Elevating type hydraulic slow-closure silencing check valve

A lifting type, check valve technology, applied in the direction of control valves, valve devices, functional valve types, etc., can solve the problems of high noise, large pipe network hazards, poor sealing effect, etc., to achieve low noise, good sealing effect, reduce The effect of water hammer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

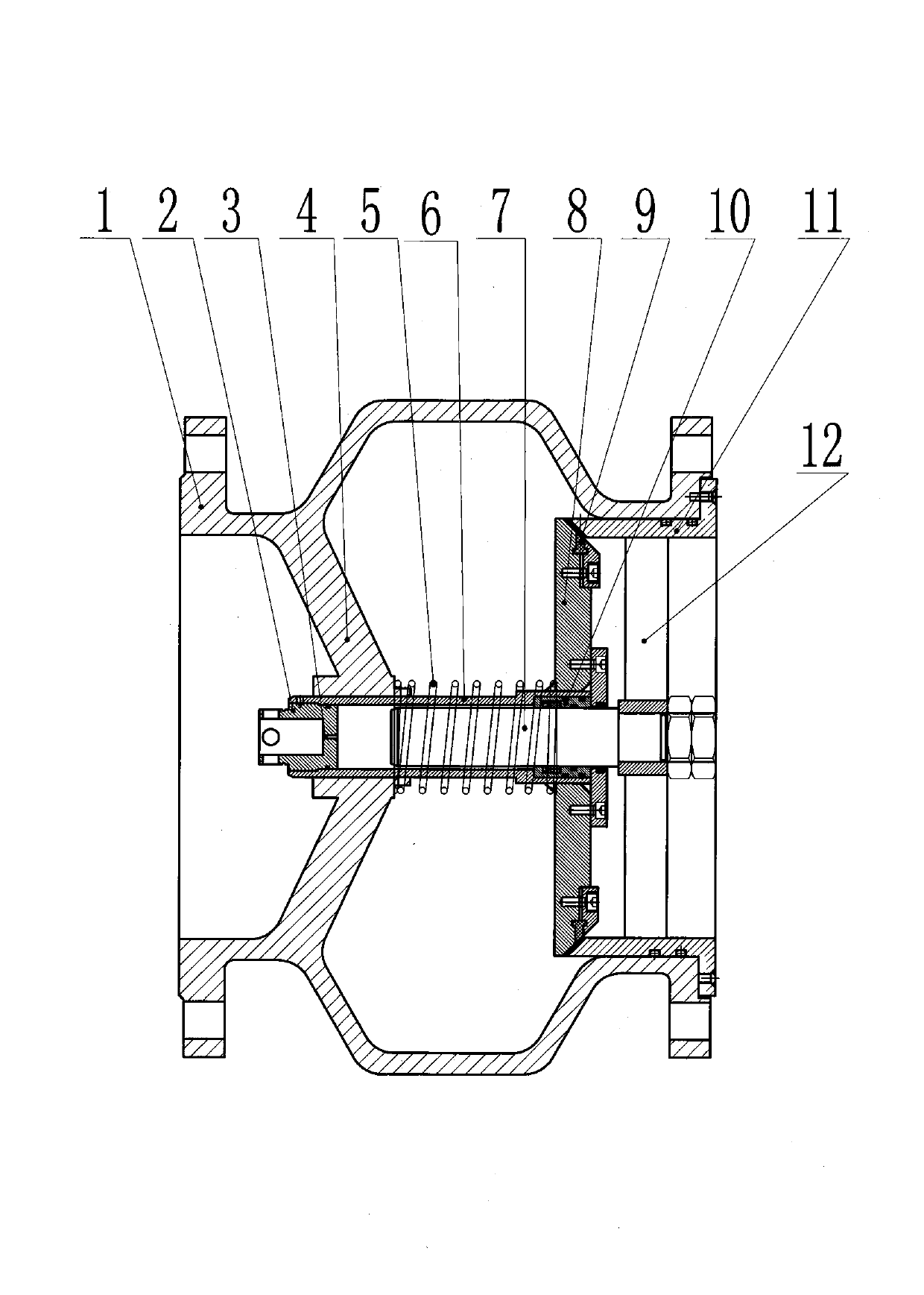

[0008] Referring to the accompanying drawings, it includes a valve body 1, a valve body support 4 is located at the rear of the valve body, the valve body support and the valve body are cast as one, the sealing seat 11 is mounted on the front end of the inner wall of the valve through bolts, and the sealing seat support 12 is fixed on the On the sealing seat, the front end of the piston rod 7 is fixed on the sealing seat bracket, the valve rod 6 is a hollow structure, the piston rod is installed in the inner cavity of the valve rod, and the rear plug 2 is fixed on the inner cavity wall at the rear end of the valve rod. There is a water inlet and outlet hole 3, the valve stem acts as a piston cylinder, the rear end of the valve stem is placed on the opening in the middle of the valve body bracket, the valve stem is in sliding contact with the valve body bracket, and the valve disc 8 is welded and fixed At the front end of the valve stem, a guide sleeve 10 is provided on the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com