Lifting-type check valve capable of reducing harm of water attack

A single-flow valve and lift-type technology, which is applied in the field of single-flow valves, can solve problems such as deformation, increased equipment or pipeline manufacturing costs, parts damage and accidents, and achieve the effects of avoiding damage and reducing water hammer phenomena and hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

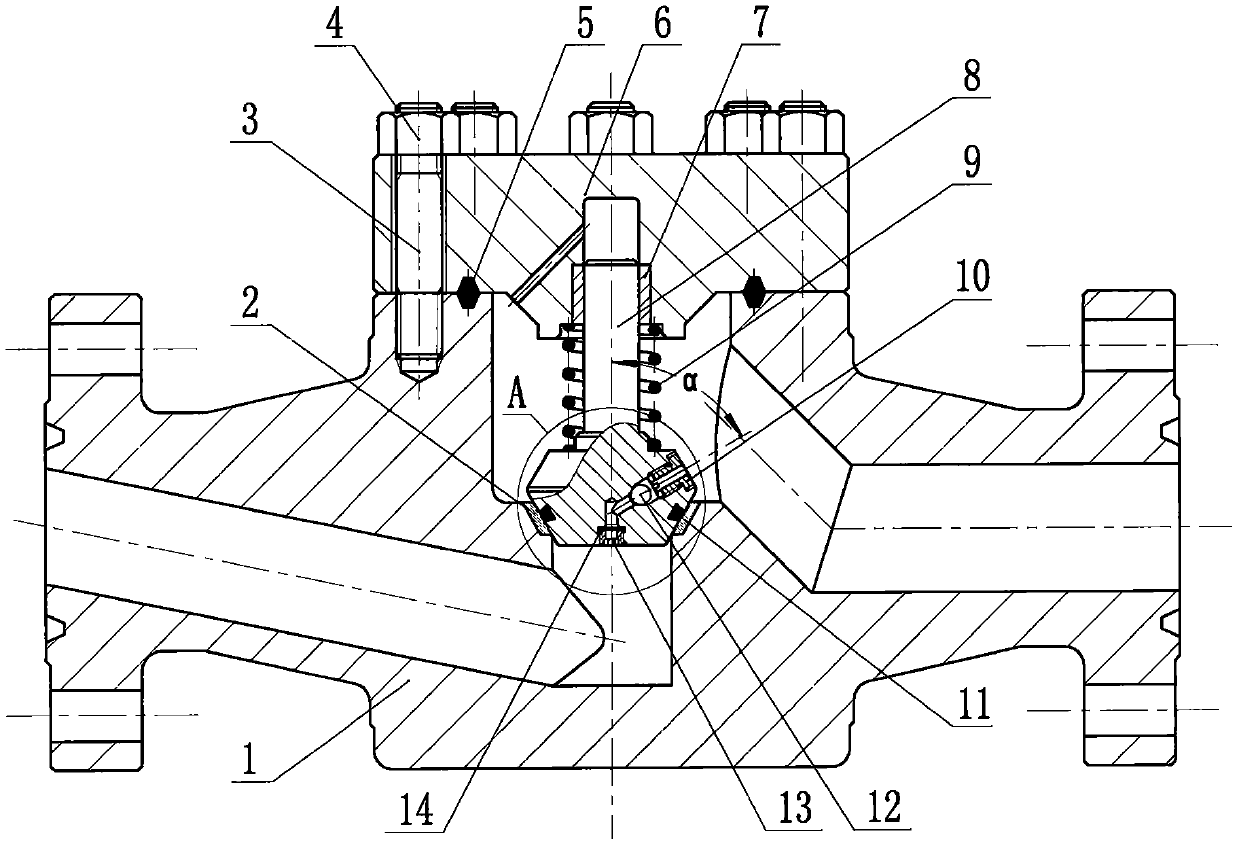

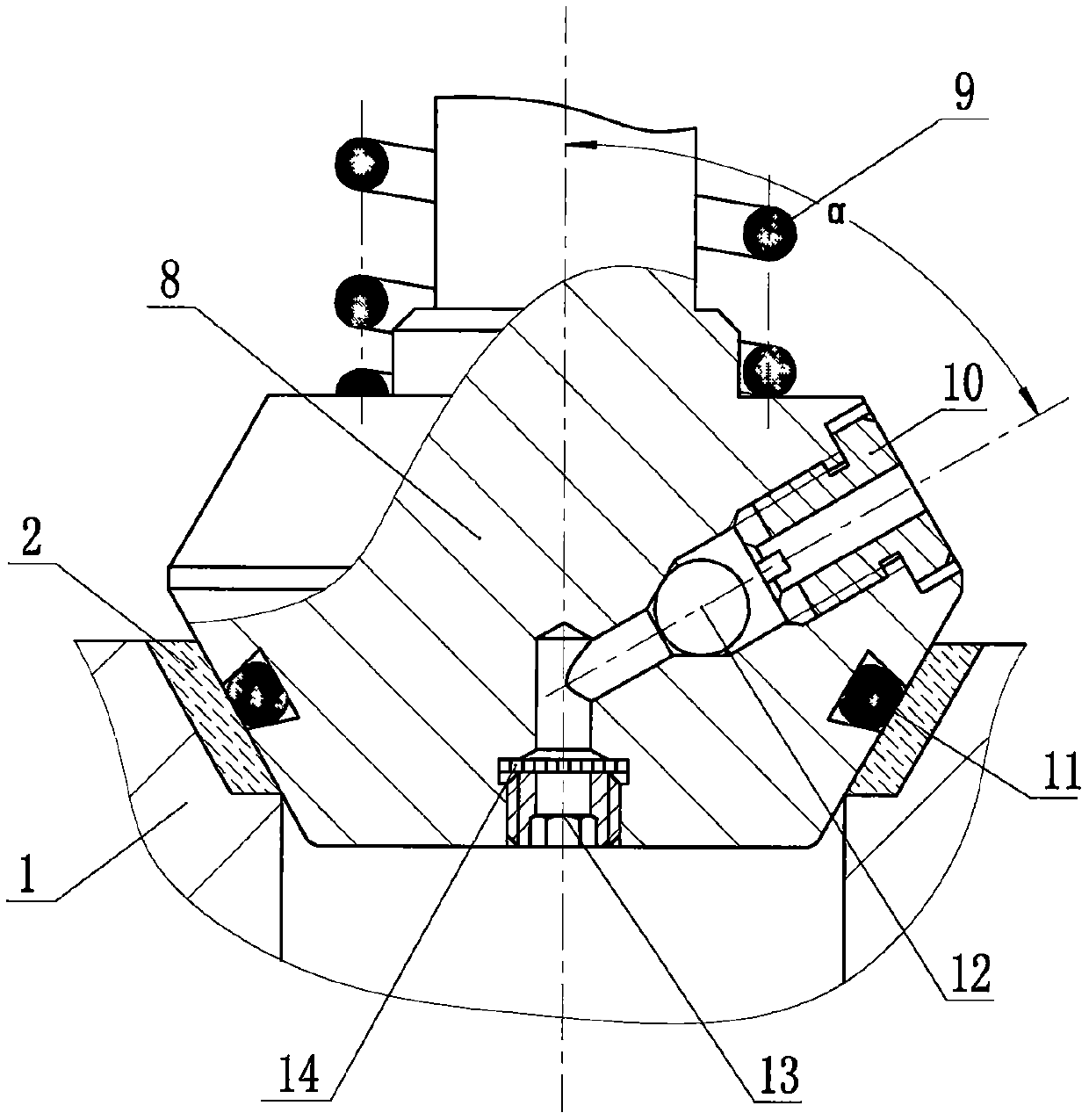

[0014] The present invention will be further described below in conjunction with the accompanying drawings:

[0015] The invention is composed of a high-pressure-resistant lift check valve commonly used in oil and natural gas drilling and production equipment, and a small check valve sealed with a small steel ball 12 attached to the sealing end of the lift check valve core 8 ; Under normal circumstances, a hexagonal hollow plug 13 and a filter screen 14 are also installed at the inlet of the small one-flow valve.

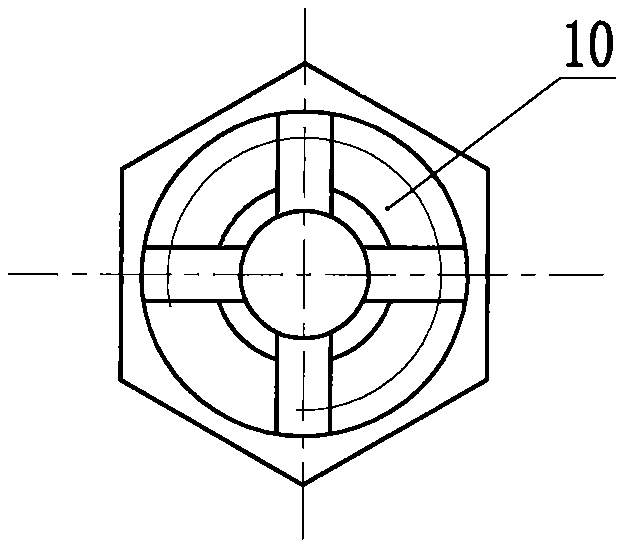

[0016] The lift check valve of the present invention includes special parts: valve body 1, valve seat 2, valve cover 6, bushing 7, valve core 8 and compression spring 9, sealing parts: sealing gasket 5 and O-ring 11 , Couplings: Stud 3 and Nut 4. The valve body 1 is a three-way part, the middle is a cylinder, and the left and right ends protrude out of the neck flange for external connection; in the middle cylinder from top to bottom are the upper cylindrical hole,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com