Variable gear pump

A gear pump and variable displacement technology, applied in pumps, pump control, rotary piston pumps, etc., can solve the problems of variable variable effect, increased leakage, complex mechanism, etc., and achieve the effect of simple structure, reduced flow, and increased flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

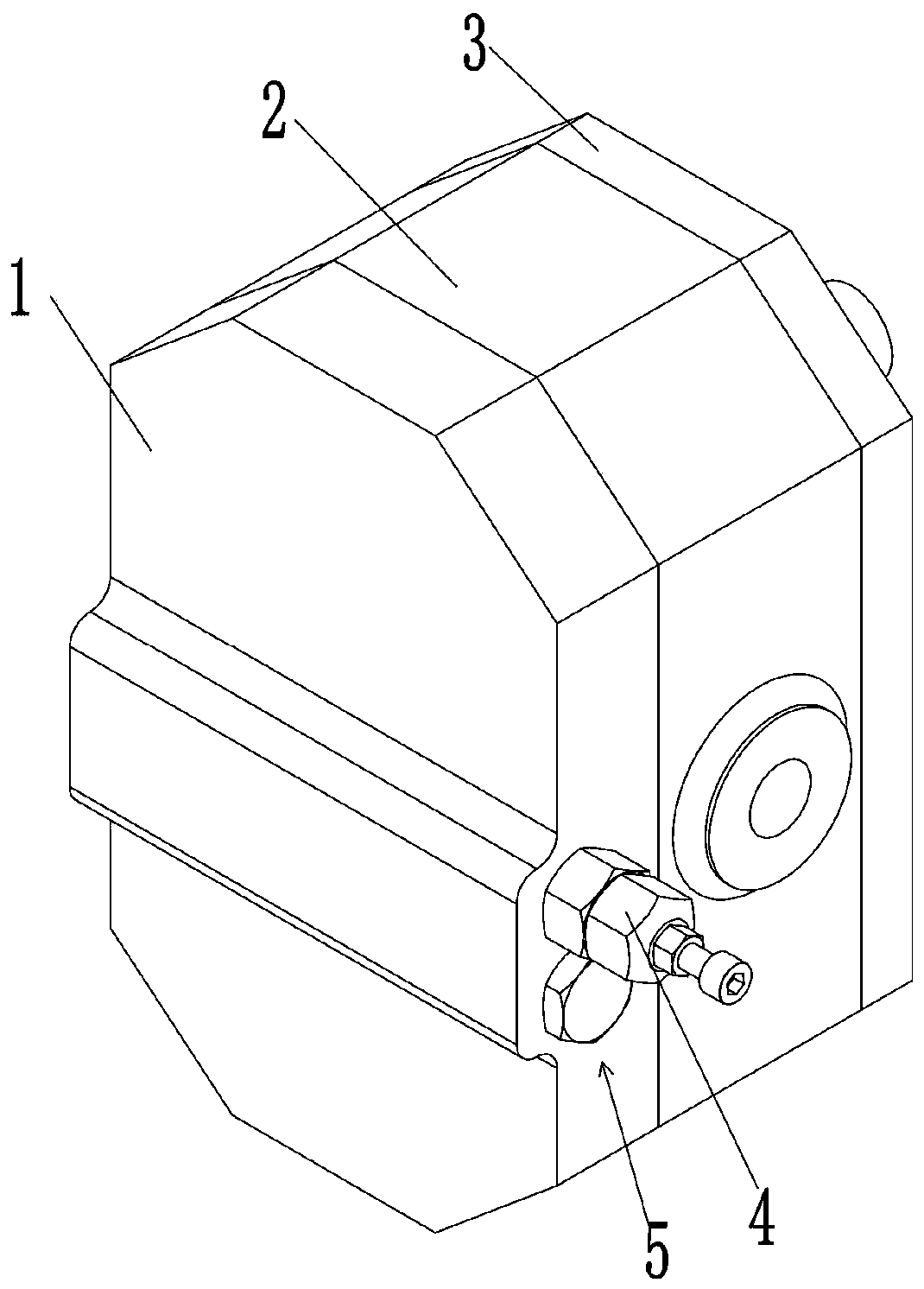

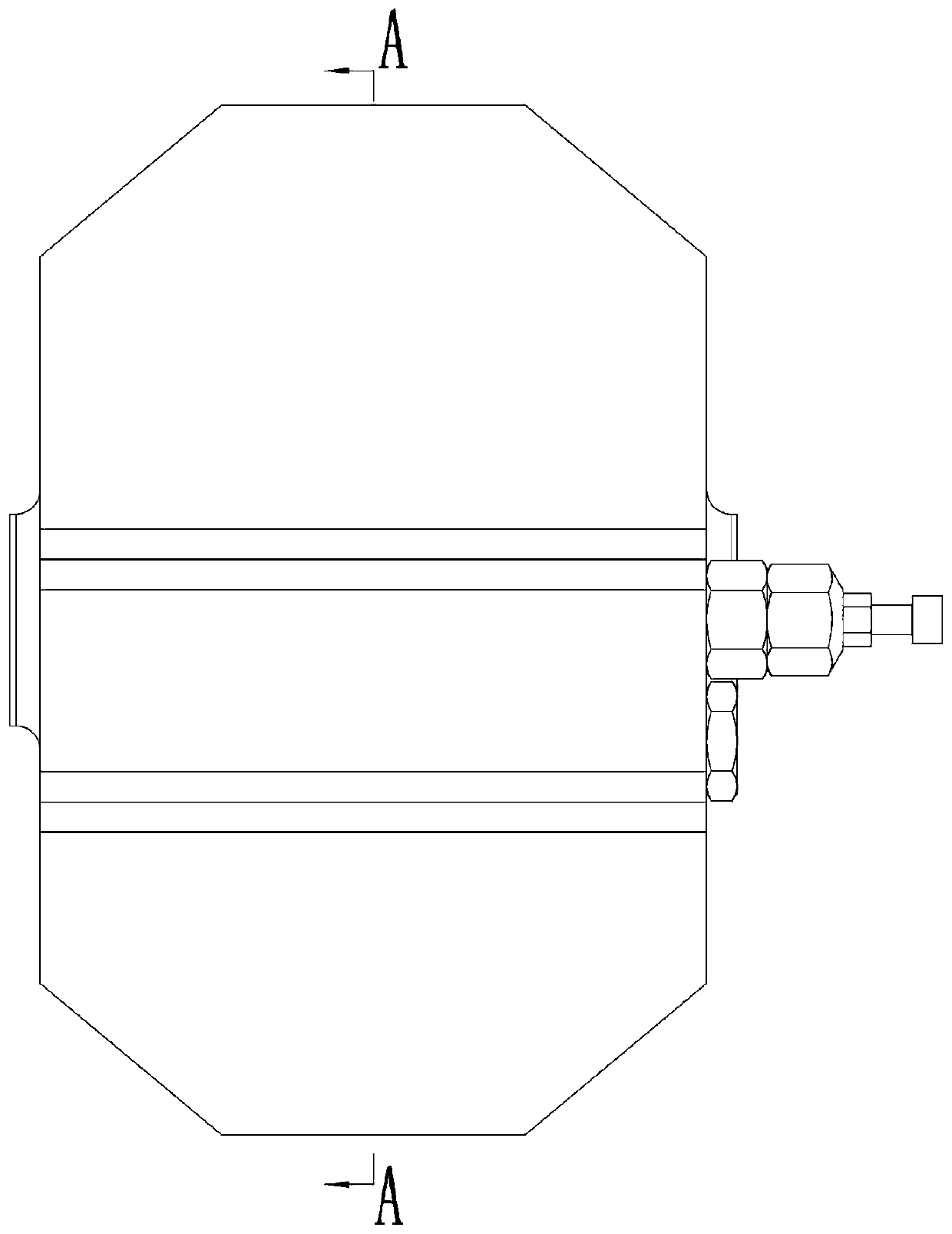

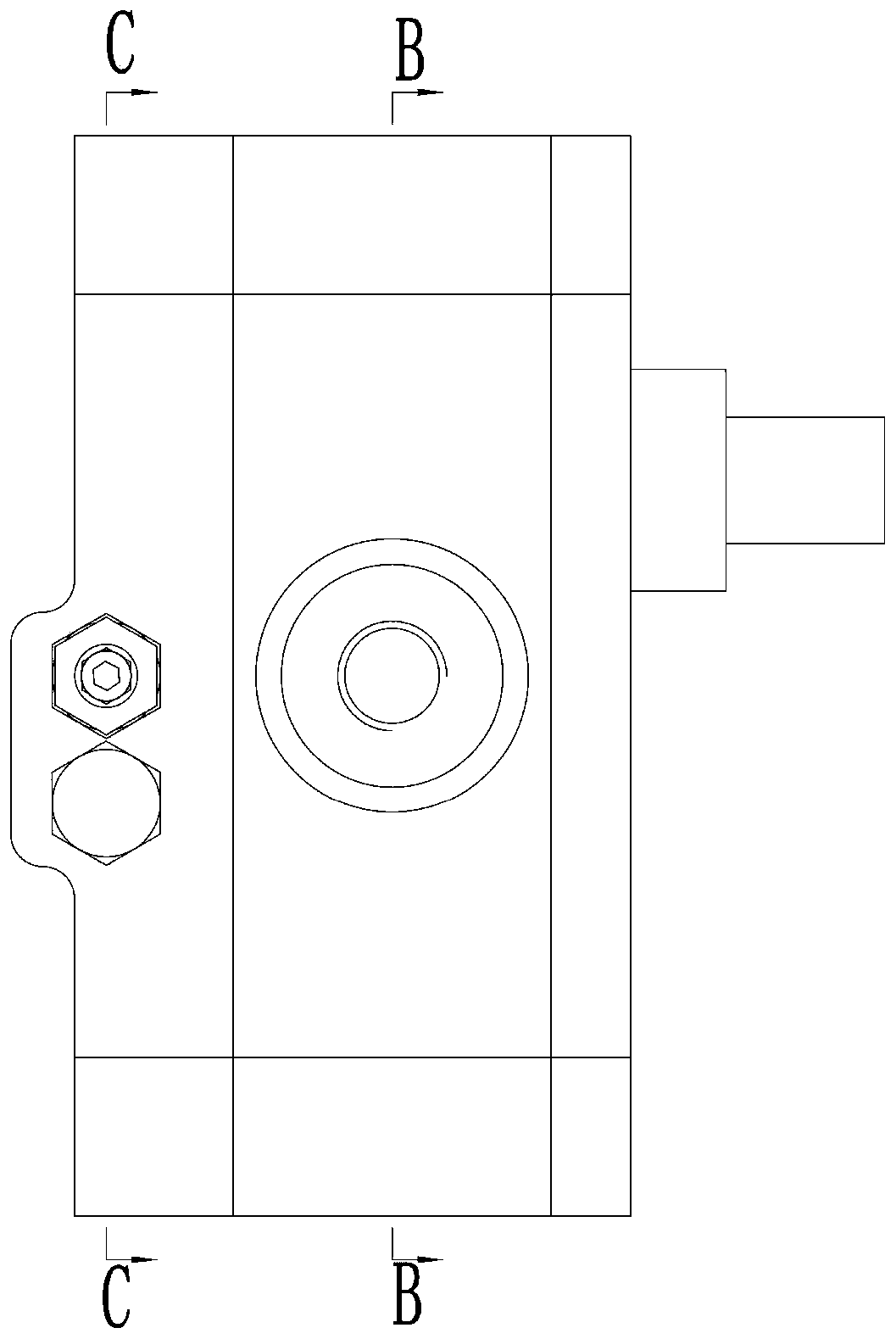

[0033] see Figure 1-18As shown, a variable displacement gear pump includes a pump casing 2, a left end cover 1 arranged at the left end of the pump casing 2, and a right end cover 3 arranged at the right end of the pump casing 2; A driven shaft 9 and a driving shaft 8 are rotatably connected between them. The right end of the driving shaft 8 protrudes from the right end cover 3, and a first driving gear 7 is fixedly installed on the driving shaft 8 in the pump casing 2. The driven shaft 9 is rotatably connected with a first driven gear 10 meshing with the first driving gear 7; the pump casing 2 is provided with oil suction ports 201 on both sides of the meshing area of the first driving gear 7 and the first driven gear 10. and the oil discharge port 202; the pump casing 2 is provided with a second driving gear 6 parallel to the first driving gear 7 on the driving shaft 8, and the driven shaft 9 is rotatably connected with the second driving gear 6. The second driven gear 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com