Patents

Literature

54results about How to "Automatically adjust the flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

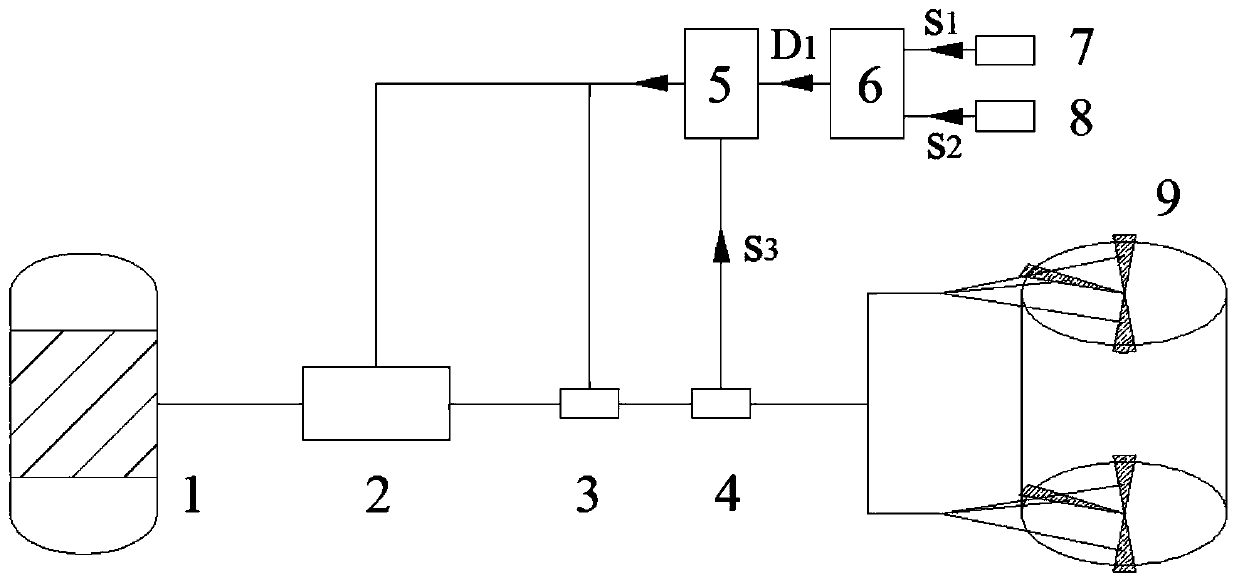

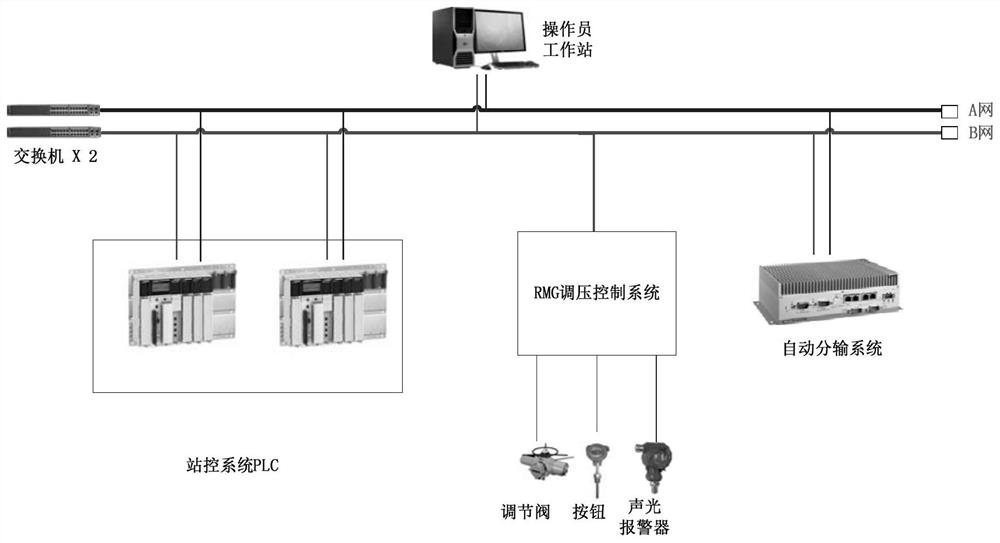

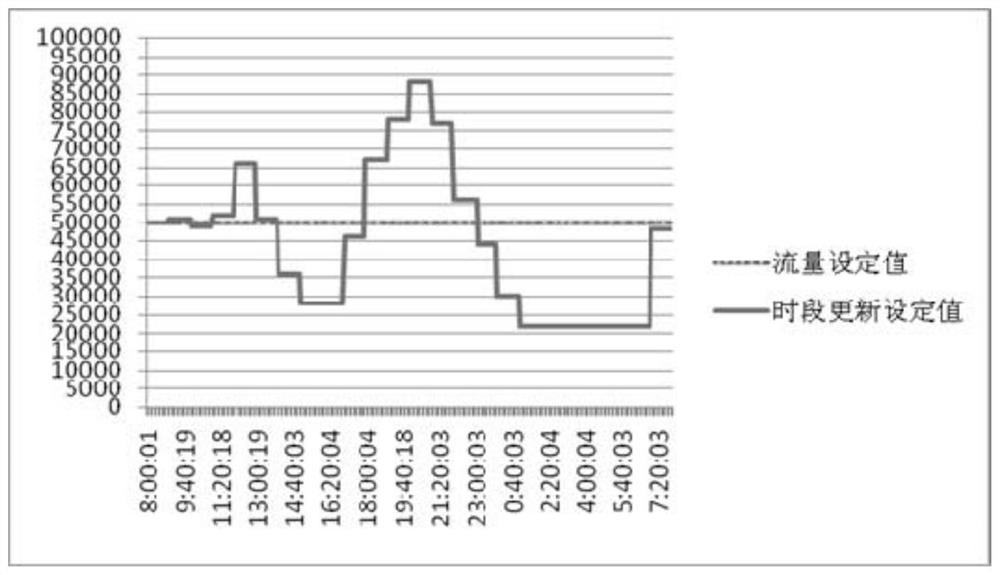

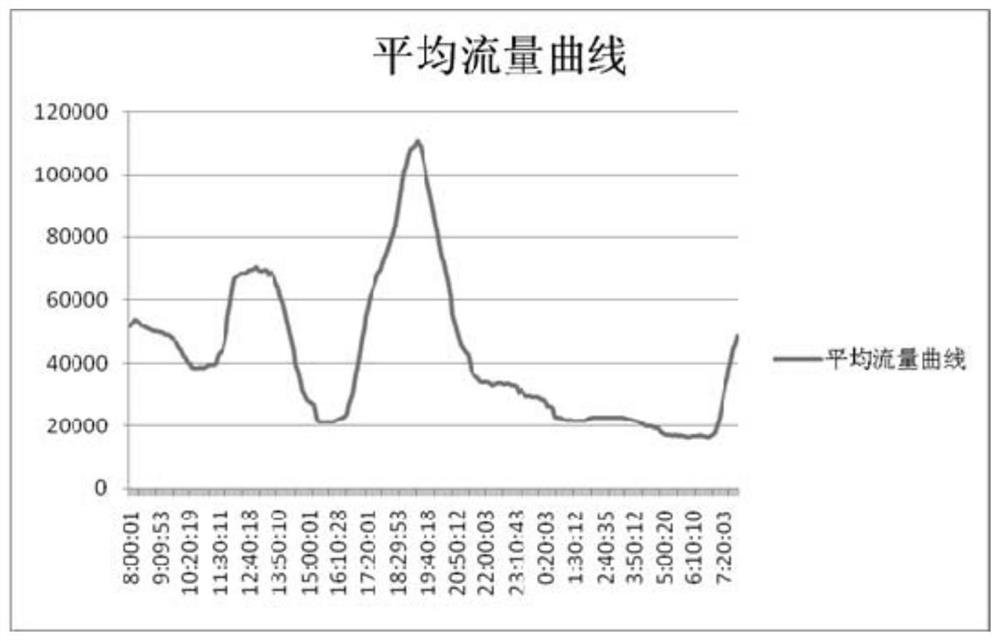

Automatic distribution method and system for natural gas

ActiveCN109210380AReduce workloadHigh degree of automation controlPipeline systemsDistribution methodControl system

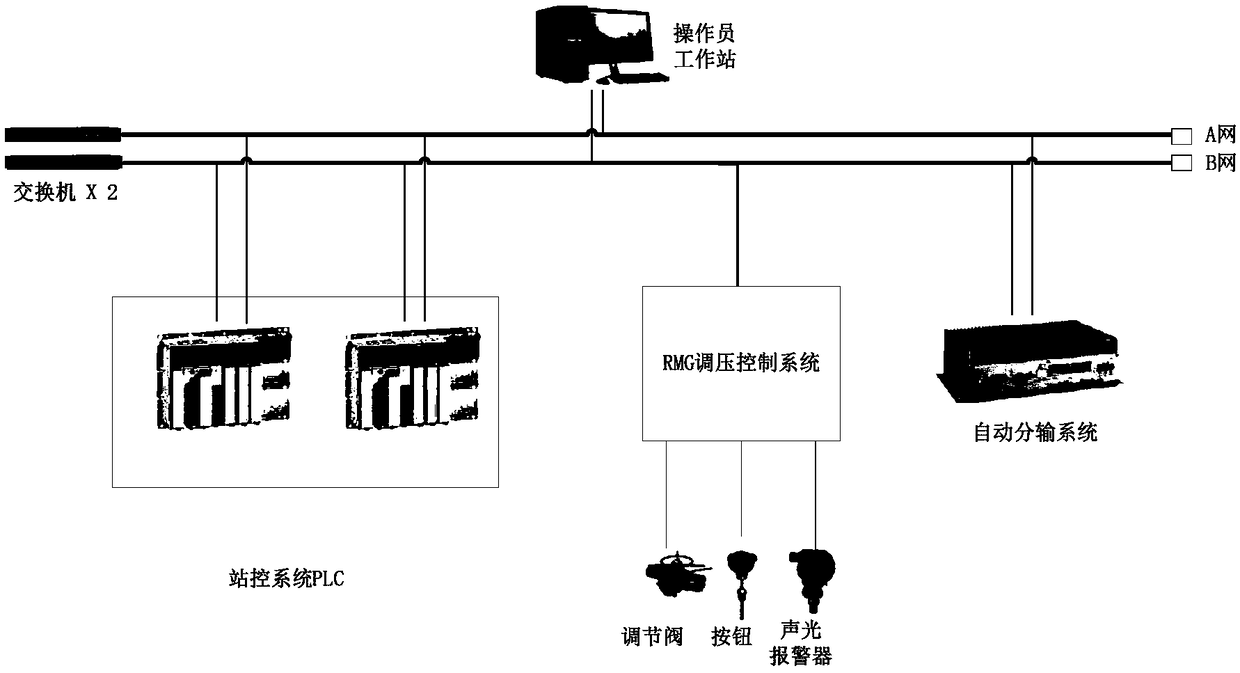

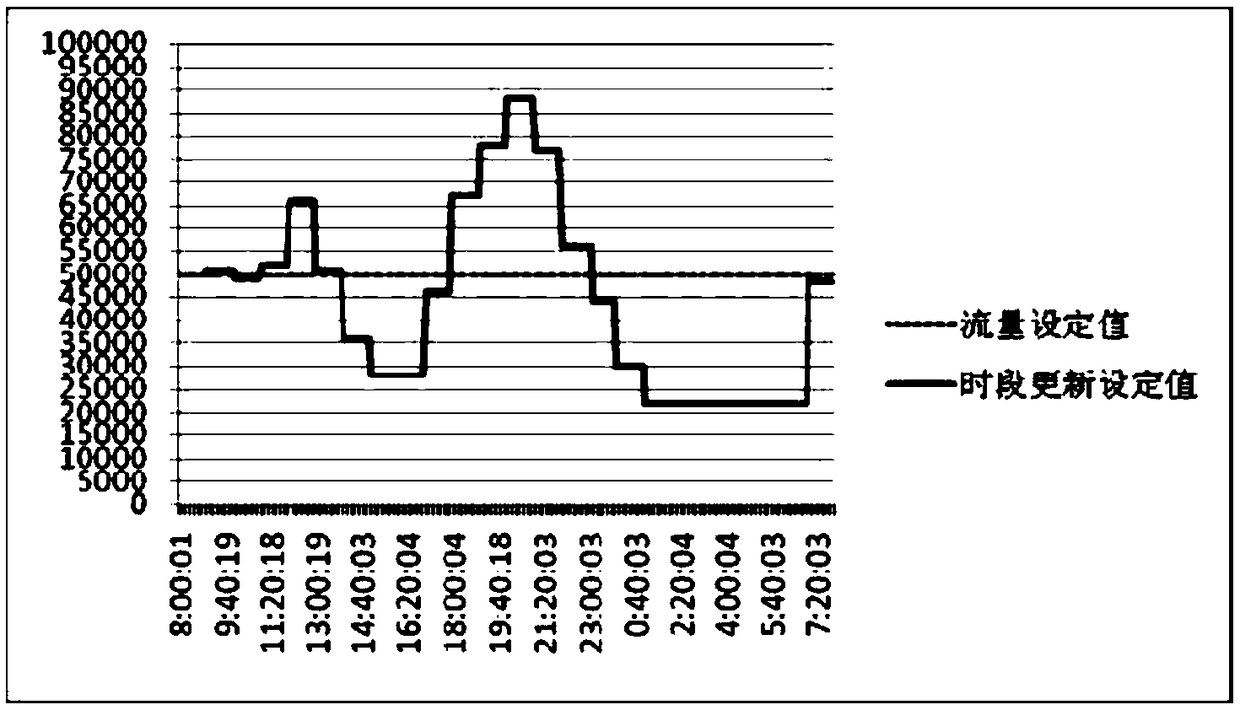

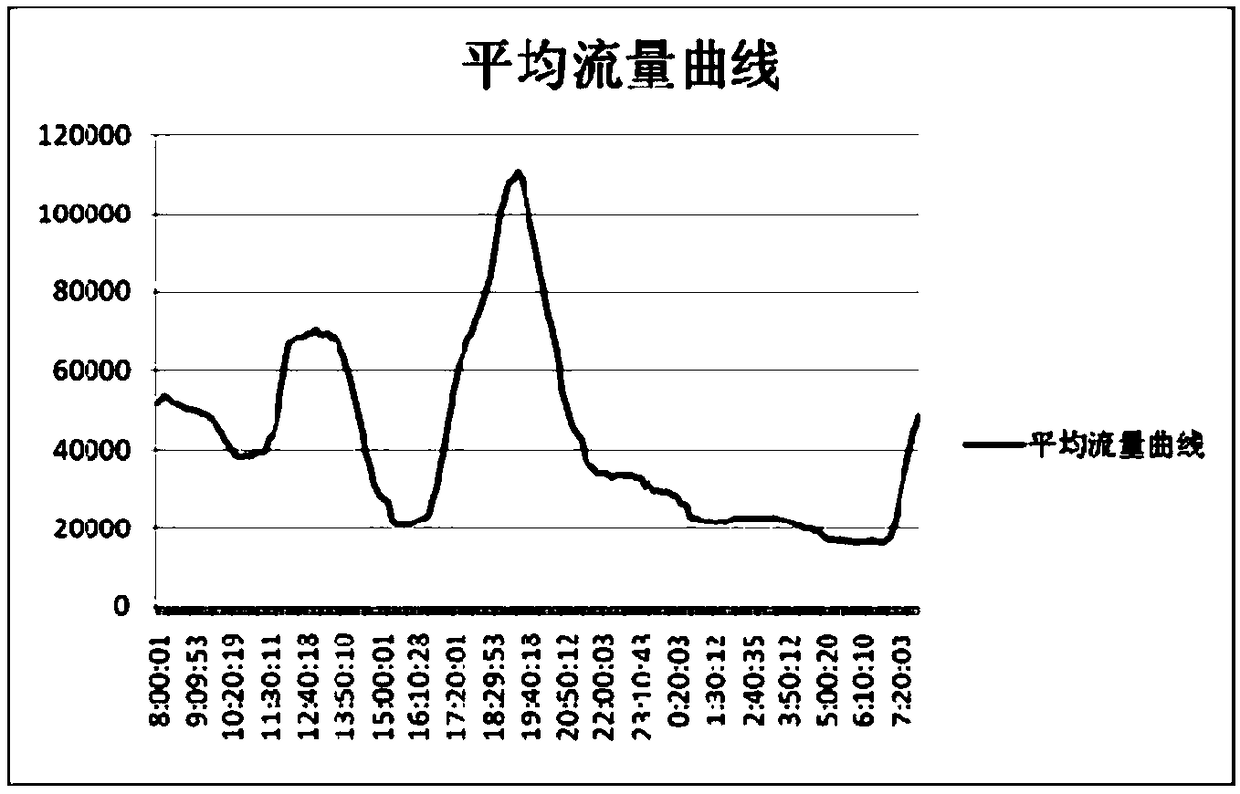

The invention discloses an automatic distribution method and system for natural gas. The system comprises a station controller, a plurality of station control system PLCs and a plurality of automaticdistribution mainframes so as to correspond to different gas supply areas, and is characterized in that the station controller sends operation parameters input from an operation interface to the station control system PLCs; the PLCs send the operation parameters to the automatic distribution mainframes; target values are returned to the station control system PLCs after relevant calculation is carried out through the automatic distribution mainframes; and the PLCs control corresponding valves to carry out gas delivery control.

Owner:ORIENT HUAZHI PETROLEUM ENG +2

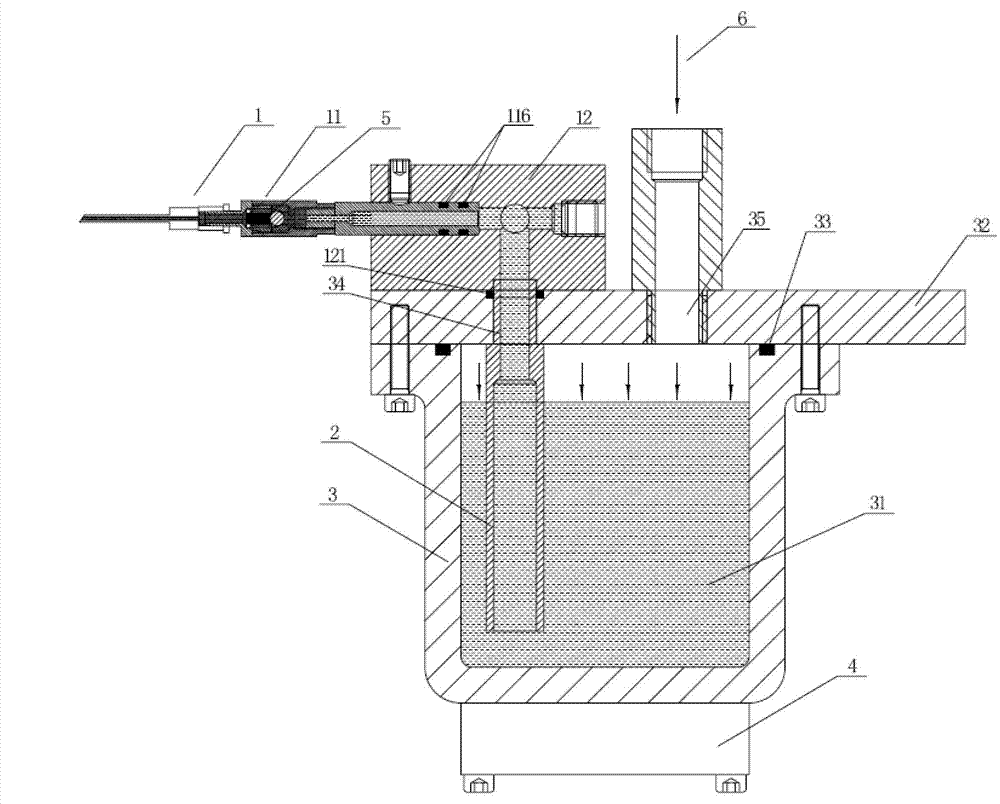

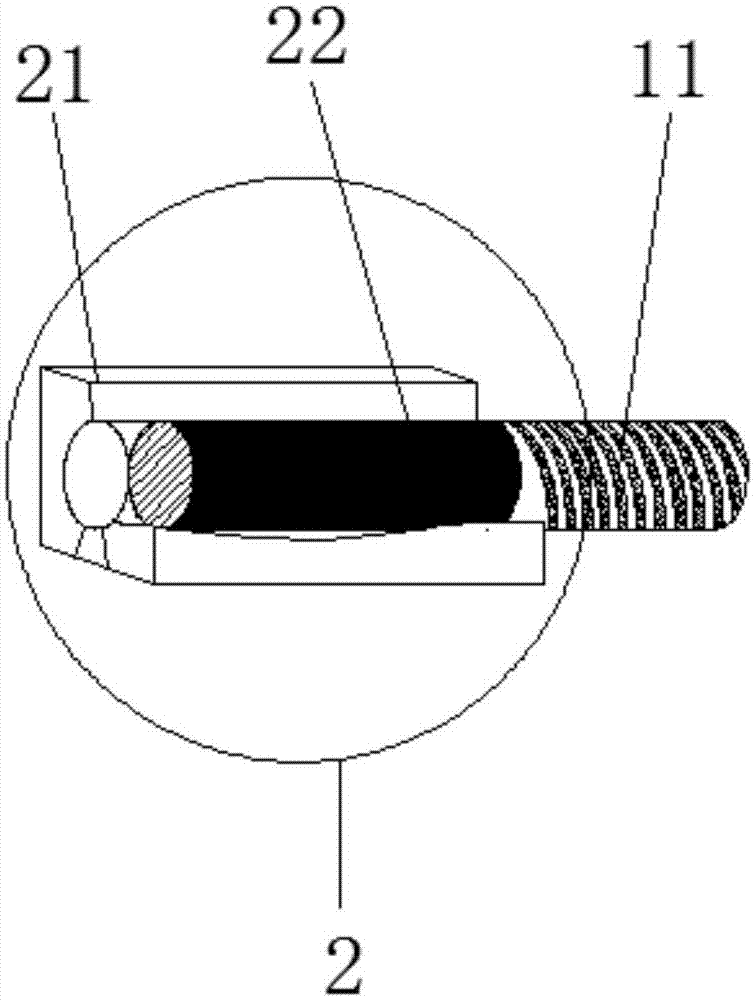

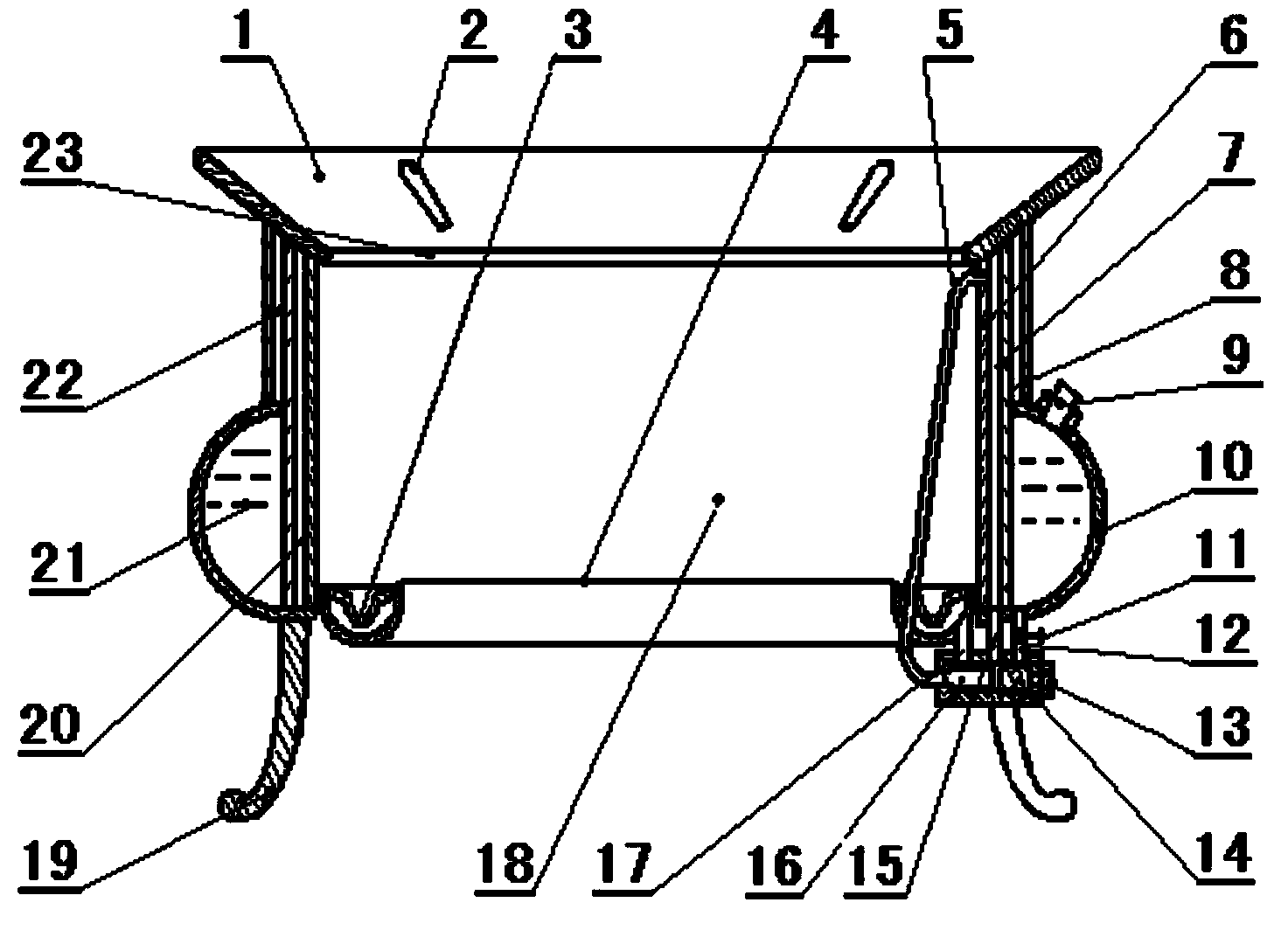

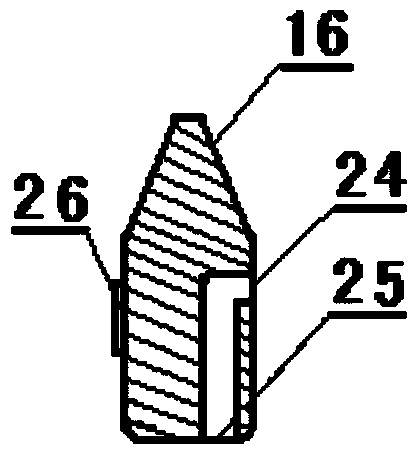

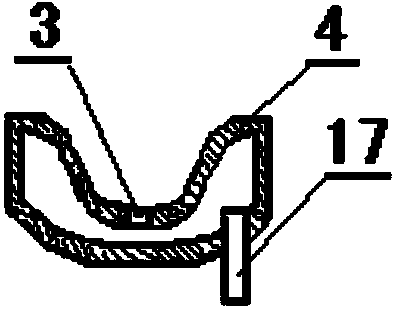

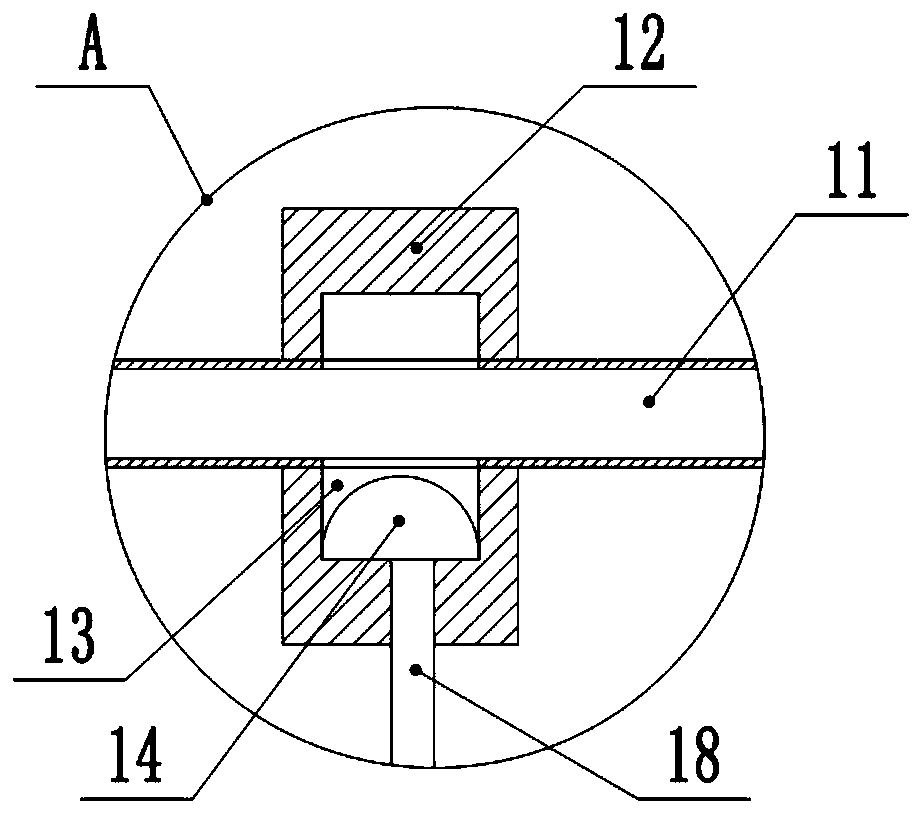

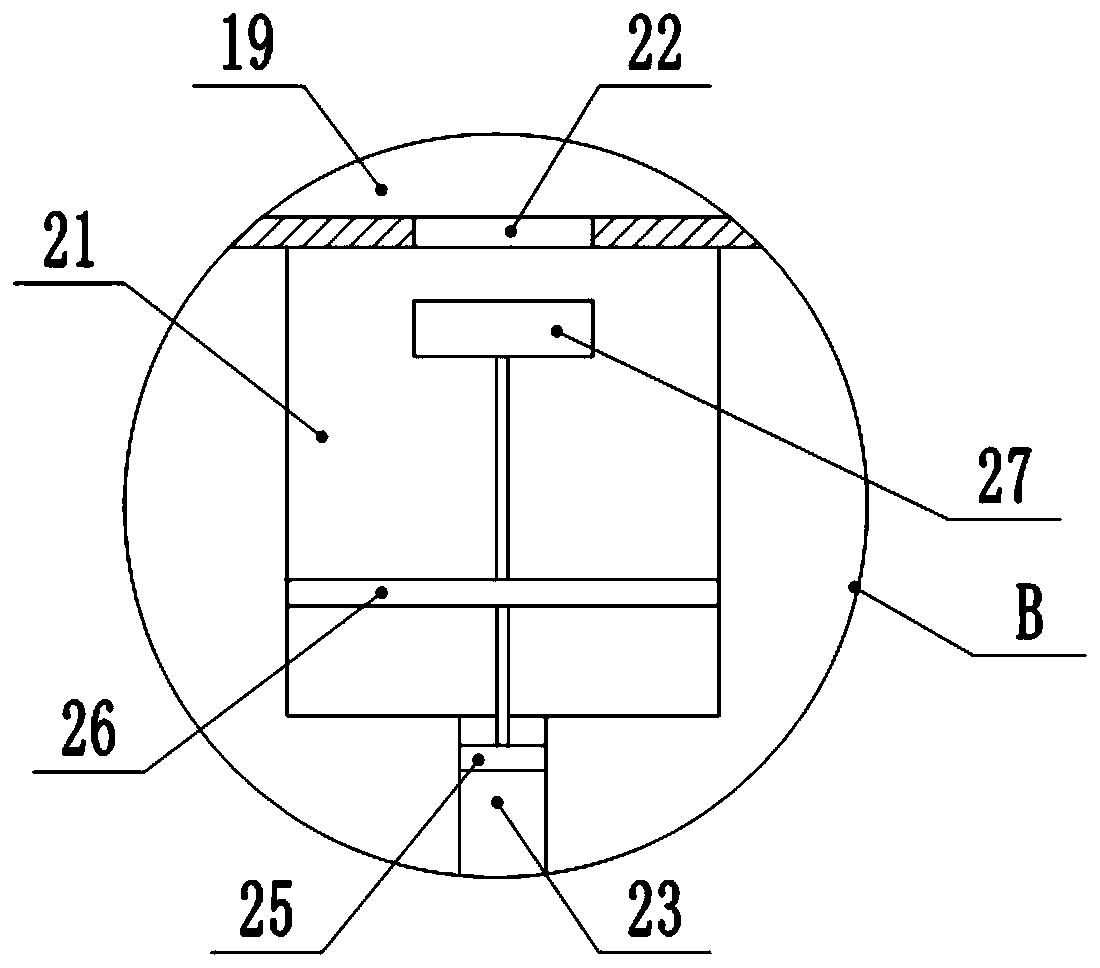

Coating device of battery sealing agent

ActiveCN103041949AGuaranteed tightnessIncrease productivityLiquid surface applicatorsCoatingsBiochemical engineeringControllability

The invention discloses a coating device of a battery sealing agent, which is characterized by comprising a coating mechanism, an agent-passing tube, an agent cylinder and a heating mechanism, wherein the heating mechanism is arranged at the bottom of the agent cylinder with the sealing agent arranged therein; the agent cylinder is communicated with a compressed air, the sealing agent in the agent cylinder is delivered to the coating mechanism through the agent-passing tube under the action of the compressed air; and a switch device used for automatically adjusting the flow of the sealing agent according to the pressure variation of the compressed air is arranged in the coating mechanism. The device has the advantages that the heating mechanism is arranged at the bottom of the agent cylinder and is used for heating the sealing agent in the agent cylinder and for maintaining the temperature of the sealing agent; the sealing agent with a viscosity number below 20,000 can be smoothly delivered through pressing; the flow of the sealing agent in the coating mechanism can be automatically adjusted as long as the pressure of the compressed air is better controlled, without the problems of glue interruption, noncontinuous glue spreading and the like, so that the continuous glue spreading and good controllability are achieved; and accordingly, the sealing of the battery is effectively ensured and the production efficiency is high.

Owner:ZHONGYIN NINGBO BATTERY CO LTD

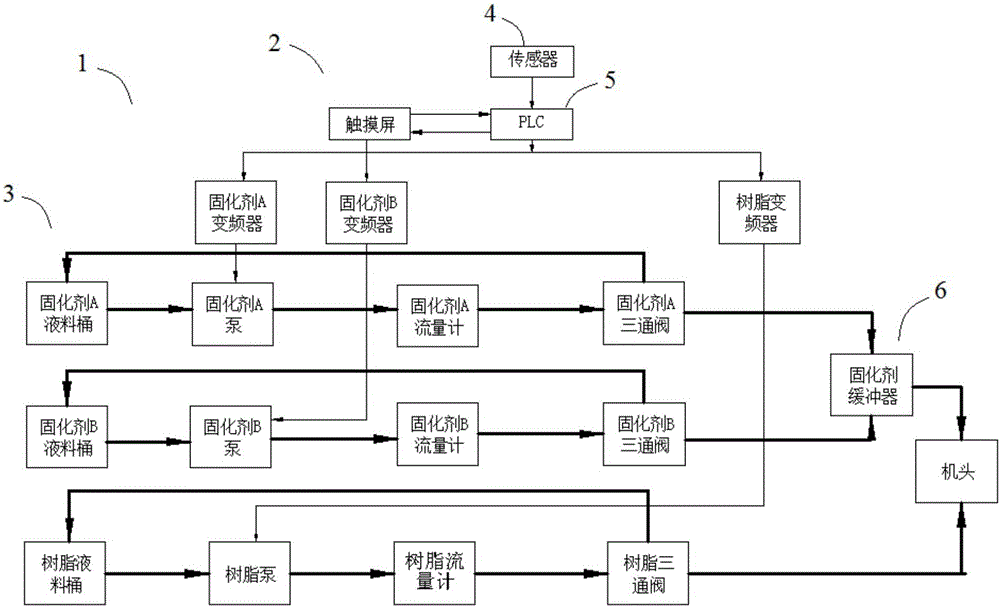

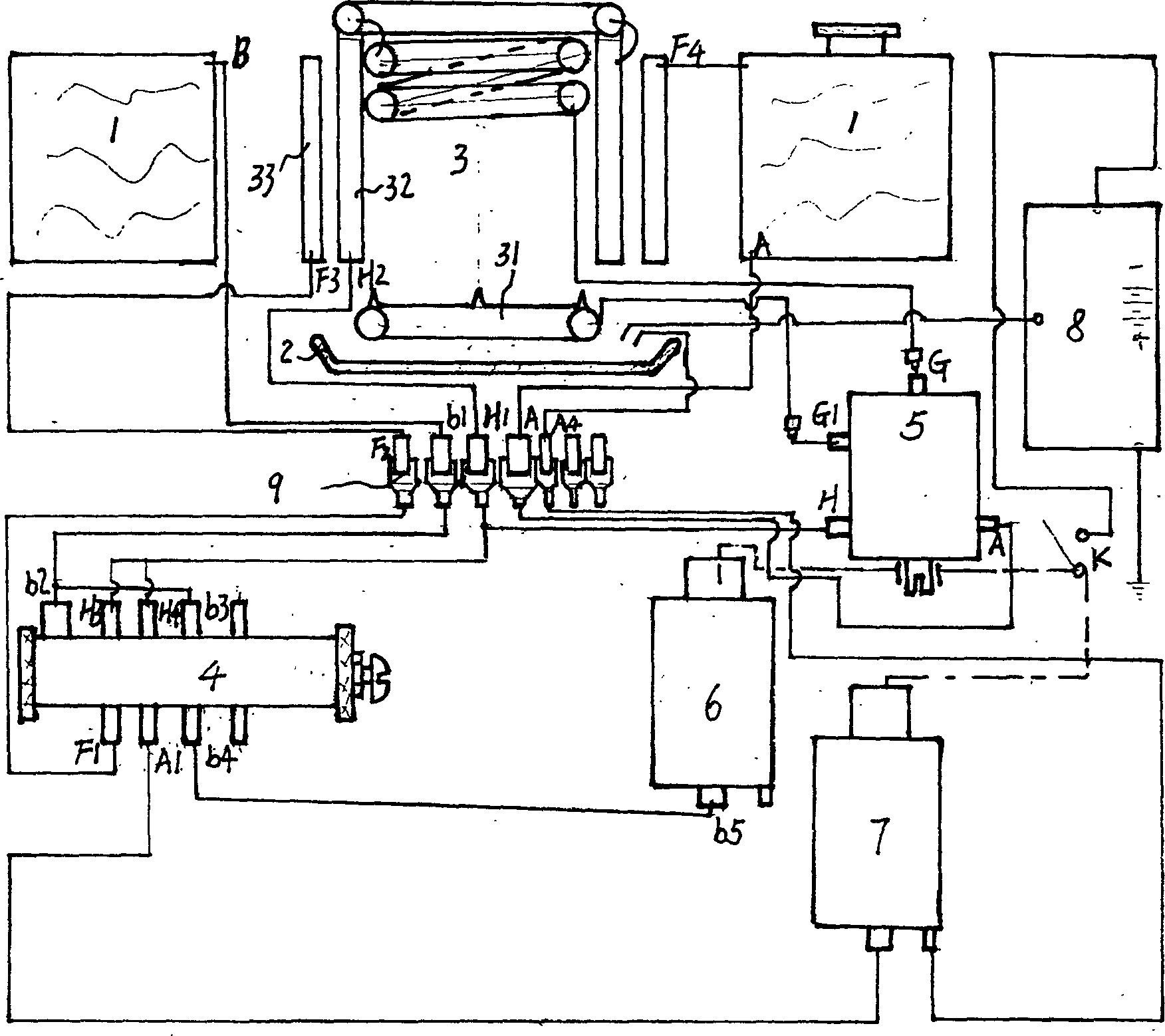

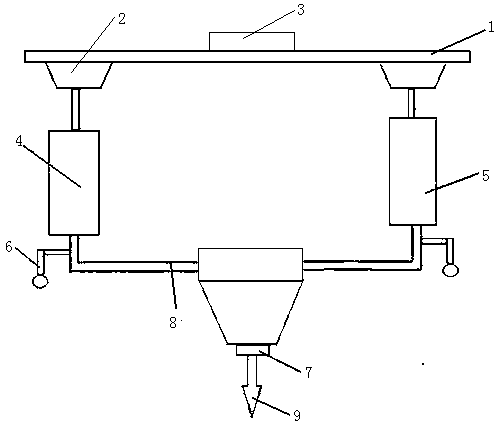

Liquid material control system of sand mixer

InactiveCN106311971AAutomatic adjustment of acid valueMolding sand quality is stableMould handling/dressing devicesControl systemEngineering

The invention provides a liquid material control system of a sand mixer. The liquid material control system comprises a liquid material control and detection system and a liquid material conveying system. The liquid material conveying system comprises a resin liquid material conveying pipeline and curing agent conveying pipelines for conveying different curing agents. Each curing agent conveying pipeline and the resin liquid material conveying pipe are each internally provided with a pump. The liquid material control and detection system comprises a temperature sensor and a PLC, wherein the temperature sensor is used for collecting the practical temperature of silica sand, and the PLC receives the temperature signal of the temperature sensor, compares the practical temperature with a preset temperature range and controls the rotating speeds of all the pumps on the basis of the comparison result. The liquid material control system aims at solving the problem that an operator cannot adjust the acid value of the added curing agents in time according to sand temperature, and the stable system which can automatically adjust the acid value of the curing agents and ensure molding sand quality is provided.

Owner:KOCEL EQUIP

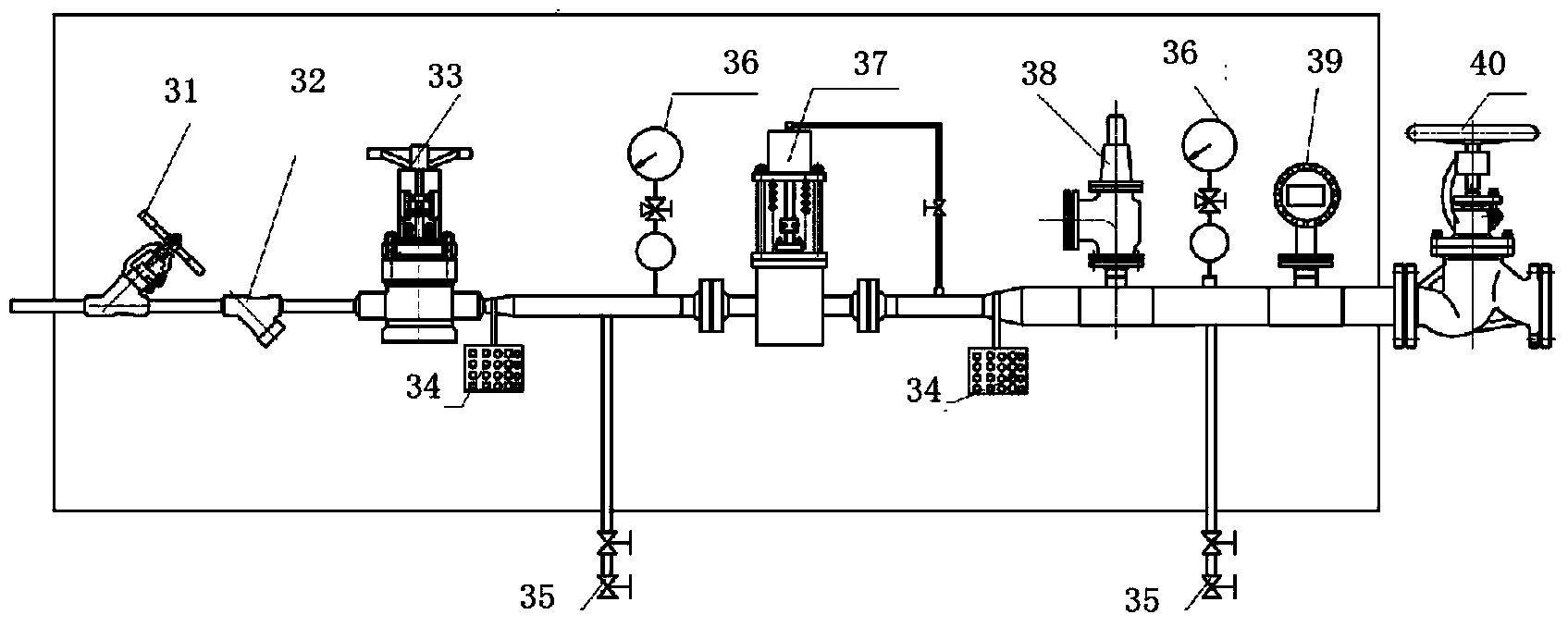

Thickened oil thermal recovery decompression method and device

ActiveCN103410487AEnsure safetyEffective pressure controlFluid removalSteam pressureHigh-pressure area

A thickened oil thermal recovery decompression method is suitable for thickened oil thermal recovery of mesohigh steam boilers and mesolow steam boilers, and a heat source for thermal recovery can supply steam through a decompression device. A decompression system of the thermal recovery decompression device is composed of a high-pressure area decompression valve and a medium-pressure area secondary decompression valve, and due to the two-stage decompression structure, the thickened oil thermal recovery decompression device is suitable for various work conditions of thickened oil thermal recovery. Mesohigh steam output pipes which are controlled by the valve and parallelly connected are arranged behind the high-pressure steam decompression valve, steam discharging pipelines for enabling steam of the mesohigh steam boilers to pass are arranged on the high-pressure steam decompression valve or the medium-pressure area secondary decompression valve, and the thickened oil thermal recovery decompression device can be steam driven or low-pressure steam driven or hot water driven. The thickened oil thermal recovery decompression device can monitor steam pressure in the steam pipelines at proper time, is convenient to operate, and can ensure safety of steam filling pipelines and steam utilization devices by arranging two check valves on steam inlet portions of the steam pipelines and placing a check valve on a steam discharging port portion.

Owner:JIANGSU WANXING PETROLEUM EQUIP

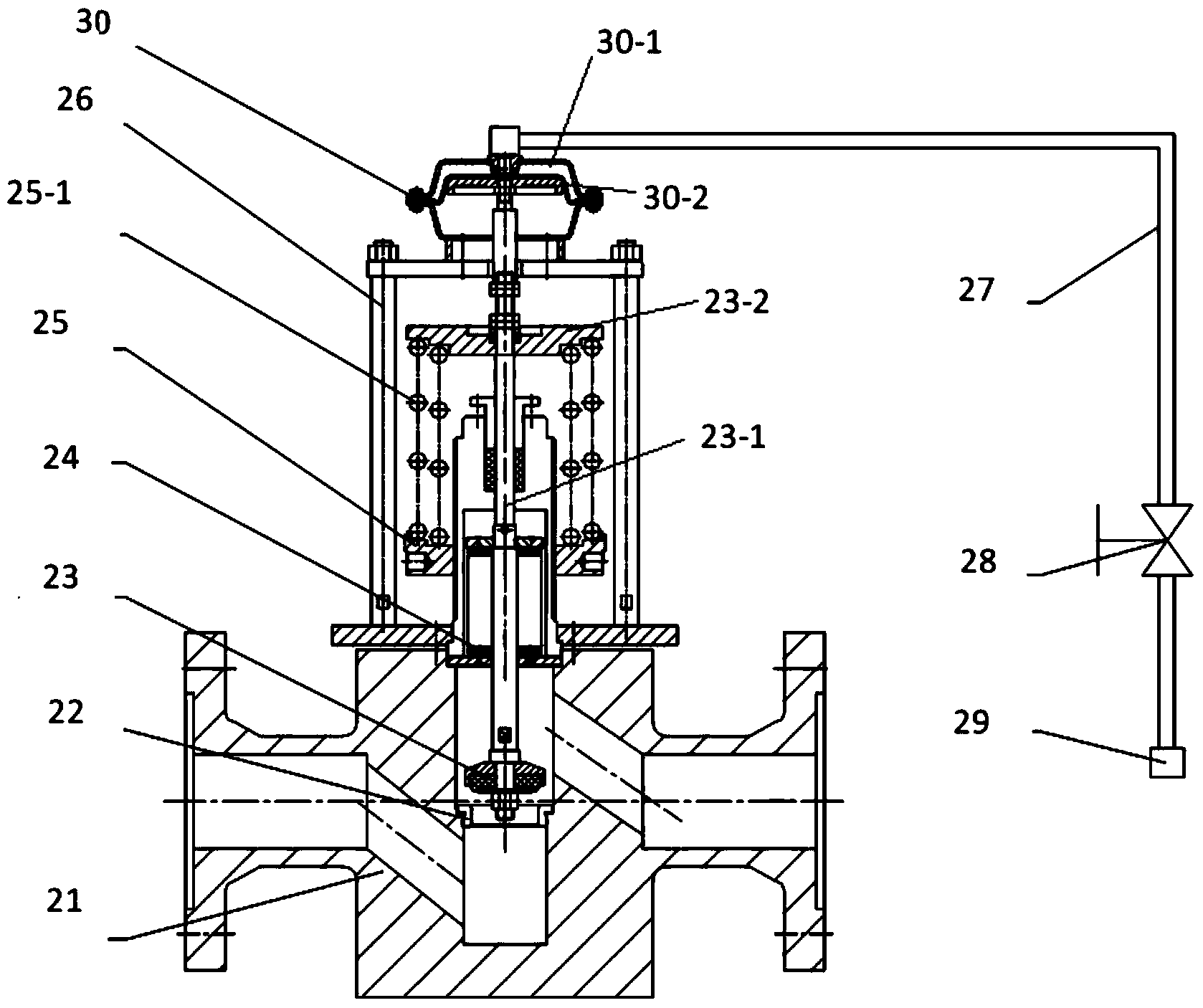

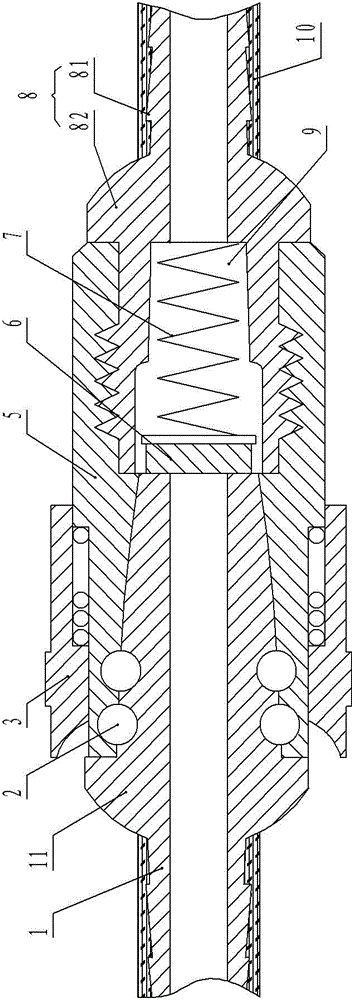

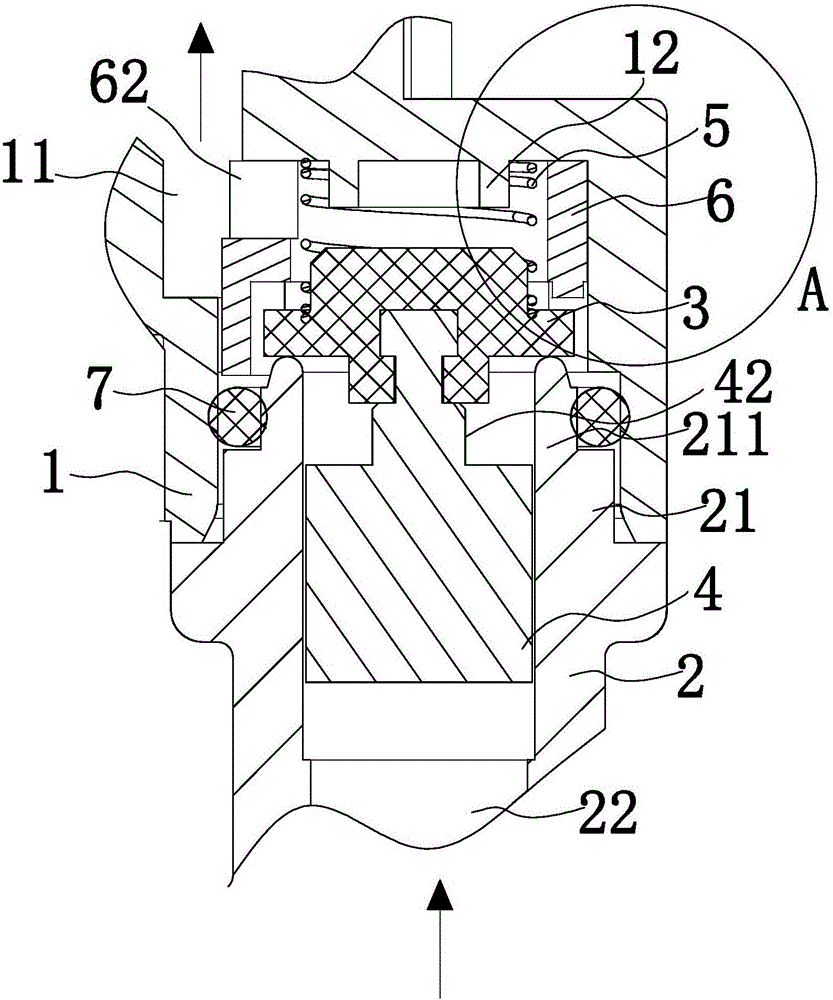

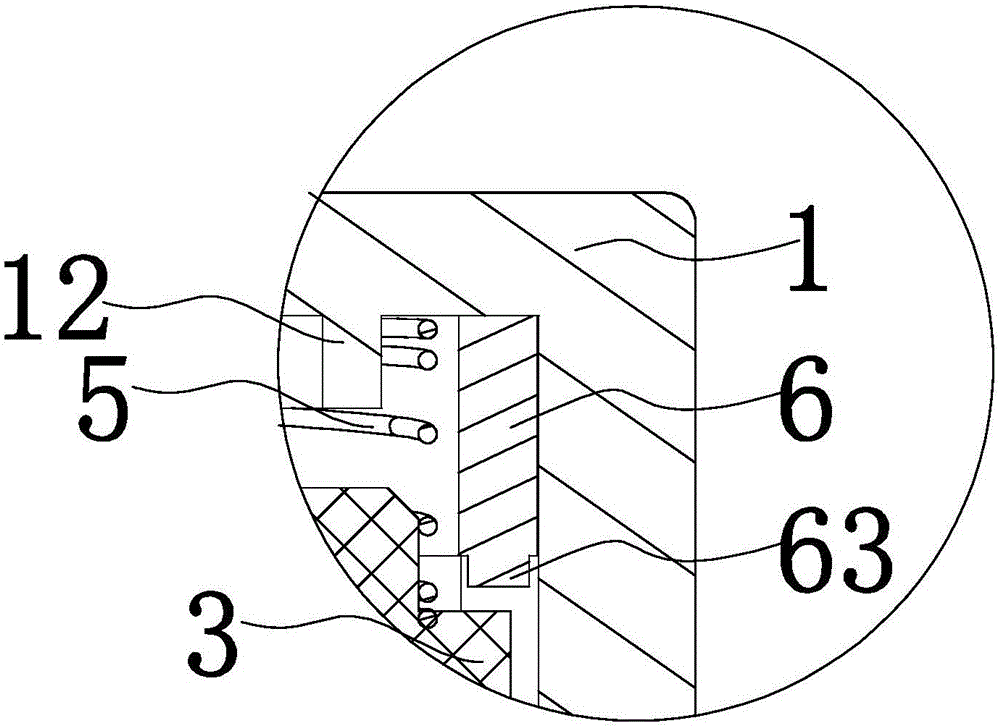

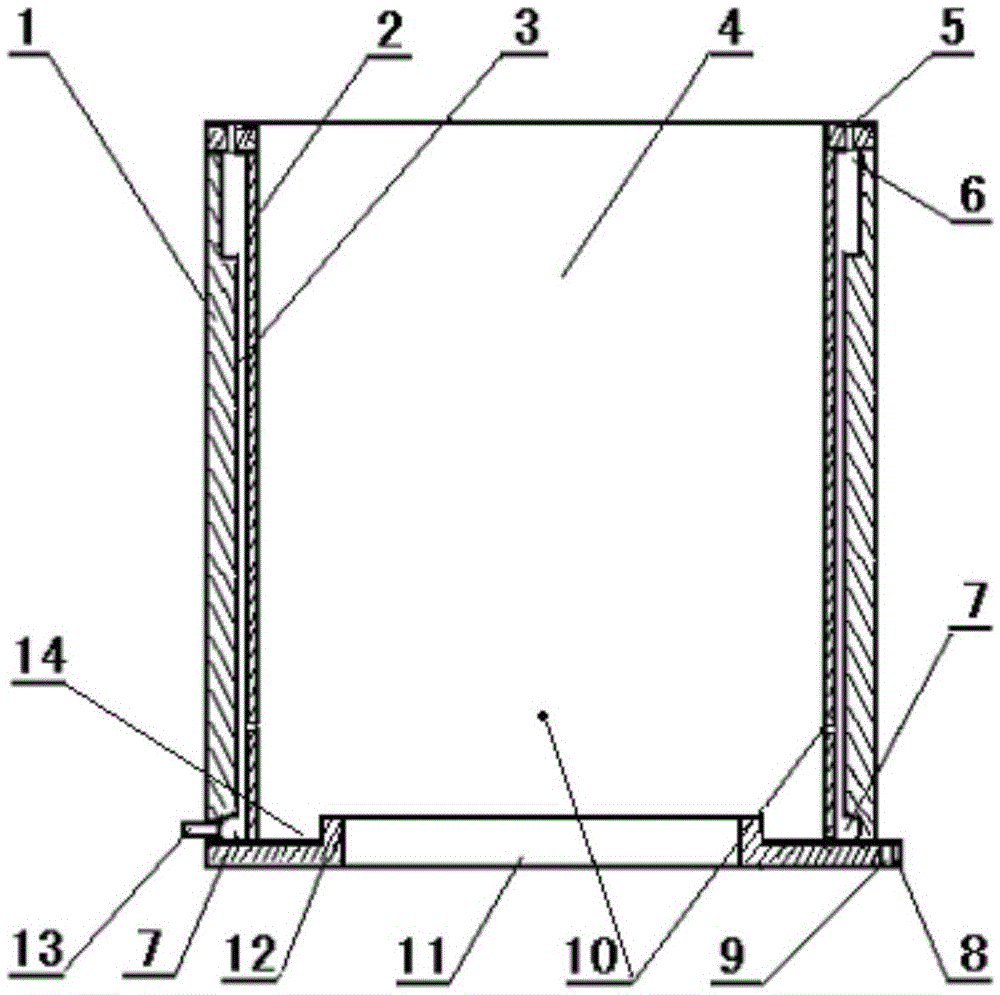

Elevating type hydraulic slow-closure silencing check valve

The invention provides an elevating type hydraulic slow-closure silencing check valve and relates to a check valve which is mounted on a pipeline and used for preventing media in the pipeline from flowing back. The elevating type hydraulic slow-closure silencing check valve is mainly designed to solve the problem that an existing check valve cannot reduce water hammers. The elevating type hydraulic slow-closure silencing check valve comprises a valve body, a valve body support is cast with the valve body into a whole, a sealing base is arranged in the valve body, a sealing base support is fixedly arranged on the sealing base, a piston rod is fixedly arranged on the sealing base support, the piston rod is arranged in the inner cavity of a valve rod, a rear cap is arranged on the wall of the inner cavity at the rear end of the valve rod, a water in-out hole is formed in the rear cap, the valve rod is arranged on an opening of the valve body support, a valve clack is fixedly arranged at the front end of the valve rod, a guide sleeve is arranged on the wall of the inner cavity of the valve rod, the guide sleeve is connected with the valve clack through a pressing cover, the outer circle of the valve clack is contacted with the sealing base, a sealing ring is arranged on the contact face of the valve clack and the sealing base, one end of a spring sleeved on the outer wall of the valve rod abuts against the valve body support, and the other end of the spring abuts against the valve clack. The elevating type hydraulic slow-closure silencing check valve has the advantage that the valve clack has a slow-closure function.

Owner:LIAOYANG TONGDE WATER SUPPLY EQUIP MFG CO LTD

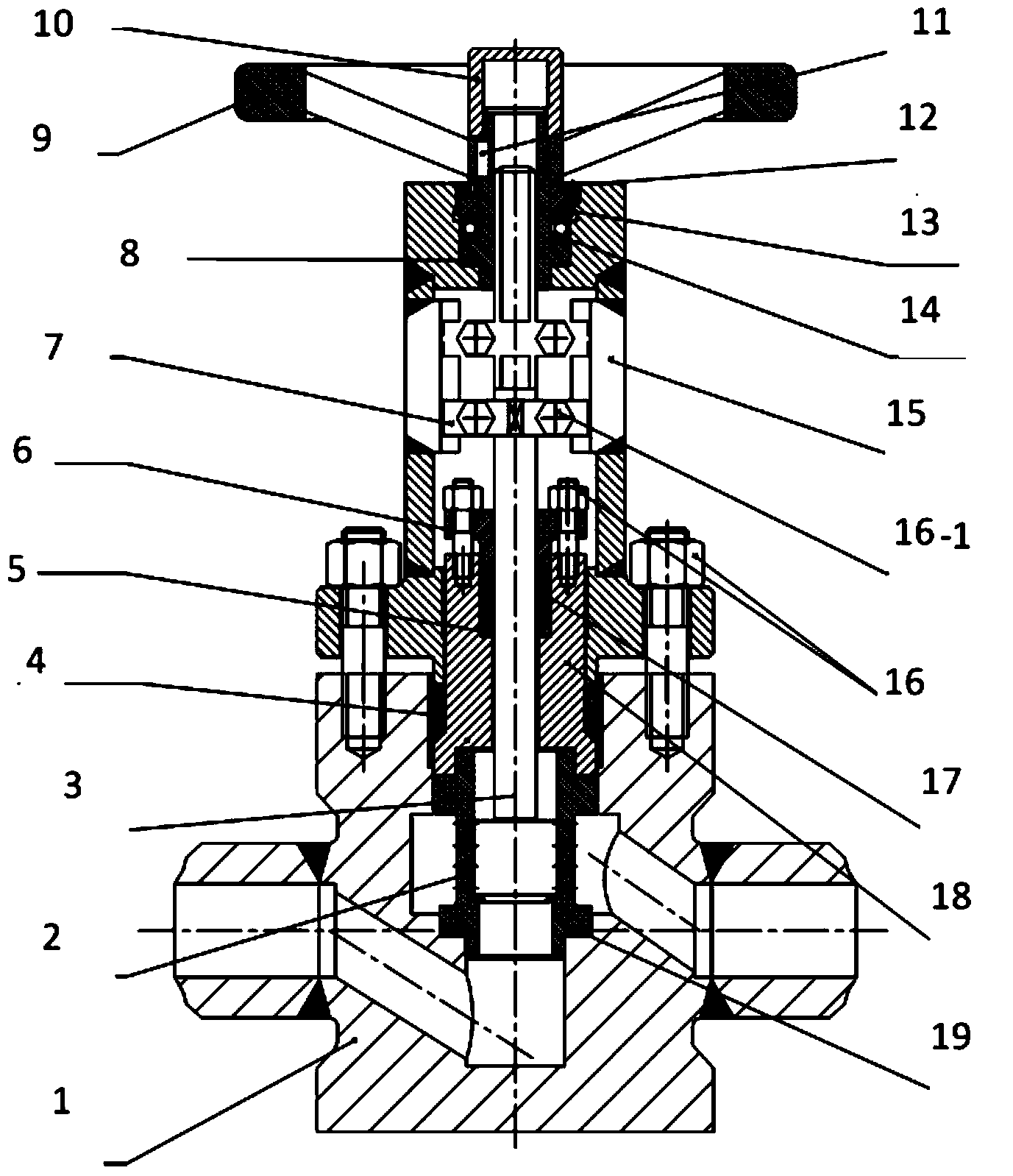

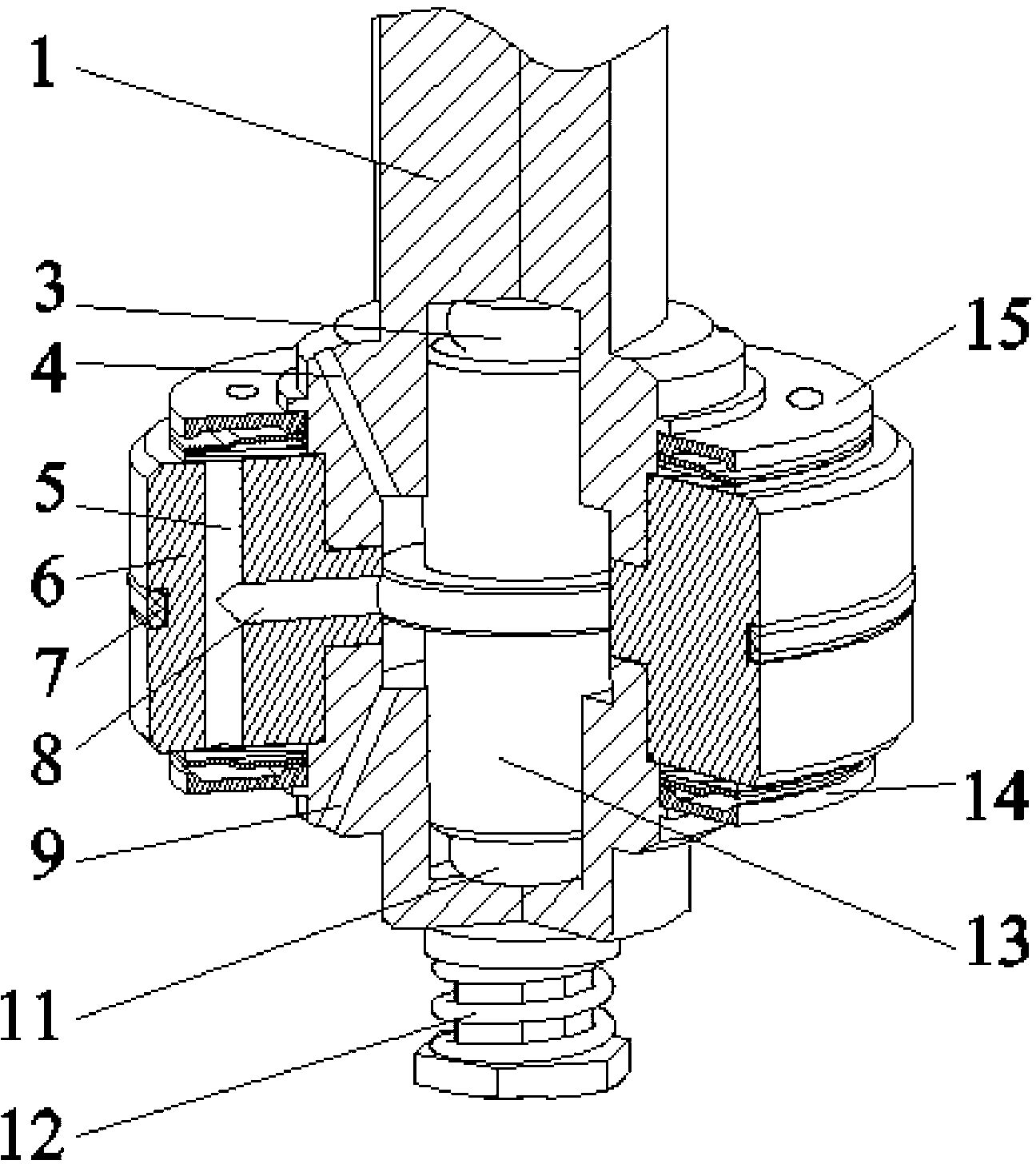

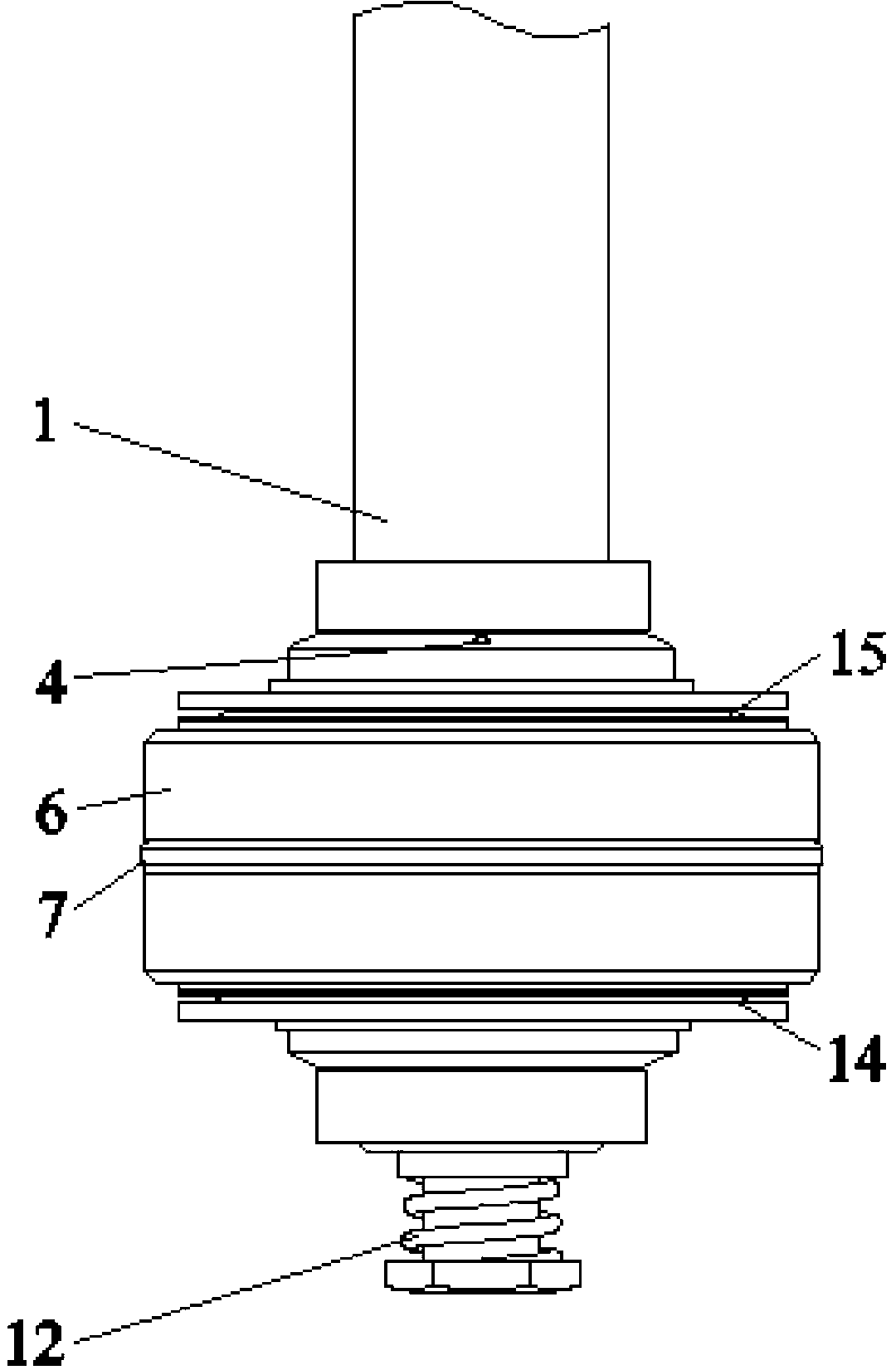

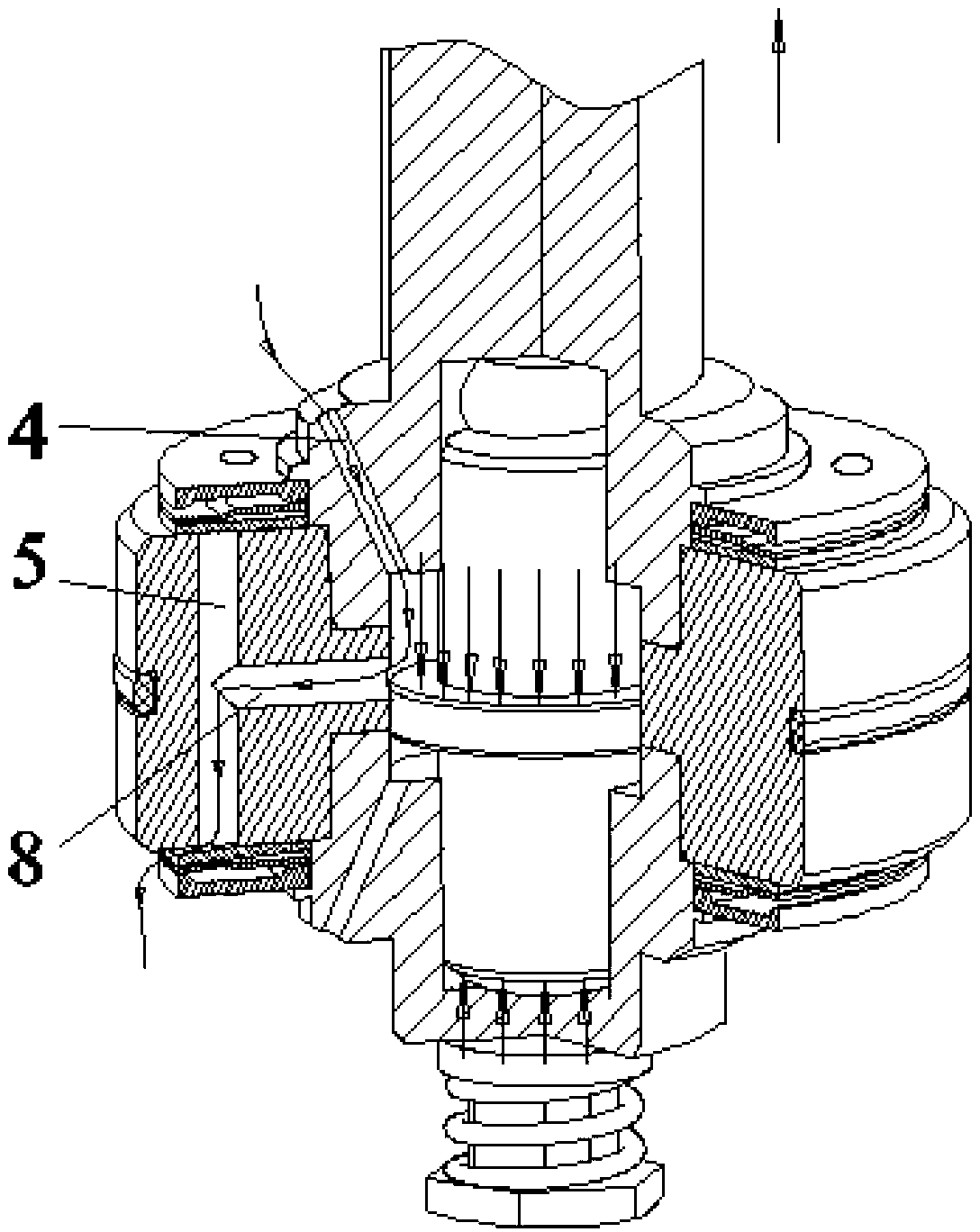

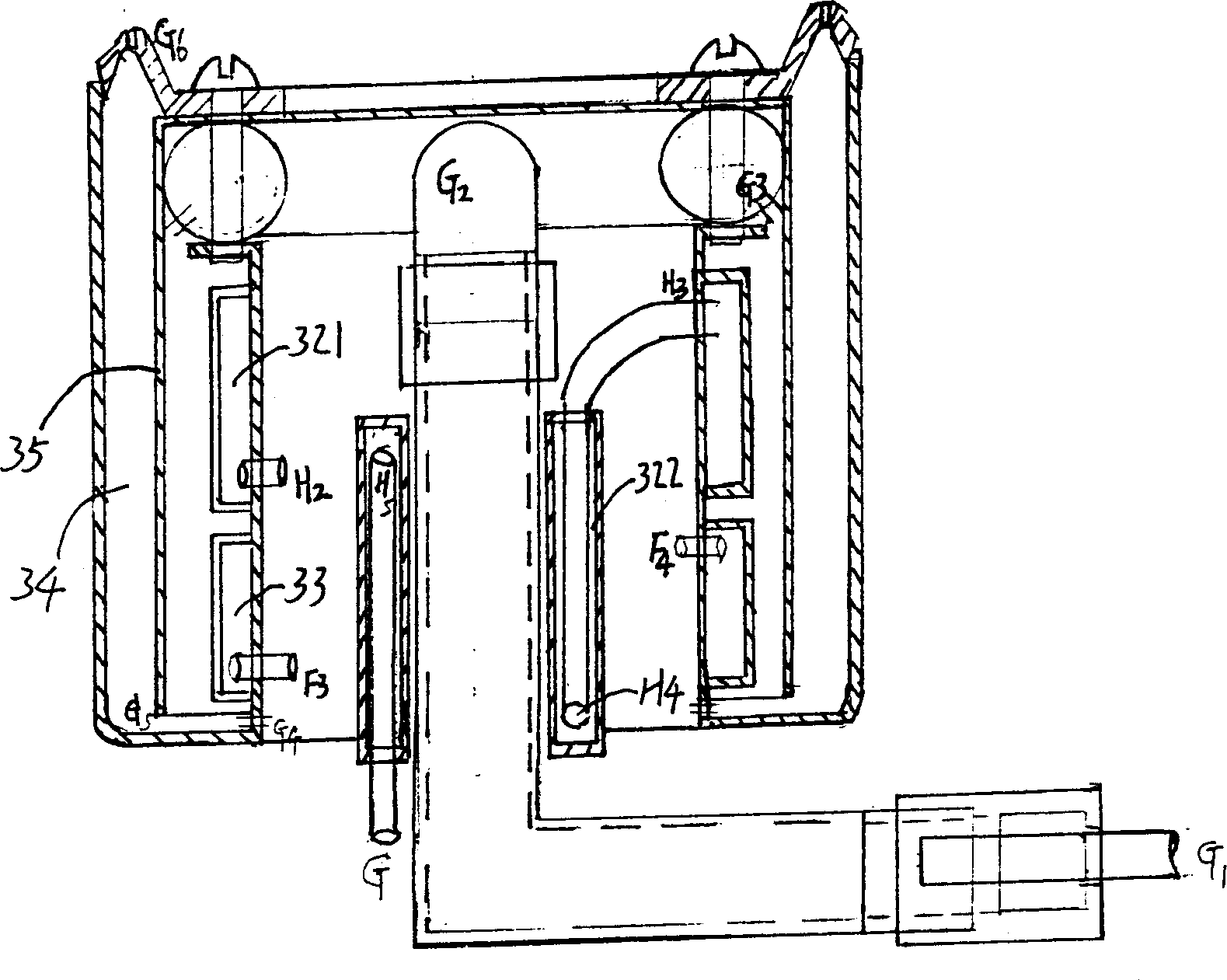

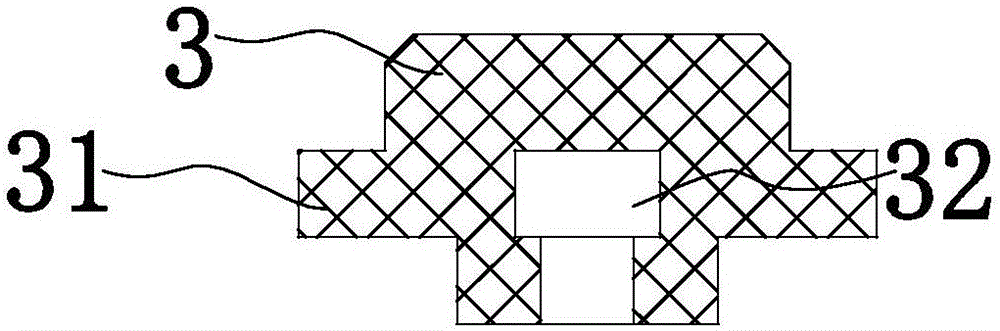

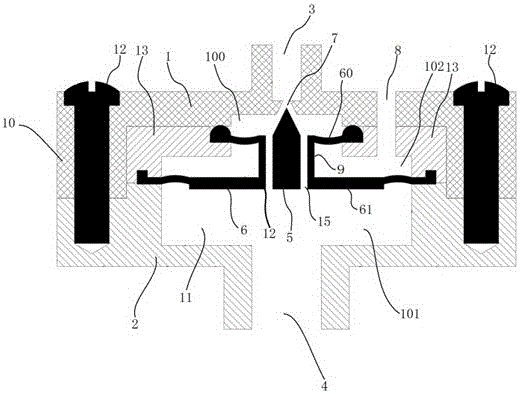

Piston self-operated regulating valve

InactiveCN105042141AIncrease the itineraryAutomatically adjust the flowOperating means/releasing devices for valvesEqualizing valvesPistonEngineering

The invention belongs to the technical field of regulating valves, and relates to a piston self-operated regulating valve. The piston self-operated regulating valve sequentially comprises three parts including a feedback mechanism, an actuating mechanism and a valve body from top to bottom. A valve element is arranged on a valve port of the valve body in a matched manner. The valve element is driven by a valve rod to open and close the valve port. The actuating mechanism comprises an upper cover and a lower cover. The upper cover and the lower cover are oppositely combined to form an installation cavity. The installation cavity is internally provided with a pressing plate and an actuating rod connected with the pressing plate. The actuating rod is fixedly connected with the valve rod through a sleeve. Return springs are arranged between the pressing plate and the lower cover. The feedback mechanism comprises a control pipeline and a piston cavity. The piston cavity is divided into an upper cavity body and a lower cavity body through a piston. The lower end of the control pipeline is communicated with a water inlet cavity in the valve body, and the upper end of the control pipeline is connected with the upper cavity body. The bottom of the piston is fixedly provided with a connecting piece in an interference manner. The connecting piece is fixedly connected with the actuating rod. Compared with a traditional membrane deformed within the short stroke, through the cooperation between the piston and the piston cavity, the piston stroke is determined by the length of the piston cavity, the stroke is longer, larger pressure can be borne, and the flow can be automatically adjusted when the pressure of a medium inside the valve body is higher.

Owner:CHONGQING BRIGHTY INSTR

Multi-cavity piezoelectric air-liquid pump

ActiveCN112412736AEasy connection and removalSimple structurePositive displacement pump componentsFlexible member pumpsPhysicsAir pump

The invention provides a multi-cavity piezoelectric air-liquid pump. The air-liquid pump comprises a piezoelectric air pump body and a piezoelectric liquid pump body, and a piezoelectric air pump baseis in threaded connection with the piezoelectric liquid pump body; and the piezoelectric air pump body comprises a threaded pump cover I, a sealing ring I, three piezoelectric vibrators I and a pumpbody I, the three piezoelectric vibrators I and the pump body I form a pump cavity and divide the pump cavity into a first pump cavity body, a second pump cavity body and a third pump cavity body, follow-up thin wafer valves are arranged in corresponding inlets and outlets of the first pump cavity body and the second pump cavity body, a first fixing frame is arranged at the bottom of the pump bodyI, and a first V-shaped bluff body is arranged on the first fixing frame. According to the air-liquid pump, the follow-up thin wafer valves are quick in response, small in opening pressure and good in pump valve following performance, and in cooperation with the disc-shaped vibrators, the pumping performance of the parallel pump is greatly improved; and a valve pump, a valveless pump, the air pump body and the liquid pump body are integrated into a whole, all the pumps can be jointly controlled or independently controlled, simultaneous pumping and independent pumping of gas and liquid can berealized, the flow range is wide, and various working requirements can be met.

Owner:QINGDAO AGRI UNIV

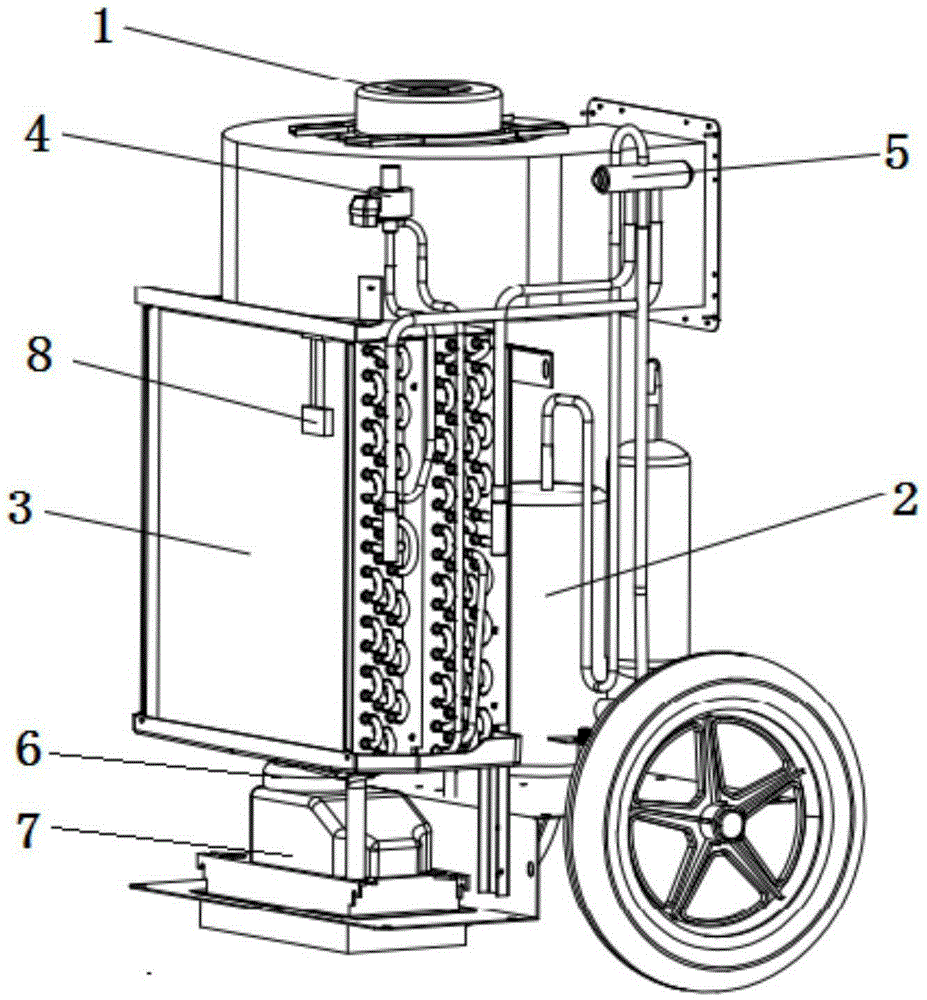

Low-low-sulfur oil cooling system

InactiveCN102052209AAutomatically adjust the flowStrong reliabilityMachines/enginesThermal treatment of fuelMarine engineeringFuel oil

The invention relates to a low-low-sulfur oil cooling system which comprises a ship water chilling unit, a refrigerant water pump module and a water and oil heat exchanging system, wherein the ship water chilling unit is connected with the refrigerant water pump module for providing low-temperature refrigerant water, and the refrigerant water pump module is connected with the water and oil heat exchanging system for realizing that oil in the water and oil heat exchanging system is cooled by using the low-temperature refrigerant water. The low-low-sulfur oil and fuel oil temperature refrigerant water with sulfur content being less than 0.1 percent is provided for water and oil heat exchange by using the ship water chilling unit, the fuel temperature can be effectively reduced, and the fuel viscosity is improved. The system has the advantages of simple structure, stability of operation, safety and reliability and convenience for maintenance, and can provide low-sulfur with high viscosity and good lubricating performance; and the problem that a ship diesel engine and a fuel oil supply system are easily worn by directly using the low-sulfur fuel is effectively solved.

Owner:JIANGSU JOSUN AIR CONDITIONER

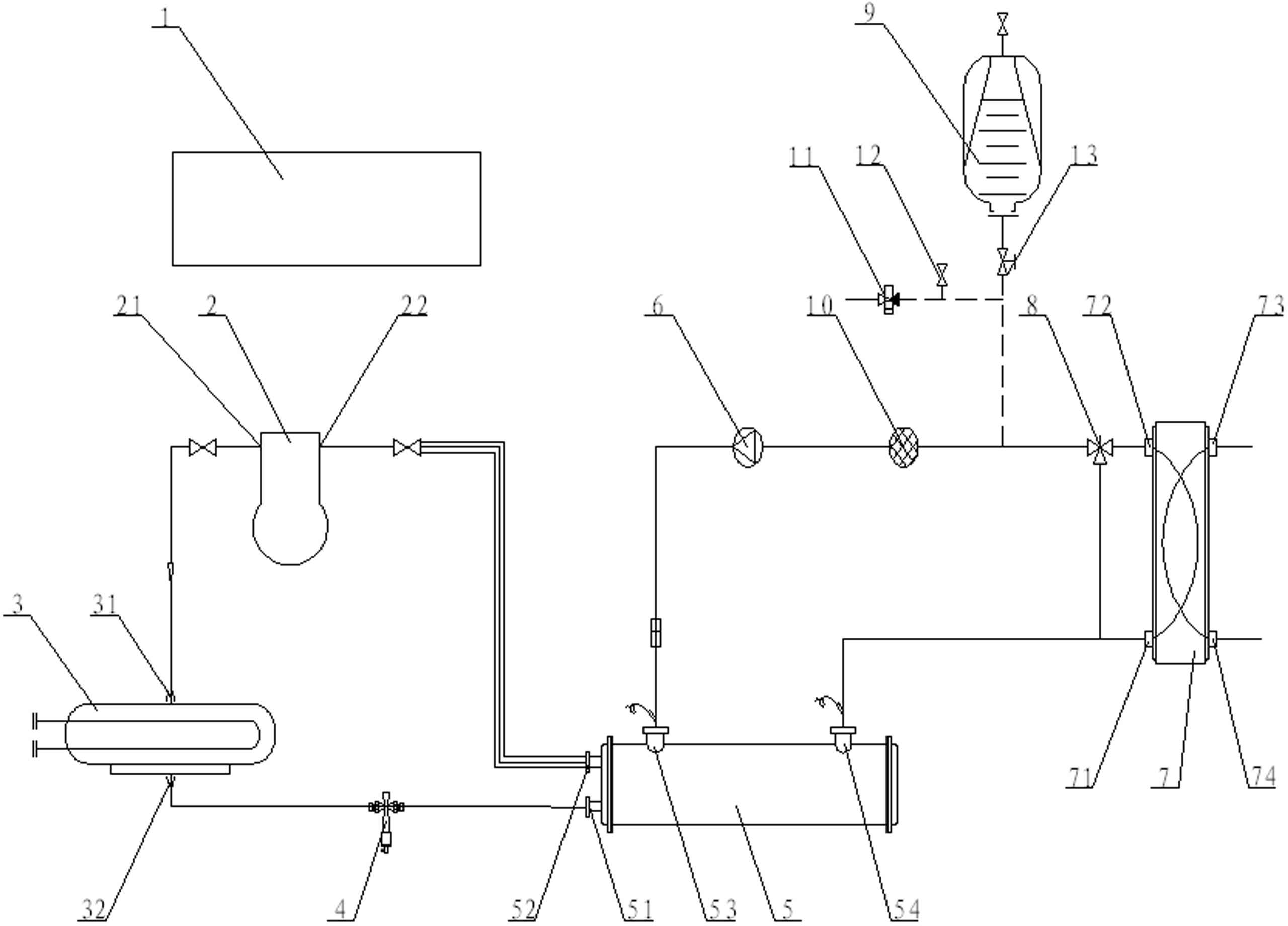

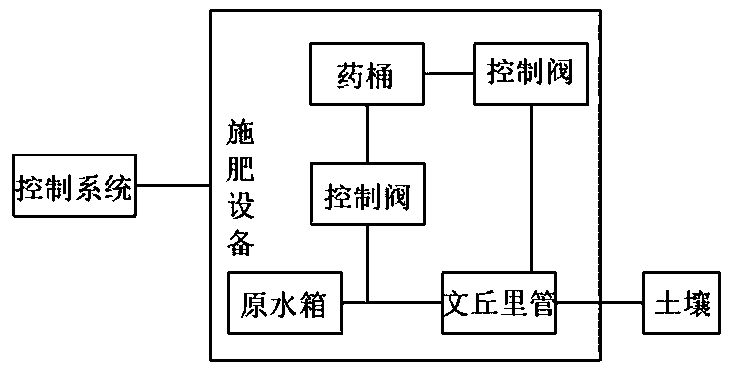

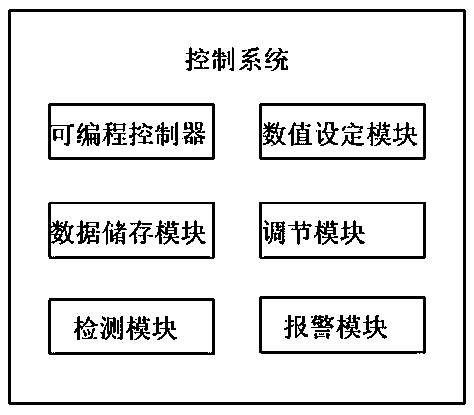

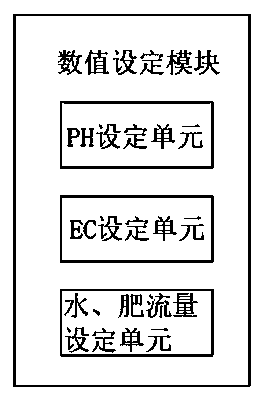

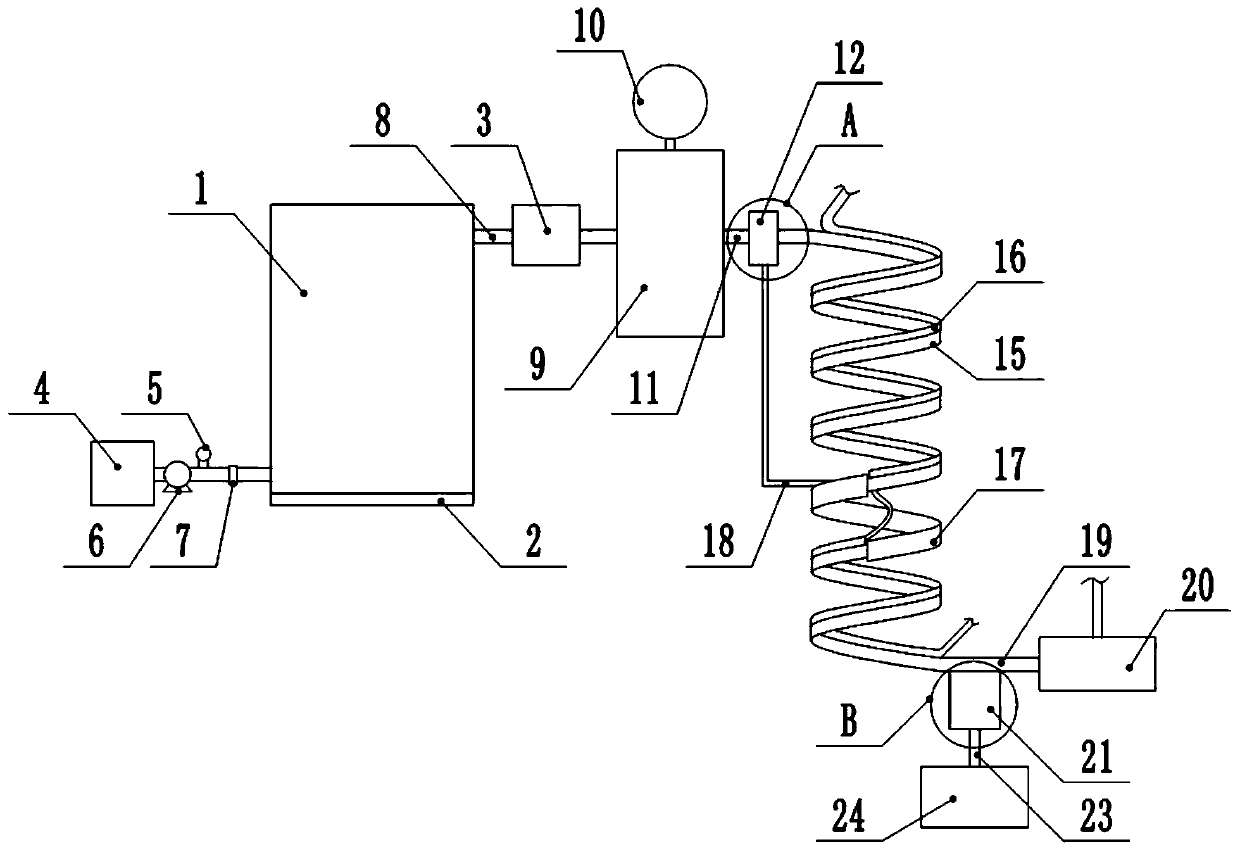

Fertilization and irrigation device and system

InactiveCN110178514AEnhanced blendingReduce the degree of leachingFlow mixersTransportation and packagingSolenoid valveControl system

The invention discloses a fertilization and irrigation device and system, and belongs to the technical field of fertilization and irrigation. The fertilization and irrigation system comprises a control system, a fertilization system, a stirring pump, a raw water pump and a solenoid valve; the control system is used for controlling the irrigation process of the irrigation system, the fertilizationsystem is used for conducting fertilization on crops on land, the stirring pump is used for starting a stirrer to mix water with fertilizer, and by controlling the raw water pump, a stand-by raw waterpump can be manually switched; the fertilization and irrigation device comprises a support plate, an irrigation main pipe, a raw water box, a stirring pump, a Venturi tube, a control box and a pesticide barrel; the raw water box and the stirring pump are located on one side of the support plate, and the stirring pump is located behind the raw water box. The fertilization and irrigation device andsystem can automatically adjust irrigation, fertilization and the water flow rate of flushing pipelines, so that nitrogen applied in soil can be left in a crop root area to the maximum extent, and meanwhile dripper blockage can be prevented.

Owner:MEGAPHOTON INC

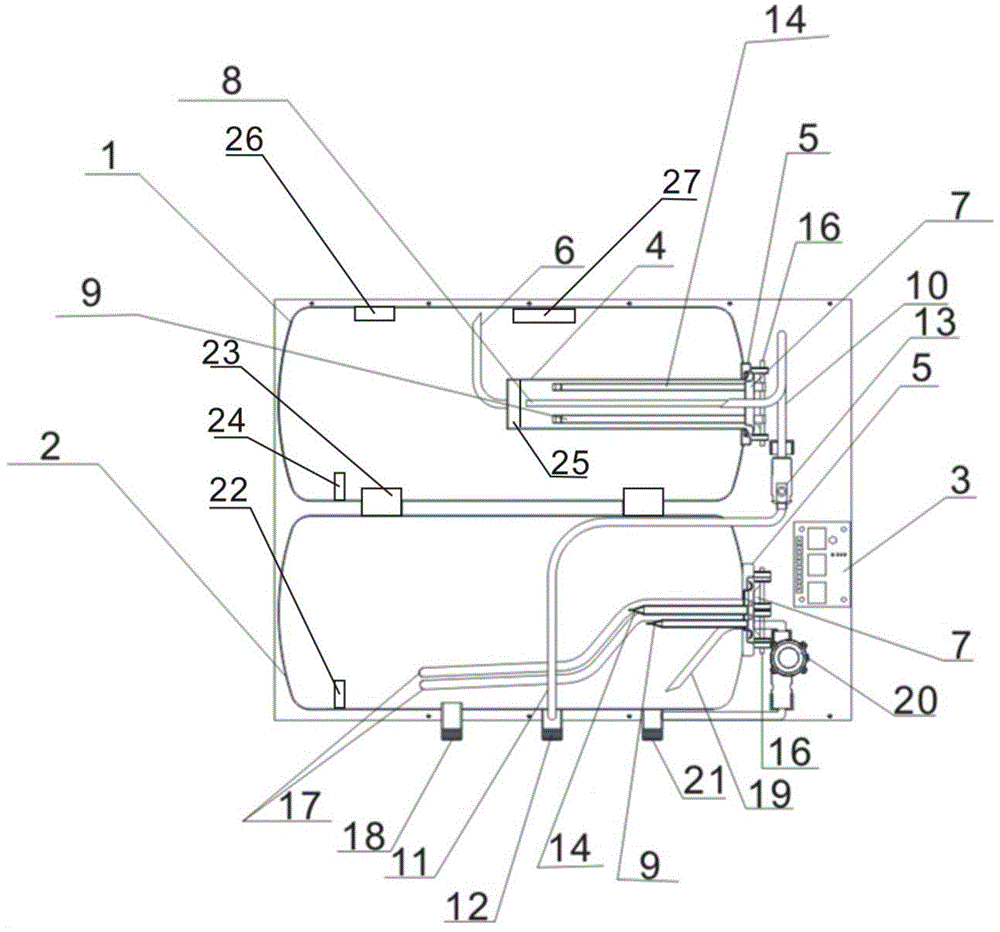

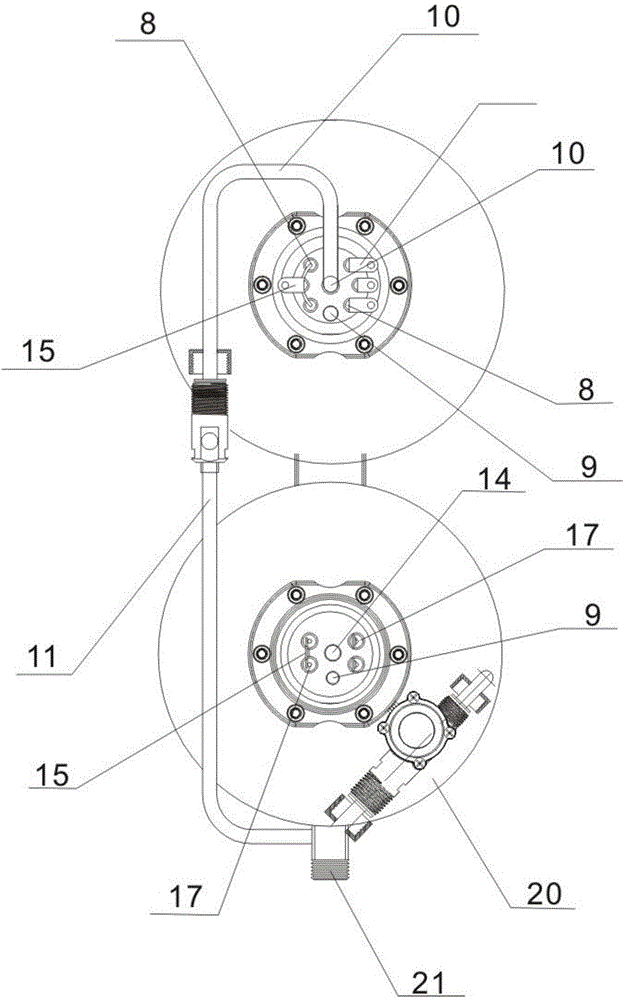

Water-stored dual-mode purifying water heater

InactiveCN104864582AAutomatically adjust the outlet water temperatureAutomatically adjust the flowMultistage water/sewage treatmentWater heatersWater dischargeDual mode

The invention discloses a water-stored dual-mode purifying water heater. The water-stored dual-mode purifying water heater comprises an upper-part inner container, a lower-part inner container and a control circuit board. The control circuit board is arranged on a shell. The upper-part inner container and the lower-part inner container are arranged in the interior of the shell and communicated by means of a communicating pipe. A first water quality detector used for detecting water quality of the lower-part inner container is arranged in the lower-part inner container. The position, where the upper-part inner container and the lower-part inner container are communicated, is provided with a first filtering device used for filtering water quality of the lower-part inner container. The upper-part inner container is provided with a second water quality detector used for detecting water quality of the upper-part inner container. The upper-part inner container is further provided with a second filtering device used for filtering water quality of the upper-part inner container.The water-stored dual-mode purifying water heater has following beneficial effects: a machine can be automatically protected; the water-stored dual-mode purifying water heater is not only capable of automatically regulating water discharge temperature and flow but also further purifying water quality; and the water-stored dual-mode purifying water heater is used conveniently and rapidly with stability and reliability.

Owner:SHANGHAI NICHOLS ELECTRONICS TECH INC

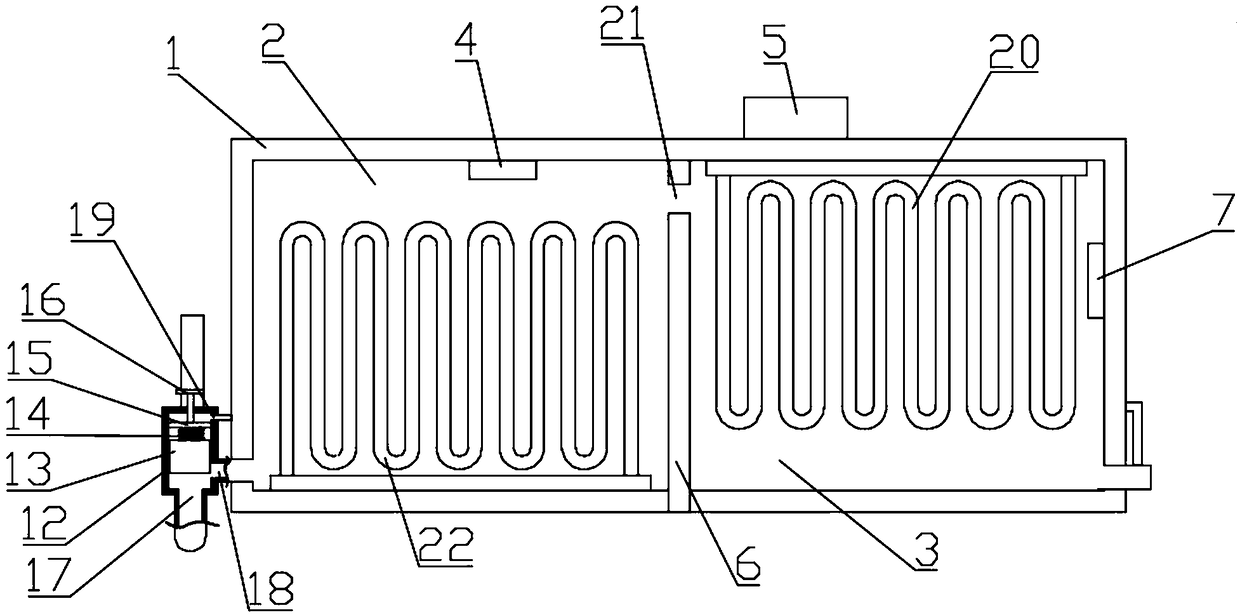

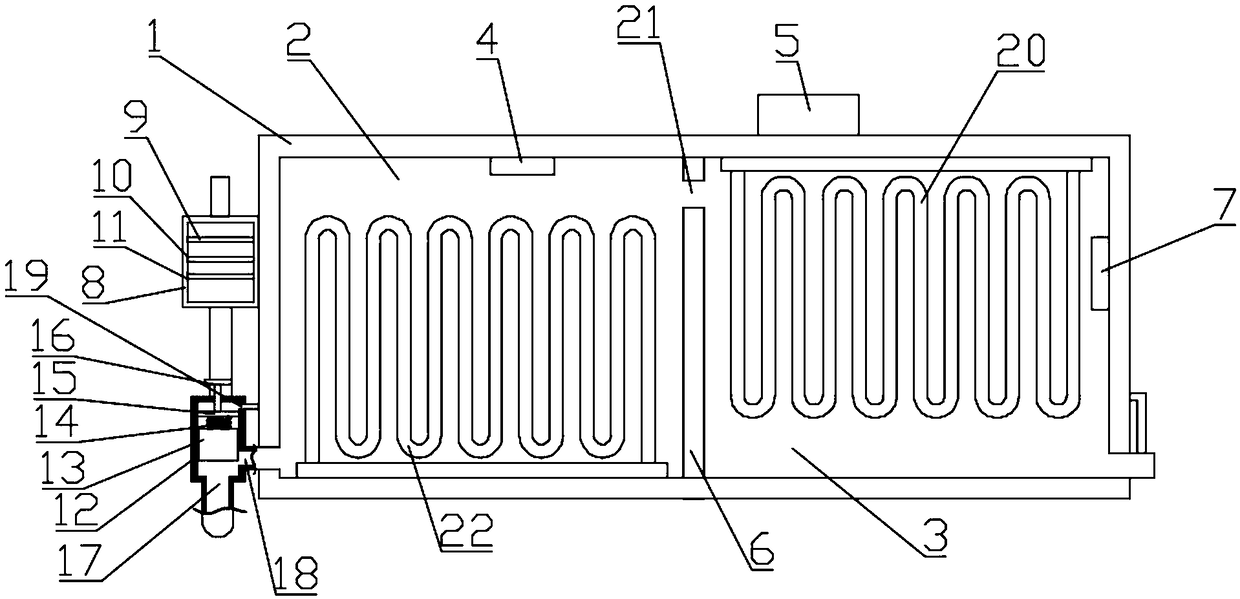

Dehumidifier

InactiveCN105299760AImprove energy efficiencyAutomatically adjust the flowMechanical apparatusSpace heating and ventilation safety systemsEngineeringMoisture sensor

The invention discloses a dehumidifier. The dehumidifier comprises a fan, an evaporator, a compressor and a four-way reversing valve, and is characterized in that the dehumidifier is further provided with a temperature and humidity sensor and a controller; the compressor is connected with a cooled heat exchanger through the four-way reversing valve; the cooled heat exchanger is connected with an electronic expansion valve connected with the evaporator; the fan, the evaporator, the compressor, the four-way reversing valve, the temperature and humidity sensor, the cooled heat exchanger and the electronic expansion valve are connected with the controller. The dehumidifier has the beneficial effects that the flow of the electronic expansion valve is automatically adjusted according to different temperature and humidity, so that the dehumidifier achieves the optimal dehumidification effect, and the dehumidifier can also normally work in a high temperature environment by adjusting the flow of the electronic expansion valve.

Owner:NINGBO FREE TRADE ZONE REFINE MOULD TECHNOLOGY CO LTD

System for automatically controlling sealing and blocking prevention of air pre-heater and control method

PendingCN110094752AStop the leakAvoid cloggingCombustion processHeat exhanger sealing arrangementHydrogen SulfateAutomatic control

The invention discloses a system for automatically controlling sealing and blocking prevention of an air pre-heater and a control method. The system comprises a compressed air system, a heating device, a gas-sealing spraying device and an automatic control system, wherein high-pressure air generated by the compressed air system enters the heating device to heat; heated high-temperature and high-pressure air is guided into the gas-spraying sealing device; a high-temperature high-pressure air curtain is formed at the cold end of the air pre-heater and a hot end fan-shaped plate, so that air is prevented from leaking towards a smoke gas side, and therefore, air leakage of the air pre-heater is reduced; and high-temperature high-pressure air further reaches the inner part of a heat exchange element of the air pre-heater, so that ammonium hydrogen sulfate is heated for being converted into a gas state from a liquid state, and accumulated dust is blown to achieve the purpose of reducing airleakage of the air pre-heater and preventing the air pre-heater from blocking. The system can effectively reduce air leakage of the air pre-heater, prevents the air pre-heater from being blocked and corroded, improves heat exchange ability of the air pre-heater, reduces a smoke discharge temperature, improves boiler efficiency, reduces unit coal consumption, and has relatively good economic benefits.

Owner:XIAN THERMAL POWER RES INST CO LTD

Pipeline connector

The invention discloses a pipeline connector and belongs to the technical field of connecting pipe fittings. The pipeline connector comprises a base sleeve. A first connector sleeve and a second connector sleeve are respectively inserted to two ends of the base sleeve, the through holes of the first connector sleeve and the second connector sleeve are coaxial, the tips of the first connector sleeve and the second connector sleeve are in butt joint, and the other ends of the first connector sleeve and the second connector sleeve are connected with a pipeline. A valve cavity communicated with the corresponding through hole is formed in the second connector sleeve, and a valve element connected with the inner wall of the valve cavity through a spring is disposed in the valve cavity at a position corresponding to the through hole. The outer walls of the first connector sleeve and the second connector sleeve are provided with annular bosses respective abutted against two ends of the base sleeve. A drop-proof sleeve is disposed outside the base sleeve. By the pipeline connector, the problems that existing pipeline connection is complex, the flow of conveying media cannot be controlled, reliability is poor, medium leakage easily occurs, and service life is affected.

Owner:LIUZHOU CITY QIANYANG MACHINERY & ELECTRIC

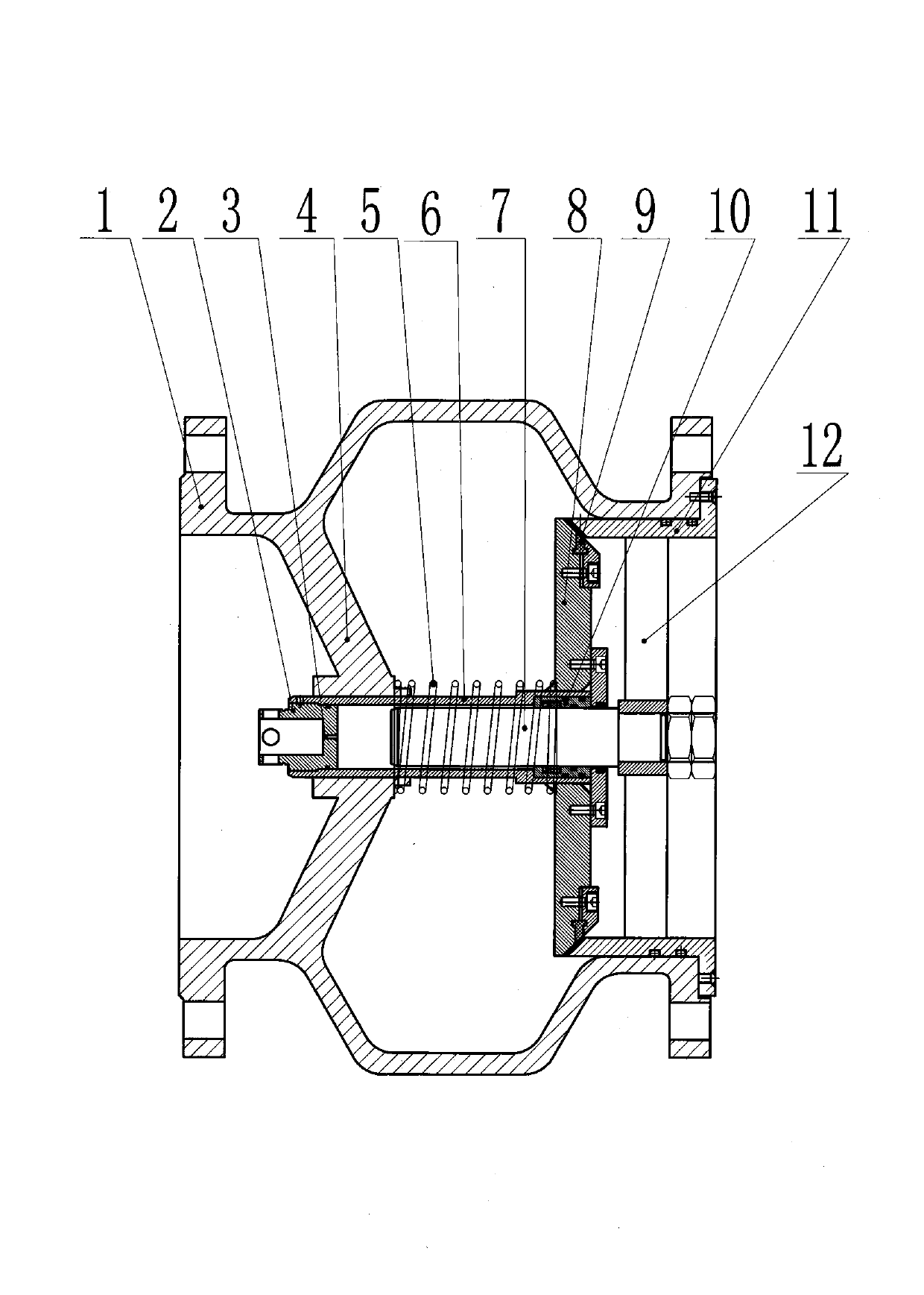

Piston assembly capable of achieving flow compensation

ActiveCN103233999AAchieve trafficDifferent circulation areaSpringsShock absorbersControl flowAutomatic control

The invention discloses a piston assembly capable of achieving flow compensation. The piston assembly comprises a piston rod, the bottom of the piston rod is hollow, the piston rod is broken to form an upper rod end and a lower rod end, a valve core is slidingly connected with the hollow inside of the piston rod, two cavities are formed by two ends of the valve core, the hollow inside of the upper rod end and the hollow inside of the lower rod end and are provided with an upper elastic cavity and a lower elastic cavity respectively, the outer end face of the upper rod end and the outer end face of the lower rod end are fixed together through a piston and provided with an upper auxiliary damping hole and a lower auxiliary damping hole respectively, an auxiliary channel which is communicated with damping holes is arranged in the inner circle of the piston, and the ideal speed compensation effect can be obtained through proper selection of the rigidity of the upper elastic cavity and the rigidity of the lower elastic cavity. By the aid of the piston assembly, the moving position of a thrust shaft can be controlled automatically according to the flow of a shock absorber to obtain different flow areas and control flow of oil, besides, electric pneumatic units and drive devices are not required to be added, and the piston assembly is simple in structure, compact, convenient to manufacture, high in transportability and capable of achieving automatic stepless control of bidirectional flow.

Owner:JILIN UNIV

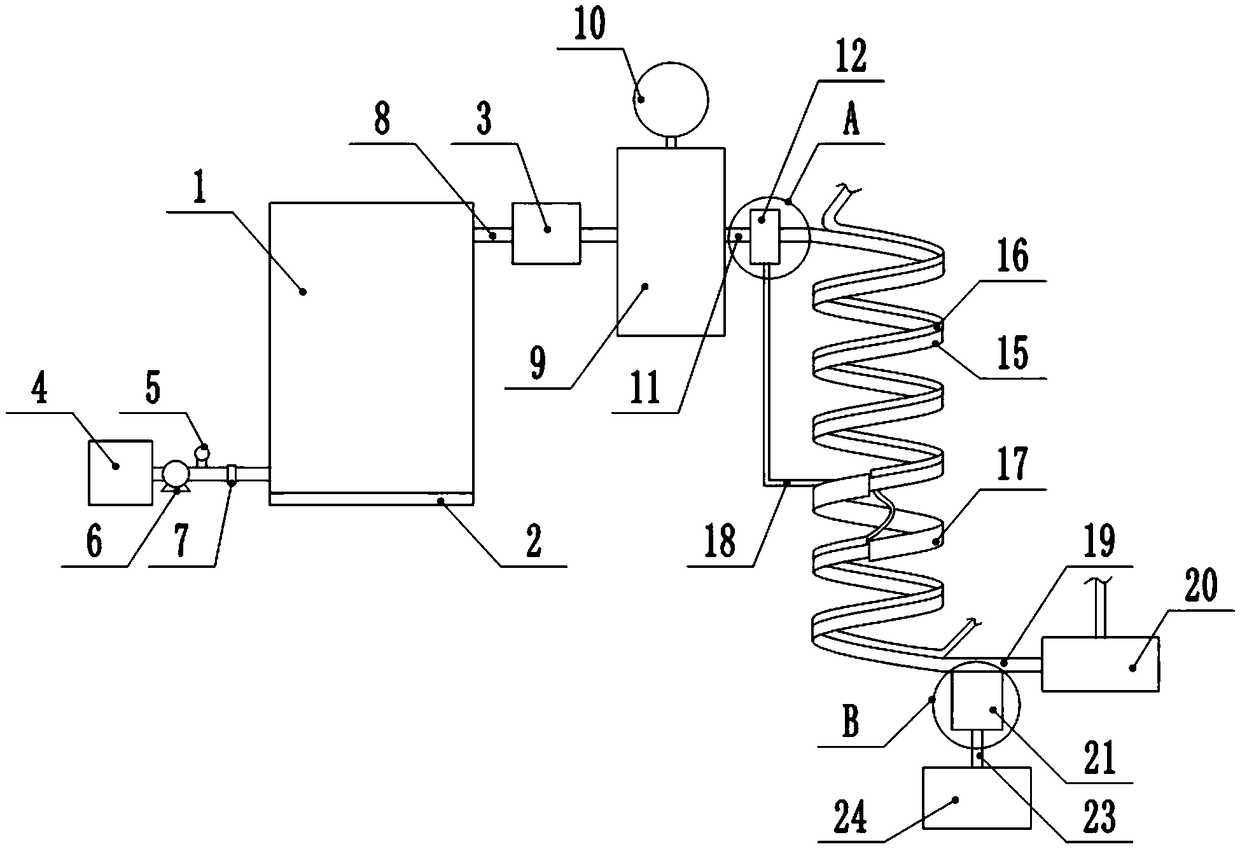

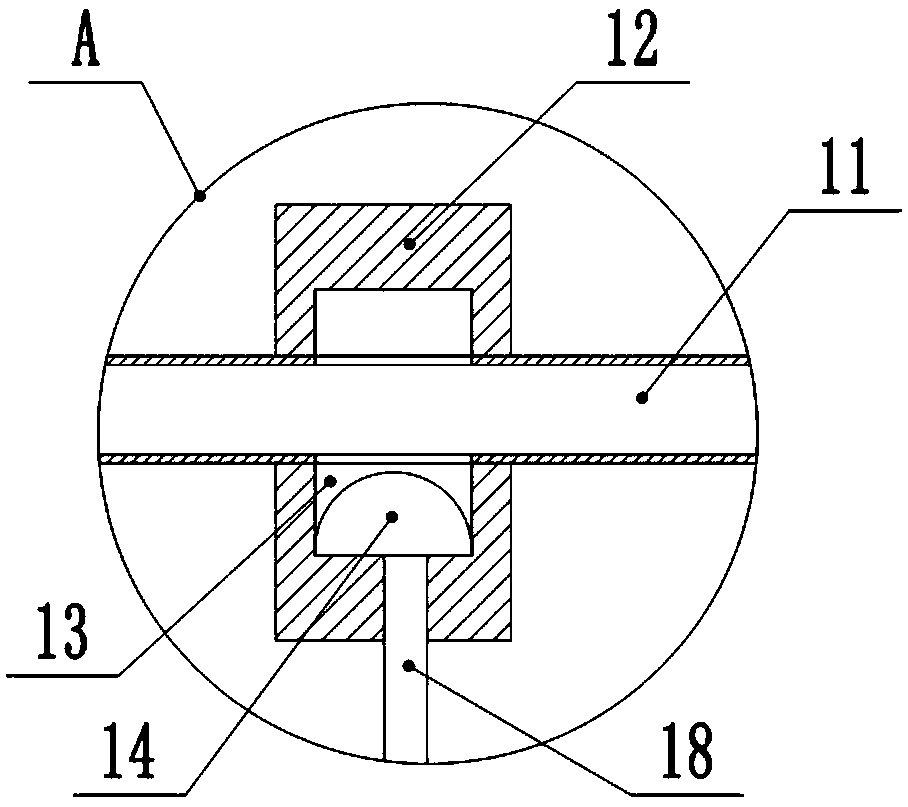

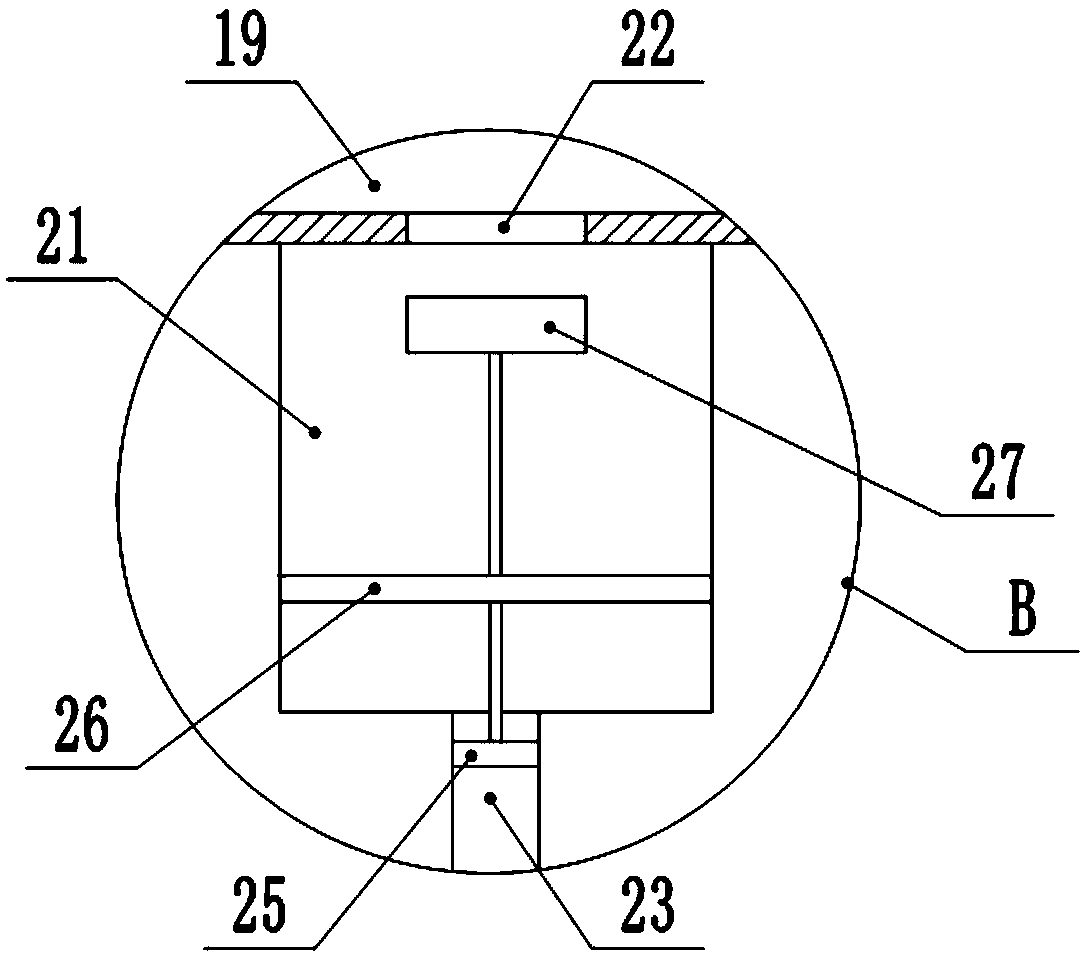

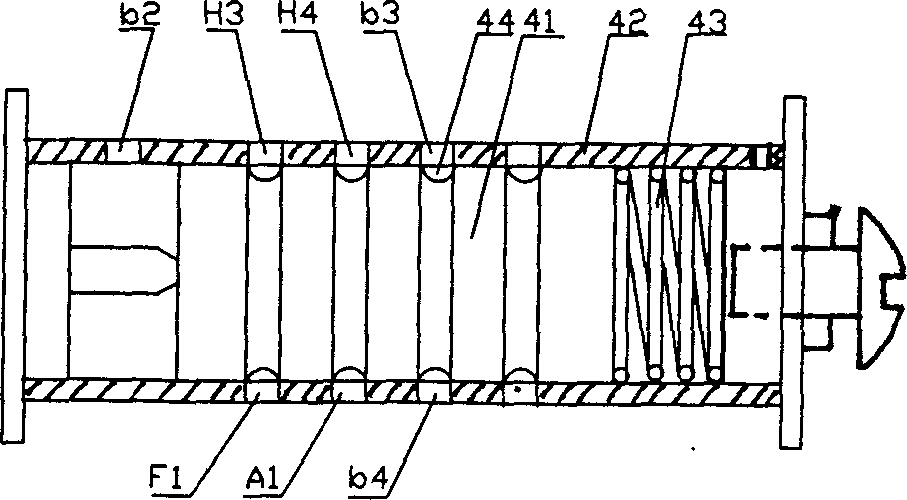

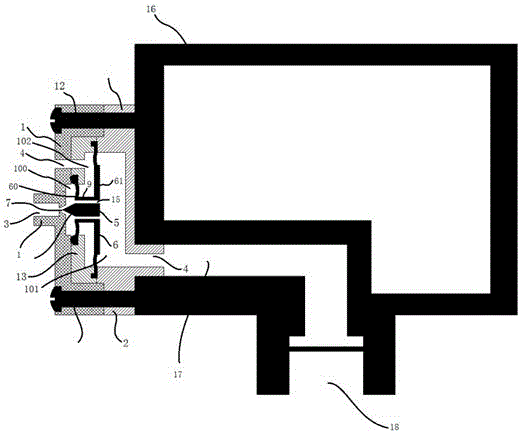

Dewaxing pre-sintering furnace

The invention relates to the technical field of dewaxing equipment, and particularly discloses a dewaxing pre-sintering furnace. The dewaxing pre-sintering furnace comprises a furnace body, a hydrogenintroducing system, a heating device and a vacuumizing device, an air extracting pipe communicates between the furnace body and the vacuumizing device, the vacuumizing device is connected with a gasstorage chamber, the gas storage chamber communicates with a gas outlet pipe, a flow control block is fixedly arranged on the gas outlet pipe, the gas outlet pipe is connected with a spiral pipe, a cooling pipe is tightly attached to the outer wall of the spiral pipe, a cavity is tightly attached to the outer wall of the spiral pipe, a glycerol liquid is contained in the cavity, a gas conveying pipe communicates between the cavity and the flow control block, the spiral pipe is connected with a horizontally-arranged second pipeline, and a liquid collecting tank used for gas-liquid separation isfixedly installed on the second pipeline. According to the furnace, the flow control block on the gas outlet pipe can be controlled through the gasification of the glycerol in the cavity, then the flow of the mixed gas entering the spiral pipe is controlled, the gaseous paraffin in the mixed gas is fully liquefied, the liquid paraffin and hydrogen are separated by utilizing the liquid collectingtank, and then recovery of the paraffin is realized.

Owner:ZUNYI ZHONGBO CEMENTED CARBIDE

Burner burning inflammable waste water containing methane

InactiveCN1421643ANo pollution in the processAvoid accidentsBurnersDomestic stoves or rangesAtmospheric airSprayer

The burner for burning inflammable waste water containing methane include fuel box, preheater, burning head and control valve, and the burning head consists of flame sprayer and gasifying cavity. It features that its fuel box has self-control valve in the upper port to atmosphere and general control valve in the lower port to both preheater and gasifying cavity; the gasifying cavity outlet is connected to the flame sprayer via the general control valve; and the self-control valve comprises valve core, valve seat and spring. By means of heating, pressurizing and gasifying, the present invention can stabilize pressure, regulate pressure and flow rate automatically, can burn completely without environmental pollution and harm to human body.

Owner:张敦自

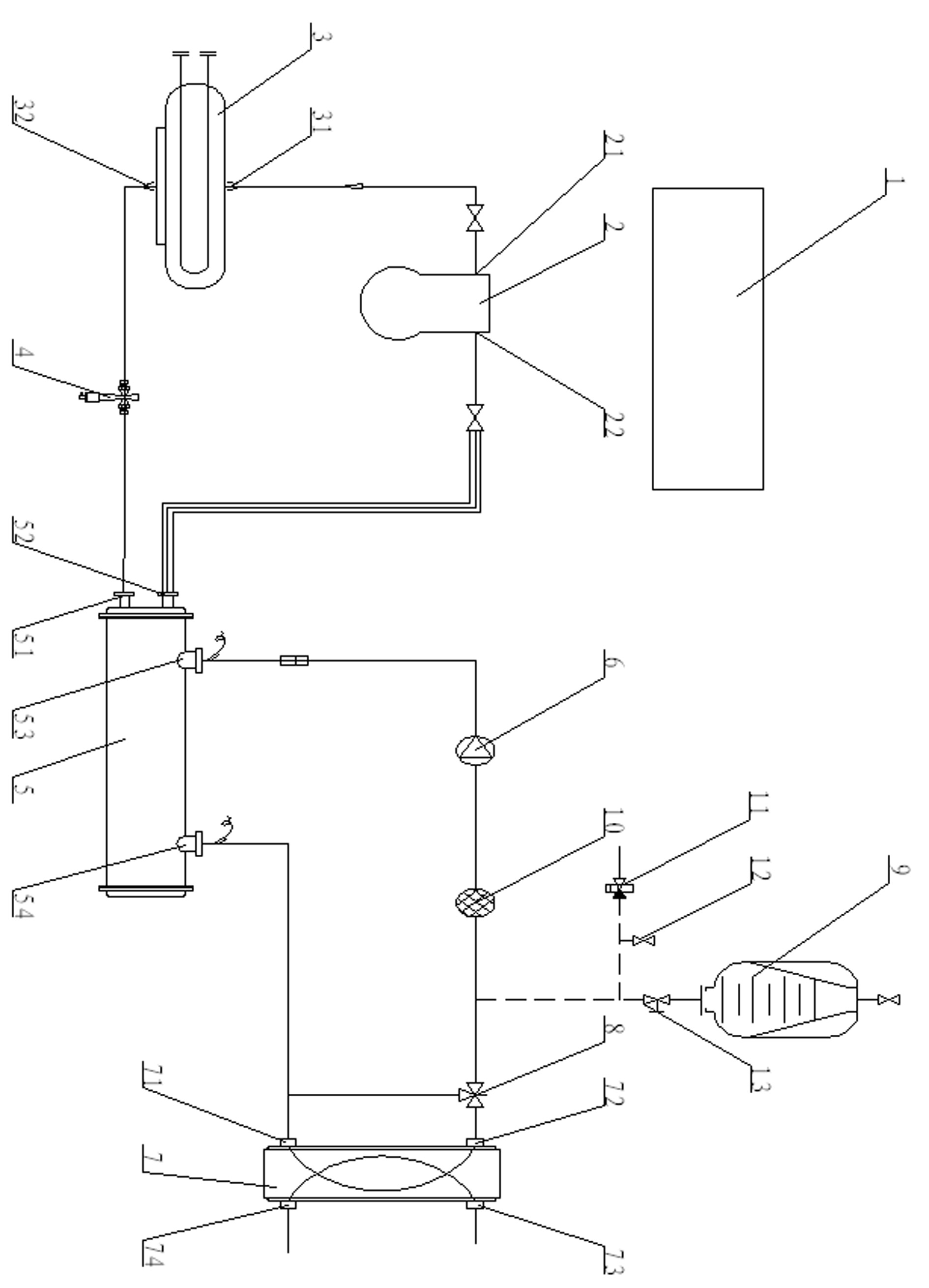

Natural gas automatic distribution method and system

ActiveCN109210380BReduce workloadHigh degree of automation controlPipeline systemsAutomatic transmissionControl system

The invention discloses an automatic distribution method and system for natural gas. The system comprises a station controller, a plurality of station control system PLCs and a plurality of automaticdistribution mainframes so as to correspond to different gas supply areas, and is characterized in that the station controller sends operation parameters input from an operation interface to the station control system PLCs; the PLCs send the operation parameters to the automatic distribution mainframes; target values are returned to the station control system PLCs after relevant calculation is carried out through the automatic distribution mainframes; and the PLCs control corresponding valves to carry out gas delivery control.

Owner:国家管网集团北京管道有限公司 +1

Novel multifunctional wall top automatic painting device

ActiveCN108179864AIncrease resistanceLower resistanceBuilding constructionsEffective powerAtmospheric pressure

The invention discloses a novel multifunctional wall top automatic painting device. The novel multifunctional wall top automatic painting device comprises a main machine body shell, a tail gas treatment device, a pneumatic connecting pipe, a paint input connecting pipe, sliding wheels, a paint spraying machine, paint spraying heads, a painting roller, a painting roller bracket, a working state display lamp and a power display lamp; the tail gas treatment device is arranged at the left portion of the inner portion of the main machine body shell, and the tail gas treatment device is fixed to theinner portion of the main machine body shell through bolts; the painting roller is arranged at the right side of the tail gas treatment device, and the painting roller is movably connected with the painting roller bracket through bearings; and the painting roller bracket is fixedly connected with the main machine body shell through welding. The effective power of equipment can be effectively improved, and when the spraying flow rate is large, the flow rate of an air pump is automatically adjusted, so that the tail gas treatment during decoration is improved, the excessive odor and toxic and harmful gas generated during the decoration are reduced, the safety of construction is improved, the electric energy is saved, and the practicability of the equipment is improved.

Owner:新疆及地建设工程有限公司

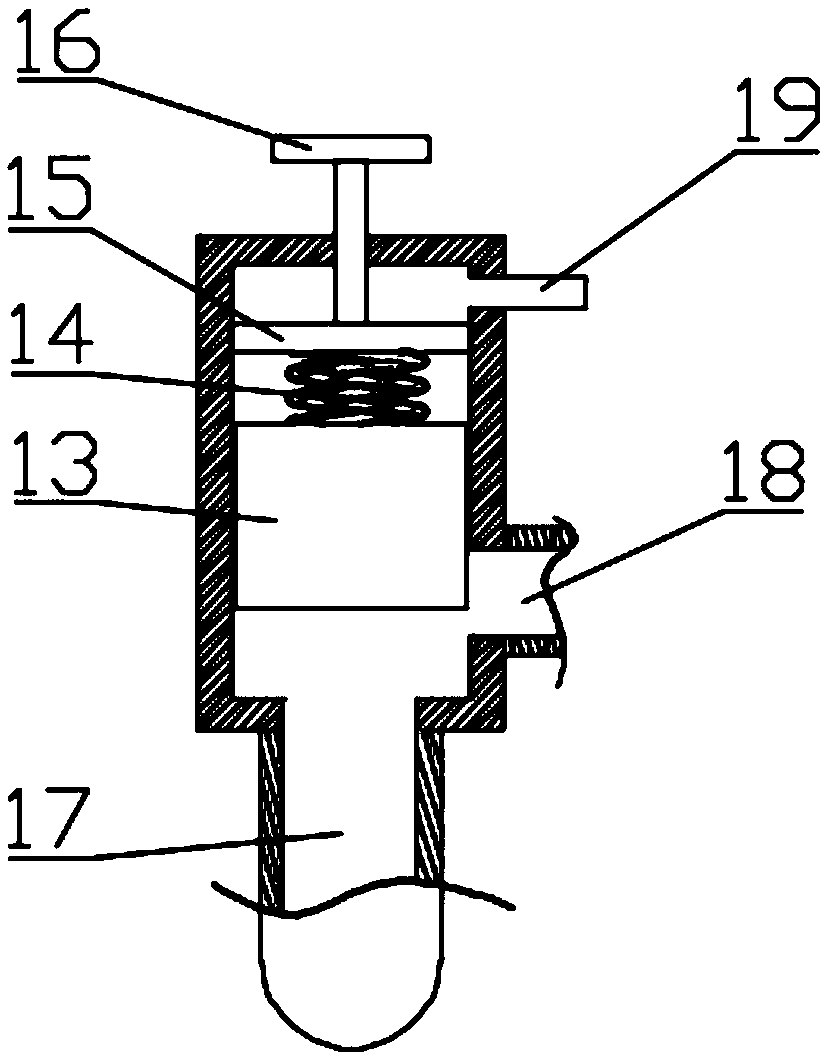

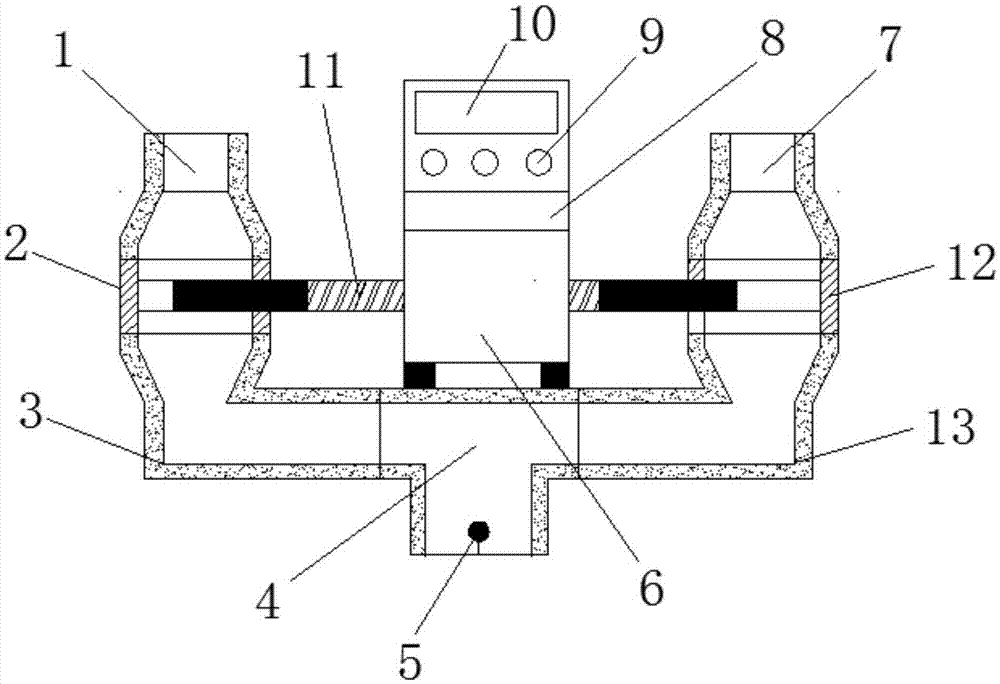

Biological garbage disposal truck constant-temperature system

InactiveCN109237785AEnsure heating uniformityGuaranteed heating effectSolid waste disposalStorage heatersWater sourceEngineering

The invention discloses a biological garbage disposal truck constant-temperature system, and relates to the technical field of environment protection devices. The constant-temperature system comprisesa body. A first heating cavity and a second heating cavity are formed in the body through a partition plate. A communicating opening for making the first heating cavity communicated with the second heating cavity is formed in the partition plate. A water inlet of the first heating cavity is connected to a first outlet of an adjusting device through a pipeline. A slider is arranged in the adjusting device. A first inlet for an external water source is formed in the bottom of the adjusting device. The slider is slidingly arranged in the adjusting device. A spring is arranged at the upper end ofthe adjusting device. The upper end of the spring is fixedly arranged on an installation rod at the lower end of a hand wheel. The hand wheel is rotationally arranged at the upper end of the adjusting device through a threaded hole. A pressure adjusting opening is formed in the upper end of the adjusting device and connected to an outlet of the body through a pressure guiding pipe. The constant-temperature system is stable in temperature, and the stability of output heat is kept.

Owner:SHIYAN HERONG AUTOMOBILE ELECTRICAL APPLIANCES

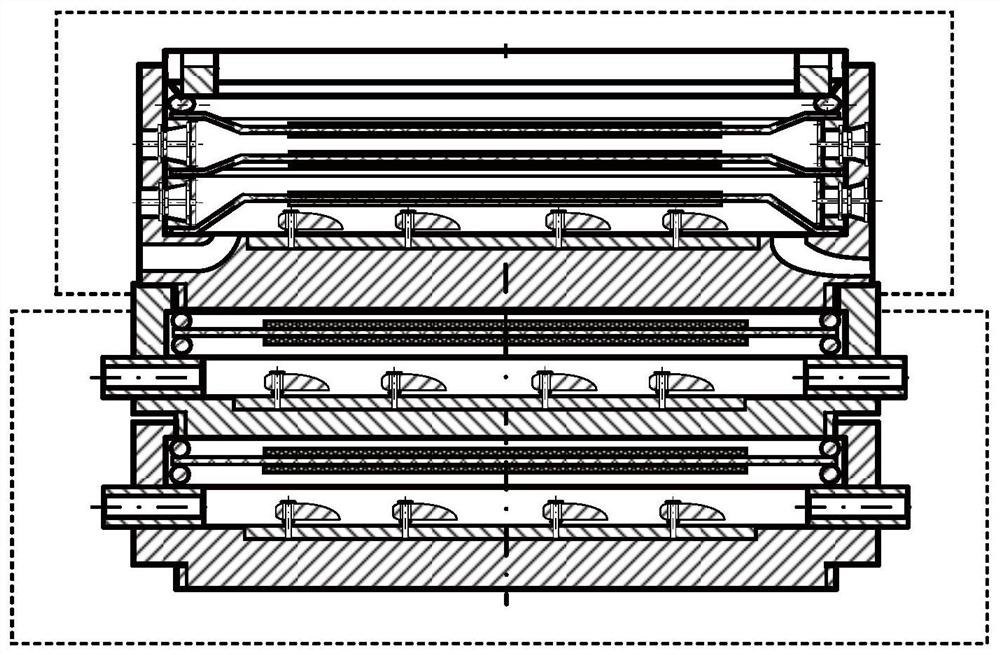

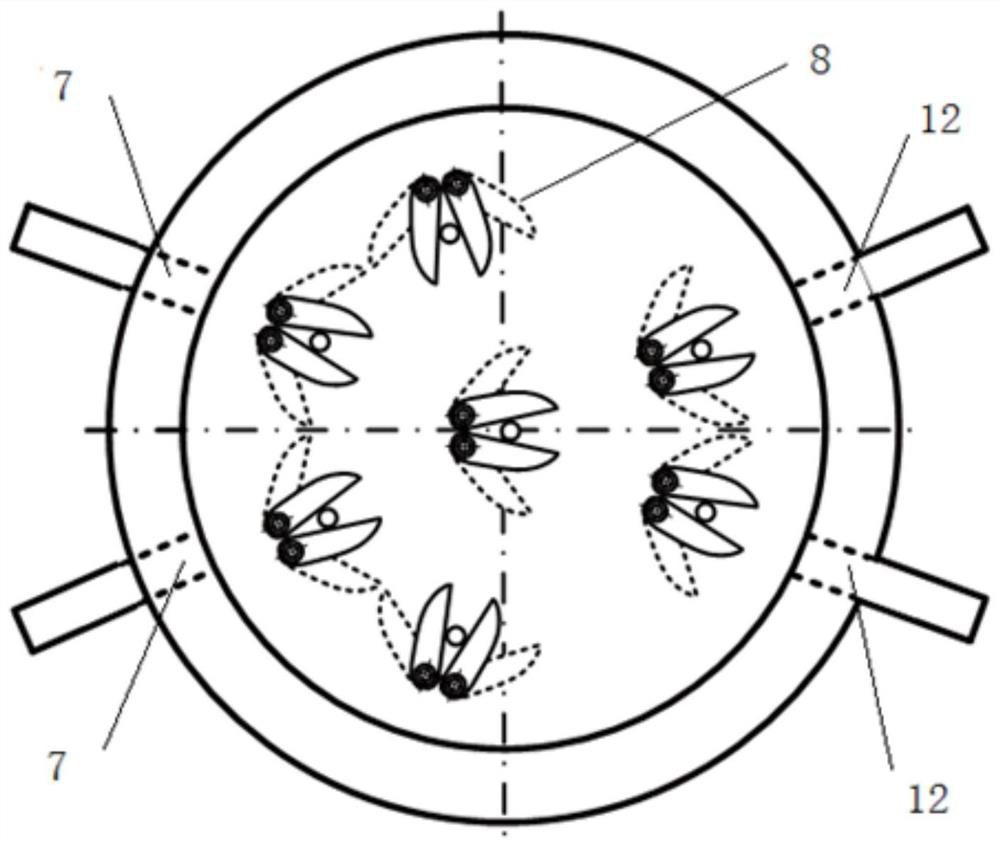

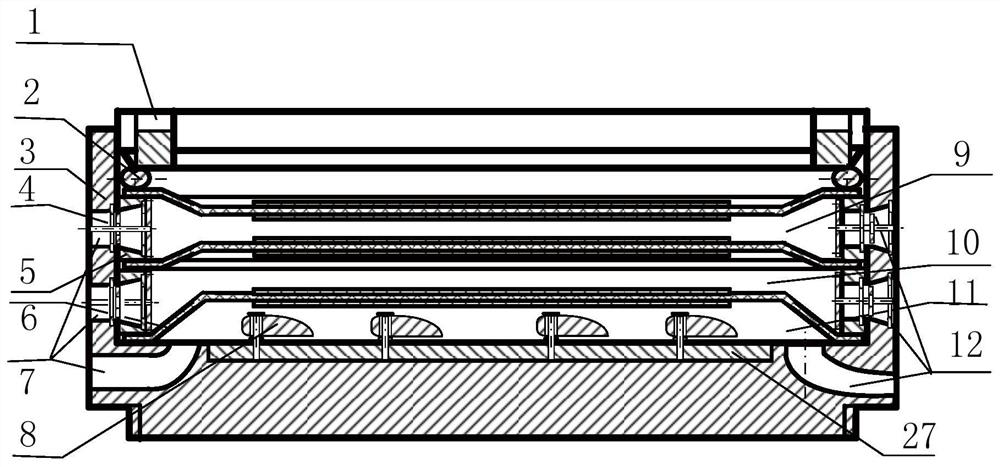

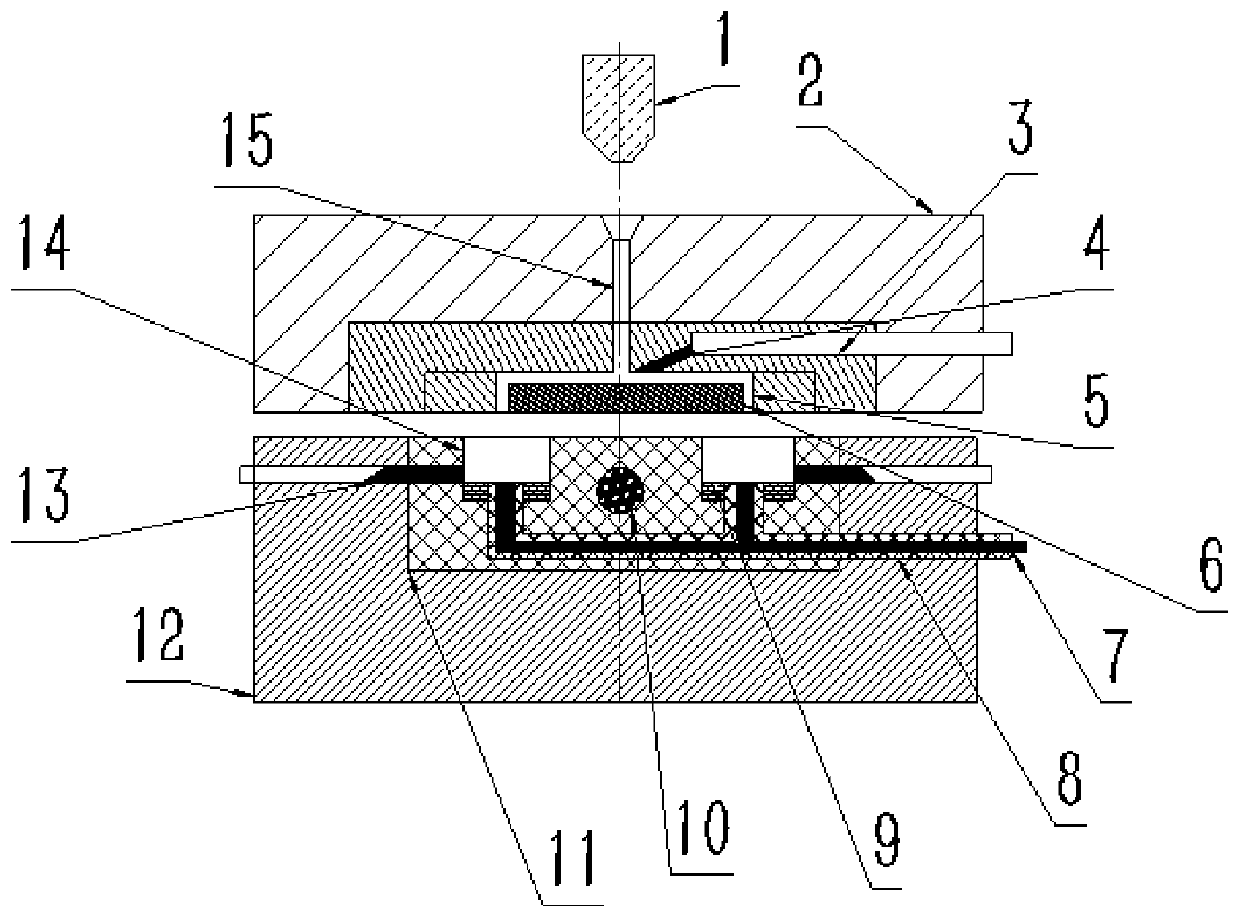

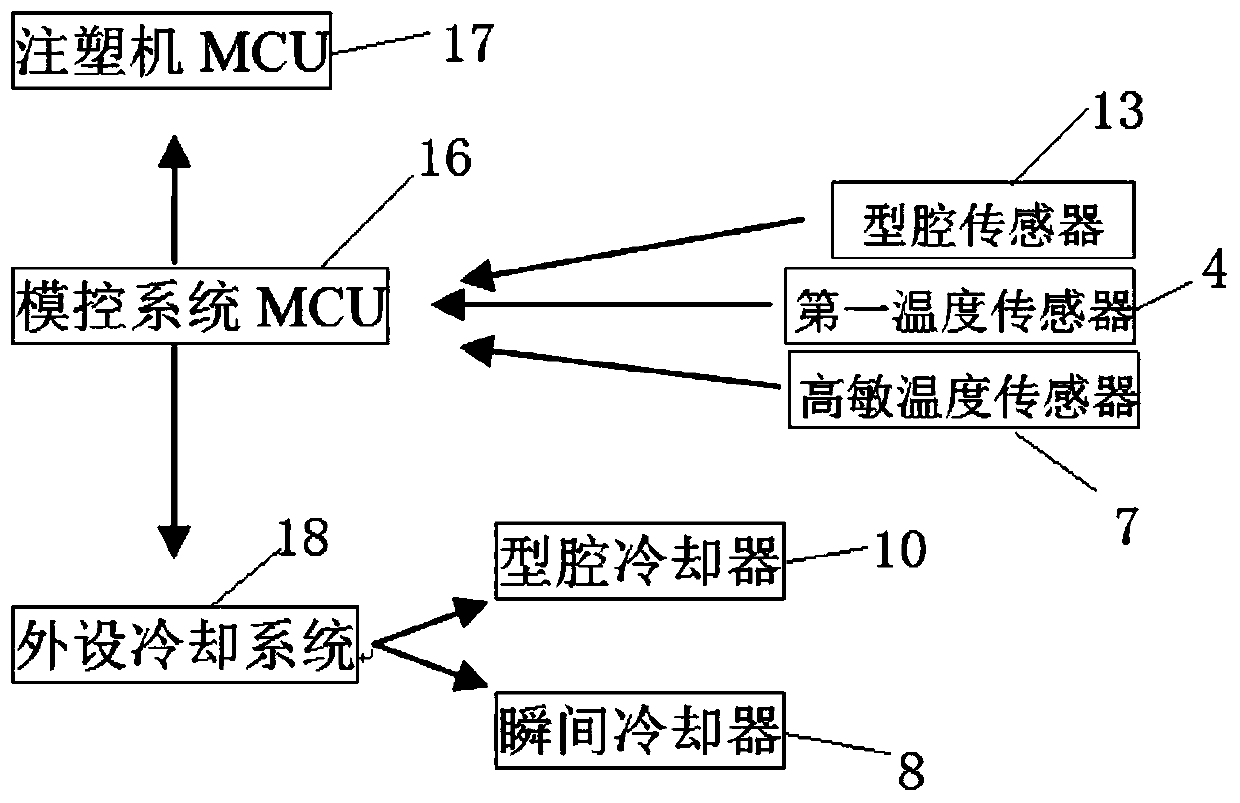

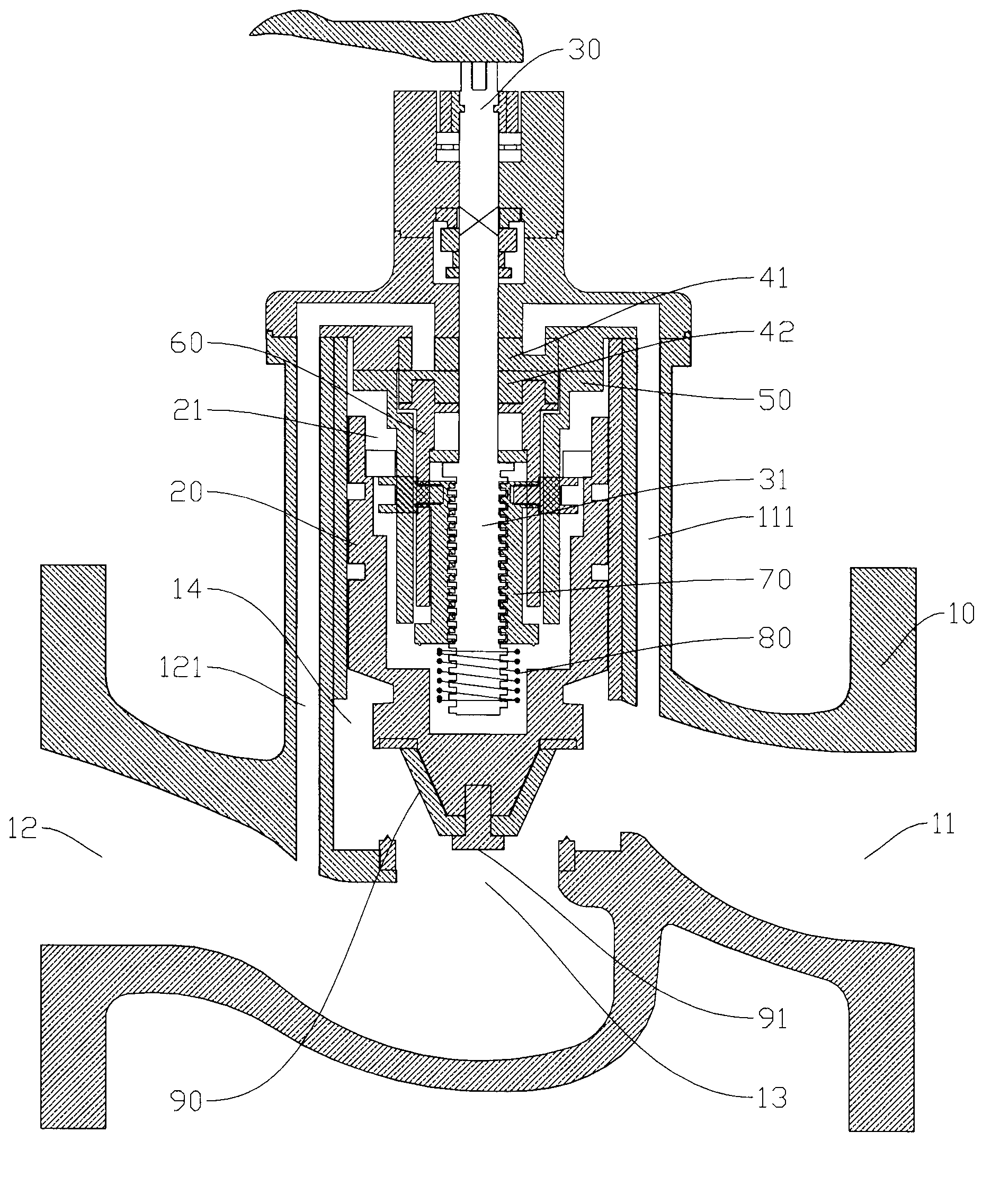

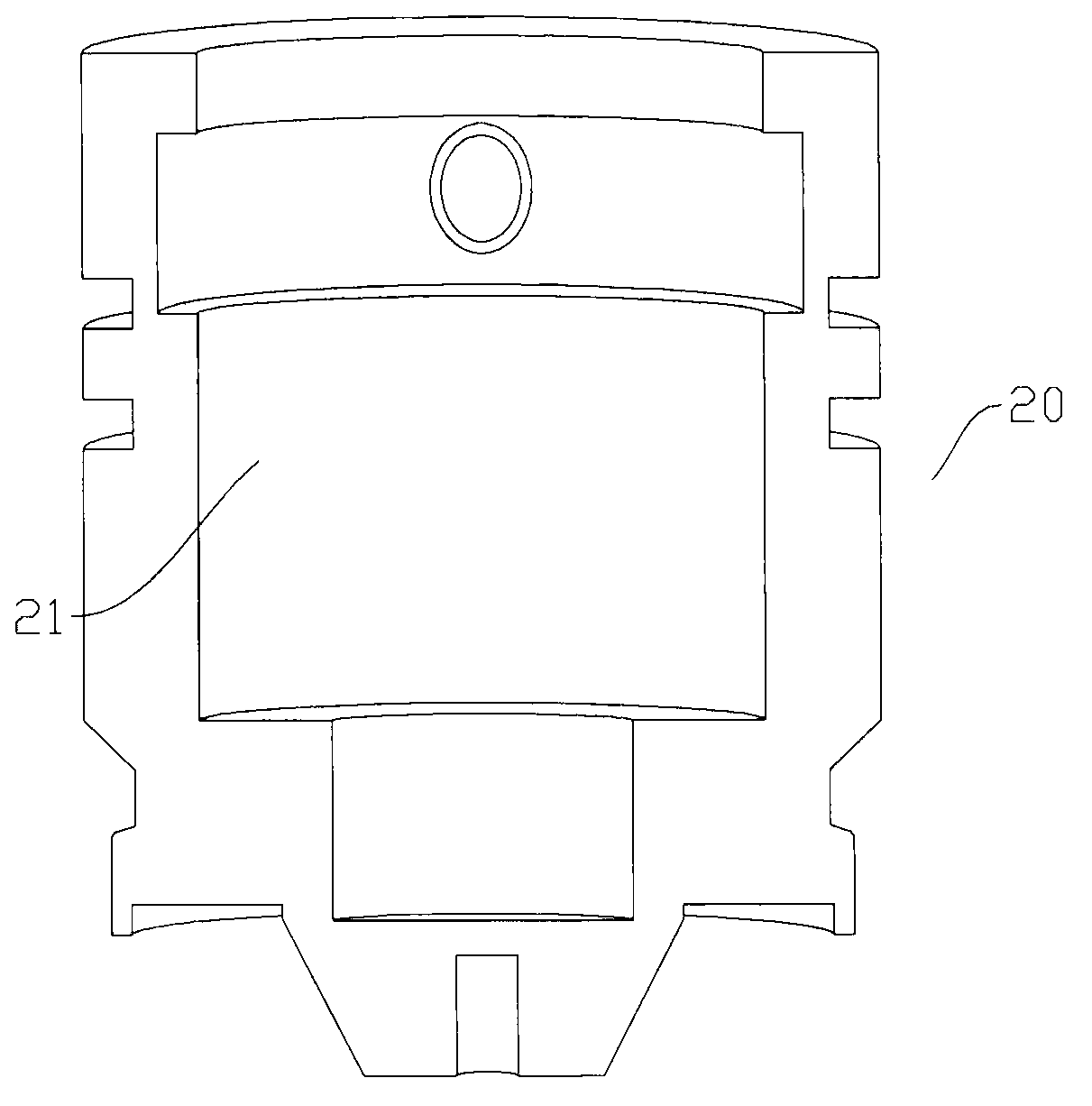

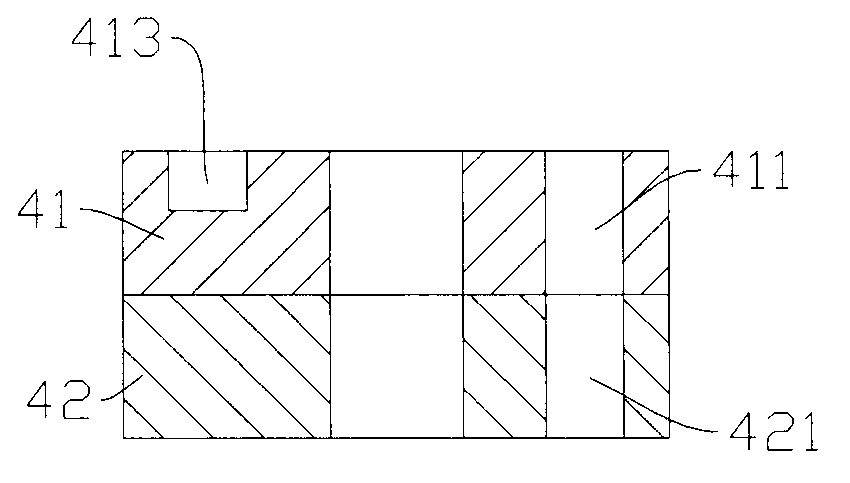

Remelting-free high-temperature high-pressure injection mold for power semiconductor device packaging

PendingCN111531802AGood value for moneyExcellent Reliability IndexSemiconductor/solid-state device manufacturingPower semiconductor deviceHeterojunction

The invention relates to a remelting-free high-temperature high-pressure injection mold for power semiconductor device packaging. The remelting-free high-temperature high-pressure injection mold comprises a movable mold part and a fixed mold part; the movable mold part comprises an upper mold plate, a hot runner plate and a temperature adjusting plate arranged in sequence, the movable mold part isprovided with a main runner penetrating through the upper mold plate and the hot runner plate, and the hot runner plate is internally provided with a first temperature sensor; the fixed mold assemblycomprises a lower mold and a cavity mold plate arranged in the lower mold, the cavity mold plate is internally provided with a cavity, the interior of the cavity is provided with a cavity cooler, andthe side wall of the cavity is internally provided with a pressure sensor and a second temperature sensor; and the first temperature sensor, the pressure sensor and the second temperature sensor areall connected with a mold control system. compared with the prior art, the remelting-free high-temperature high-pressure injection mold cooperates with a sub-millisecond response speed temperature andpressure sensing control technology to achieve the temperature, pressure, recrystallization speed and remelting preventing system having the three-dimensional target control characteristics, and reliable packaging of a part embedded in a third-generation semiconductor chip heterostructure is achieved.

Owner:芜湖鼎联电子科技有限公司 +1

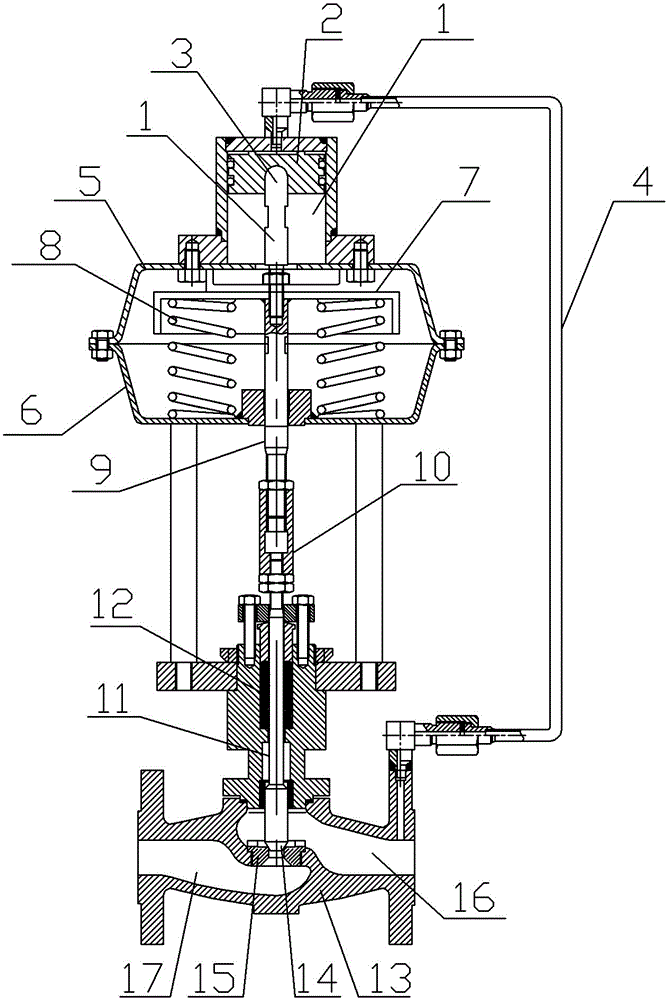

Assisted constant valve

The invention discloses an assisted constant valve which is modified for opening and closing manner and process in valves. Opening or closing is performed according to the change of pressure borne by an inner cavity of a spool, the spool is driven to move up and down in such way that a stem thread is driven by a valve stem to rotate in an internal thread of a moving screw connector, and accordingly the valve can be opened or closed by extremely low power and gradual opening or closing of the valve is achieved then. The assisted constant valve is applicable to large-sized valves.

Owner:SUZHOU YUDONG HVAC TECH CO LTD

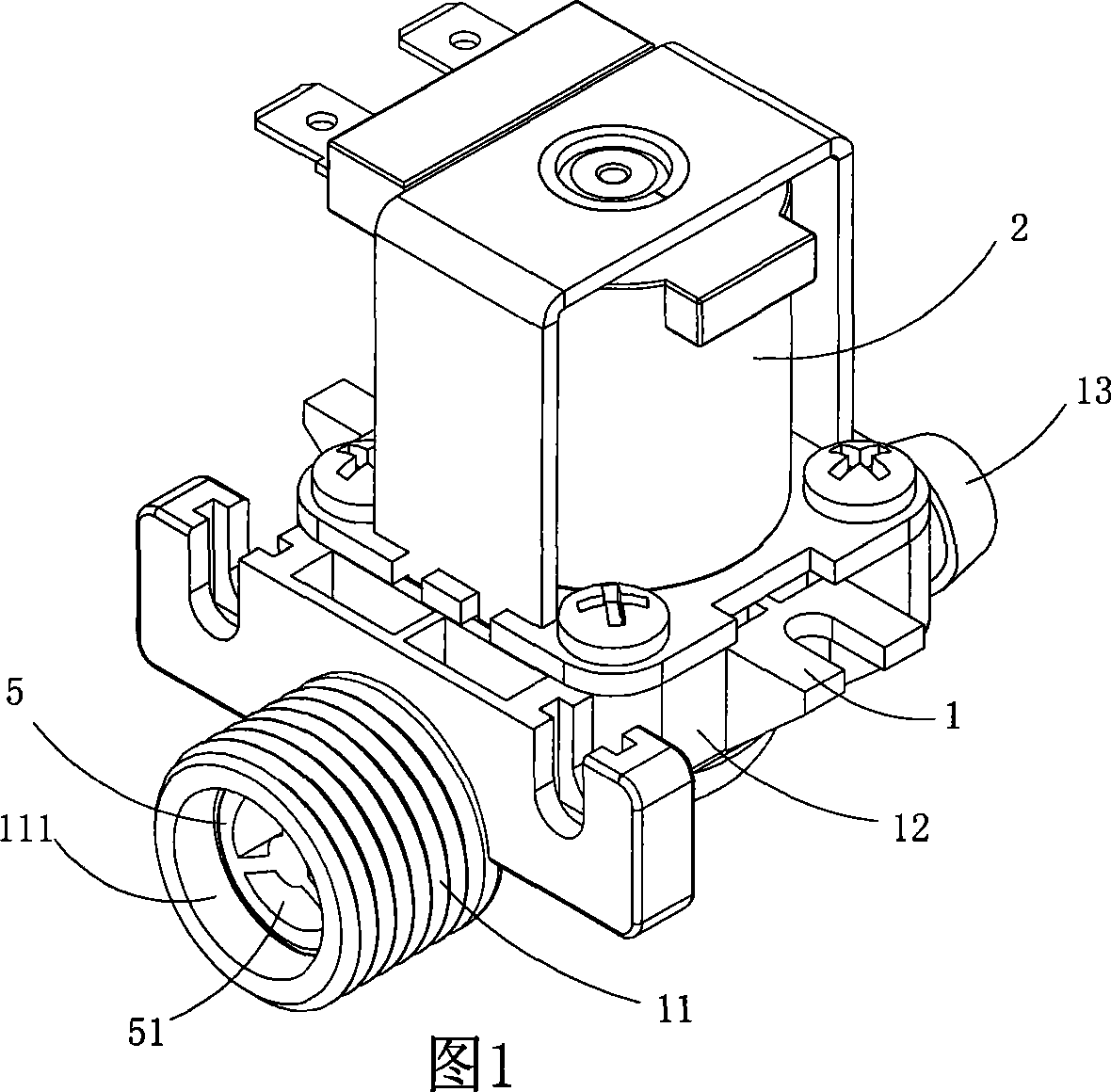

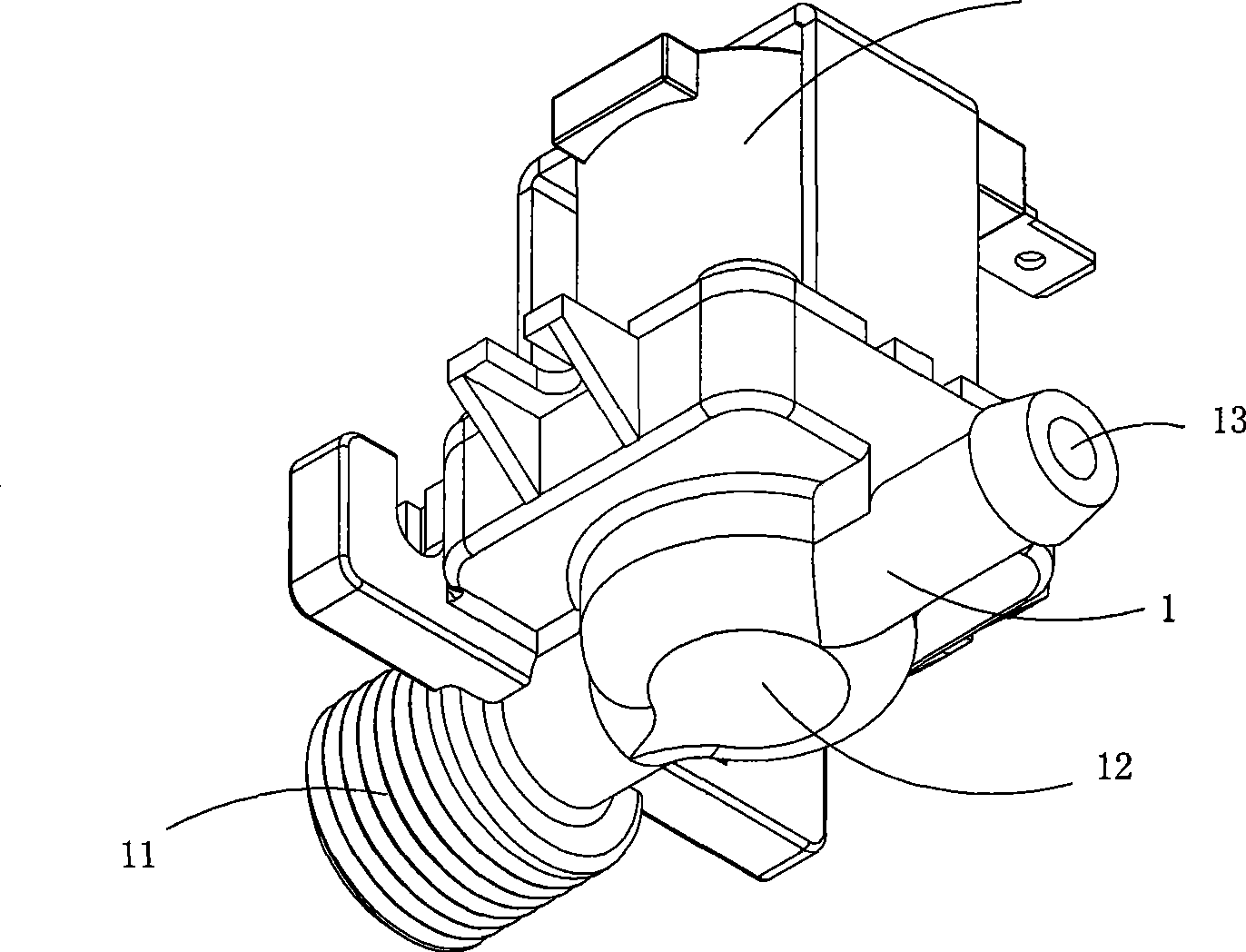

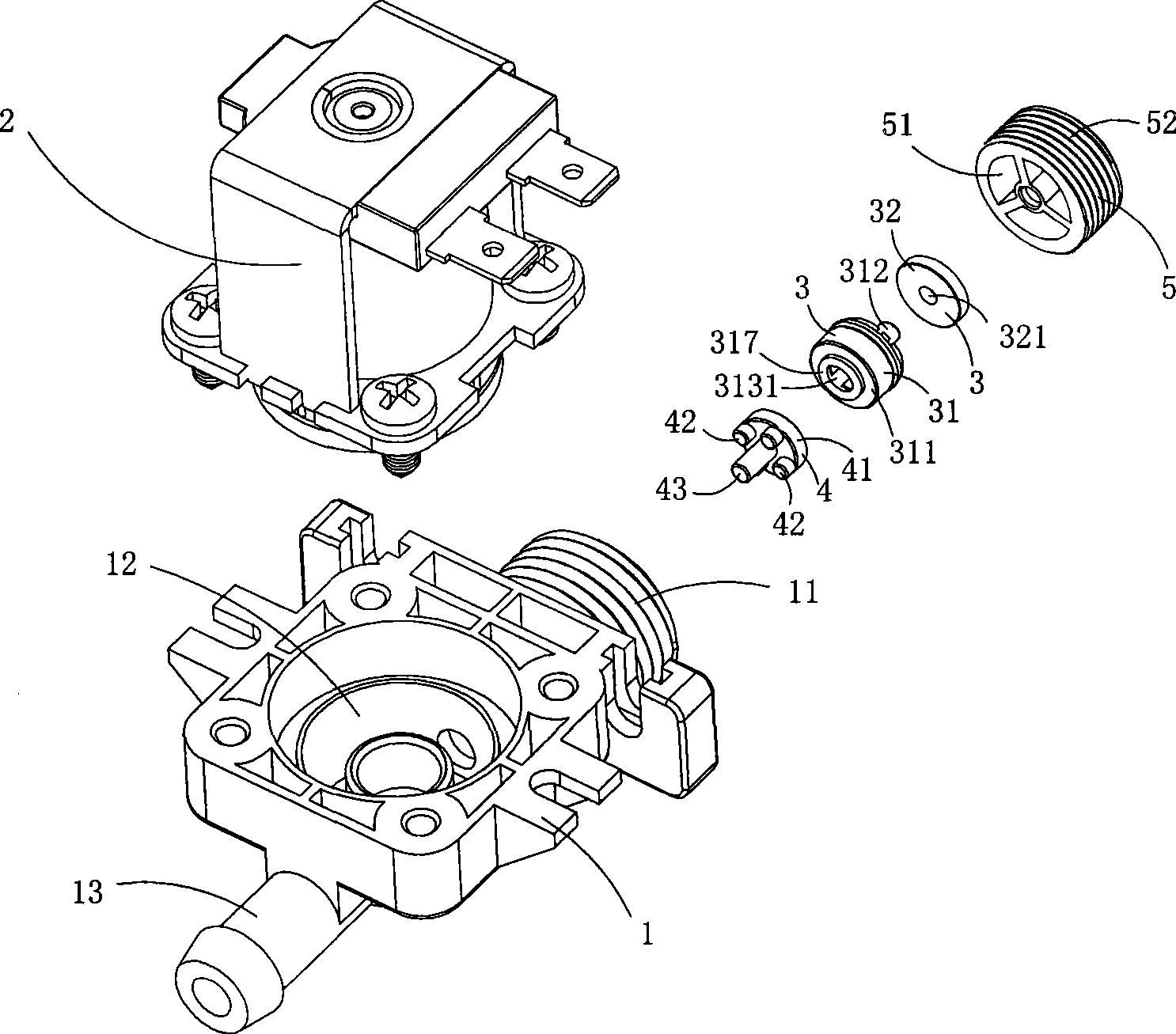

Hydraulic control device

ActiveCN106015715AEasy to installPrevent backflowOperating means/releasing devices for valvesInlet channelWater flow

The invention discloses a hydraulic control device. The device comprises a shell, the shell comprises an upper shell body and a lower shell body, the lower shell body is provided with a sleeve section sleeved with the upper shell body, a water inlet is formed in the lower shell body, a water outlet is formed in the upper shell body, a water inlet channel connected with the water inlet is arranged in the sleeve section, and a water backflow prevention mechanism is arranged in the shell. The water backflow prevention mechanism comprises a sealing pad between the sleeve section and the upper shell body, and a return spring abutting between the sealing pad and the upper shell body. The sealing pad is provided with a water backflow prevention position driven by the return spring and covering the end face of the sleeve section, and a water passing position driven by water flow in the water inlet channel and separated from the end face of the sleeve section. The hydraulic control device can effectively prevent the action of water backflow.

Owner:JINHUA HONGCHANG ELECTRLCAL EQUIP CO LTD

Automatic water temperature regulating device

InactiveCN106870776AAutomatically adjust the flowControl flowOperating means/releasing devices for valvesMultiple way valvesDisplay deviceControl valves

The invention discloses a water temperature automatic adjustment device, which includes a cold water port, a cold water control valve is fixedly installed at the lower end of the cold water port, the cold water control valve includes a valve body, and a valve stem is installed inside the valve body. The right end of valve rod is fixedly connected with leading screw, and the outside of described leading screw is equipped with stepping motor, and the top of described stepping motor is provided with controller, and the top of described controller is provided with control button, and the top of described control button The upper part is provided with a display, the lower part of the cold water control valve is fixedly connected with a first elbow, the right end of the first elbow is fixedly connected with a three-way pipe, and a temperature sensor is arranged inside the three-way pipe. The right end of the pipe is fixedly connected with a second elbow, the upper part of the second elbow is fixedly connected with a hot water control valve, and the upper part of the hot water control valve is fixedly installed with a hot water port. The invention is simple in structure, convenient and practical, and realizes the intelligent control of the outlet water temperature by the automatic water temperature adjustment device.

Owner:CHONGQING LIYOU SOFTWARE TECH CO LTD

Instant liquefied fuel gasifying combustion stove

InactiveCN104075352AEvenly spread fireBurn fullyDomestic stoves or rangesLiquid heating fuelProcess engineeringCombustion chamber

The invention discloses an instant liquefied fuel gasifying combustion stove which is characterized by comprising a stove bench, an annular pipe of a combustion groove, a heat conduction layer, a gas-liquid separation layer, a heat preservation layer, an annular liquid supply groove and a liquid-gas control valve, wherein the heat conduction layer is arranged at the inmost layer of the combustion stove and is connected with the annular pipe of the combustion groove to form a combustion chamber; the gas-liquid separation layer is arranged at the middle layer of the combustion stove; the annular liquid supply groove is arranged at the outer wall of the lower section of the gas-liquid separation layer; the fuel gas and liquid control valve is arranged at the bottom of the annular pipe of the combustion groove and the annular liquid supply groove; the fuel gas and liquid control valve is separately connected with the annular pipe of the combustion groove, the annular liquid supply groove and a gasification chamber. According to the combustion stove, liquefied fuel can be gasified instantly; fuel gas can be supplied continuously; a flame is uniformly dispersed; the combustion is sufficient; the heating effect is good; the time is saved; no black smoke pollutes the environment; energy is save; the combustion stove has relatively good economical, social and ecosystem benefits and is suitable for indoor and outdoor stoves such as restaurant stoves, hotel and grogshop stoves, canteen stoves, household stoves and camping stoves.

Owner:邹鑫

One-way constant flow check valve

InactiveCN101413600APrevent backflowReduce volumeOperating means/releasing devices for valvesCheck valvesAuto regulationEngineering

The invention discloses a unidirectional constant-current check valve, comprising a valve body and an electromagnetic on-off component which is used for turning on and turning off the liquid pipe in the valve body; the valve body comprises a liquid inlet passage, a connection pipe which is used for arranging the electromagnetic on-off component, and a liquid outlet pipeline; a constant current device and a check device are sequentially arranged in the liquid inlet passage in the liquid passage direction; the constant-current device is fixedly arranged in the liquid inlet pipeline and is provided with a liquid outlet; the check device can reciprocate to move in the liquid inlet pipeline under the driving of the liquid flow; when the check device moves approaching to the constant current device with the liquid flowing, the liquid outlet of the constant current device is finally jammed, thus preventing the circumfluence of the liquid. The unidirectional constant-current check valve has the functions of automatically adjusting the liquid inlet quantity and obtaining stable liquid outlet quantity (namely realizing the constant flowing function), and has the advantages of preventing the circumfluence of the liquid.

Owner:吴方忠

Liquid fuel gasification burner

The invention discloses a liquid level gasification burner. The liquid level gasification burner comprises a shell, a heat transfer layer, a gasification interlayer, a fuel gas hole, a gas storage tank, a liquid distribution tank, a fuel liquid hole, an air opening and a feed liquid connecting pipe, wherein a tubular burner with the gasification interlayer is constituted by the connection of the shell and the heat transfer layer, and a bottom plate is arranged at the bottom of the tubular burner; the gas storage tank is arranged on an inner ring of upper section of the shell, the fuel gas hole is formed in the end of the shell, the liquid distribution tank is arranged on the inner ring of the upper section of the shell, and the feed liquid connecting pipe is arranged on the shell located on the liquid distribution tank; the fuel liquid hole is formed the lower section of the heat transfer layer; and the air opening is formed in the middle of the bottom plate. According to the liquid level gasification burner, an atomized liquid fuel of the fuel liquid hole is arranged at the lower section of the heat transfer layer, so that the liquid fuel entering from the gasification interlayer can be fully gasified, the flue flame can be formed, the liquid fuel can be fully burnt, the thermal efficiency can be improved, the fuel can be saved, and the fire can be uniformly dispersed; and moreover, the environment is not polluted, and the safety performance is good, therefore, the burner is applied to boiler equipment and kitchen stoves with organic liquid fuel, and has good economic benefit, social benefit and ecological benefit.

Owner:邹鑫

Pressure reduction throttling valve and application method

InactiveCN105736781AImprove spraying effectSimple structureOperating means/releasing devices for valvesEqualizing valvesHigh pressurePressure reduction

The invention relates to a pressure reducing and throttling valve, comprising a valve body (10), a liquid inlet (3) arranged at the upper end of the valve body (10), and a liquid inlet (3) arranged at the lower end of the valve body (10) and the liquid inlet (3). The liquid outlet (4) corresponding to the position is the conical valve tip (5) set in the cavity of the valve body (10), wherein the conical valve tip (5) is connected to the valve body through a flexible diaphragm (6) (10) Upper, the valve body (10) includes the upper valve body (1), the lower valve body (2), and the middle valve body (13). The beneficial effect is that the structure is simple, reliable and stable, and the flexible diaphragm (6) inherently Features Automatic adjustment of pressure and flow, suitable for synchronous working conditions of low pressure, discontinuous, small flow, and also suitable for high pressure delivery, but must work at a lower pressure with a small flow of large microporous atomization spray device, so that Overcome the interference caused by pressure fluctuations, improve the spray effect of the microporous spray atomization device, and prevent liquid leakage.

Owner:SHANGHAI AOSHENG CLEANING TECH CO LTD

Dewaxing pre-fired furnace

The invention relates to the technical field of dewaxing equipment, and particularly discloses a dewaxing pre-sintering furnace. The dewaxing pre-sintering furnace comprises a furnace body, a hydrogenintroducing system, a heating device and a vacuumizing device, an air extracting pipe communicates between the furnace body and the vacuumizing device, the vacuumizing device is connected with a gasstorage chamber, the gas storage chamber communicates with a gas outlet pipe, a flow control block is fixedly arranged on the gas outlet pipe, the gas outlet pipe is connected with a spiral pipe, a cooling pipe is tightly attached to the outer wall of the spiral pipe, a cavity is tightly attached to the outer wall of the spiral pipe, a glycerol liquid is contained in the cavity, a gas conveying pipe communicates between the cavity and the flow control block, the spiral pipe is connected with a horizontally-arranged second pipeline, and a liquid collecting tank used for gas-liquid separation isfixedly installed on the second pipeline. According to the furnace, the flow control block on the gas outlet pipe can be controlled through the gasification of the glycerol in the cavity, then the flow of the mixed gas entering the spiral pipe is controlled, the gaseous paraffin in the mixed gas is fully liquefied, the liquid paraffin and hydrogen are separated by utilizing the liquid collectingtank, and then recovery of the paraffin is realized.

Owner:ZUNYI ZHONGBO CEMENTED CARBIDE

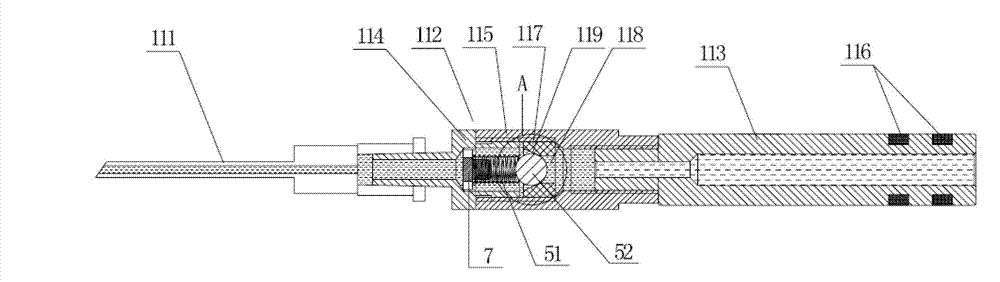

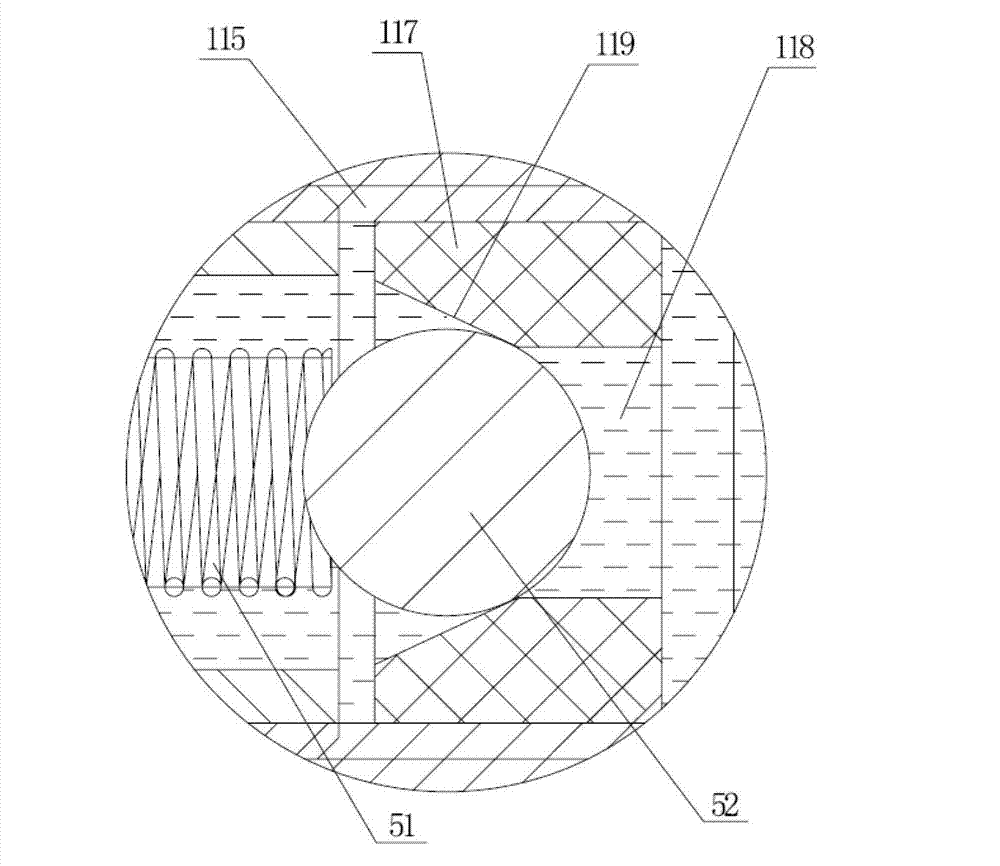

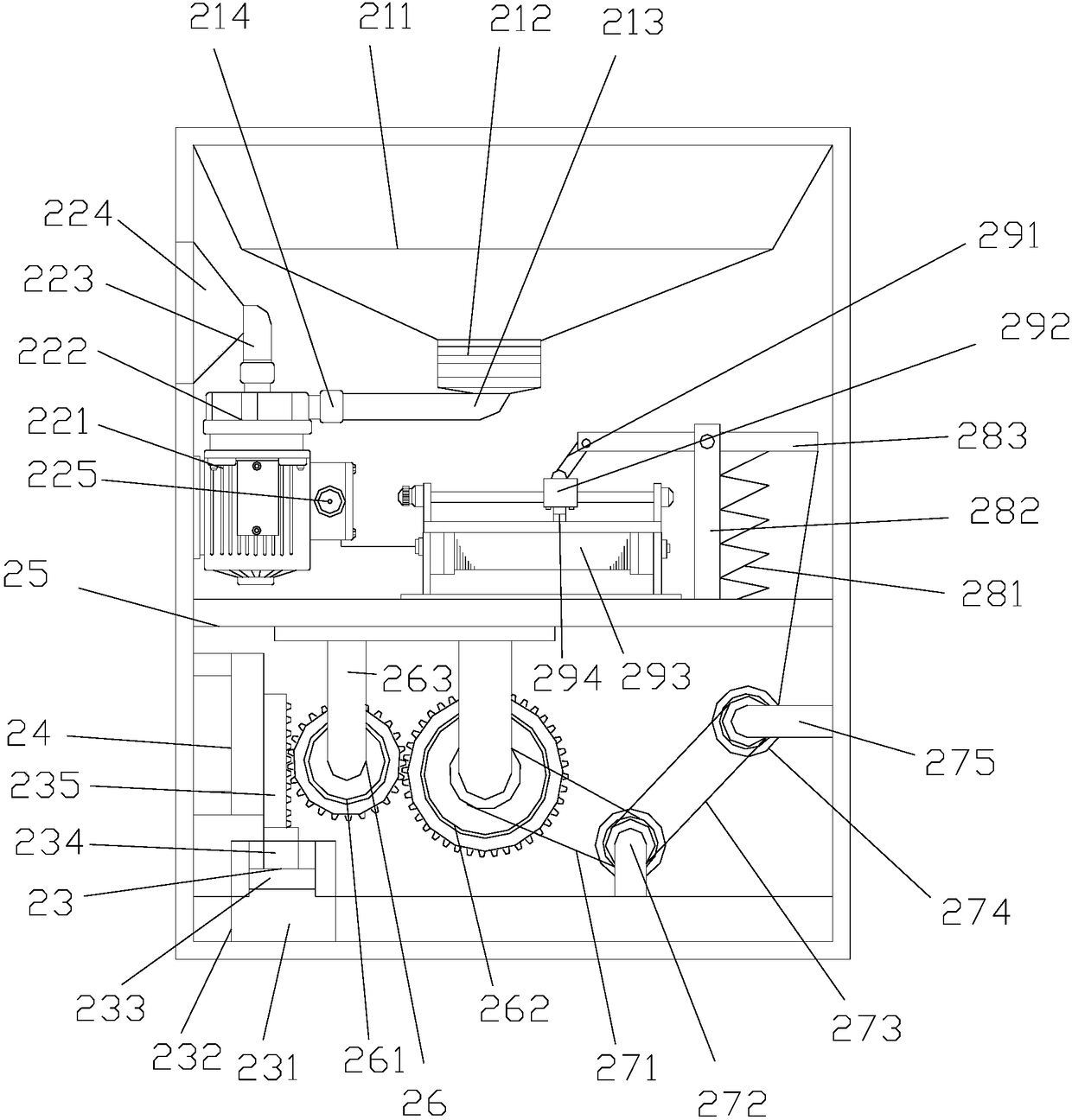

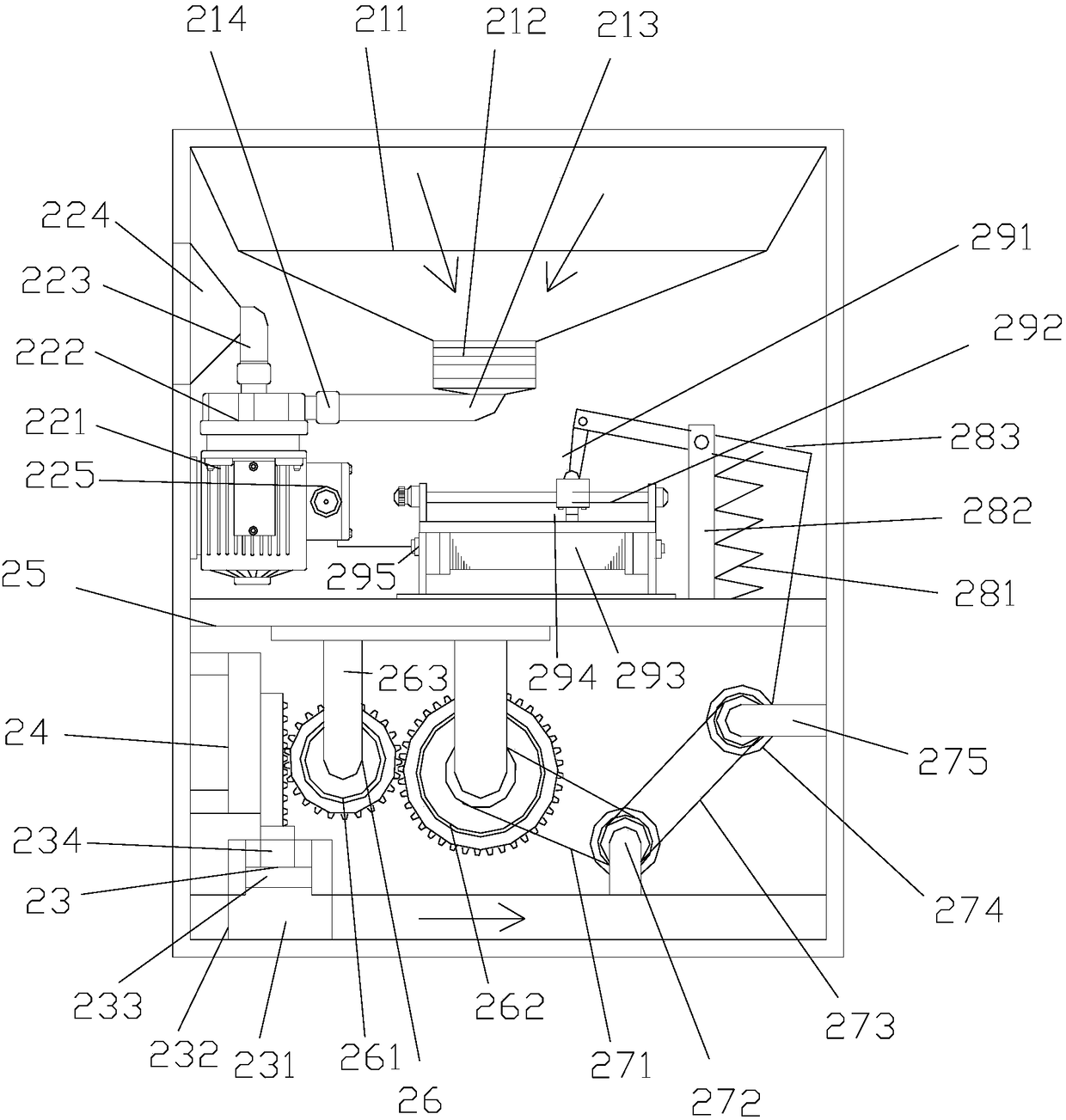

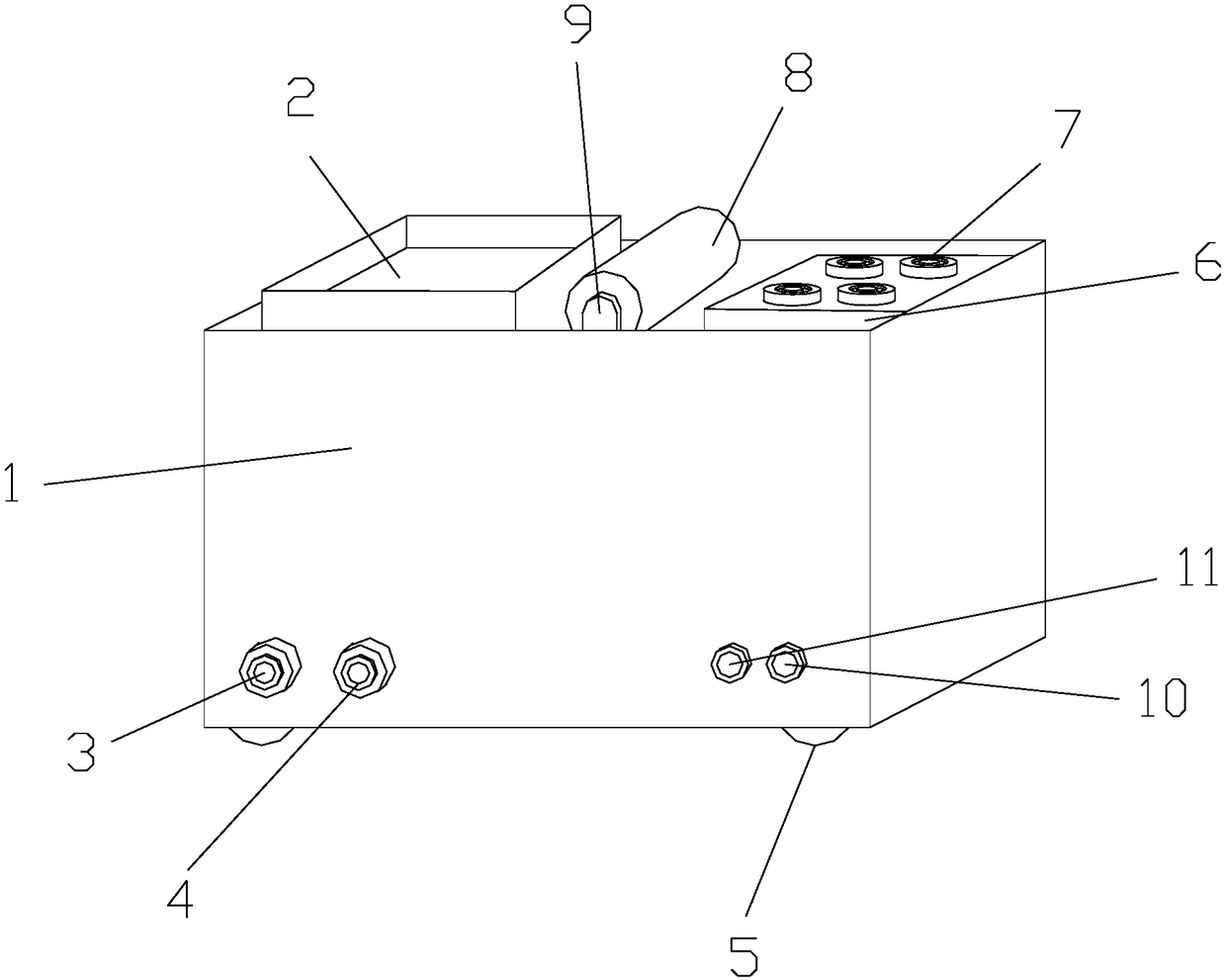

Automatic dual-liquid glue-injecting mechanism

InactiveCN108745784ASave spaceAutomatically adjust the flowLiquid surface applicatorsCoatingsAgricultural engineeringControl valves

The invention discloses an automatic dual-liquid glue-injecting mechanism including a horizontal supporting frame, a fixed base, a main controller, a first glue storage tank, a second glue storage tank, a switch control valve, a glue mixing chamber, a glue pipe and a glue-injecting head. The first glue storage tank and the second glue storage tank are mounted on the horizontal supporting frame through the fixed base; the first glue storage tank and the second glue storage tank are communicated with the glue mixing chamber through the glue pipe; and the main controller can control the switch control valve to be switched on or switched off. The automatic dual-liquid glue-injecting mechanism can automatically display the glue amount and control a glue discharging speed, is intelligent and efficient, and can be widely applied to high-end industrial manufacture.

Owner:SUZHOU SHELE INTELLIGENT TECH CO LTD

A liquid fuel gasification burner

The invention discloses a liquid fuel gasification burner. The thermal layer is connected to form a tubular burner with a gasification interlayer, and a bottom plate is set at the bottom; a gas storage tank is set at the inner ring of the upper part of the shell, a gas hole is set at the end of the shell, a liquid distribution tank is set at the inner ring of the upper part of the shell, and a liquid distribution tank is located at the inner ring of the upper part of the shell. The shell of the tank is provided with a liquid supply connecting pipe; the lower part of the heat transfer layer is provided with a liquid fuel hole; and the middle of the bottom plate is provided with an air port. The burner is provided with a liquid burning hole in the lower part of the heat transfer layer to atomize the liquid fuel, so that the liquid fuel entering the gasification interlayer can be fully gasified to form a blue flame, and the liquid fuel can be fully burned, which can improve thermal efficiency and save fuel. The fire is evenly dispersed, does not pollute the environment, and has good safety performance. It is suitable for boiler equipment and kitchen stoves using organic liquid fuels, and has good economic, social and ecological benefits.

Owner:邹鑫

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com