Operating method of drain valve of washing machine

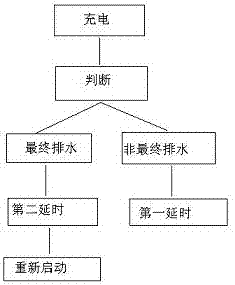

A working method and washing machine technology, applied in the field of washing machines, can solve the problems of slow falling of water droplets or residues, high hygiene requirements of washing machines, and failure to discharge in time, so as to achieve the effect of reducing bacterial growth, avoiding water and stain residues, and smooth water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

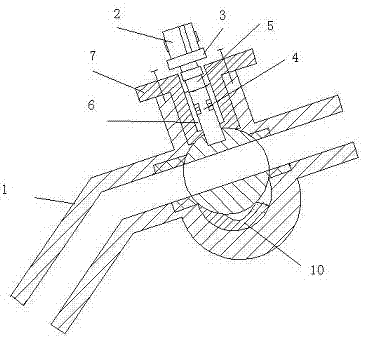

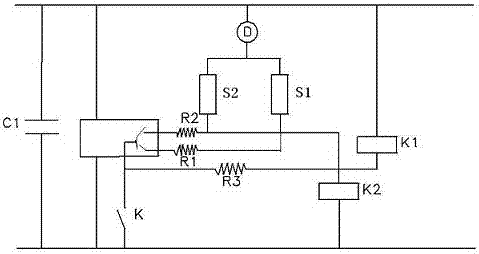

[0021] The technical scheme of the present invention is as follows: a working method of a washing machine drain valve, the washing machine includes a washing machine drain valve and an opening and closing control circuit; the washing machine drain valve includes a valve body module, a drive module, a sealing compensation module, a valve ball, and a control module; the valve The body module includes the upper left valve body, the upper right valve body, the middle valve body and the lower valve body; A recess is formed, a reserved space is formed between the recess and the valve ball, and a support structure 10 is arranged on the arc-shaped wall surface, and the support structure is asymmetrically arranged; the arc-shaped wall surface connects the upper right valve body and the upper section of the lower valve body, and the upper section of the lower valve body is arc-shaped.

[0022] The drive module includes a motor 2, a connecting transmission structure, and a valve stem 4. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com