Remelting-free high-temperature high-pressure injection mold for power semiconductor device packaging

A power semiconductor and device packaging technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of chip position drift, metallographic structure affecting electrothermal characteristics, electrode bonding lead open circuit, etc., to achieve high cost performance, The effect of good reliability indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

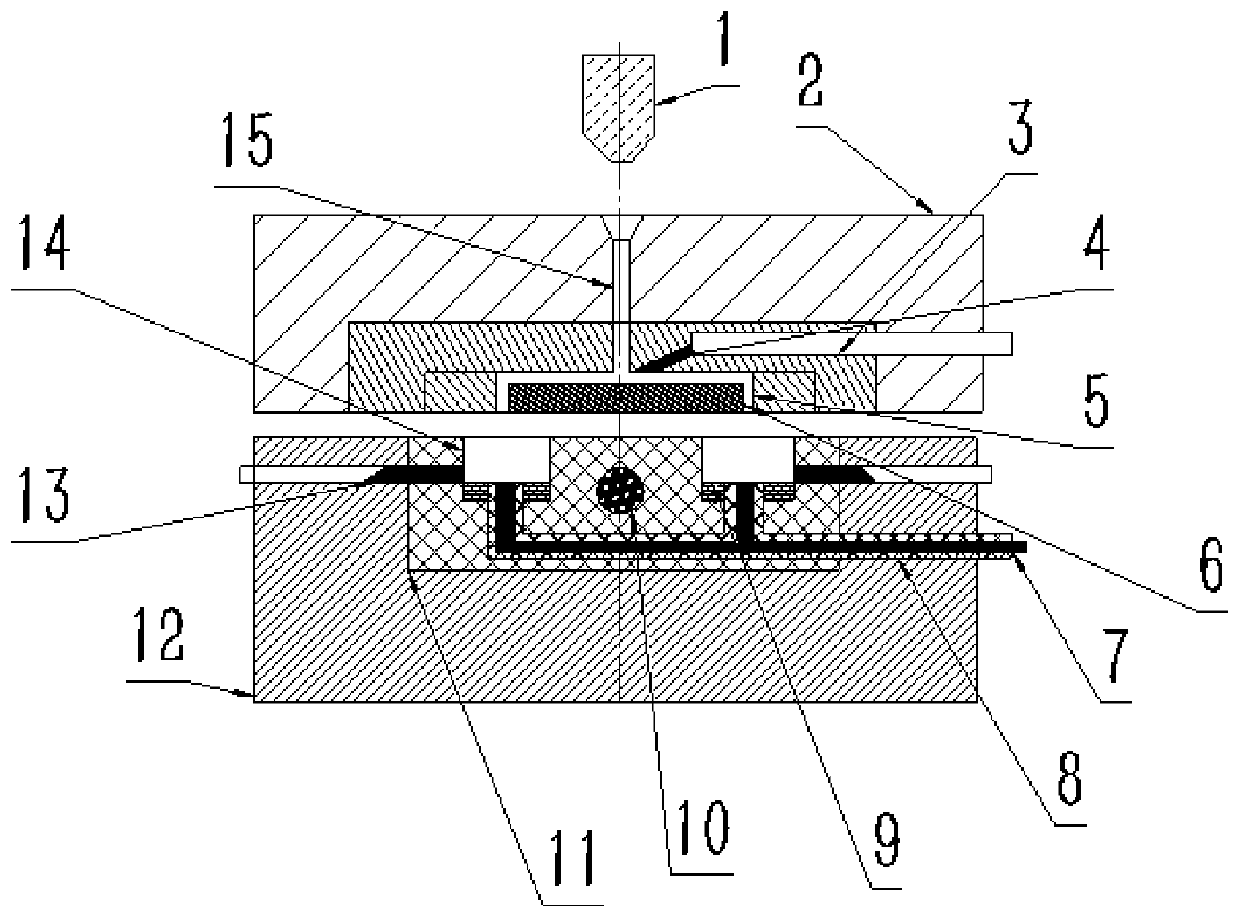

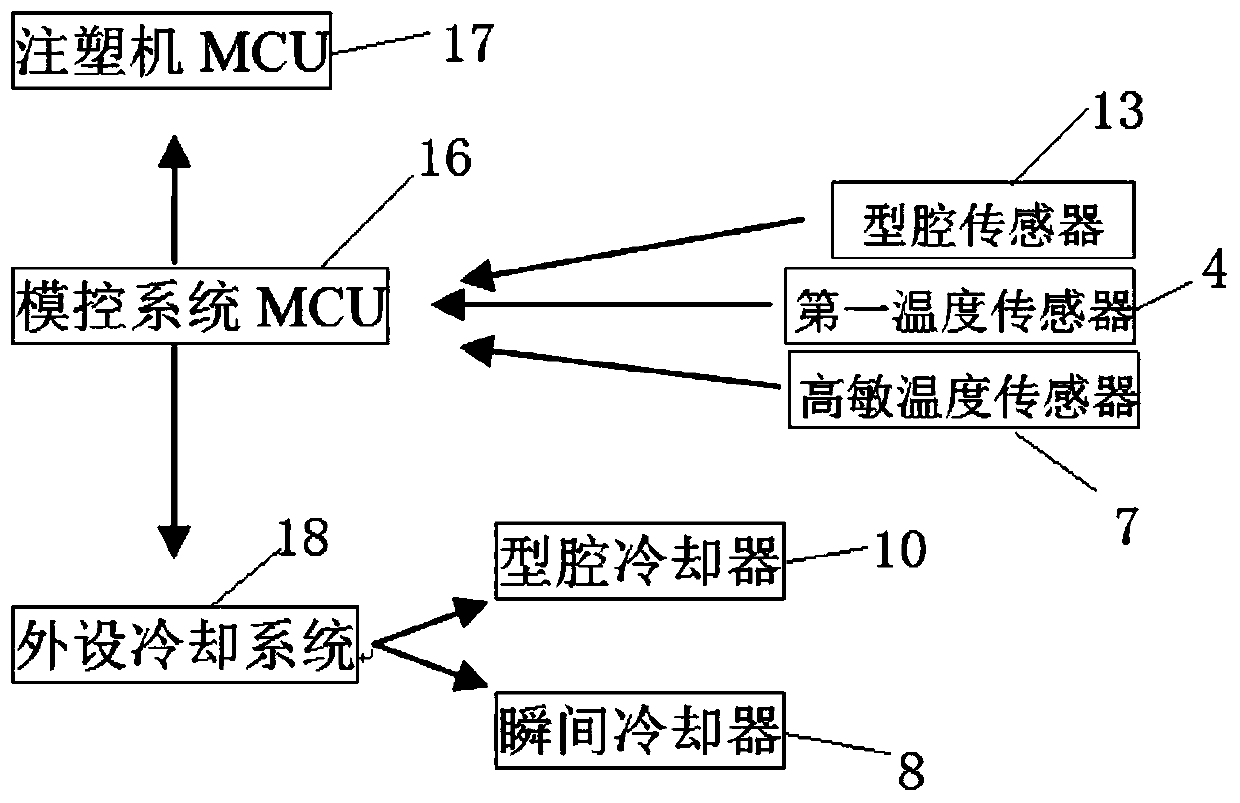

[0032] Such as figure 1 As shown, the application proposes a non-remelting high-temperature and high-pressure injection mold for power semiconductor device packaging, including a moving mold part and a fixed mold part.

[0033] The moving mold part includes an upper mold plate 2, a hot runner plate 3 and a temperature regulating plate 6 arranged in sequence. The movable mold part is provided with a main channel 15 that runs through the upper template 2 and the hot runner plate 3, and the main channel 15 is connected with the injection nozzle 11 of the thermoplastic material injection molding machine. The hot runner plate 3 is provided with a first temperature sensor 4, and the first temperature sensor 4 is connected with an external sub-millisecond response speed temperature and pressure sensing control system for signal interaction processing. Between the temperature regulating plate 6 and the hot runner plate 3 is provided a press-fit runner heat shielding layer 5 of high h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com