Liquid material control system of sand mixer

A technology of control system and sand mixer, which is applied in the direction of manufacturing tools, cleaning/processing machinery of casting mold materials, casting molding equipment, etc. The effect of stable quality and ensuring the quality of molding sand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

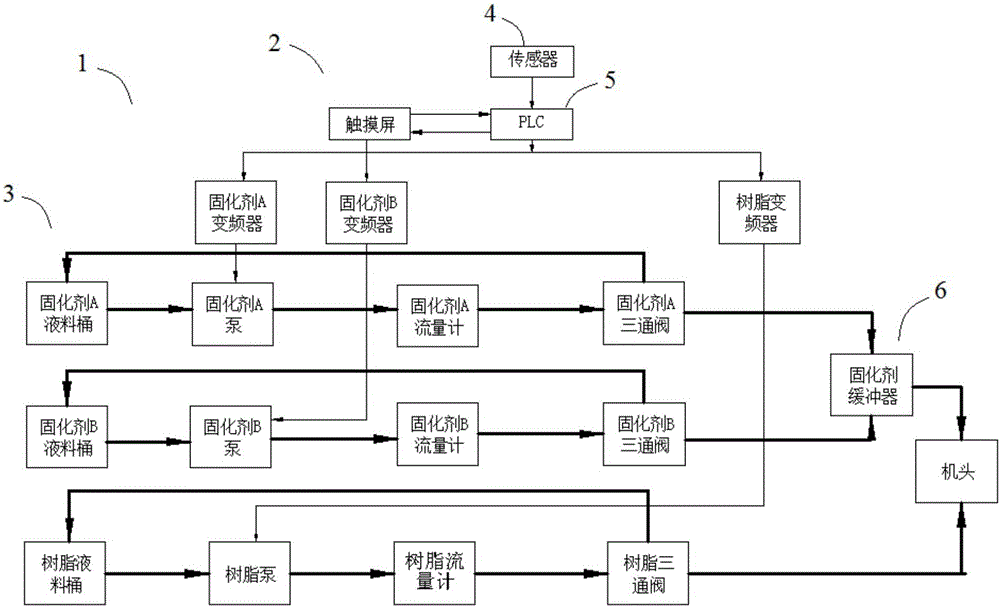

[0025] The present invention provides a liquid material control system for a sand mixer. The system includes a liquid material control and detection system and a liquid material conveying system. The liquid material conveying system includes a resin liquid material conveying pipeline and different curing agents. The curing agent delivery pipeline is equipped with a pump in each curing agent delivery pipeline and resin liquid delivery pipeline. The liquid material control and detection system includes: a temperature sensor used to collect the actual temperature of the silica sand; a PLC controller that receives the temperature signal from the temperature sensor, compares the actual temperature with a preset temperature range, and controls the speed of all pumps based on the comparison result.

[0026] More specifically, in a preferred embodiment, the PLC controller is configured to adjust the rotation speeds of all pumps when the actual temperature exceeds the preset temperature ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com