Thickened oil thermal recovery decompression method and device

A decompression device and heavy oil technology, applied in the direction of production fluid, earthwork drilling, wellbore/well parts, etc., can solve the problems of joint or alternate use, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

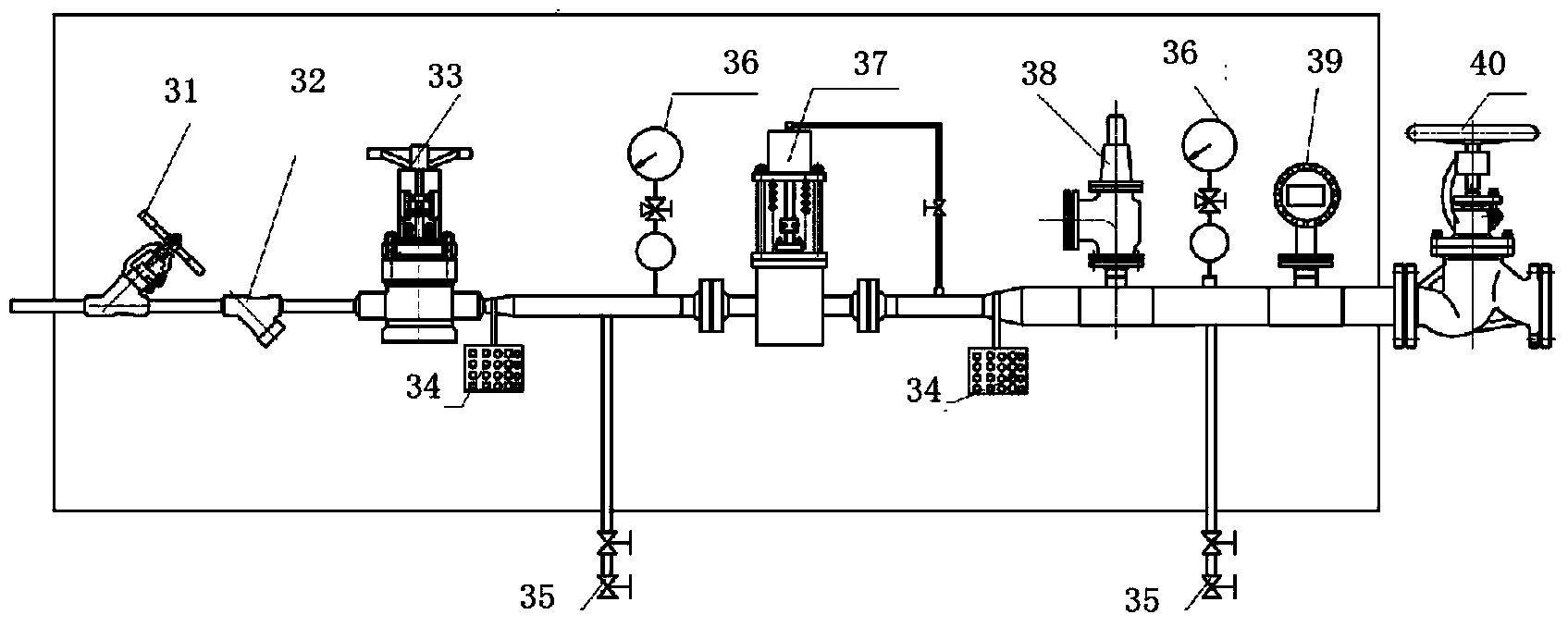

[0057] as the picture shows, figure 1The structural diagram of the thermal recovery decompression device includes a thermal recovery steam valve 31, a filter 32, a pressure reducing valve 33 in the high pressure area, a noise reduction throttle 34, a drainage antifreeze valve 35, a pressure gauge 36, and a secondary pressure reducing valve in the medium pressure area 37. Safety valve 38, vortex flow meter 39, stop valve 40. The thermal recovery and decompression device is an integrated structure, which is composed of thermal recovery and decompression integrated system, main steam pipe body, safety protection system, thermal control system, buffer explosion-proof system, instrumentation, throttling and noise reduction system, thermal insulation materials, etc. All are integrated in one instrument box, which reduces the trouble and labor intensity of installation and commissioning for users; it not only protects various systems and components from wind and sand erosion, but als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com