A plasma cleaning device

A technology for plasma cleaning and cleaning equipment, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as uneven plasma, and achieve the effects of achieving uniformity, uniform flow, and improving mixing uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

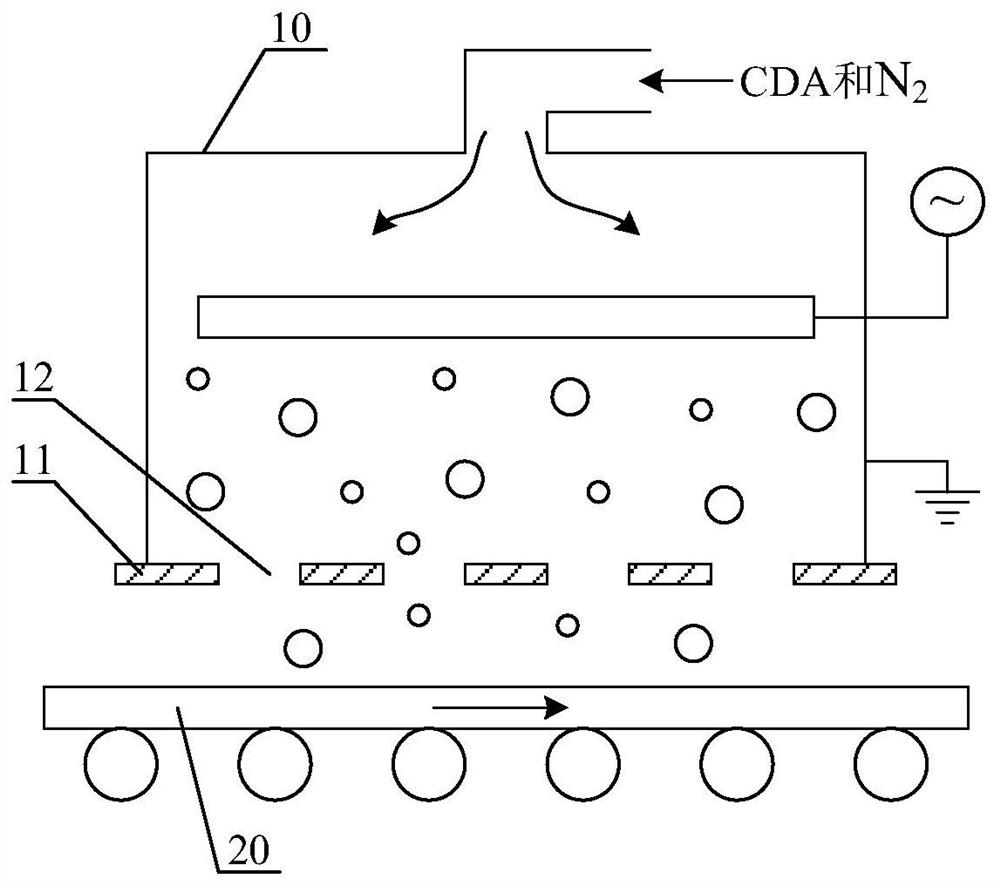

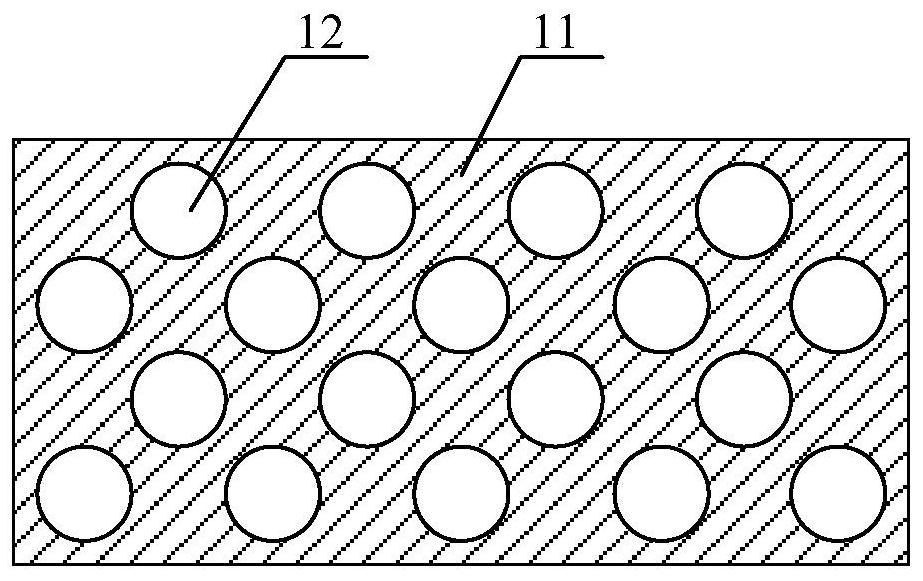

[0042] figure 2It is a schematic structural diagram of the plasma cleaning equipment according to the first embodiment of the present invention. The cleaning device includes a cavity 10 for generating plasma and a baffle structure for ejecting the plasma toward a substrate 20 . The baffle structure includes at least two baffles provided with a plurality of spray holes, and the spray holes on adjacent baffles are interlaced. In this embodiment, the baffle structure includes a first baffle 31 and a second baffle 41 . The first baffle 31 is disposed close to the cavity 10 , and the second baffle 41 is disposed between the first baffle 31 and the substrate 20 . The first baffle 31 is provided with a plurality of first spray holes 32 , the second baffle 41 is provided with a plurality of second spray holes 42 , and the first spray holes 32 and the second spray holes 42 are interlaced.

[0043] In this embodiment, CDA and N are introduced into the chamber 10 from the top of the ...

no. 2 example

[0052] Figure 4 It is a schematic structural diagram of the plasma cleaning equipment according to the second embodiment of the present invention. The main structure of the cleaning equipment of this embodiment is the same as that of the cleaning equipment of the first embodiment, the difference is that, as Figure 4 As shown, the cleaning equipment in this embodiment further includes a first moving device 60 for moving the first baffle 31 .

[0053] In this embodiment, the first moving device 60 makes the first baffle 31 move back and forth in the plane where the first baffle is located, so that the difference in the flow rate between different first nozzle holes 32 can be further eliminated, and the spraying rate to the substrate can be improved. The uniformity of the plasma flow rate, and at the same time further improve the mixing uniformity of different plasmas, eliminate the difference in the cleaning effect of the substrate surface, and improve the quality of the subs...

no. 3 example

[0055] Figure 5 It is a schematic structural diagram of the plasma cleaning equipment according to the third embodiment of the present invention. The main structure of the cleaning equipment of this embodiment is the same as that of the cleaning equipment of the first embodiment, the difference is that, as Figure 5 As shown, the cleaning device in this embodiment further includes a third baffle 51 , and the third baffle 51 is disposed between the second baffle 41 and the substrate 20 . A plurality of third spray holes 52 are arranged on the third baffle plate 51 , and the third spray holes 52 and the second spray holes 42 are interlaced. The third injection holes 52 and the second injection holes 42 are interlaced, which can further mix and diffuse the plasma ejected by different second injection holes 42, eliminate the difference in the flow rate of plasma ejected by different second injection holes 42, and further improve the injection efficiency. The uniformity of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com