Piston assembly capable of achieving flow compensation

A piston assembly and flow compensation technology, applied in the field of hydraulic vibration reduction, can solve problems such as difficult to achieve stepless control, high precision requirements, and poor product consistency, and achieve the effects of convenient manufacture, strong portability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings.

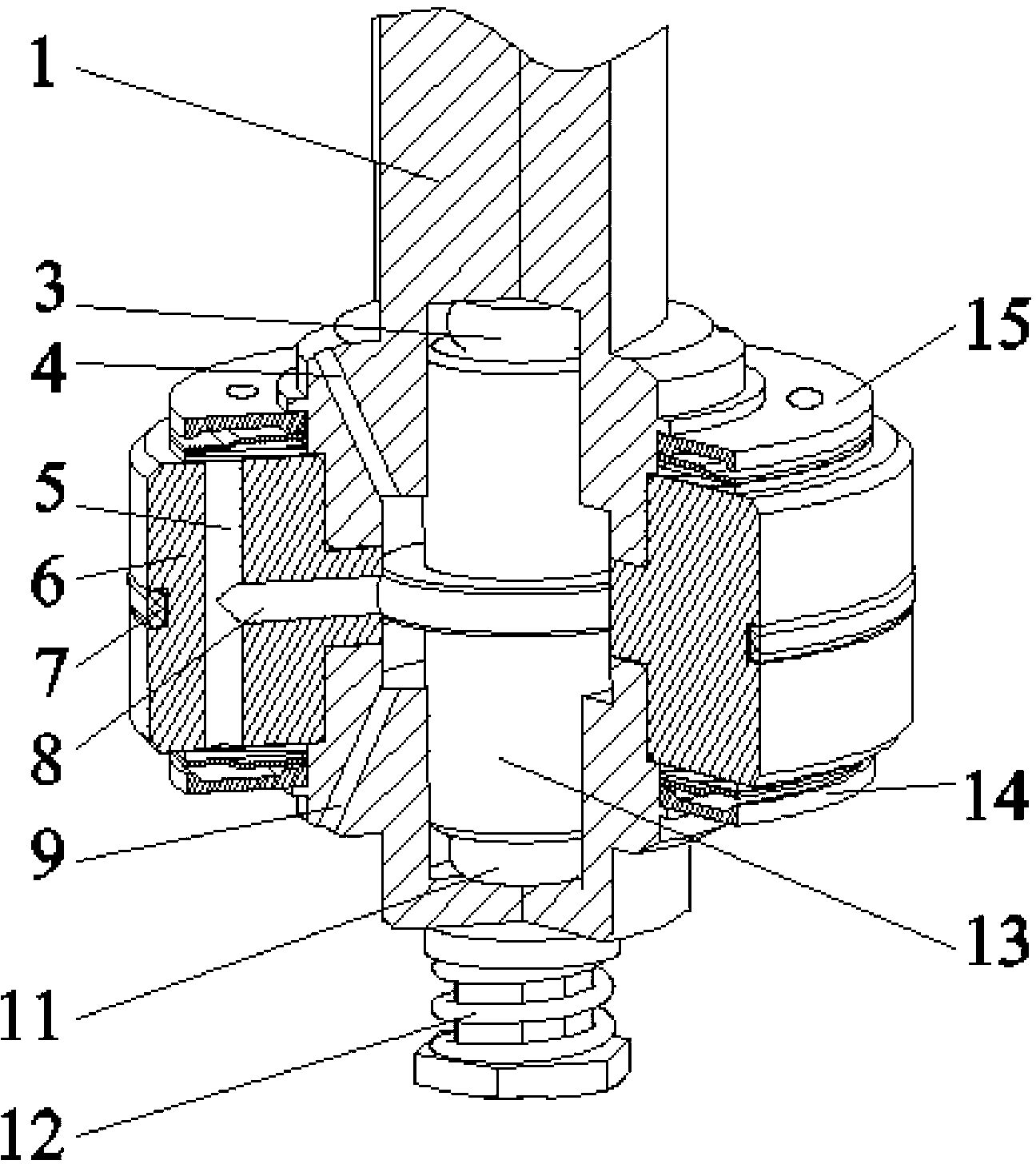

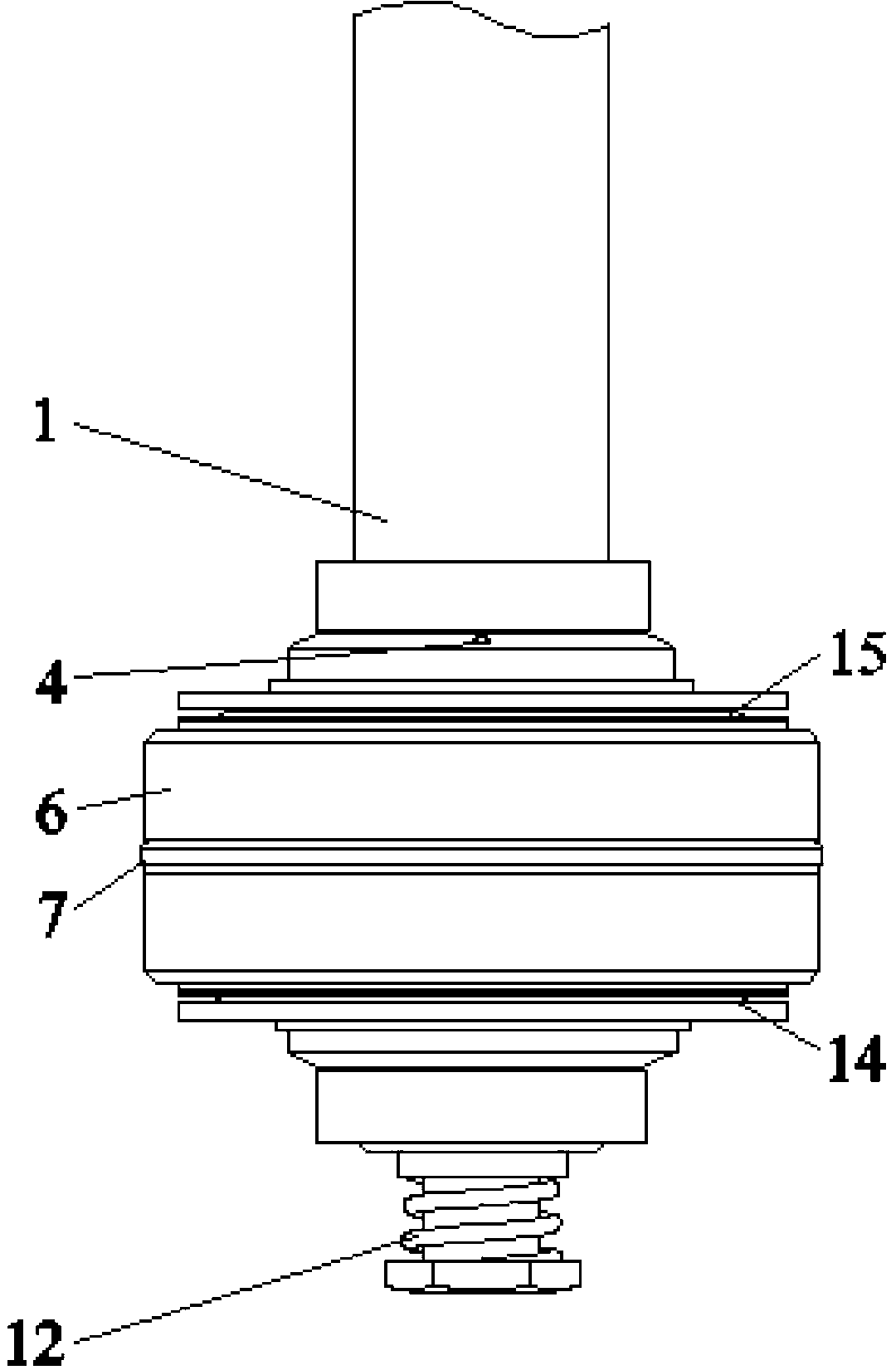

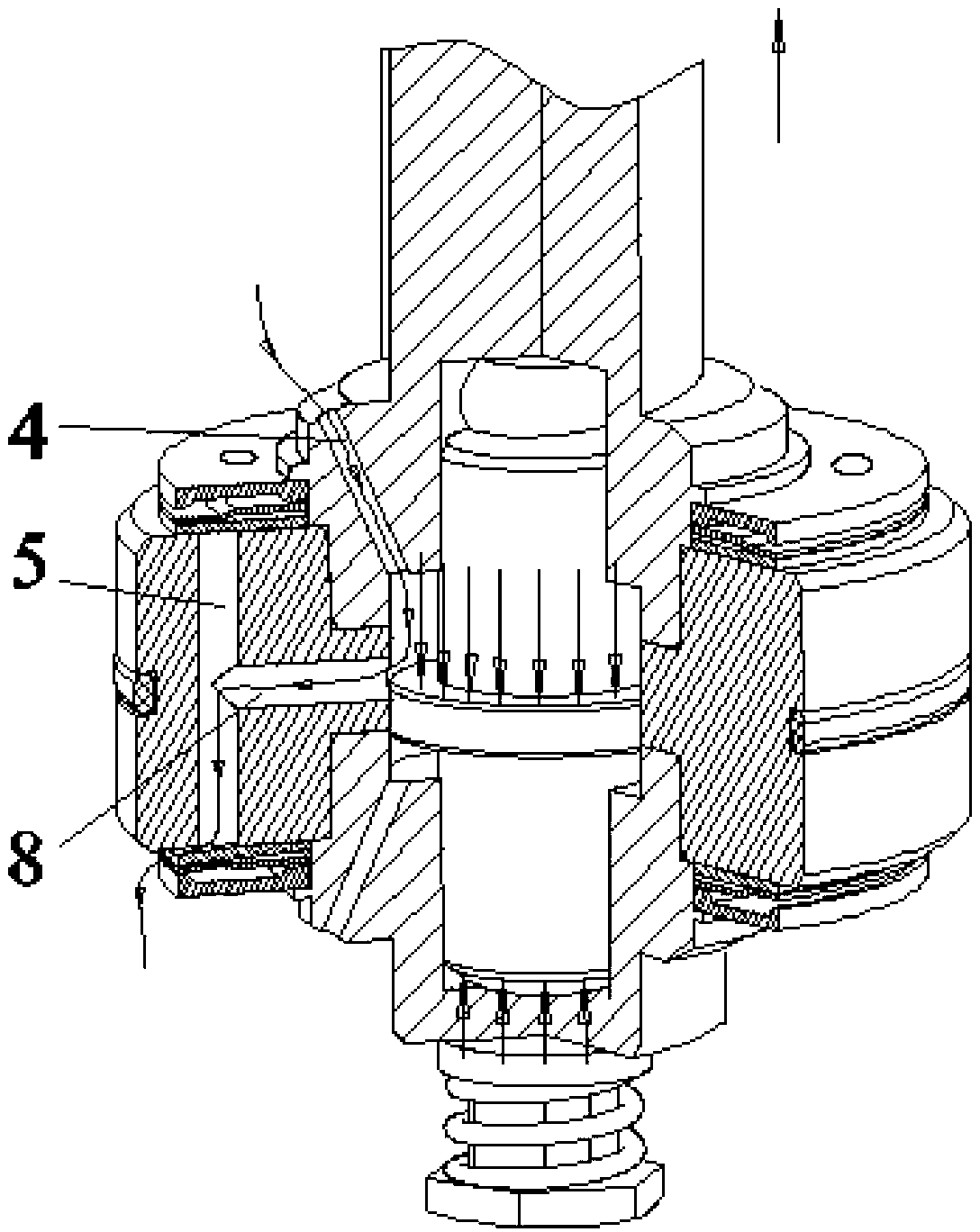

[0045] figure 1 It is an axonometric sectional view of the optimal embodiment of the present invention, showing a piston assembly with flow compensation, including: a piston rod 1, the bottom of which is hollow and disconnected to form an upper rod end 1a and a lower rod end 1b, The hollow interior is slidingly connected with a spool 13;

[0046] The two ends of the spool 13 and the hollow interior of the upper rod end 1a and the lower rod end 1b form two cavities, and the upper elastic chamber 3 and the lower elastic chamber 11 are installed respectively;

[0047] The outer end surfaces of the upper rod end 1a and the lower rod end 1b are fixed together by the piston 6, and the upper rod end 1a and the lower rod end 1b are respectively provided with an upper auxiliary damping hole 4 and a lower auxiliary damping hole 9, as Figure 6 and Figure 7 As shown, the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com