Piston self-operated regulating valve

A self-operated regulating valve and piston technology, applied in the field of regulating valves, can solve the problems of damaged diaphragm, self-operated regulating valve flow regulation failure, limited deformation of the diaphragm, etc., and achieve the effect of long stroke and automatic flow adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

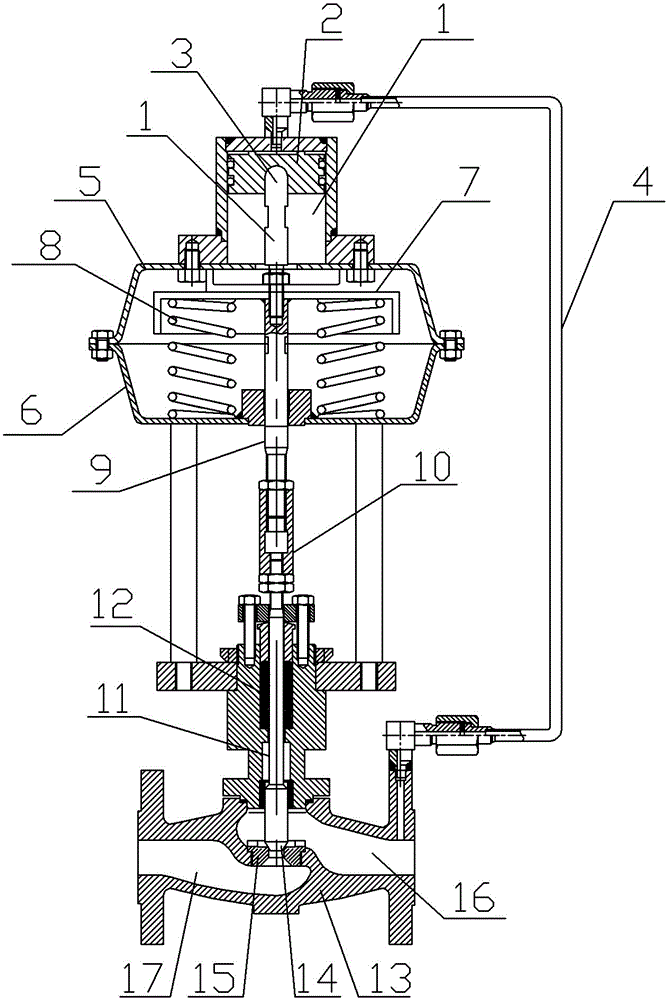

[0013] The reference signs in the drawings of the description include: piston cavity 1, piston 2, connecting piece 3, control pipeline 4, upper cover 5, lower cover 6, pressure plate 7, return spring 8, actuator rod 9, sleeve 10, valve Rod 11, sealing stuffing box 12, valve body 13, valve core 14, valve seat 15, water inlet chamber 16, water outlet chamber 17.

[0014] Embodiment The piston self-operated regulating valve is basically as attached figure 1 Shown:

[0015] The piston self-operated regulating valve is divided into three parts: the feedback mechanism, the actuator, and the valve body 13 from top to bottom.

[0016] The valve body 13 is provided with a water inlet chamber 16 and a water outlet chamber 17, and the water inlet chamber 16 and the water outlet chamber 17 are connected through the valve port, and the water flows from the clean water chamber to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com