Magnetic valve

A solenoid valve and valve body technology, applied in the field of solenoid valves, can solve problems such as easy leakage, solenoid valves cannot effectively reduce water hammer, and poor sealing effect, and achieve the effects of reducing water hammer, simple structure, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

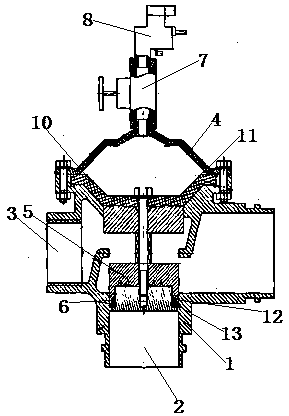

[0014] As shown in Figure 1, a solenoid valve includes a valve body 1 made of aluminum alloy material. The valve body 1 is provided with a water inlet 2 and a water outlet 3, and also includes a valve cover 4, a valve disc 5, a sealing assembly 6, Two-way constant flow valve 7, pilot valve 8, valve stem 9, diaphragm 10, diaphragm 10 is a water sealing diaphragm, and said diaphragm 10 is located between said valve body 1 and said bonnet 4, said valve stem 9 and said The valve flap 5 is located below the diaphragm 10, and on both sides of the valve flap 5, a plurality of circular grooves 11 are arranged on the side near the diaphragm 10, and a conical surface is arranged on the side near the water inlet 3, sealing The component 6 is a sealing ring 12 and a retaining ring 13, wherein the retaining ring can play the role of guiding and preventing damage.

[0015] The work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com