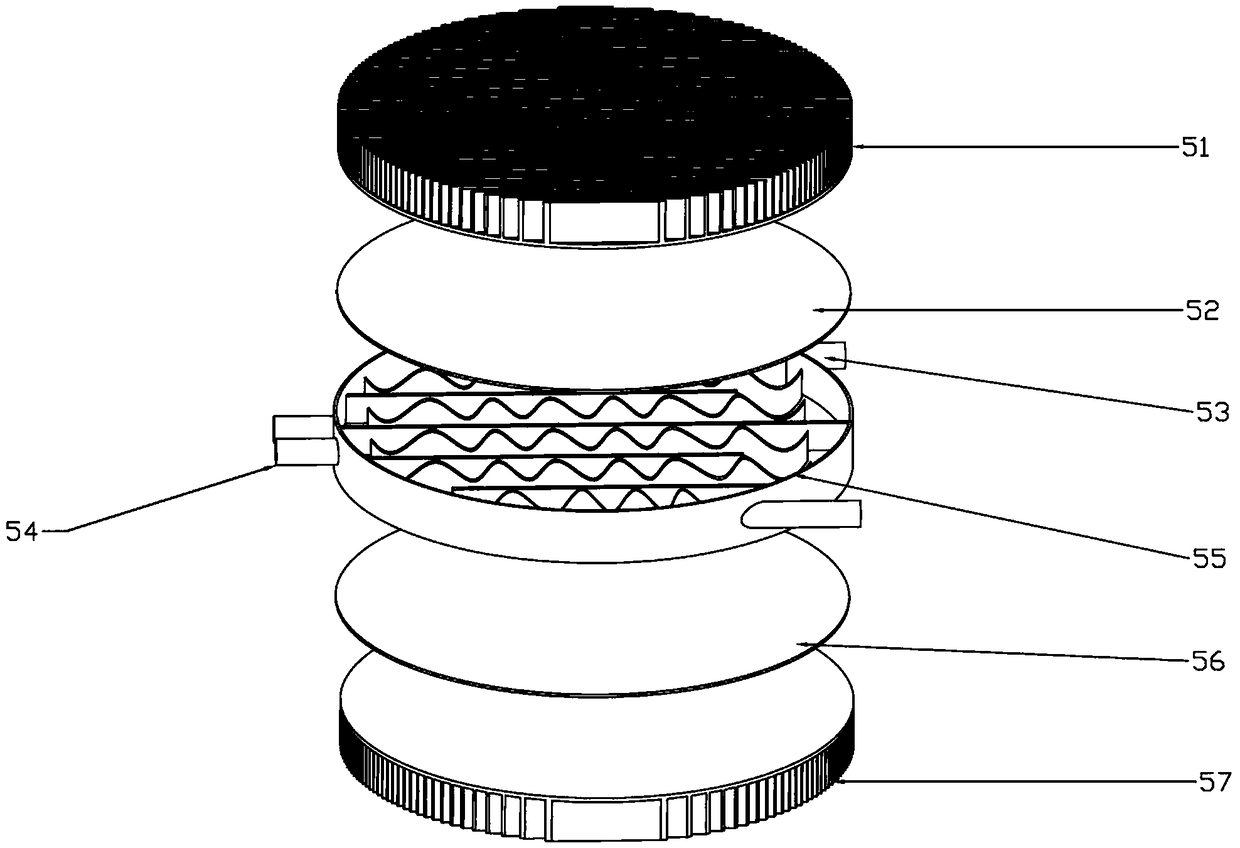

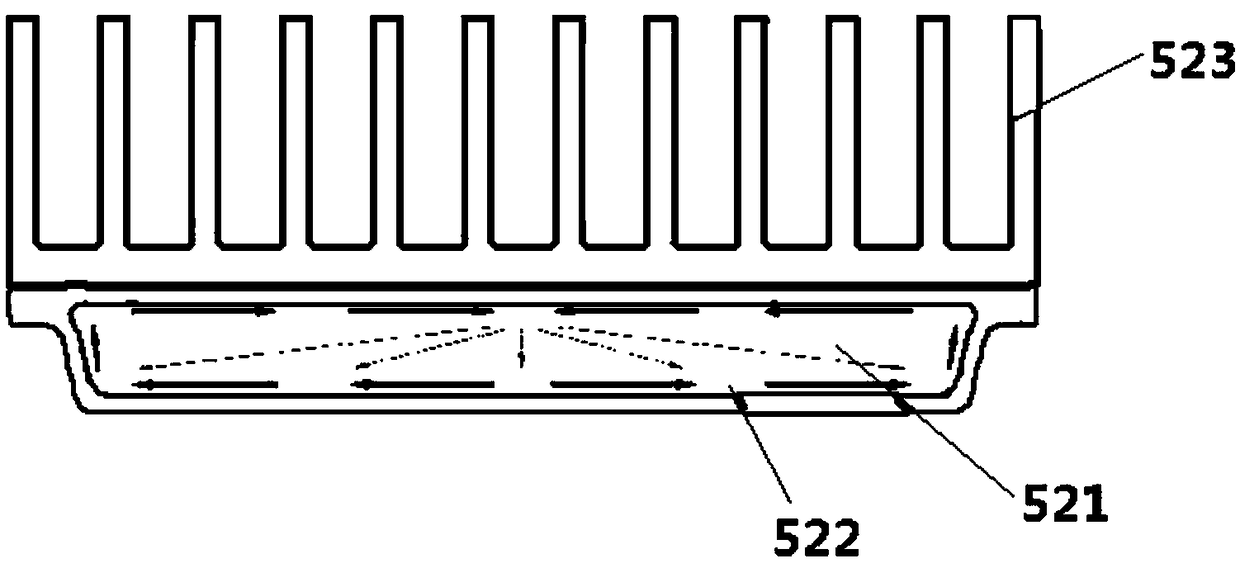

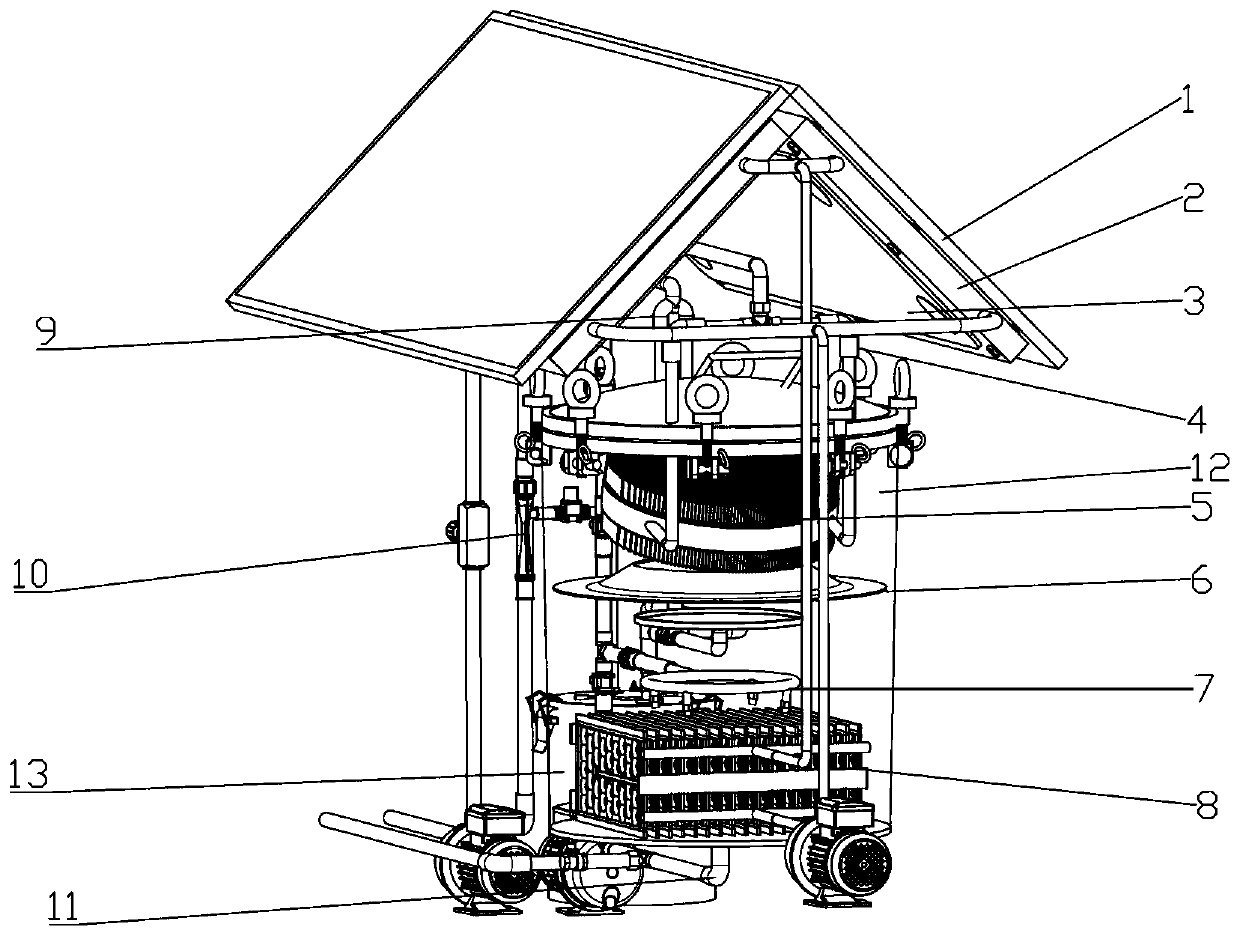

Intelligent monitoring water purifying machine applicable to hospital disinfecting and supply center

ActiveCN104787911AImprove water purification efficiencyQuality improvementMultistage water/sewage treatmentFiltrationWater storage tank

The invention discloses an intelligent monitoring water purifying machine applicable to a hospital disinfecting and supply center. A running water inlet is connected with a water hammer arrestor; the water hammer arrestor is connected with a composite-filter core filtering device; the composite-filter core filtering device is connected with a booster pump; the booster pump is connected with a water inlet of a RO membrane filtration device; a clean water outlet of the RO membrane filtration device is connected with a clean water pipeline; a concentrated water outlet of the RO membrane filtration device is connected with a concentrated water pipeline; a water quality sensor and a tee joint are sequentially arranged on the clean water pipeline; one end of the tee joint is connected with a water outlet; the other end of the tee joint is connected with a pressure water storage tank; a cleaning pipe is connected onto a pipeline between the tee joint and the pressure water storage tank, and connected with a cleaning air pump. Through the adoption of the intelligent monitoring water purifying machine, the water purifying efficiency and the water purifying quality are improved, so that the intelligent monitoring water purifying machine is worthy of large-scale popularization and application.

Owner:上海荷福人工智能科技(集团)有限公司

Water-hammer-resisting multi-flow-channel multi-seal check valve

InactiveCN107202185AAvoid wear and tearGuaranteed tightnessCheck valvesValve members for absorbing fluid energyEngineeringPressure difference

The invention provides an anti-hammer multi-channel multi-seal check valve, which includes a valve body, a guide body, a first bush, a valve flap, a guide shaft and a spring, and the valve flap is fitted on the guide shaft and the first bush through the guide shaft and the first bush. Inside the fluid, the spring is assembled on the guide shaft, and also includes a buffer body, which is fixed on the valve body through a bracket. The buffer body is arranged on one side of the valve disc closing direction and is in sealing contact with the valve disc when the valve disc is closed; the buffer body has Protruding arc-shaped buffer wall, inside the arc-shaped buffer wall is a buffer cavity, inside the arc-shaped buffer wall is a second bushing, the guide shaft passes through the valve disc and is connected with the second bushing, and the valve disc is also equipped with There are diversion holes connected with the buffer cavity. The valve of the present invention has a buffer body structure, which can reduce the water hammer caused by the excessive pressure difference of the fluid when the valve is working normally, avoid the wear of the valve caused by the excessive impact force, and can also realize the silent check role.

Owner:BENSV VALVE CO LTD

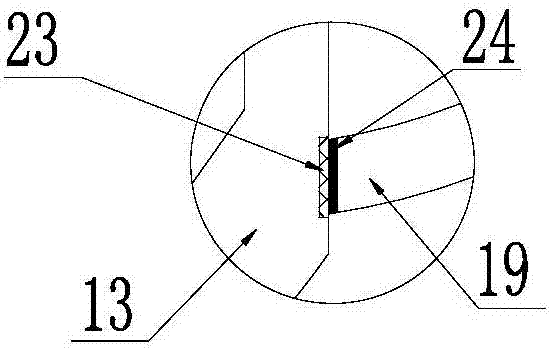

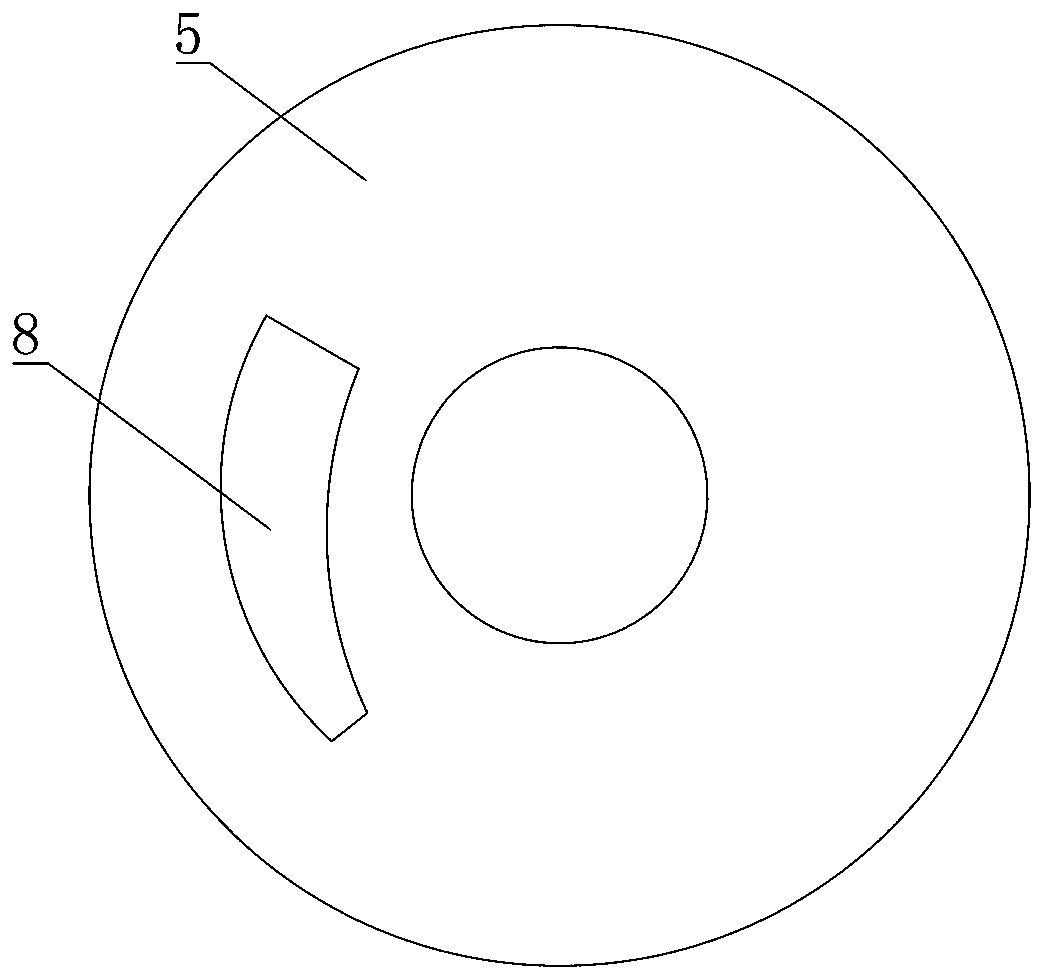

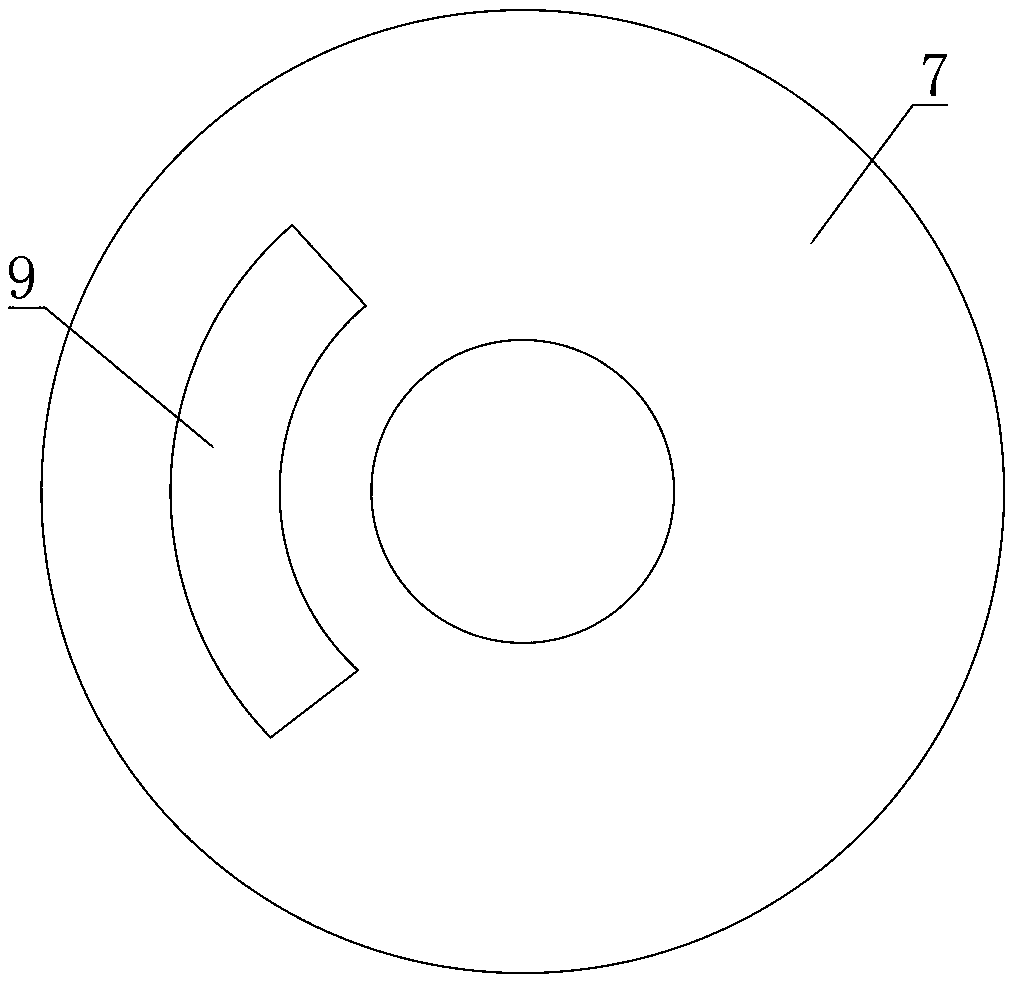

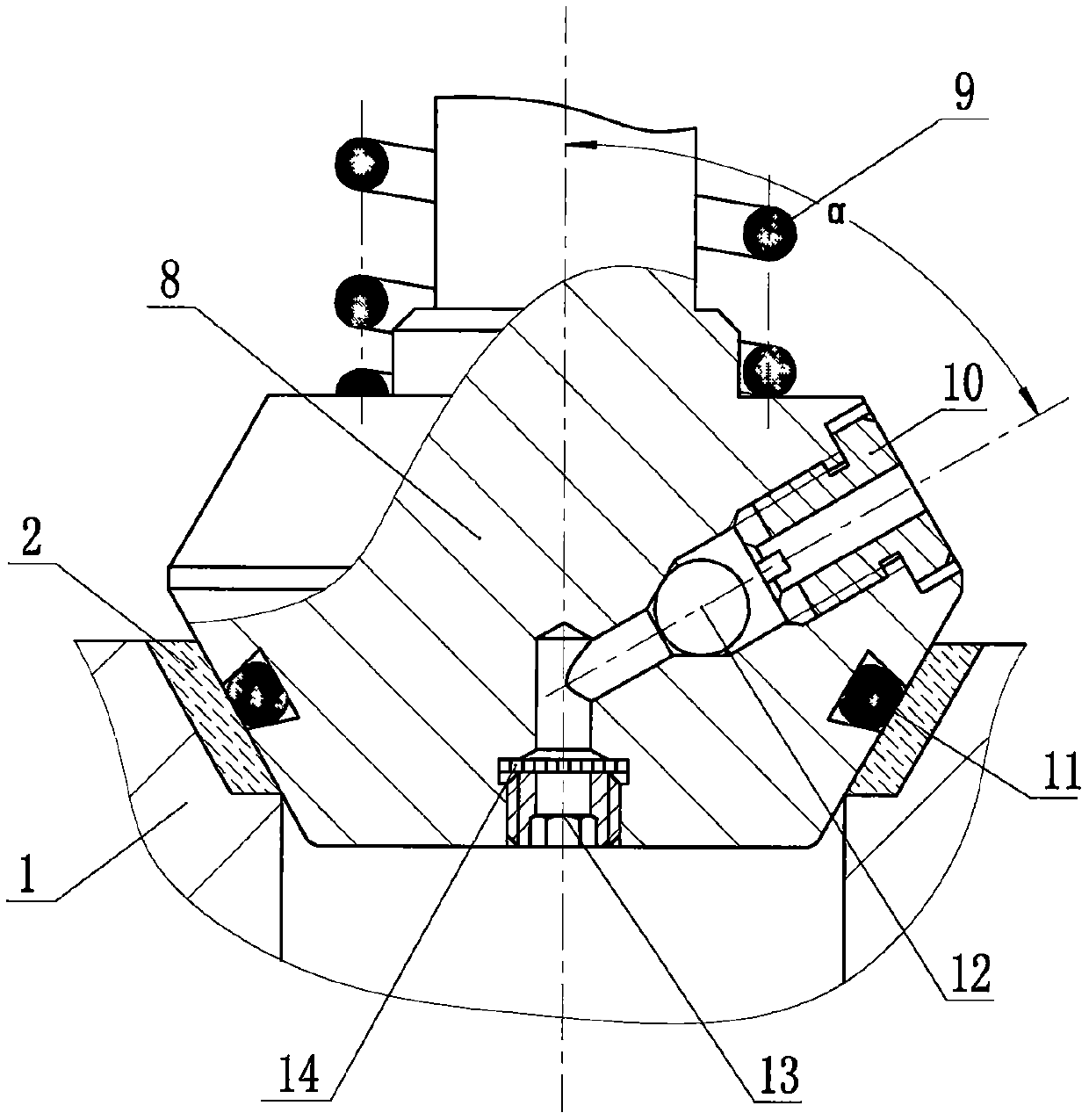

C-shaped four-eccentric slurry pump control valve

InactiveCN104565425AAvoid scourImprove operational efficiencyPlug valvesPositive displacement pump componentsEngineeringControl valves

The invention relates to a C-shaped four-eccentric slurry pump control valve. The control valve comprises a valve body, a valve seat, a valve element, a valve shaft, a valve shaft and an oil cylinder; the valve body consists of a left valve body and a right valve body; the valve element has a C-shaped hemisphere structure; the pipeline diameter of the C-shaped hemisphere is the same as the diameter of an inlet and outlet pipeline; a valve clack matched with the valve seat is fixedly installed on the outer spherical surface of the C-shaped hemisphere; the valve clack is provided with a cone sealing surface; the valve shaft and the valve clack sealing surface, the valve shaft and a valve clack central line, and a valve clack sealing surface central line and a valve body passage central line form a three-eccentric structure; a valve shaft central line and the valve body passage central line are eccentrically installed; a piston rod of the oil cylinder is fixedly connected with the end of the valve shaft through a connecting lever; the end of the valve shaft is fixedly connected with a heavy hammer; and the heavy hammer is in a horizontal state when the valve element is opened. The C-shaped four-eccentric slurry pump control valve has the advantages of erosion resistance, leakproofness, reliability, long service life, small flow resistance, simplicity in pipeline cleaning, high operation efficiency, low operation noise and small closed water hammer, and is applicable to a protection valve for avoiding backflow of media on an outlet pipeline of a water pump.

Owner:应建忠

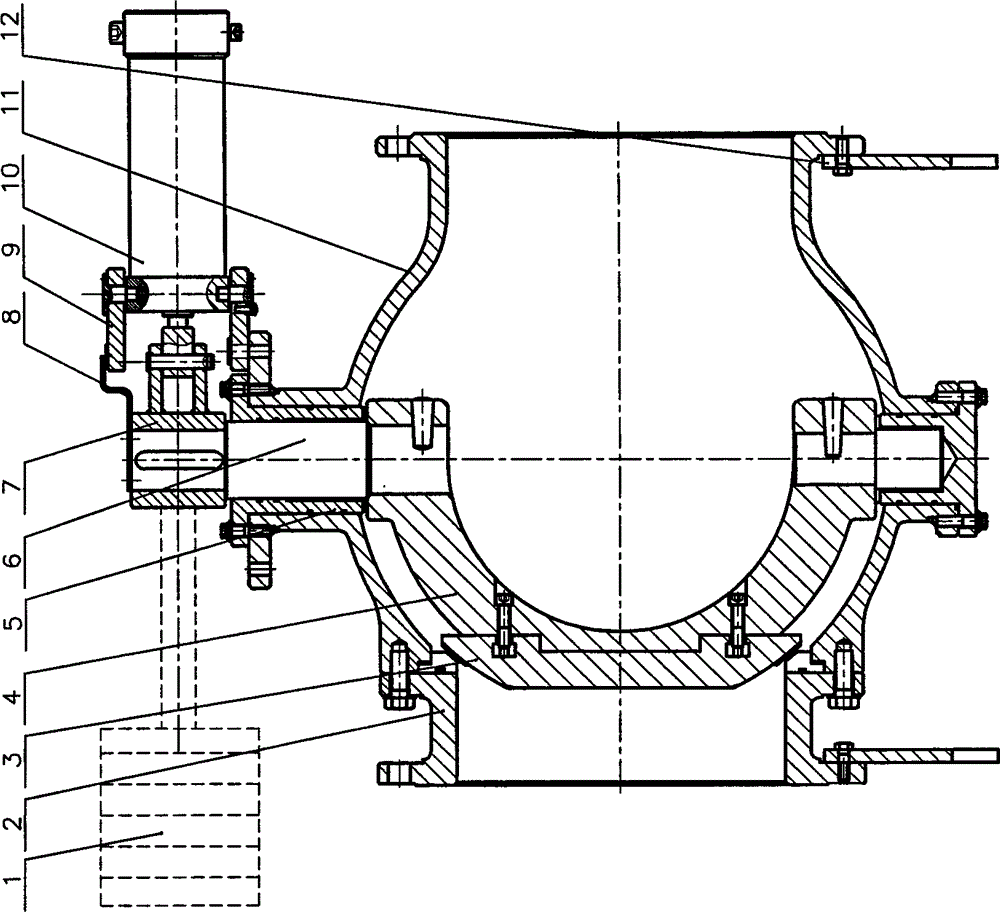

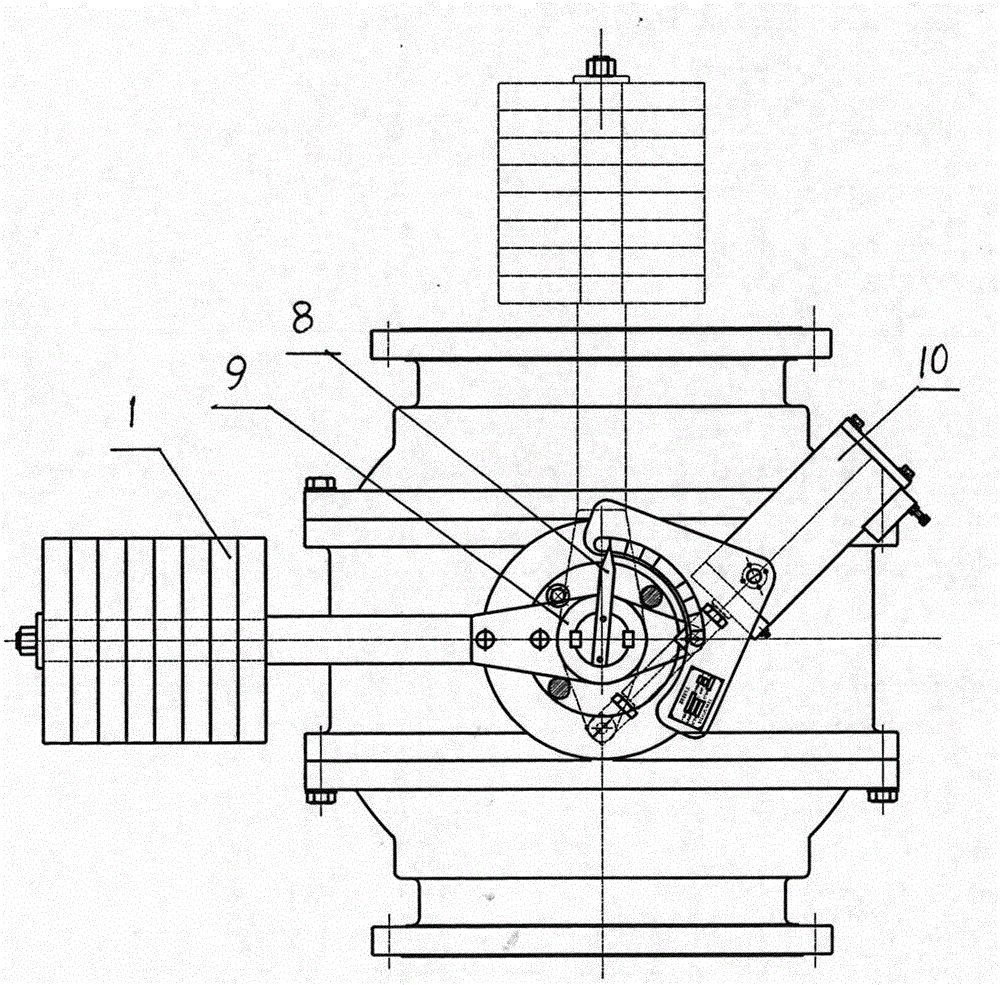

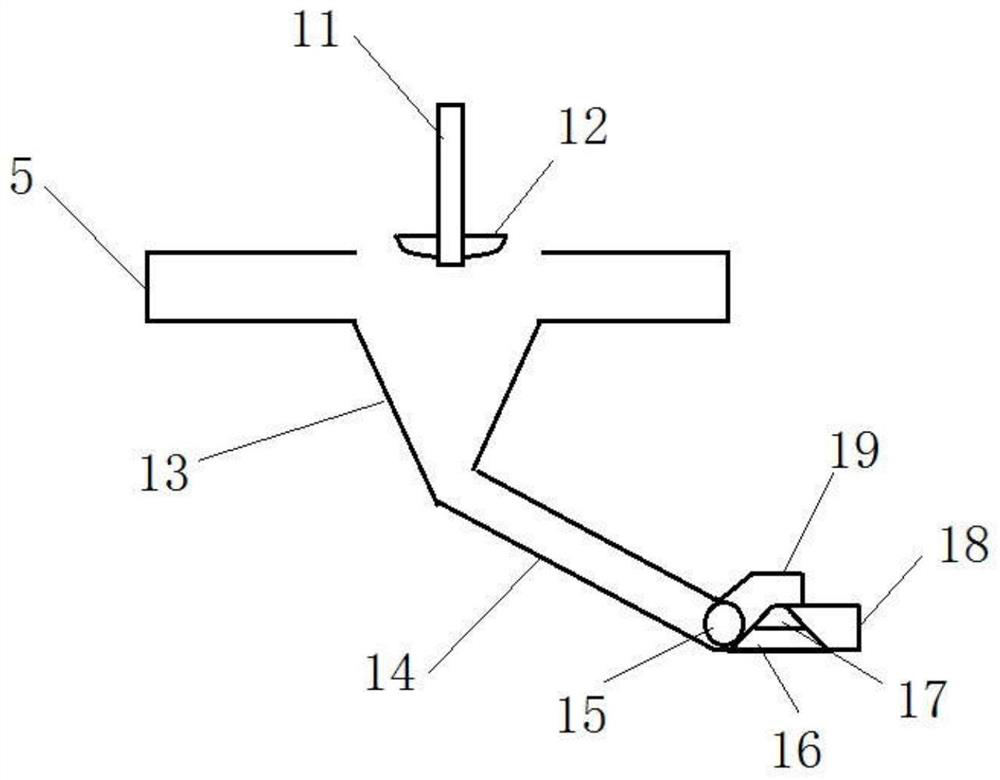

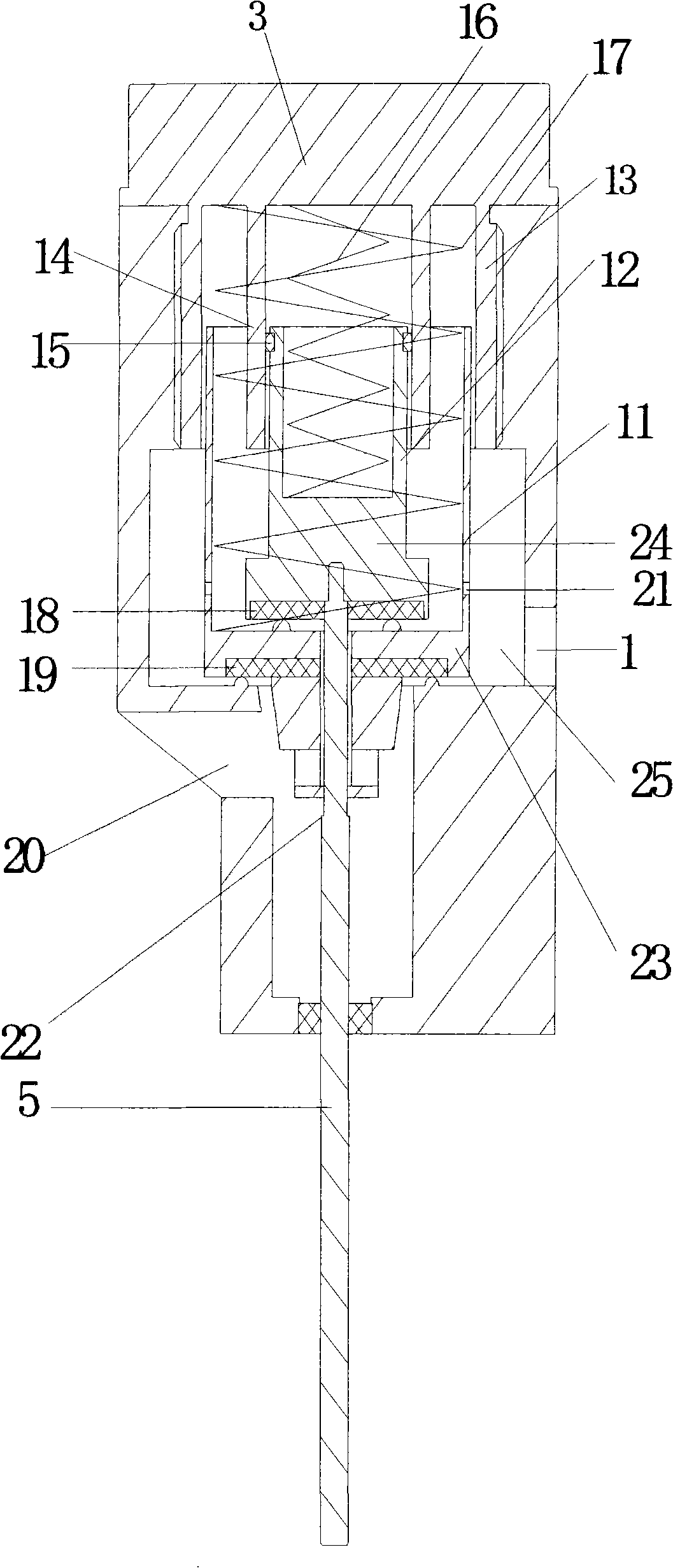

Elevating type hydraulic slow-closure silencing check valve

The invention provides an elevating type hydraulic slow-closure silencing check valve and relates to a check valve which is mounted on a pipeline and used for preventing media in the pipeline from flowing back. The elevating type hydraulic slow-closure silencing check valve is mainly designed to solve the problem that an existing check valve cannot reduce water hammers. The elevating type hydraulic slow-closure silencing check valve comprises a valve body, a valve body support is cast with the valve body into a whole, a sealing base is arranged in the valve body, a sealing base support is fixedly arranged on the sealing base, a piston rod is fixedly arranged on the sealing base support, the piston rod is arranged in the inner cavity of a valve rod, a rear cap is arranged on the wall of the inner cavity at the rear end of the valve rod, a water in-out hole is formed in the rear cap, the valve rod is arranged on an opening of the valve body support, a valve clack is fixedly arranged at the front end of the valve rod, a guide sleeve is arranged on the wall of the inner cavity of the valve rod, the guide sleeve is connected with the valve clack through a pressing cover, the outer circle of the valve clack is contacted with the sealing base, a sealing ring is arranged on the contact face of the valve clack and the sealing base, one end of a spring sleeved on the outer wall of the valve rod abuts against the valve body support, and the other end of the spring abuts against the valve clack. The elevating type hydraulic slow-closure silencing check valve has the advantage that the valve clack has a slow-closure function.

Owner:LIAOYANG TONGDE WATER SUPPLY EQUIP MFG CO LTD

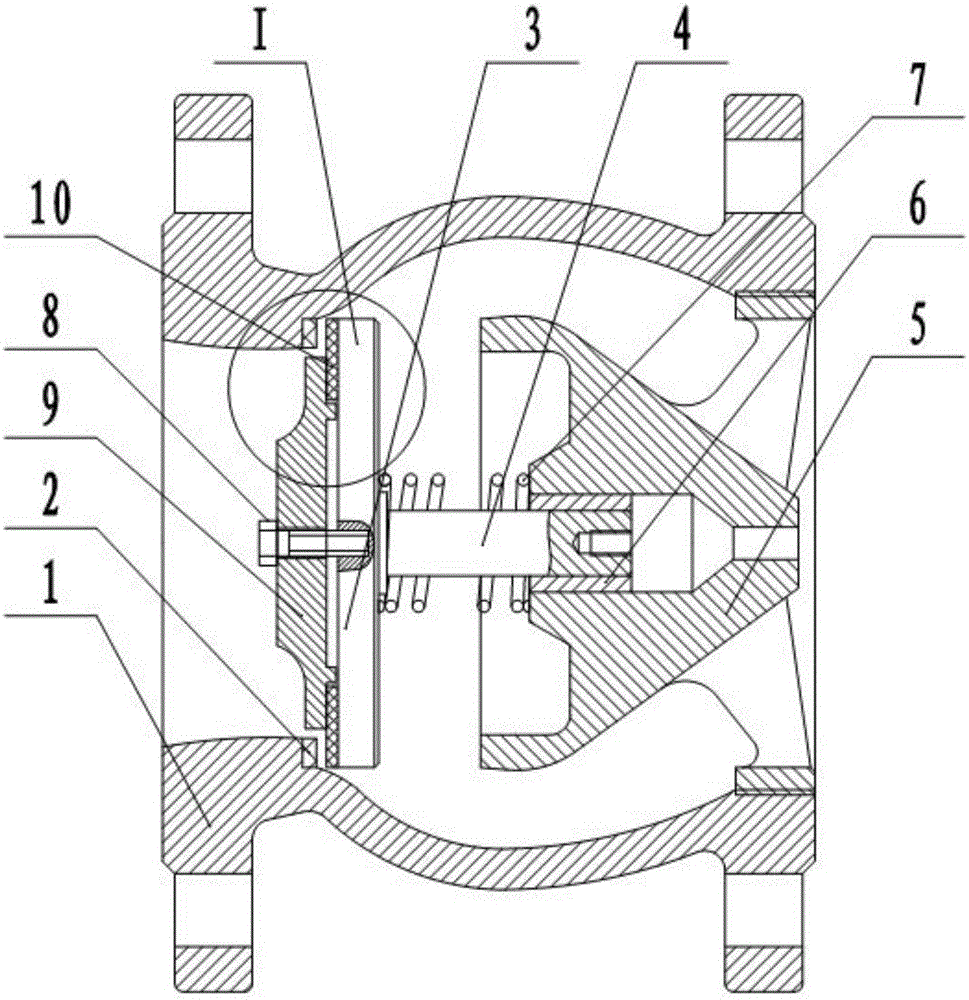

Low-shake low-noise water-hammer-free check valve

InactiveCN104676055AReduce vibrationReduce noiseCheck valvesValve members for absorbing fluid energyHydraulic cylinderLow noise

The invention discloses a low-shake low-noise water-hammer-free check valve which comprises a valve body and a valve cover and further comprises a valve flap and a fixing device. The valve body is provided with a passage formed through front-rear penetration in the inside. The valve cover is detachably installed at the upper end of the valve body. The valve flap is installed in the passage of the valve body. A sealing device provided with a sealing face is arranged at one end of the valve flap, the sealing face of the sealing device can seal the passage of the valve body, and a gravity balancing device is arranged at the other end of the valve flap. A shaft hole is formed in the valve flap, a rotary shaft penetrates through the shaft hole, and the valve flap can rotate around the rotary shaft. The fixing device is located in the cavity of the valve body and fixes the rotary shaft. By using the low-shake low-noise water-hammer-free check valve, water-hammer-free low-shake low-noise operation is achieved through a high-speed starting-stopping function and a low-speed starting-stopping function during starting and stopping. A slow starting and stopping function is achieved without an additional heavy hammer, a hydraulic cylinder or a pneumatic cylinder and other structures, and the using demand under any working condition is met.

Owner:SHANGHAI SUBNUCLEAR VALVE IND COMPLETE CO LTD

Flow regulating valve of high performance water-free hammer

InactiveCN109944969AStable pressureAvoid wear and tearEqualizing valvesSafety valvesInlet channelDrive shaft

The invention discloses a flow regulating valve of a high performance water-free hammer. A disc valve element is arranged at the lower end of a valve shaft in a sleeving manner, the valve element is rotatably and hermetically connected to the valve seat, a first arc-shaped groove is formed in the valve seat, a second arc-shaped groove aligned to the first arc-shaped groove is formed in the valve element, a pressure spring, through which the valve element compresses the valve seat, is arranged between a boss and the valve element in a sleeving manner, the valve shaft stretches upward out of a valve cover and a driven bevel gear is mounted at the stretching end, a cylinder is fixed to a valve body, the lower end of the valve body communicates to an inlet channel, a piston rod is fixed to theupper end of a piston, a rack is fixed to the upper end of the piston rod, a driving bevel gear engaged to the driven bevel gear is mounted on a transmission shaft, and the greater the fluid pressurein the inlet channel is, the areas, aligned to the first and second arc-shaped grooves, are . The size of an opening between the inlet channel and the valve seat is adjusted according to the fluid pressure of the inlet channel, and the response time is short. The pressure spring can overcome relative wear between the valve element and the valve body, so that the sealing property of the flow regulating valve is good.

Owner:HENAN UNIVERSE VALVE CO LTD

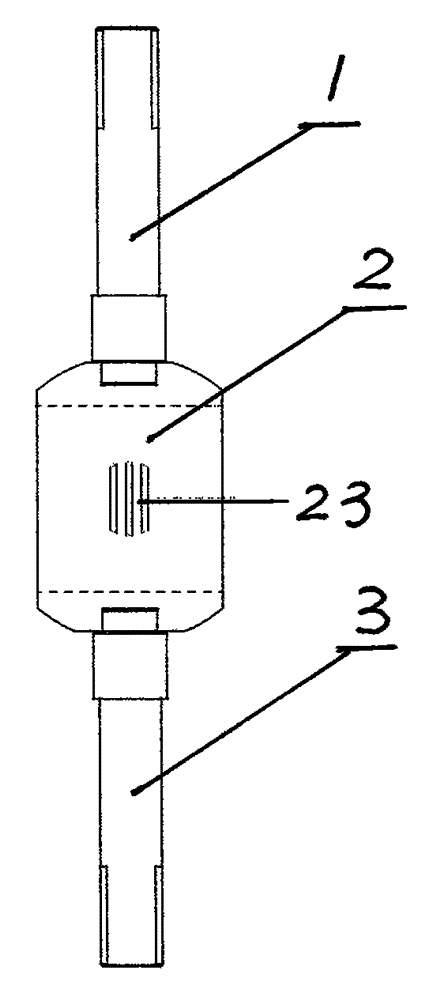

Noise-reducing and water-hammer-effect-reducing long-handle welding type valve ball and ball valve manufactured by valve ball

InactiveCN104421453AReduce water hammerReduce noisePlug valvesValve members for absorbing fluid energyBall valveEngineering

The invention discloses a noise-reducing and water-hammer-effect-reducing long-handle welding type symmetrical valve ball and a ball valve manufactured by the valve ball. The ball valve comprises a first valve rod, a valve ball, a second valve rod and a valve body, wherein the first valve rod and the second valve rod are welded on the valve ball, and in addition, the first valve rod and the second valve rod are symmetrical and coaxial, and have the same length. The ball valve is characterized in that a noise reducing plate is welded in a flow passage of the valve ball, the noise reducing plate is provided with a plurality of noise reducing holes, the non-sealing surface of the valve ball is provided with a flow guide groove, and the first valve rod and the second valve rod respectively extend out of the valve body. The ball valve manufactured by the noise-reducing and water-hammer-effect-reducing long-handle welding type symmetrical valve ball has the advantages that the noise is reduced, and the water hammer effect is reduced.

Owner:姜欣芳

Valve of sealing arrangement in two stages

A valve with double stages of seal device is composed of valve body, connection unit, spring and flow guide unit. It is featured as setting the first seal device at inlet section of valve body and the second seal device at outlet section of valve body, connecting valve clack of the first seal device to valve clack of the second seal device by connection unit. The said valve can not only be used on pressure control, flow rate control and flow direction control but also can be used on water level control, temperature control, multiloop control, electromagnetic ¿C automatic control, etc.

Owner:SHANGHAI SHANGLONG VALVE FACTORY

Overflow buffering silent check valve

InactiveCN106224602AEasy to replaceAvoid damageCheck valvesValve members for absorbing fluid energyEngineeringPressure difference

The invention provides an overflow buffering silent check valve comprising a valve body, a valve seat, a valve flap, a valve rod and a flow guide body; the valve seat, the valve flap, the valve rod and the flow guide body are arranged inside the valve body; the flow guide body is integrated with the valve body; the valve seat is arranged at the front end inside the valve body; a bushing is arranged between the valve rod and the flow guide body; one end of the valve rod is inserted to the bushing, and the other end of the valve rod is connected with the valve flap; a spring is arranged between the valve flap and the bushing; the front end of the valve flap is fixedly provided with a pressing plate through a bolt; and a sealing ring is arranged between each of two ends of the front end of the valve flap and the pressing plate. The overflow buffering silent check valve is small in size and light in weight; the sealing rings are pressed by the pressing plate, so that the sealing rings are convenient to replace, and time and labor are saved; and meanwhile, the pressing plate is a buffering pressing plate, therefore, when the valve is in normal overflow working, a water hammer generated by an overlarge pressure difference of fluids can be reduced, damage caused by an overhigh impact force of the valve is avoided, and the double effects of silent checking and a buffer plug are achieved.

Owner:BENSV VALVE CO LTD

High-performance silent slow-closing check valve

InactiveCN106286908AFirmly connectedEasy to openCheck valvesValve members for absorbing fluid energyEngineeringCheck valve

The invention discloses a high-performance silent slow-closing check valve, which comprises a valve body, a valve seat, and a valve clack. A valve body passage is disposed in the valve body. Two sides of the valve seat are in detachably fixed connection with the valve body, and a middle part of the valve seat extends into a cavity within the valve body. A first connecting rod is connected to one face, opposite a sealing face of the valve clack, of the valve seat, and a second connecting rod is connected to one end of the first connecting rod. A cylinder is disposed at one side, far away from the valve seat, of the valve body. A piston is disposed in the cylinder, and a first spring and a second spring are disposed at two sides within the cylinder, respectively. A piston rod is connected to one side of the piston, and one end of the piston rod is connected to the second connecting rod. With such a structure, the valve body is reliably connected to the valve seat; for usual leakage, the valve seat is detached and then treated without entire replacement, and convenient and rapid repair or field maintenance is achieved. The design of the valve body with a large expanded cavity allows an obvious silent effect, and the arrangement of the cylinder allows easy opening and slow closing of the valve clack.

Owner:YINGNUOWEI VALVE IND

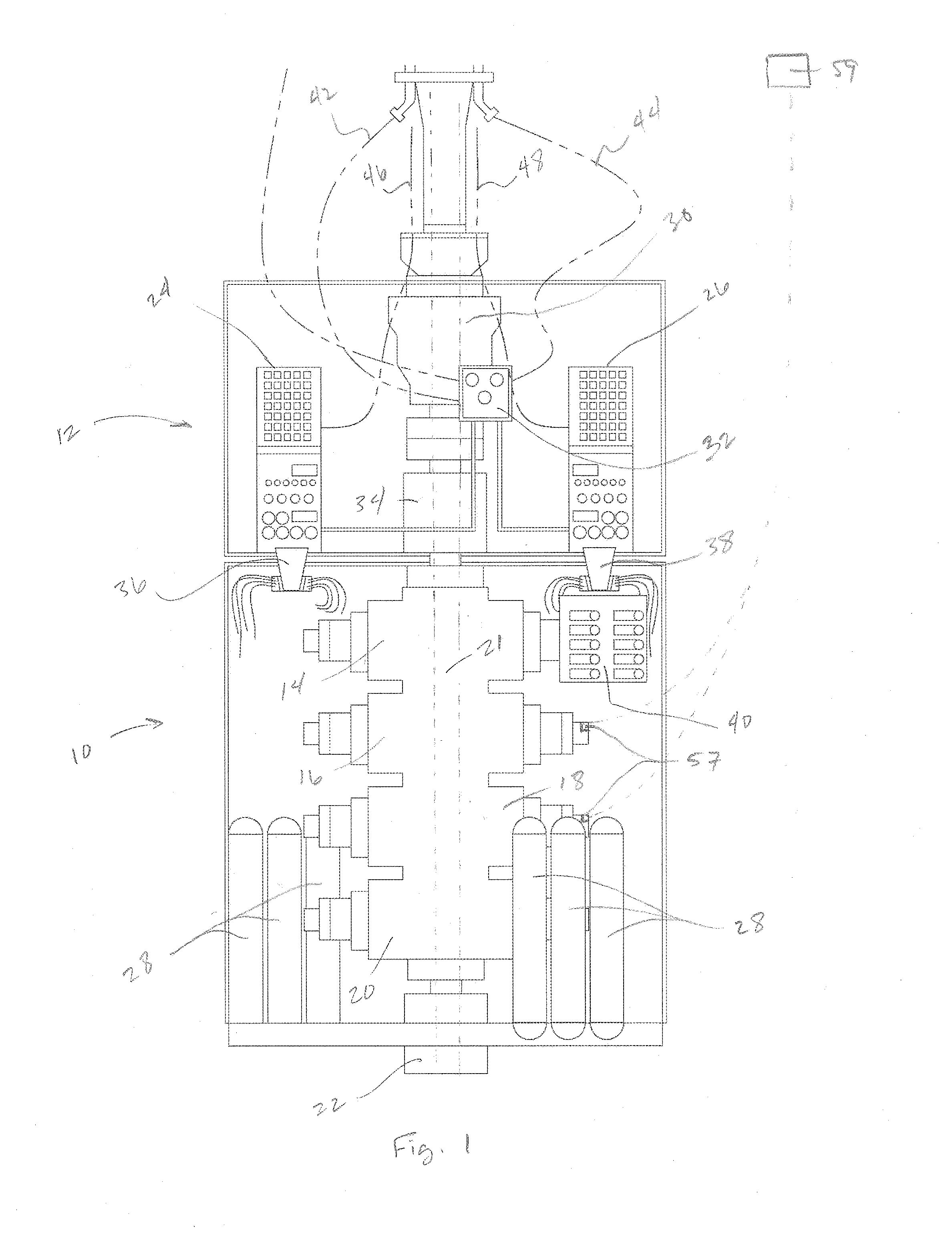

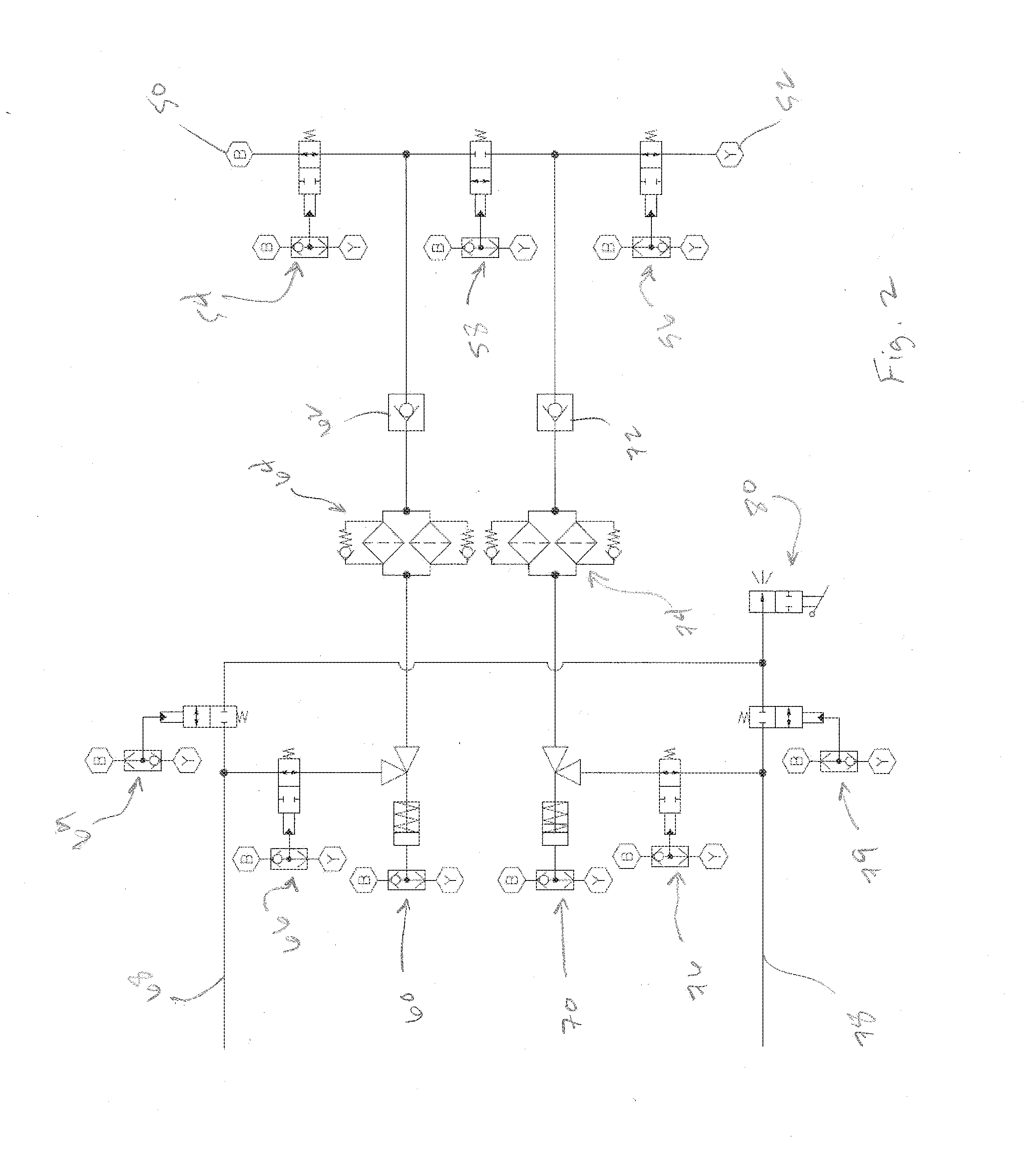

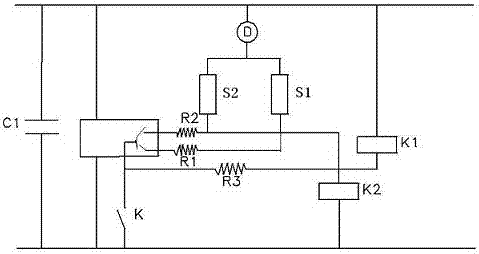

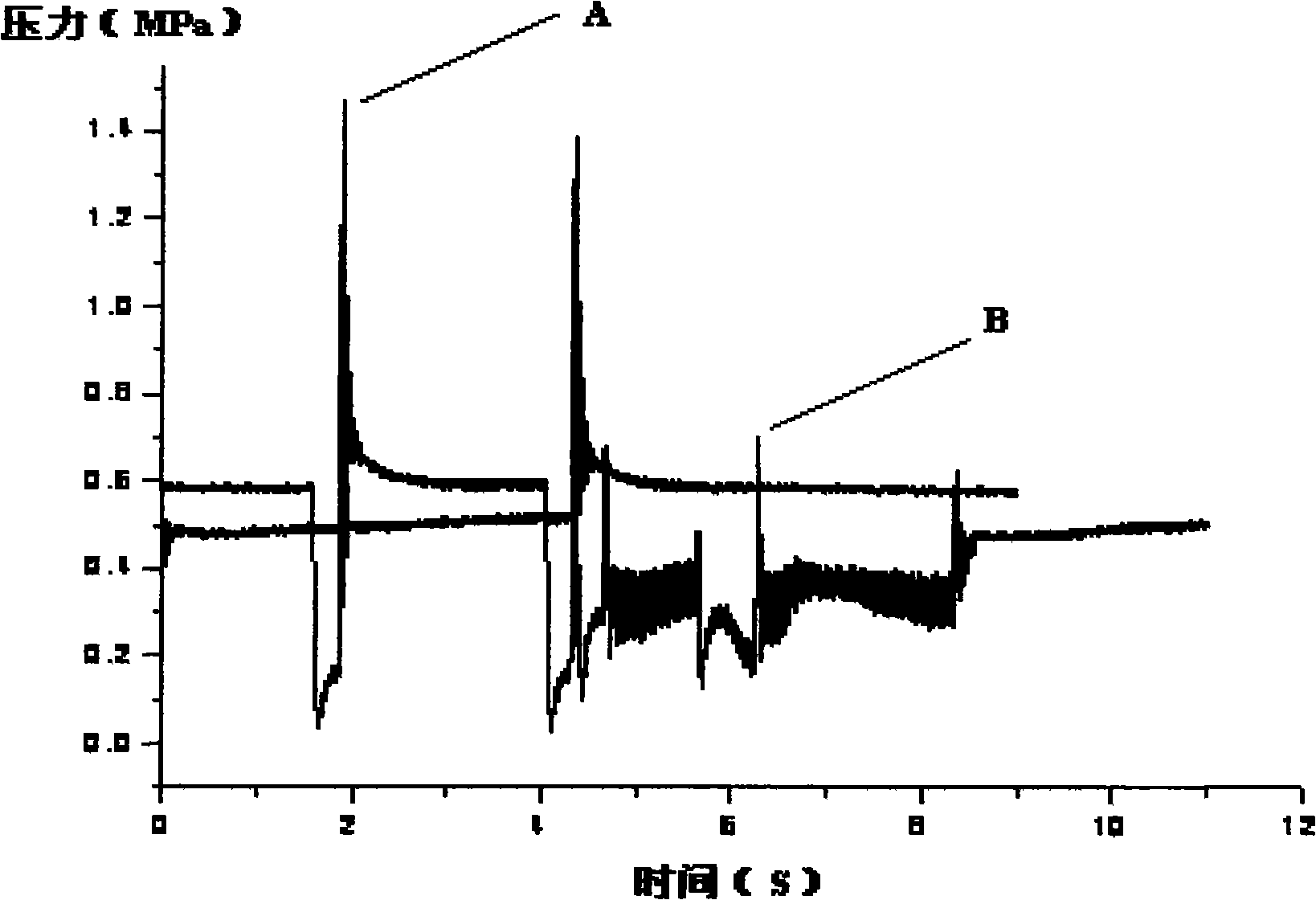

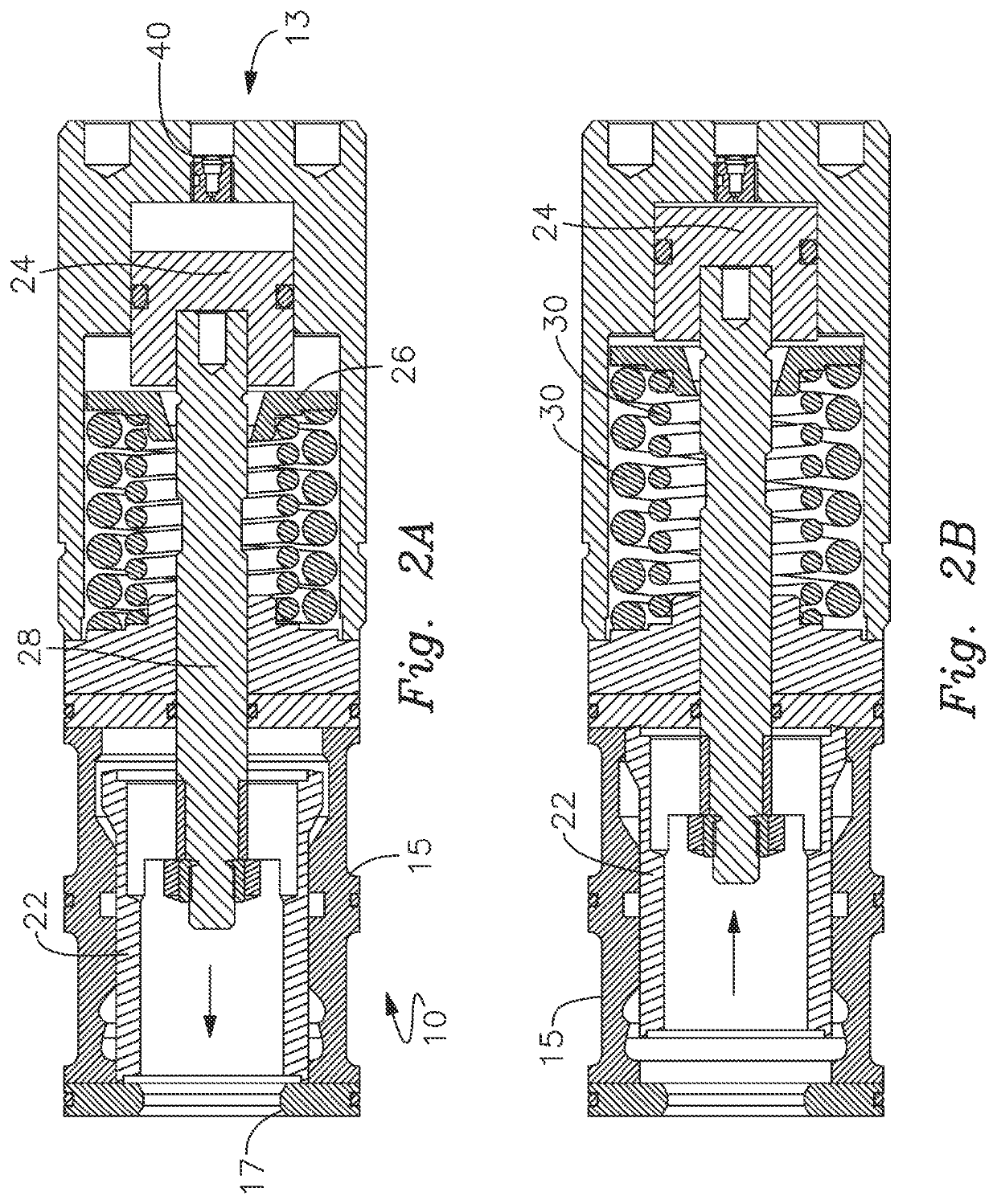

Bop control system circuit to reduce hydraulic flow/water hammer

ActiveUS20160222746A1Reduce water hammerReduce pressure spikeWell/borehole valve arrangementsSealing/packingControl systemEngineering

A subsea blowout preventer (BOP) hydraulic control system to reduce water hammer that includes a hydraulic fluid source. The system further includes a fluid supply conduit in fluid communication with the hydraulic fluid source at an upstream end, and with a BOP function at a downstream end. The system further includes a supply valve in the fluid supply conduit that controls the amount of fluid flow through the fluid supply conduit to the BOP function, the supply valve having an open state and a closed state. The supply valve has a choke that controls movement of the supply valve between the open state and the closed state and vice versa so that such movement is retarded when the supply valve state approaches the fully open or the fully closed state to reduce pressure spikes in the fluid of the fluid supply conduit.

Owner:HYDRIL USA DISTRIBUTION LLC

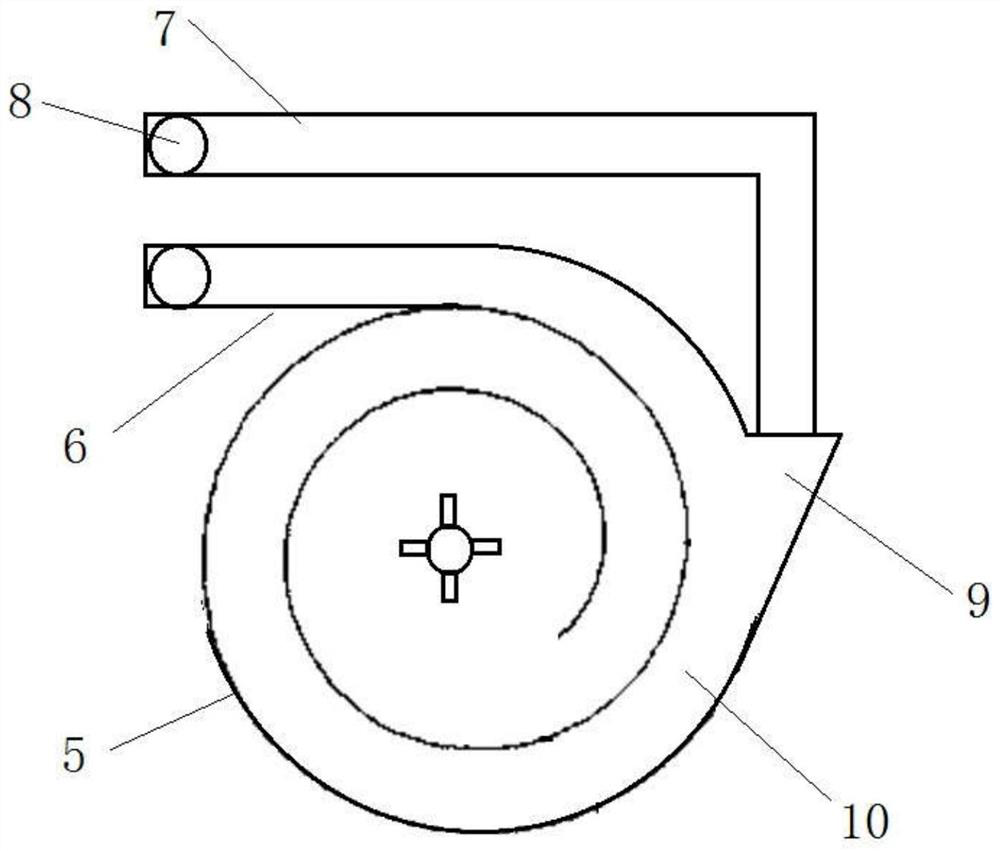

Working method for sewage treatment fluid control device

ActiveCN111928121AImprove mixing efficiencySpeed up the mixingWater treatment parameter controlPlug valvesFluid controlStream flow

The invention discloses a working method for a sewage treatment fluid control device. The sewage treatment fluid control device comprises a rotational flow disc, a first charging pipe, a second charging pipe, a control ball valve, a flow collection conical pipe, a stirring rod, a stirring blade, a funnel, an inclined flow channel, a one-way valve ball, a drainage channel, a blockage block, a flowinlet pipe, a yielding pipe end, a liquid level sensor and a controller, wherein the control ball valve comprises a valve body, a ball body, a valve rod, a sealing valve base and a valve neck; the ball body comprises a small-flow channel, a large-flow channel, a first area, a second area, a third area, a fourth area, a fifth area, a sixth area, a seventh area and an eighth area; the large-flow channel comprises a first port and a second port; and the small-flow channel comprises a third port and a fourth port. The working method comprises a ball valve circulation control method and a linkage control method.

Owner:RAILWAY NO 5 BUREAU GRP FIRST ENG CO LTD +2

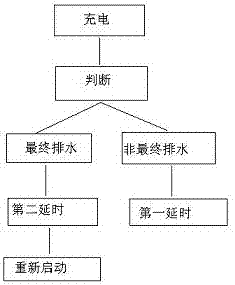

Operating method of drain valve of washing machine

InactiveCN107061779AAvoid residueReduce breedingPlug valvesOperating means/releasing devices for valvesStart stopControl system

The invention relates to an operating method of a drain valve of a washing machine. The washing machine comprises the drain valve of the washing machine and a start-stop control circuit. The operating method comprises the following drain steps that (1) a power supply is controlled by a control system so as to charge C1 when drainage is prepared, after the C1 is charged, a switch K is connected, a relay K1 is connected, and a motor is controlled to start so as to drain; (2) whether the drainage stage belongs to final drainage is determined; when the drainage stage belongs to non-final drainage, after the non-final drainage is finished, the washing machine enters a first delay procedure, at the moment, the switch K is disconnected, a normally open contact of a time relay S1 is connected, and the motor D is controlled to turn on for T1; after the whole washing process is fully finished, the washing machine enters a final drainage stage, after drainage is finished, the washing machine enters a second delay procedure, at the moment, the switch K is disconnected, a normally open contact of a time relay S2 is connected, and the motor D is controlled to turn on for T2; and the T2 is greater than the T1.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

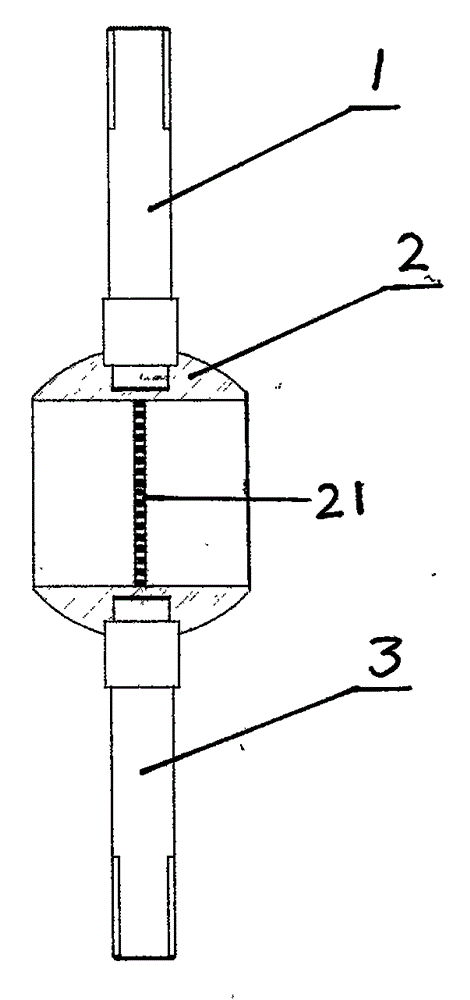

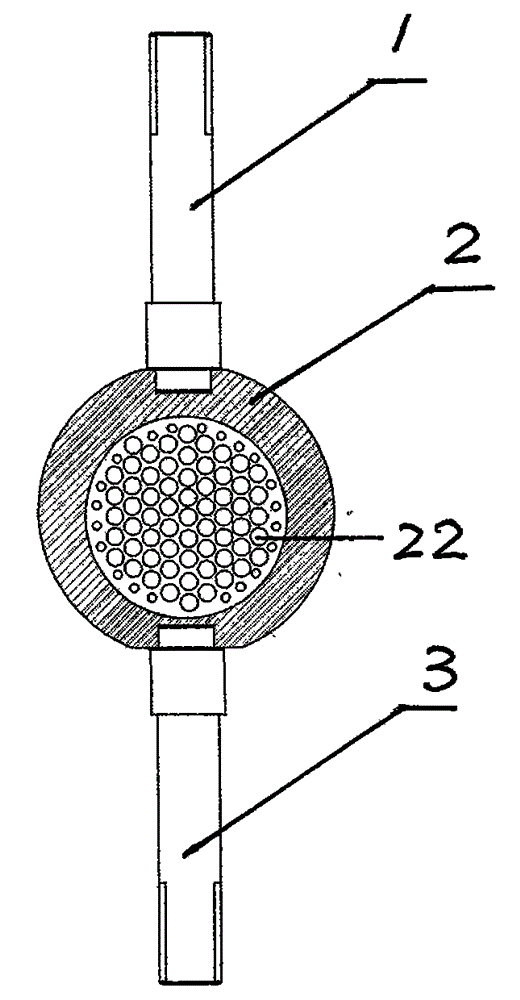

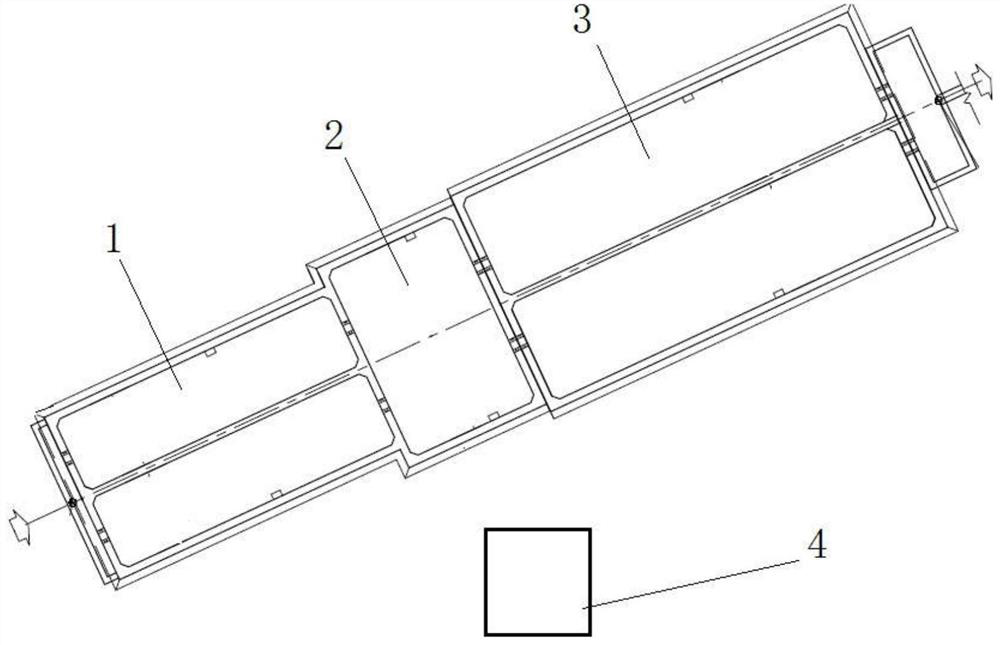

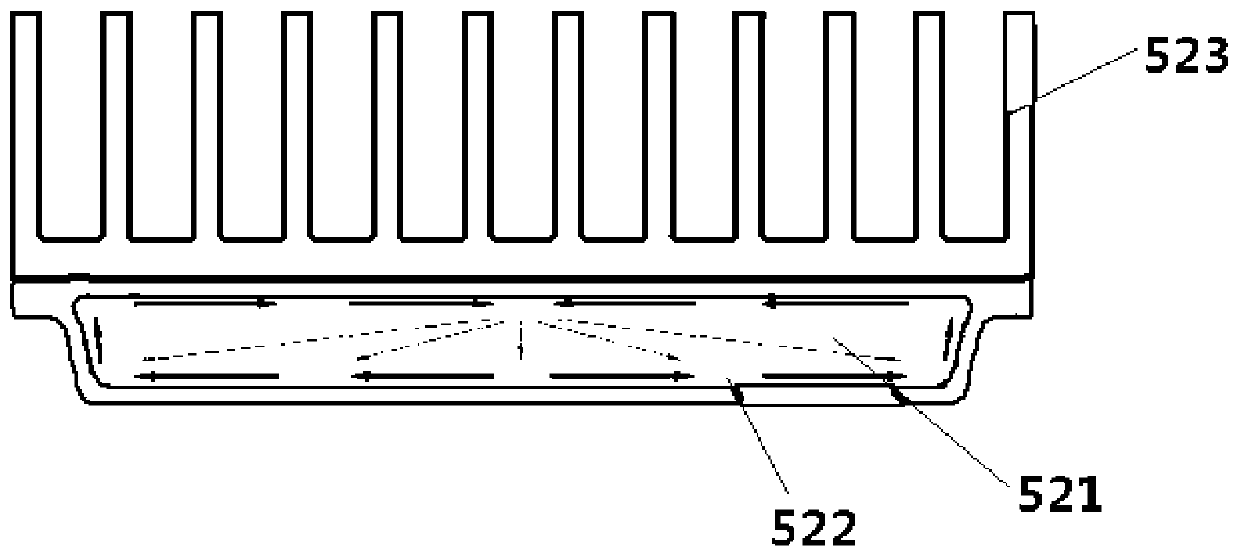

Steady flow evaporator and seawater desalination system

ActiveCN109231320AReduce water hammerImprove utilizationGeneral water supply conservationSeawater treatmentEvaporationEngineering

The invention provides a steady flow evaporator. The steady flow evaporator comprises an inlet header, an outlet header, and a heat exchange component connected between the inlet header and the outletheader, wherein the inlet header and the outlet header are respectively connected with a steam inlet pipe and a condensate outlet pipe; the steam inlet pipe of the inlet header is internally providedwith a flow stabilizer, and the flow stabilizer has a sheet structure; the sheet structure is arranged on the cross section of the steam inlet pipe; the flow stabilizer is formed by a square structure and a regular octagonal structure, so that a square through hole and a regular octagonal through hole are formed. The flow stabilizer with the novel structure is adopted, namely, a flow stabilizer in a loop heat pipe is subjected to field transfer and is applied to an inlet pipe at an evaporation end of the loop heat pipe, so that a water hammer phenomenon caused by the space expansion when a steam-water mixture enters the inlet header can be reduced.

Owner:SHANDONG UNIV

Magnetic valve

InactiveCN104074987ASimple structureReduce water hammerOperating means/releasing devices for valvesValve members for absorbing fluid energyEngineeringConical surface

The invention discloses a magnetic valve. The magnetic valve comprises a valve body, wherein a water inlet and a water outlet are formed inside the valve body. The magnetic valve also comprises a valve cover, a valve clack, a sealing assembly, a permanent flow valve, a guiding valve, a valve rod and a separation film; the separation film is arranged between the valve body and the valve cover; the valve rod and the valve clack are arranged below the separation film; one side of the valve clack, which is close to the separation film, is provided with a groove; one side of the valve clack, which is close to the water inlet, is a conical surface. The magnetic valve has the advantages of being simple in structure, effectively reducing water attack and being good in sealing effect.

Owner:SUZHOU GUJI ELECTRONICS TECH

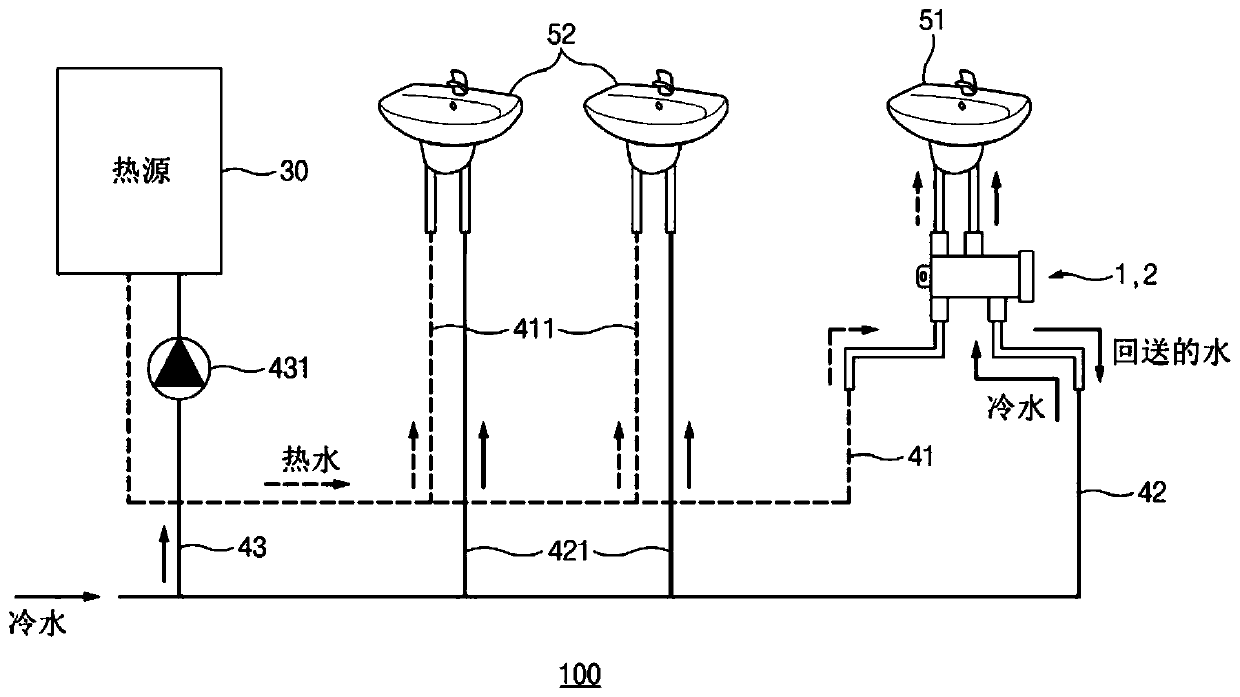

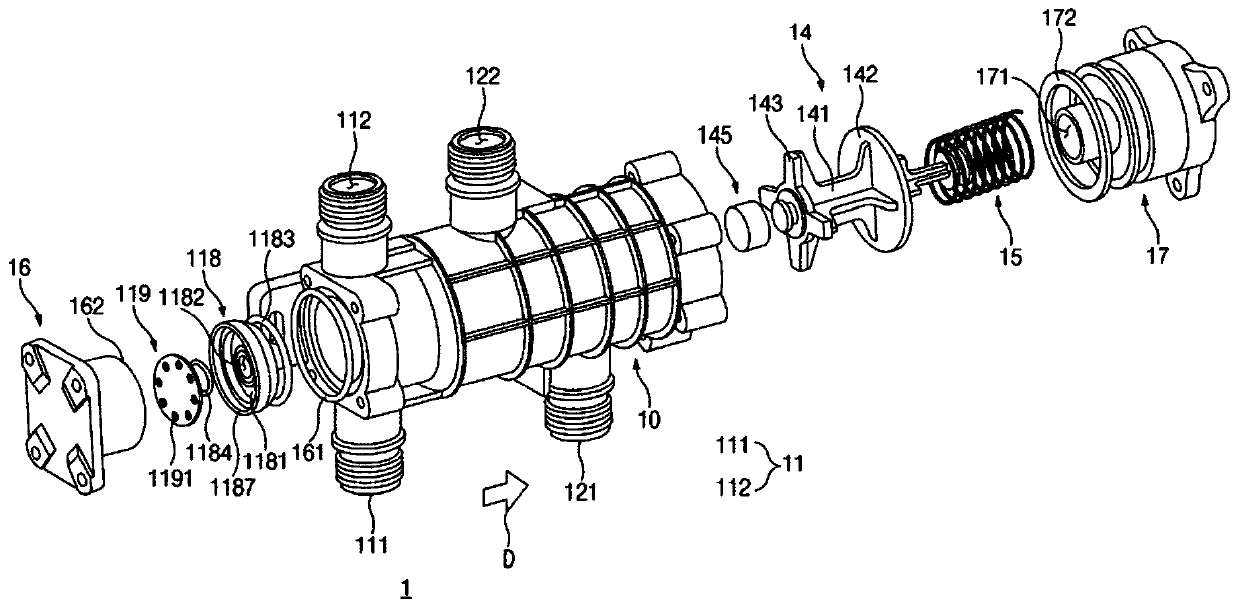

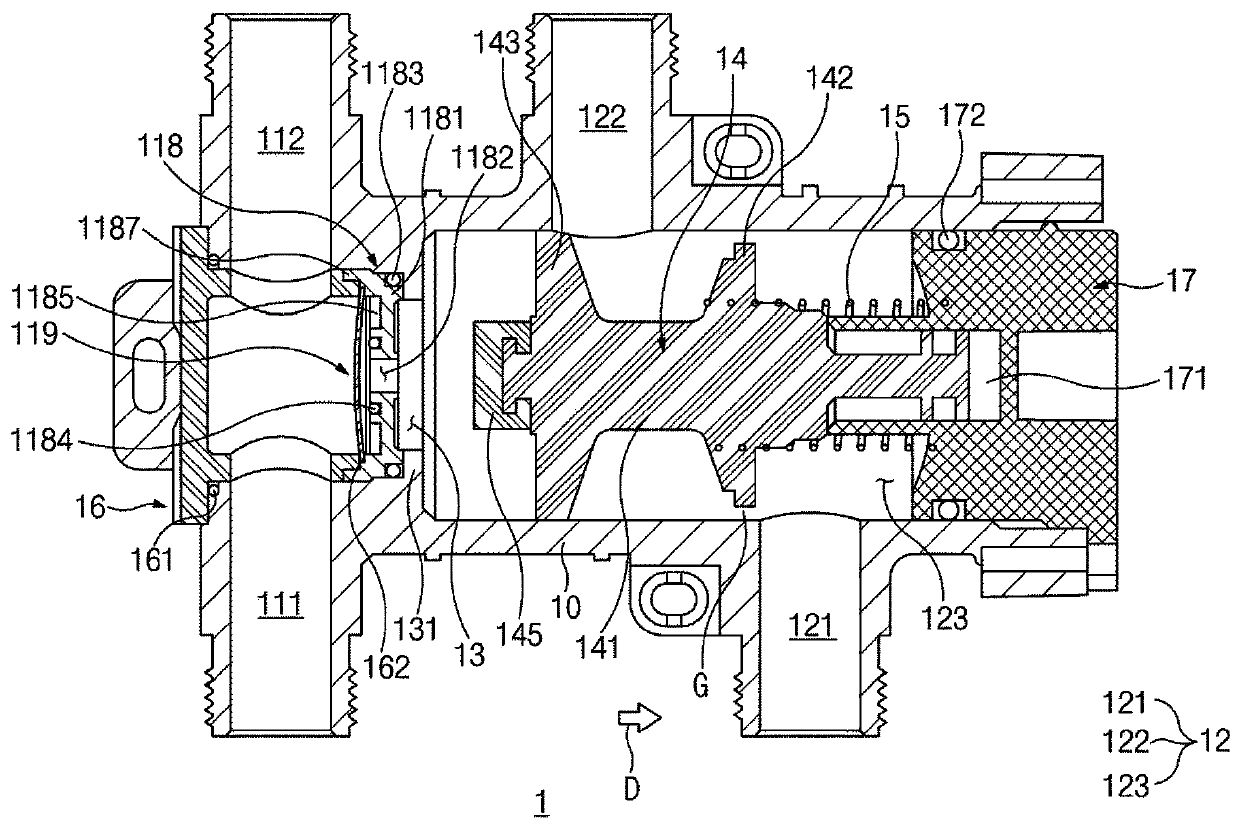

Recirculation valve and hot water recirculation system using the same

ActiveCN111102390AReduce water hammerReduce noiseOperating means/releasing devices for valvesCentral heating componentsWater flowEngineering

A recirculation valve includes a housing including a hot water fluid passage which is used to allow the hot water to flow through, a cold water fluid passage to allow the cold water to flow through, and a recirculation fluid passage to allow the hot water in the hot water fluid passage to flow into the cold water fluid passage, a water pressure plate provided to close the recirculation fluid passage when the cold water or the hot water is used, and to open the recirculation fluid passage when the cold and hot waters are not used, and a bimetal plate configured to open the recirculation fluid passage as the bimetal plate is spaced apart from a recirculation opening and to close the recirculation fluid passage by making contact with the recirculation opening, and positioned downstream of therecirculation opening in a direction in which the hot water flows.

Owner:KYUNGDONG NAVIEN

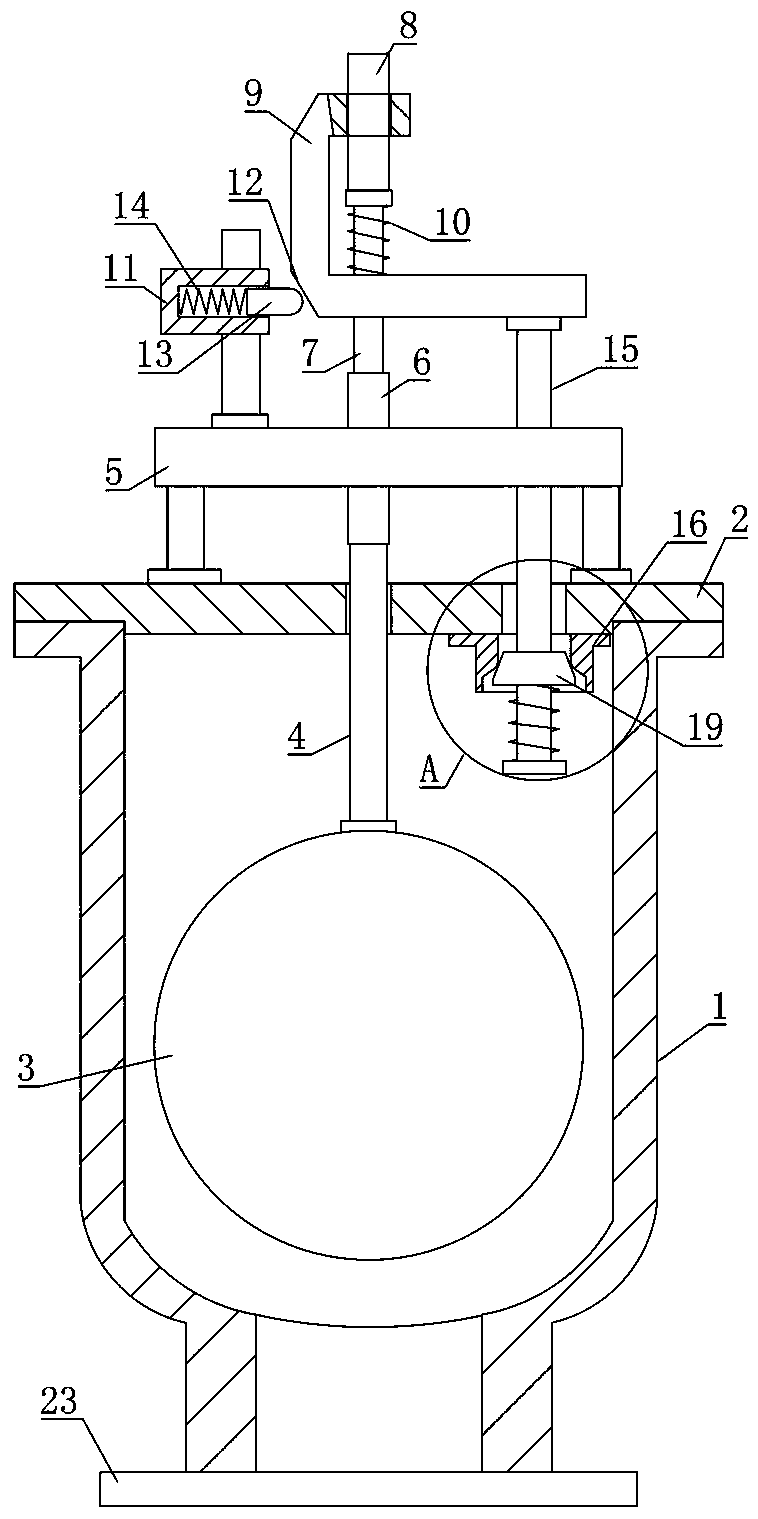

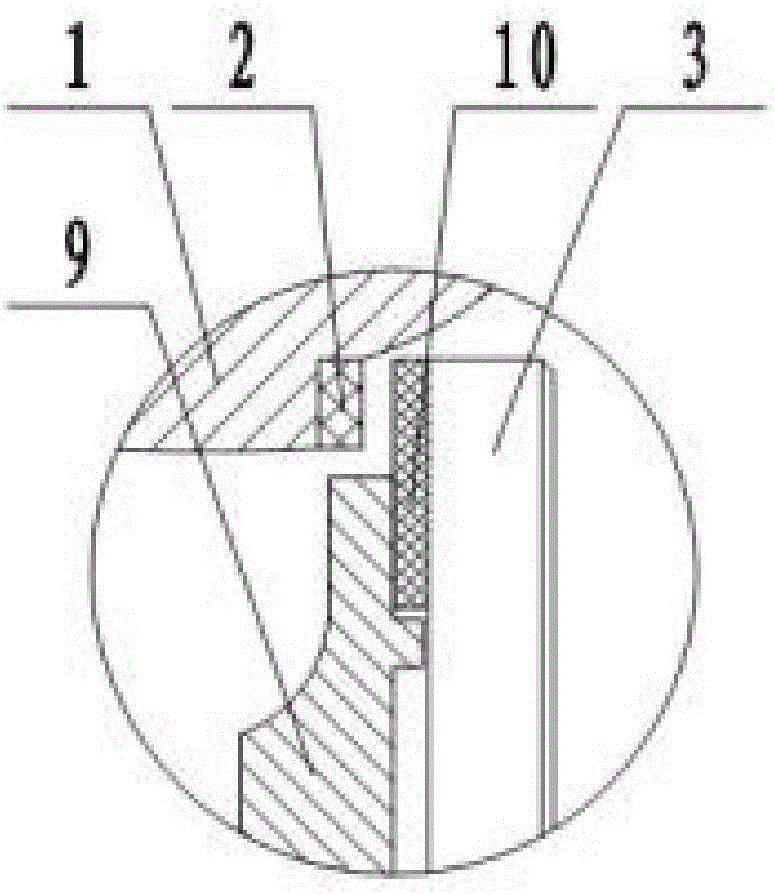

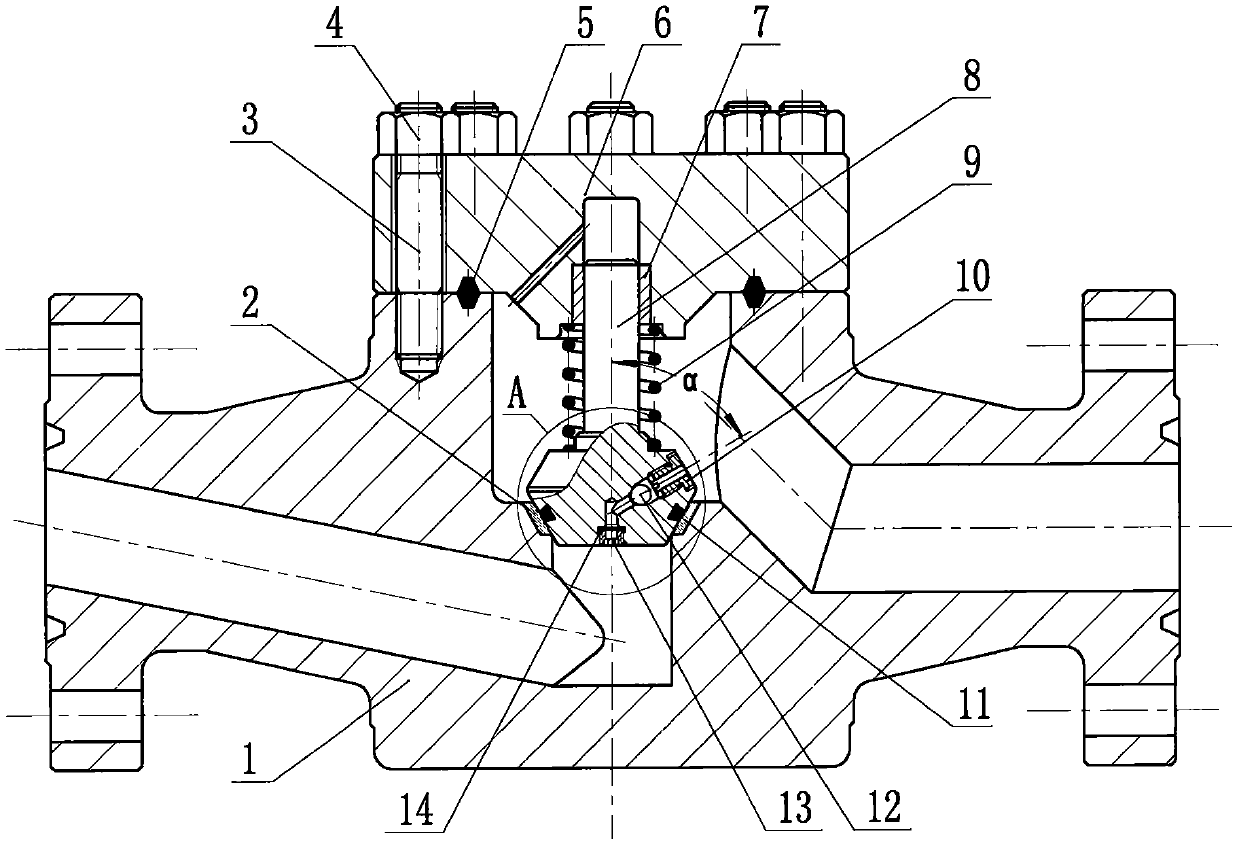

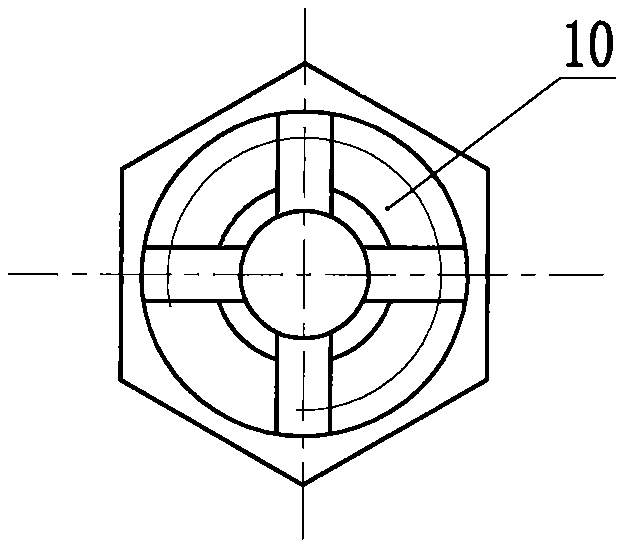

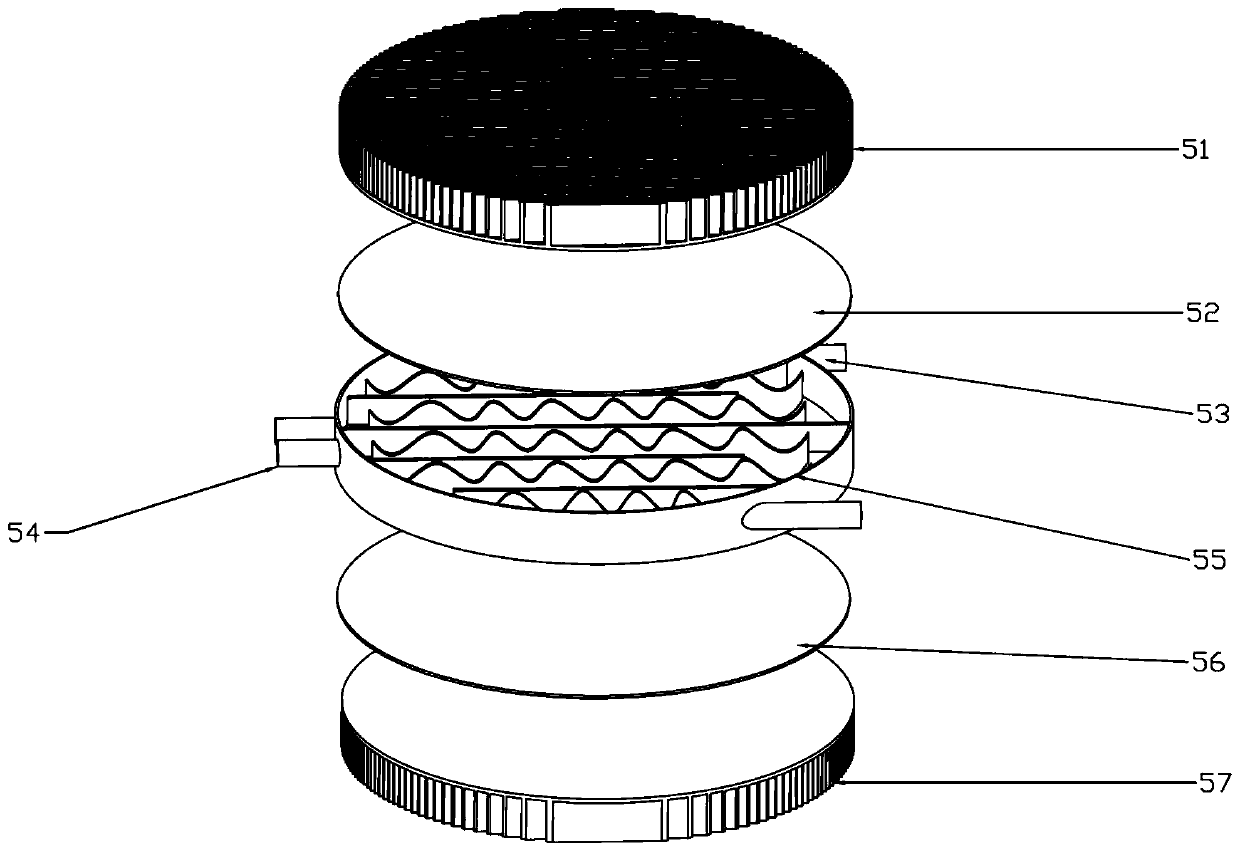

Lifting-type check valve capable of reducing harm of water attack

PendingCN111306354AAvoid damageReduce water hammerCheck valvesValve members for absorbing fluid energyStructural engineeringSteel ball

The invention provides a lifting-type check valve capable of reducing the harm of water attack. The lifting-type check valve comprises a valve body, a valve seat, a valve deck, a bush, a valve elementand a compression spring and further comprises a sealing piece and a connecting piece which are adopted. The lifting-type check valve is characterized in that a small check valve sealed by a small steel ball is arranged in the sealed end of the valve element of the lifting-type check valve; the small check valve is formed by adopting the sealed end of the valve element of the lifting-type check valve as a valve body and adding an outer hexagonal hollow plug and the small steel ball for combination; and an inner hexagonal hollow plug and a filter net are further mounted at an inlet of the small check valve. When the water attack phenomenon occurs, the pressure is relieved through the small check valve, thus the phenomenon and harm of water attack are reduced, and compared with other measures for preventing and reducing the phenomenon of water attack, the advantages that the size of original equipment or pipeline is not increased, and the cost is the lowest are achieved.

Owner:JIANGSU HONGTAI PETROCHEM MACHINERY

Check valve of double non-return device with cylindrical diaphragm of rubber

A check valve of double no ¿C return units with rubber diaphragm barrel is composed of valve body, the first non ¿C return unit and the second non ¿C return unit. It is featured as setting fixed bush being fixed by support rib plate in valve body, setting the second non ¿C return unit at outlet section of valve, forming outlet section by barrel ¿C type rubber diaphragm valve clack and support screen case, fixing front end of said valve clack in fixed bush of valve body and fixing support screen case at internal side of valve body.

Owner:SHANGHAI SHANGLONG VALVE FACTORY

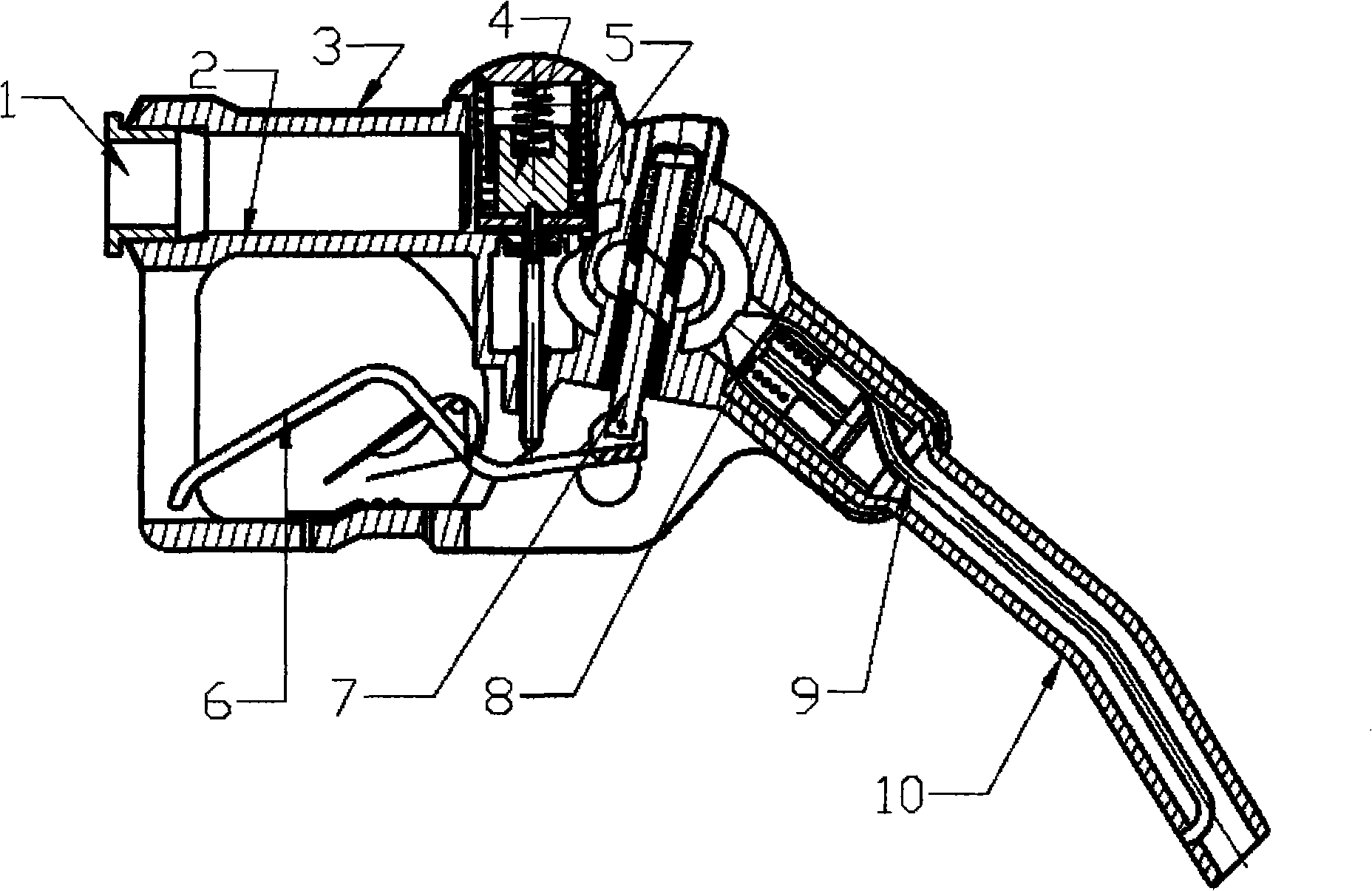

Fuel truck nozzle

ActiveCN101298312AAvoid frictionExtended closing timeLiquid transferring devicesThin segmentPiston ring

The invention discloses a fuel filling gun which has a control valve; the control valve includes a master valve and a secondary valve arranged inside the master valve; the master valve consists of an external ring that is fixedly arranged under the a gun cover, a master valve body that has clearance fit with the external ring and a master valve spring pack with two ends respectively touches against the gun cover and the bottom of the head valve at the bottom of the master valve body; the secondary valve consists of an internal ring that is fixedly arranged under the gun cover, a secondary valve body and a secondary spring pack with two end respectively touches the gun cover and the secondary valve at the bottom of the secondary valve body. The internal ring has tight fit with the secondary valve by a piston ring; a knockout-pin which is connected with the control handle has a spindle shoulder, the thin segment of the knockout-pin passes through the head valve and the top end is fixedly connected with the secondary valve; the spindle shoulder is limited out of the head valve, and a clearance is left between the head valve and the spindle shoulder when the head valve is closed. The fuel filling gun makes improvement on the control valve, which greatly reduces the water hammer phenomenon, reduces the impact on the hydraulic units of the filling machine when the filling gun is switched on or switched off and improves the performance stability and working reliability of the hydraulic units of the fuel filling machine.

Owner:TOKHEIM HENGSHAN TECH GUANGZHOU

Design method of steam pipe flow stabilizing device and seawater desalination system thereof

ActiveCN110038314AReduce water hammerImprove utilizationGeneral water supply conservationSeawater treatmentGas phaseEngineering

Owner:SHANDONG UNIV

Water hammer prevention method for medium plate quenching machine

ActiveCN111154967AReduce water hammerAdd speed moduleFurnace typesHeat treatment process controlPressure stabilizationEngineering

The invention provides a water hammer prevention method for a medium plate quenching machine, and belongs to the technical field of metal heat treatment cooling. The method comprises the following technological processes of heating a steel plate with the thickness range of 8-120mm to 800-980 DEG C by a roller hearth heating furnace, conveying the heated steel plate to a furnace rear quenching machine area by a conveying roller way to quench the heated steel plate to room temperature or normalize and cool the heated steel plate to be lower than or equal to 680 DEG C, and conveying the cooled steel plate to a cooling bed through the conveying roller way. According to the water hammer prevention method, a buffer water drum is additionally arranged between a water supply main pipe and a coolerwater supply branch pipe, the water supply main pipe and the buffer water drum are connected through a multi-branch corrugated pipe, the two ends of the water supply main pipe are provided with pressure maintaining and releasing valves separately, a cooler pneumatic opening and closing valve is additionally provided with a speed regulation module and is opened and closed in a time-staggered manner and an overpressure alarm is given. After the water hammer prevention method is adopted, it is guaranteed that the high-pressure water pressure of the quenching machine is stabilized at 0.8 MPa + / -0.02 MPa, and the low-pressure water pressure is stabilized at 0.4 MPa + / -0.02 MPa; and the phenomena of water hammer and water pressure fluctuation of the quenching machine are avoided, and the structure performance of the steel plate subjected to quenching and normalizing and cooling by the method well meets the requirements.

Owner:UNIV OF SCI & TECH BEIJING

Process for manufacturing DC waterproof pump controlling valve with small water hammer

InactiveCN101096963AReasonable workmanshipIngenious ideaPump componentsPump controlInlet valveEngineering

The invention discloses a preparing craft of straight-flow type water pump controlled valve of small water hammer, which comprises the following steps: providing a cane axle and connected bolt between outlet valve clad and inlet valve clad; connecting through nut; getting the product. This invention possesses reasonable craft and good idea, which can be spreaded widely.

Owner:SHANGHAI SHANGLONG VALVE FACTORY

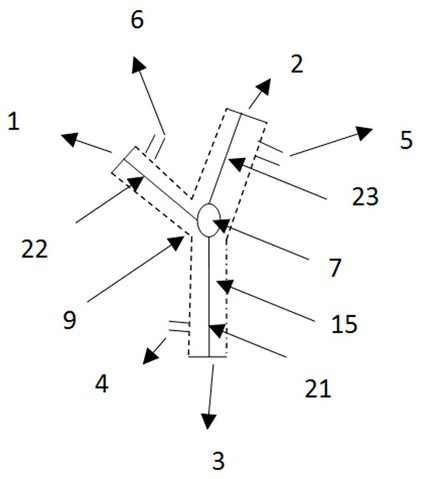

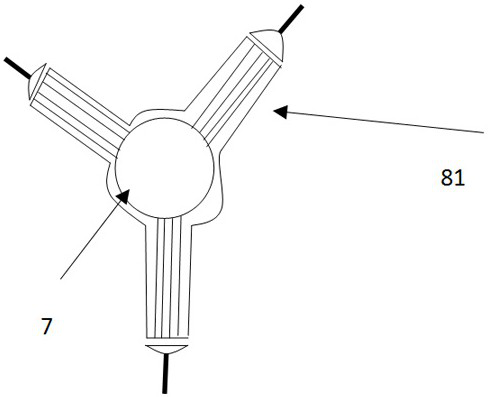

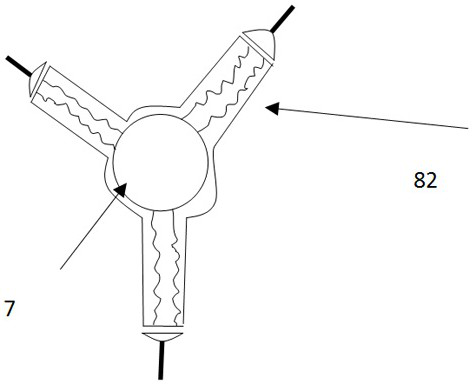

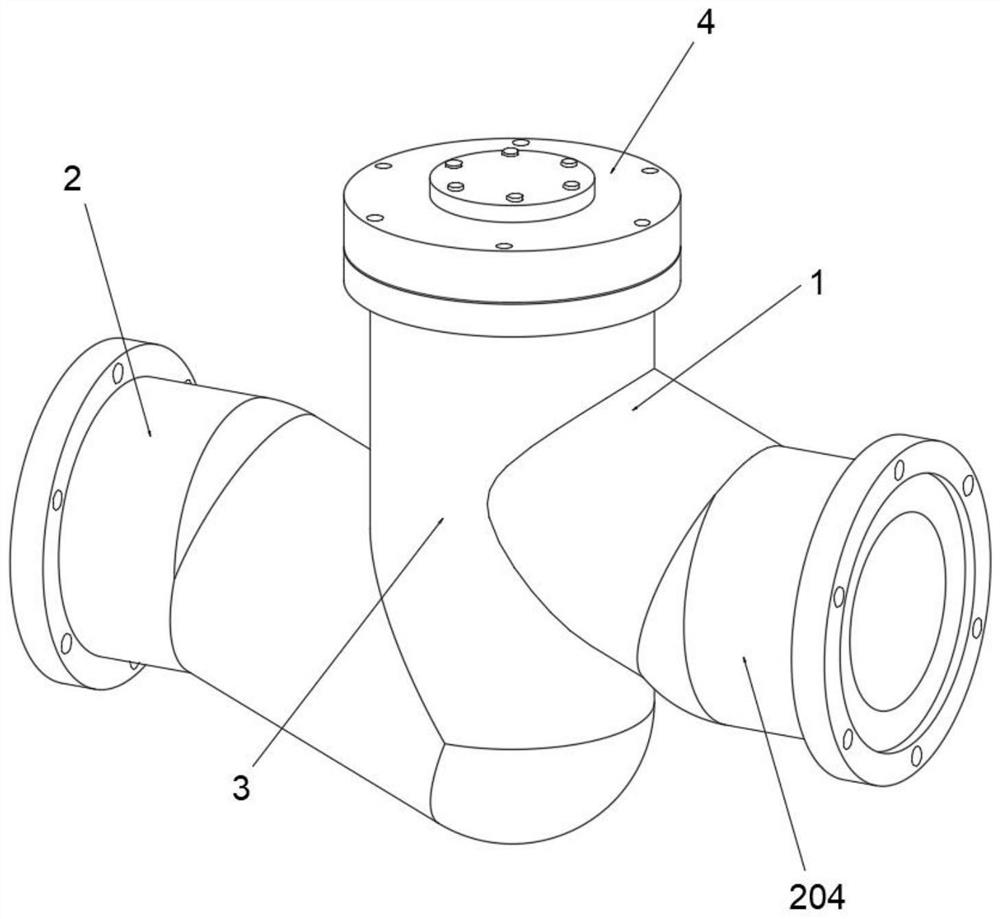

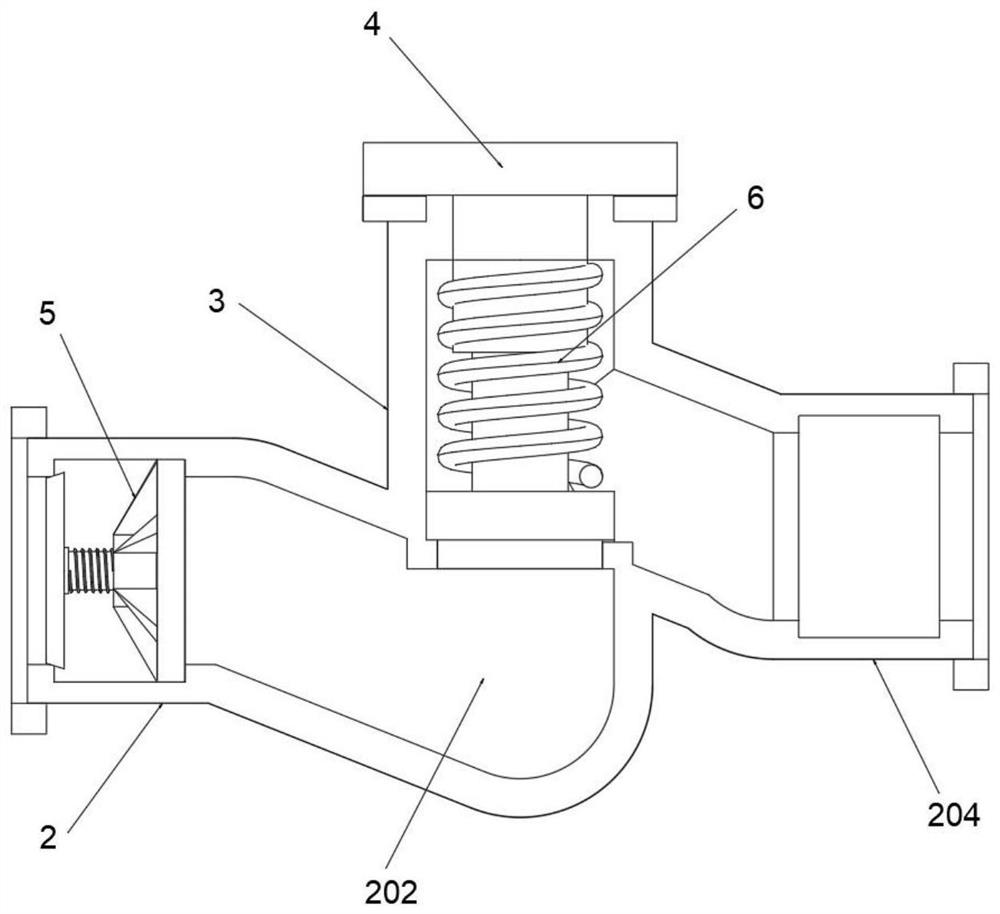

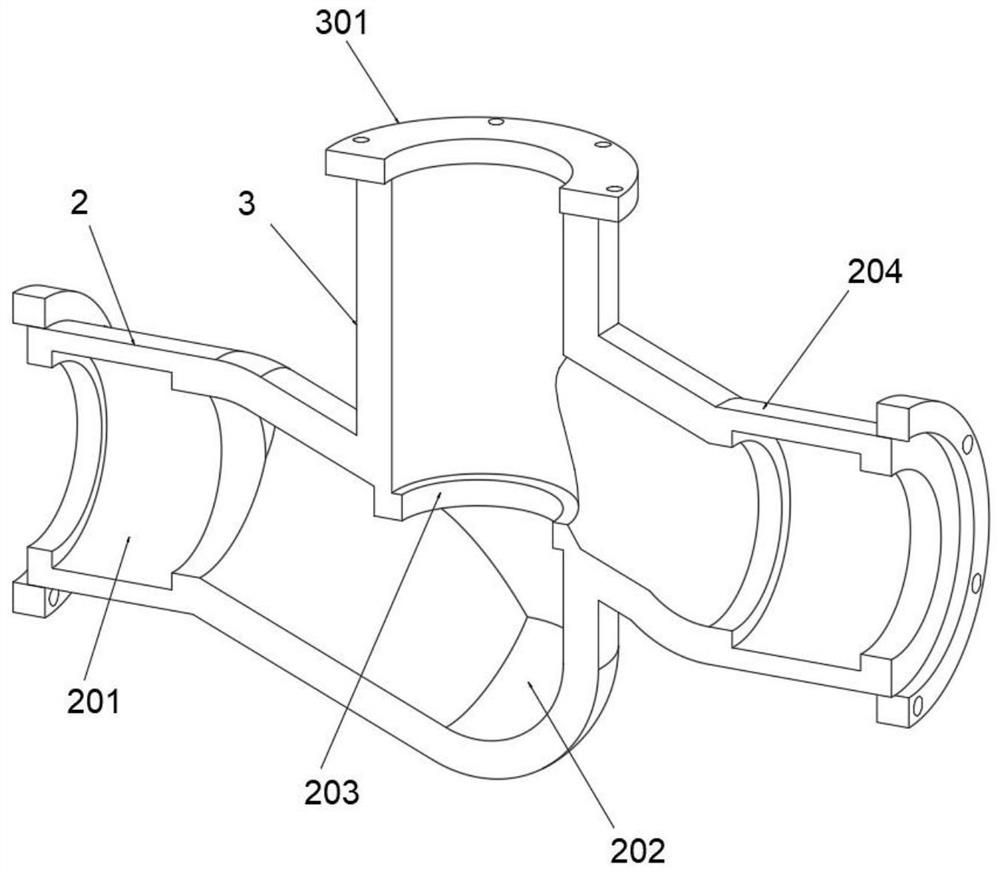

Y-shaped heat exchanger and reactor with heat exchange device

PendingCN114577036AAvoid damageGuaranteed separation effectDispersed particle filtrationChemical industryChemical reactionEngineering

The invention discloses a Y-shaped heat exchanger and a reactor with a heat exchange device.The Y-shaped heat exchanger comprises a heat exchanger shell (9), a gas-liquid separation cavity (7), a heat exchange tube A (21) arranged downwards along the horizontal plane, a heat exchange tube B (22) arranged upwards along the horizontal plane and a heat exchange tube C (23) arranged upwards along the horizontal plane, and the heat exchanger shell (9), the heat exchange tube A (21), the heat exchange tube B (22) and the heat exchange tube C (23) form a heat exchange cabin (15); the heat exchange tube A (21), the heat exchange tube B (22) and the heat exchange tube C (23) are respectively communicated with the gas-liquid separation cavity (7); the lower end of the heat exchange tube A (21) is provided with a backflow port (3), the upper end of the heat exchange tube B (22) is provided with a gas inlet (1), and the upper end of the heat exchange tube C (23) is provided with a gas outlet (2). The device is used for the physical and chemical reaction process, dangerous gas gathering can be completely avoided, and the gas-liquid separation effect and the heat exchange effect are guaranteed.

Owner:LIMING RES INST OF CHEM IND

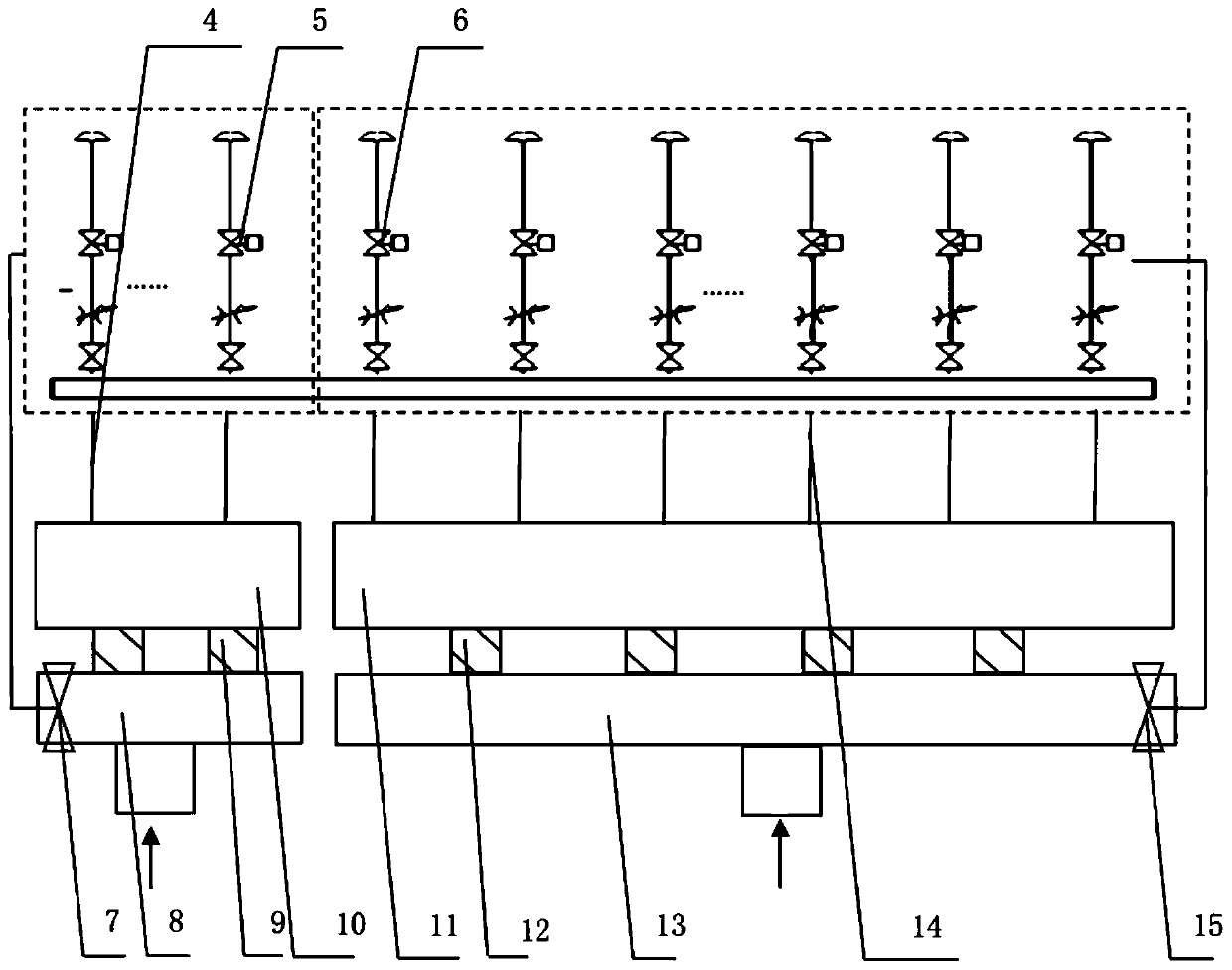

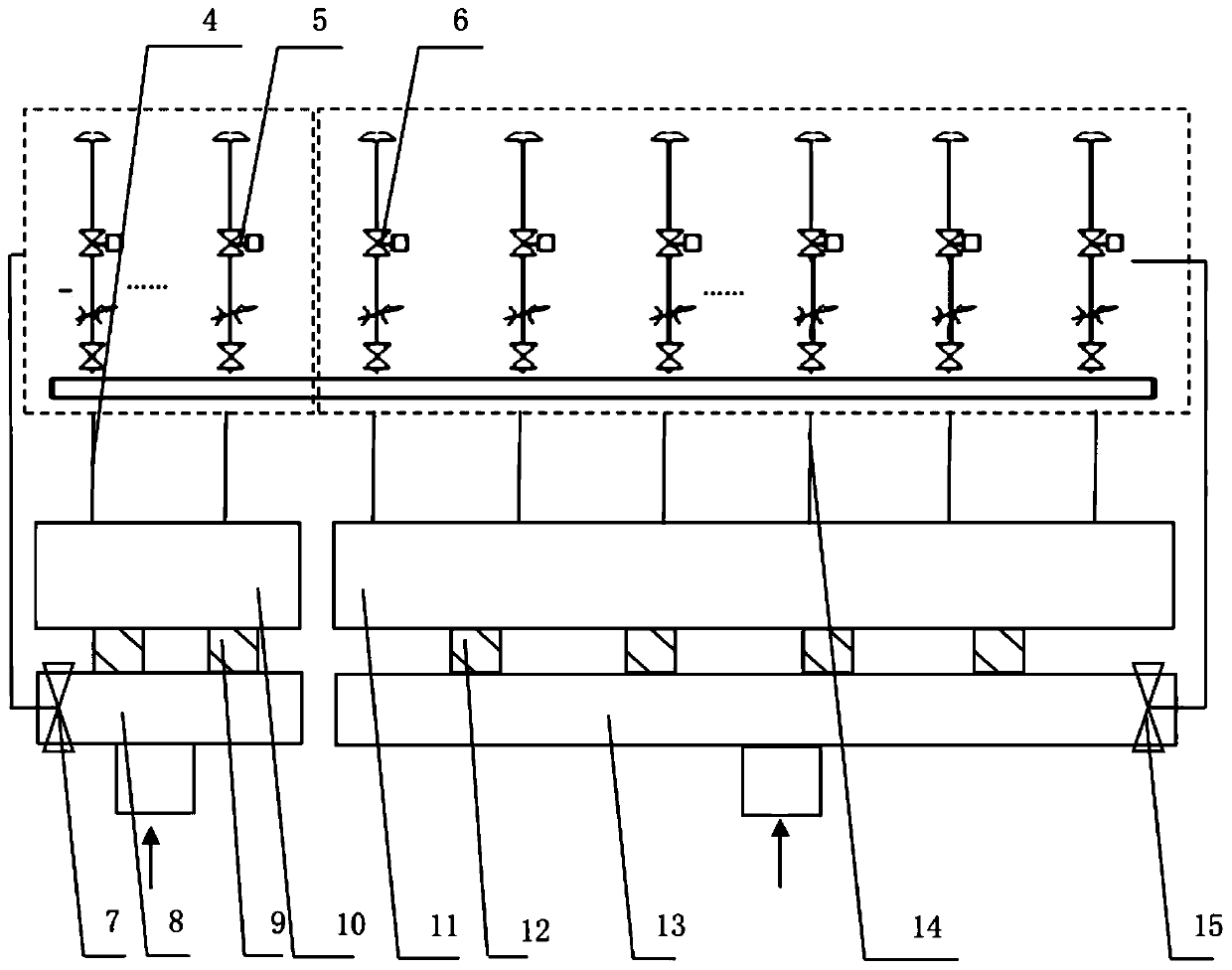

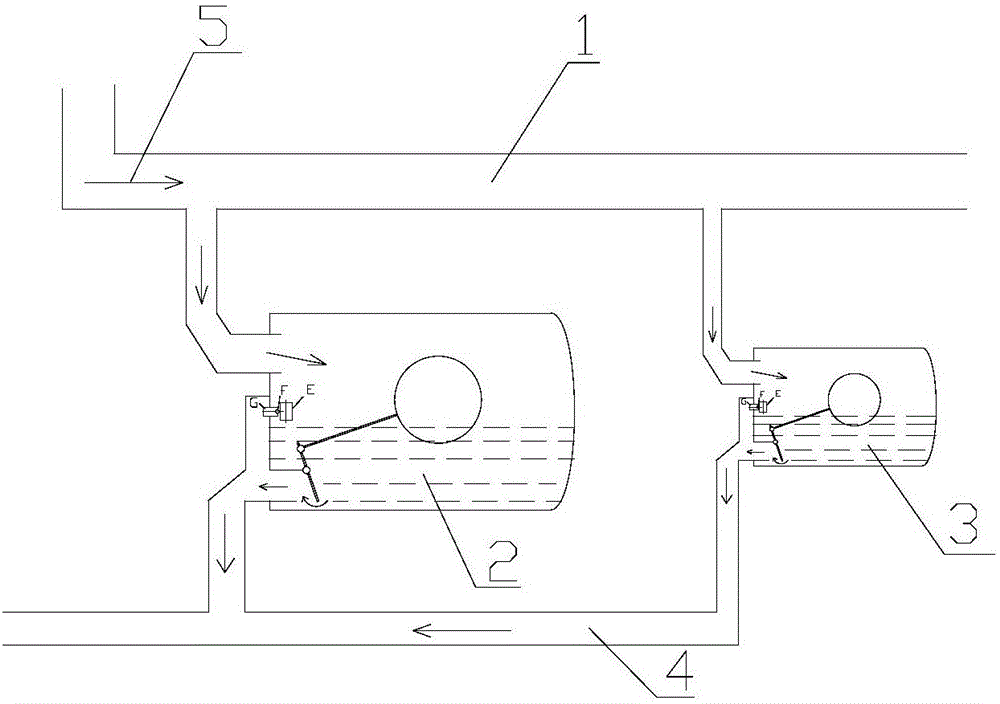

Condensed Water Discharge System for Reducing Water Hammer

ActiveCN106338001AAvoid secondary steamWater hammerSteam trapsWater dischargeEnvironmental engineering

The invention relates to a condensation water discharge system for reducing the occurrence of water hammer. It's used for discharge of condensed water from heat exchanger, including a controller, a pre-valve condensation water pipe (1) connected to a heat exchanger, two floating ball type water drain valves arranged in parallel on the pre-valvet condensation water pipe (1) and behind-valve condensation water pipes (4) connected respectivedly with each floating ball type steam trap. The condensed water inlet of each floating ball type steam trap is respectively provided with a control valve, and the control valve is communicated with the controller. Compared with the prior art, the present invention takes advantages in its wide application range, its high drainage function according to different working conditions, as well as its safety and reliability, and the like.

Owner:SHANGHAI DAZHONG XIANGYUAN POWER SUPPLY

External anti-backflow mechanism for water meter in high-fall installation environment

InactiveCN112128437APrevent backflowAvoid enteringCheck valvesVolume meteringWater stopAmbient water

The invention relates to the technical field of anti-backflow mechanisms for water meters, in particular to an external anti-backflow mechanism for a water meter in a high-fall installation environment. The external anti-backflow mechanism for the water meter in the high-fall installation environment comprises a water blocking piece, wherein the water blocking piece comprises a second valve clack;a water stop plug is fixedly connected to the center of the lower surface of the second valve clack; a guide rod is fixedly connected to the center of the upper surface of the second valve clack; sliding blocks are arranged on the side walls of the periphery of the guide rod; a guide cylinder is fixedly connected to the center of the upper surface of a first sealing plug and is sleeved with a second spring; a guide hole is formed in the center of the lower surface of the guide cylinder; limiting grooves are formed in the periphery of the inner wall of the guide hole; and the guide hole and ascrew hole are concentric holes which are through up and down. Through arranging a first non-return device, a first valve clack is closely fitted to a water inlet pipe, so that water is effectively prevented from flowing back; and through the first valve clack, the problems that water in a flow storage cavity flows back, the pressure on one side of the flow storage cavity is increased, and a waterflow on one side of a water outlet pipe permeates into the flow storage cavity from a gap of a valve seat under the action of the pressure, so that water backflow is caused are solved.

Owner:湖南常德牌水表制造有限公司

Integrated self-condensation drainage device

The invention provides an integrated self-condensation drainage device. The device comprises a shell, a steam pipeline, a condensate pipeline and a drainage pipeline, wherein the steam pipeline, the condensate pipeline and the drainage pipeline are all arranged in the shell, the first end of the steam pipeline is in communication with the exterior of the shell, the second end of the steam pipeline is in communication with the first end of the drainage pipeline, the second end of the drainage pipeline is in communication with the first end of the condensate pipeline, the second end of the condensate pipeline is in communication with the exterior of the shell, a drainage valve is arranged on the drainage pipeline, and a cooling assembly is arranged on the condensate pipeline. The device is installed at the low point or the tail end wherein a condensate is generated of an existing steam pipe, the steam pipeline is in communication with the existing steam pipe, the condensate pipeline is in communication with an existing condensate pipe, the condensate generated in the existing steam pipe enters the steam pipeline and flows through the condensate pipeline through the drainage valve of the drainage pipeline to be drained into the existing condensate pipe, when the condensate is flash-evaporated into steam through the drainage valve to enter the condensate pipeline, the condensate is condensed again into condensate through the cooling assembly, and thus the steam generated through flash evaporation can be effectively treated, and the water hammer phenomenon is reduced.

Owner:BEIJING PETROCHEM ENG

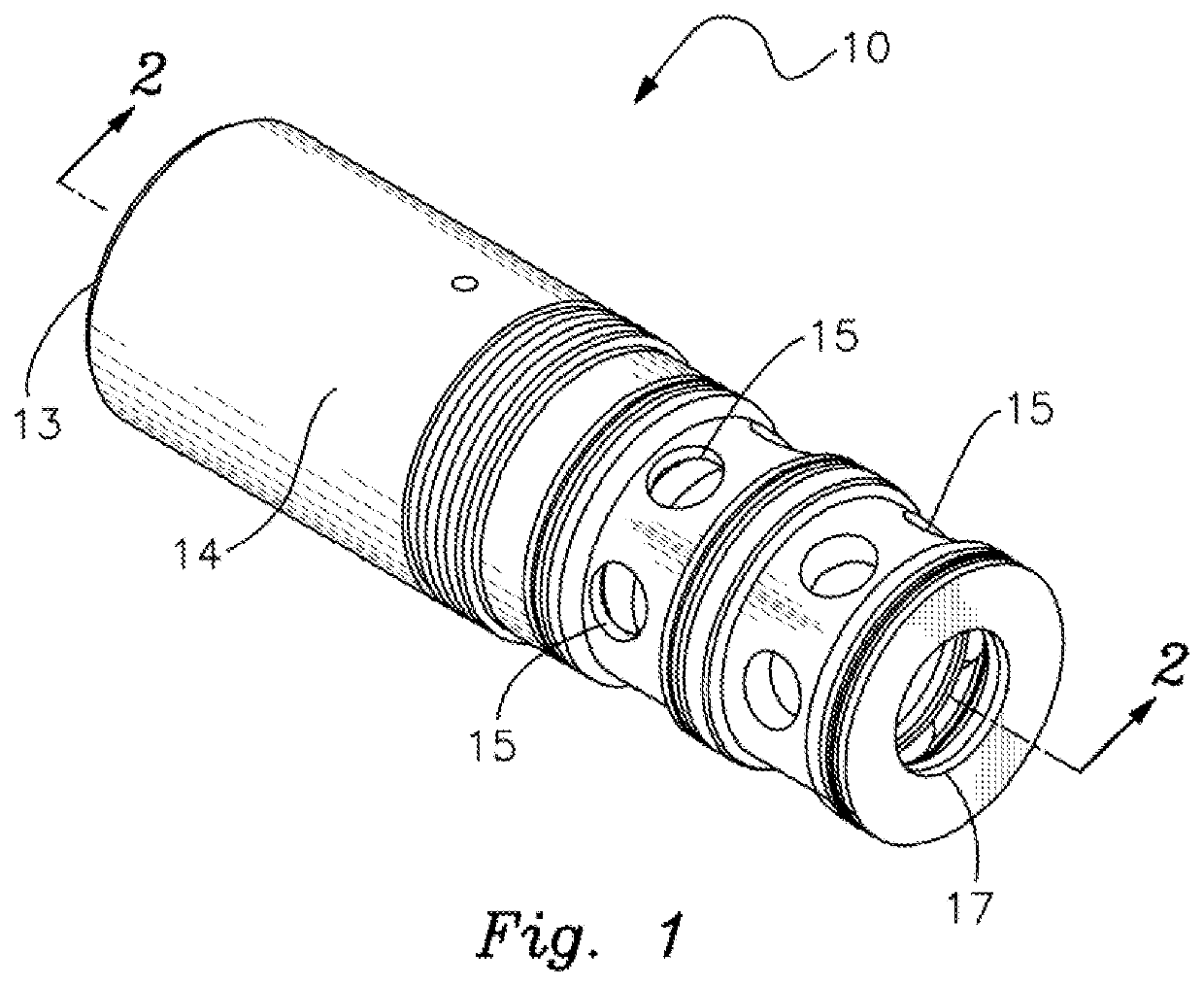

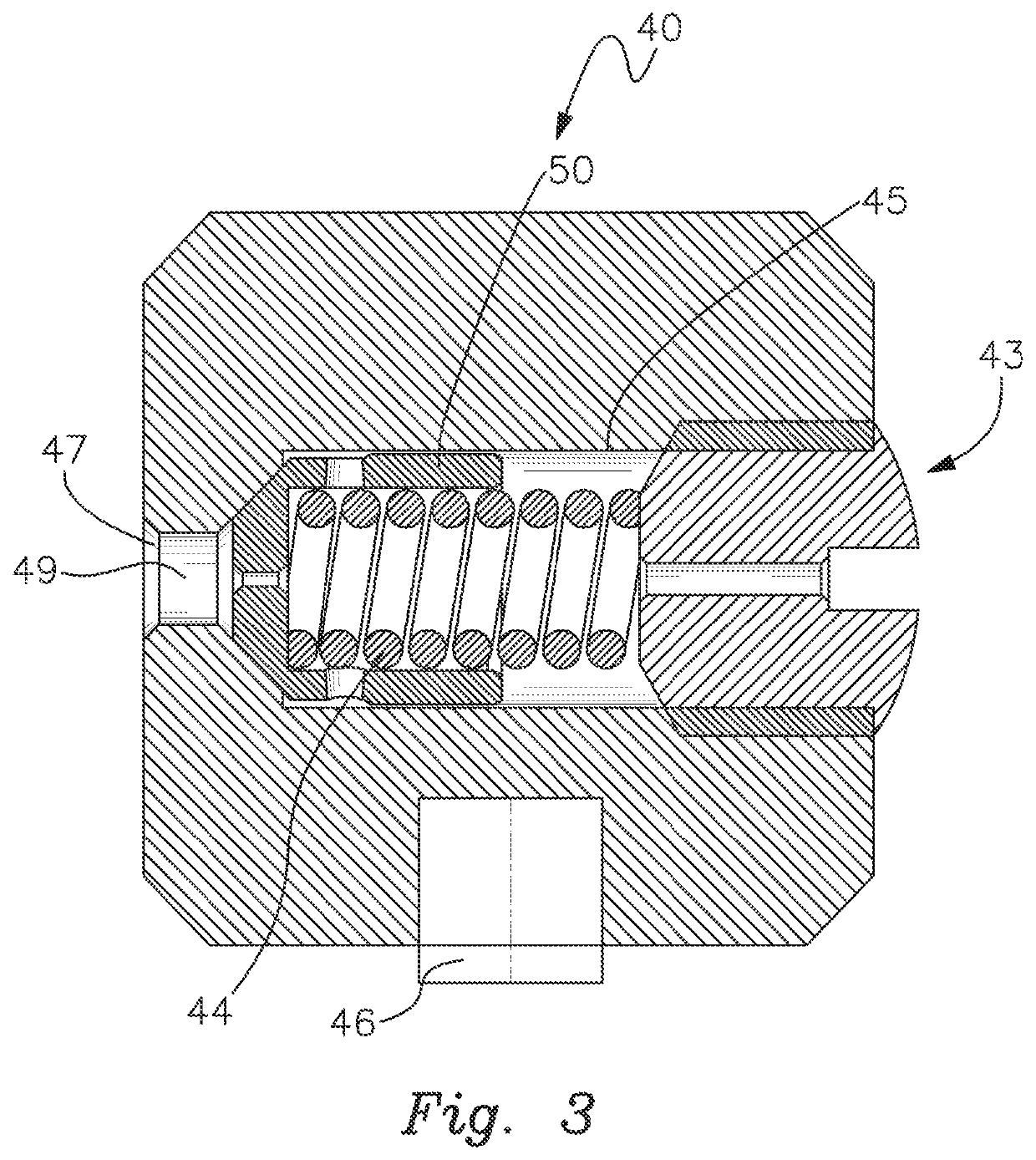

Soft shift SPM valve

ActiveUS11326716B2Avoid damageShorten the timeValve members for absorbing fluid energyFluid removalEngineeringWater hammer

A subplate mounted valve is disclosed having an open position and a closed position. The valve includes at least one pilot pressure intake port, a plurality of functional fluid ports, a spool movable between the open position and the closed position, and spring biasing the spool to either the open position or the closed position. To reduce water hammer due to quickly opening or quickly closing the valve, a flow regulation assembly is positioned at the pilot pressure intake port and has a chamber with a larger inlet channel at the intake position and transitioning to a smaller channel at the outlet position such that fluid flow at the intake port is reduced, thereby slowing the transition between the open position and the closed position and the transition between the closed position and the open position.

Owner:THE SUBSEA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com