One-way constant flow check valve

A check valve, one-way technology, applied in valve details, control valves, safety valves, etc., can solve the problems of increased workload, excessive water flow, and high cost, and achieve the purpose of preventing liquid backflow, reducing volume, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

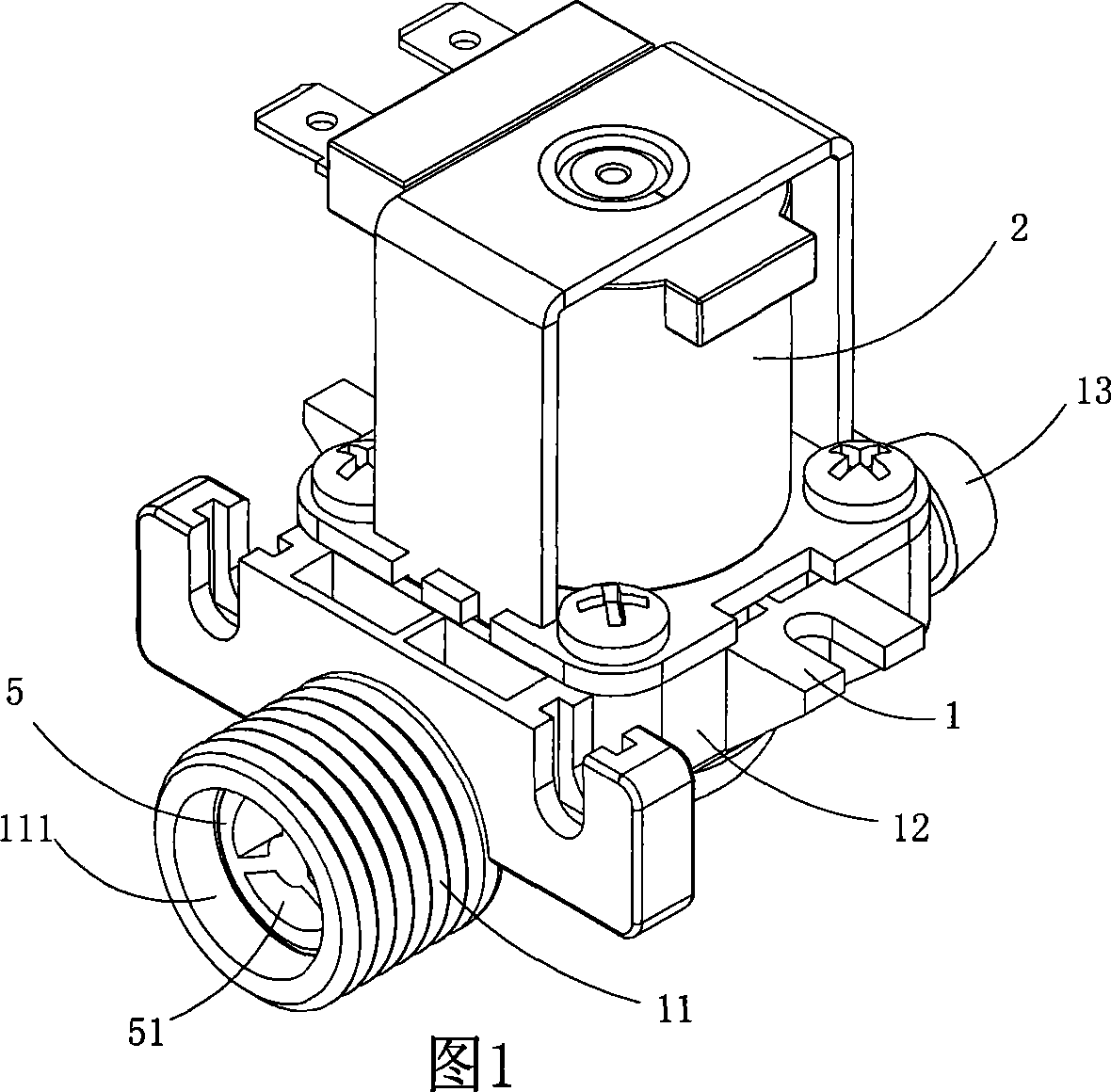

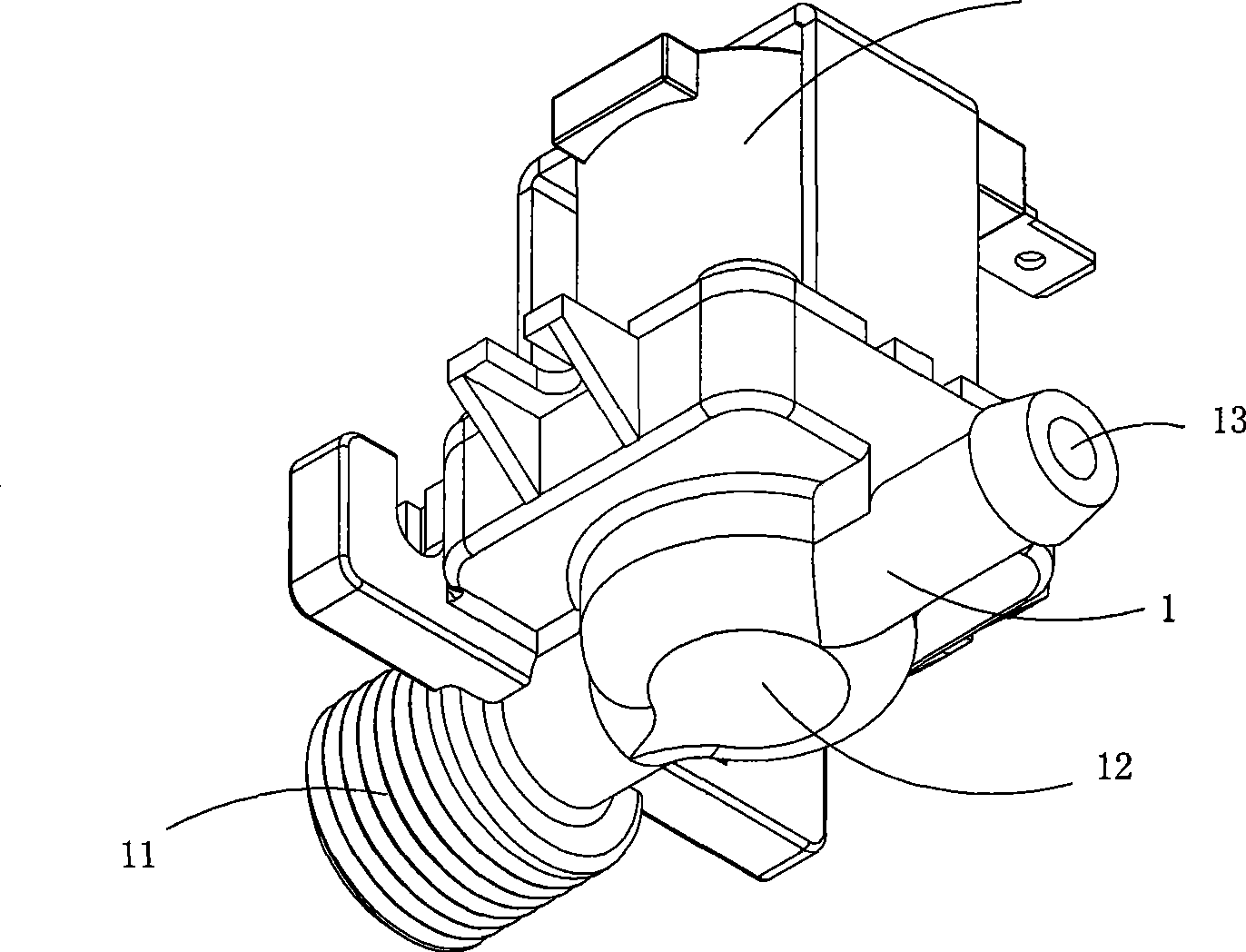

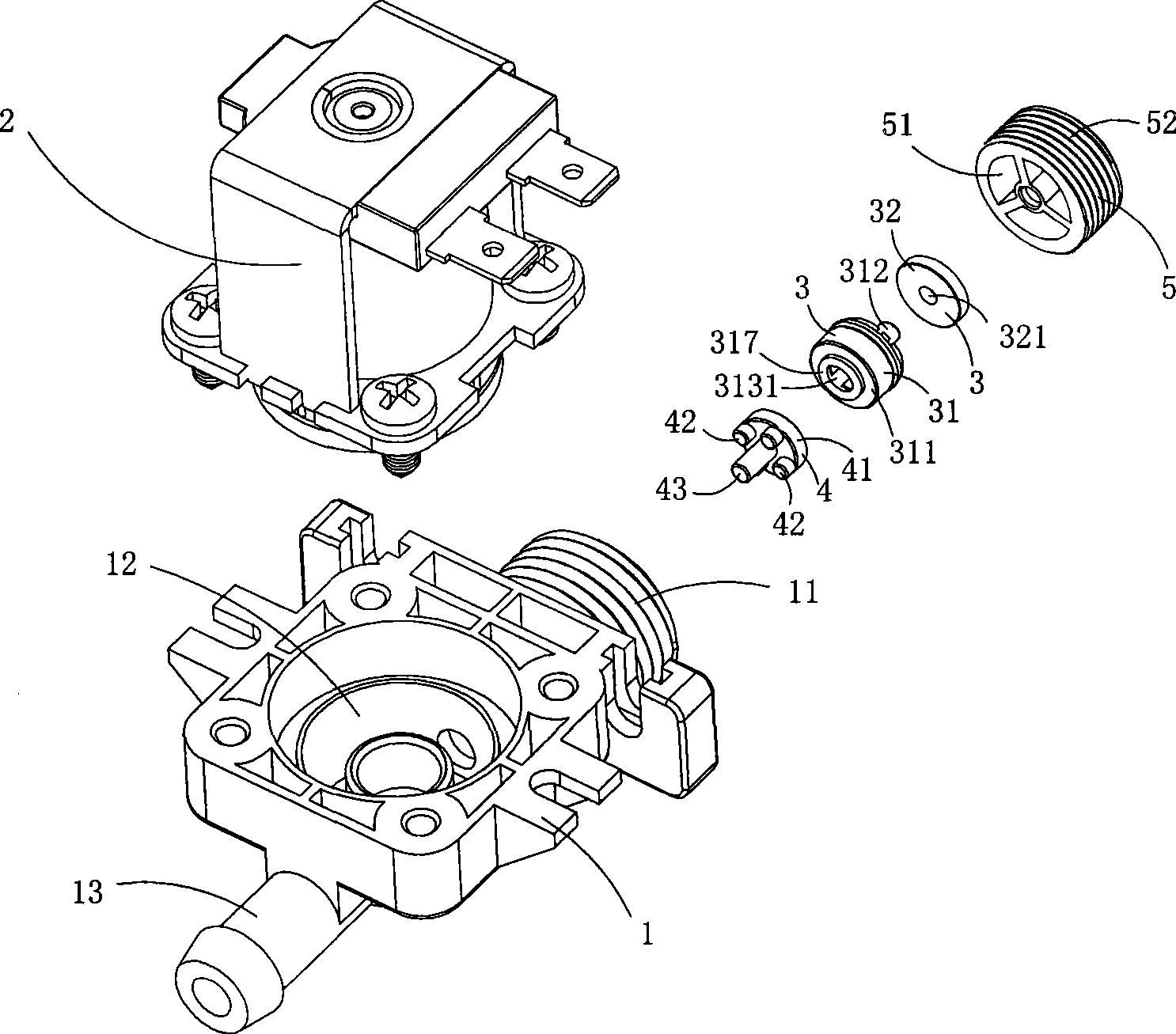

[0049] Figures 1 to 16 show the first specific embodiment of the present invention, wherein Figure 1 is a schematic perspective view of the first structure of the invention; figure 2 It is a three-dimensional structural diagram of the one-way constant flow check valve shown in Figure 1 viewed from another angle; image 3 It is a schematic diagram of an exploded structure of the one-way constant-current check valve shown in FIG. 1; FIG. 4 is a schematic diagram of an exploded structure of the one-way constant-current check valve shown in FIG. 1 viewed from another angle; Figure 5 It is a three-dimensional structural diagram of the one-way constant current check valve shown in Figure 1 after the electromagnetic on-off device is removed; Figure 6 yes Figure 5 The schematic diagram of the half-section structure of the one-way constant-current check valve after the electromagnetic on-off device is removed; Fig. 7 is a three-dimensional structure of the positioning element of th...

Embodiment 2

[0059] Figure 17 and Figure 18 A second embodiment of the invention is shown in which, Figure 17 It is a schematic diagram of a three-dimensional structure of the deflector in the second structure of the present invention; Figure 18 yes Figure 17 The three-dimensional structure schematic diagram of the deflector shown when viewed from another angle.

[0060] This embodiment is basically the same as Embodiment 1, the difference is: see Figure 17 and Figure 18 The main body 311 of the deflector is provided with two to six pillars 314 protruding axially for supporting the flow restrictor 32 at its liquid inlet end, and the gaps between adjacent pillars 314 form a liquid inlet channel, The liquid inlet channel communicates with the liquid outlet channel 313 in the deflector body 311 . At the liquid inlet end, there is no longer a radially concave liquid inlet groove 315 . This embodiment only relies on the deformation of the flow restrictor 32 in different degrees un...

Embodiment 3

[0062] Figure 19 and Figure 20 A third embodiment of the invention is shown in which, Figure 19 It is a three-dimensional structural schematic diagram of the deflector in the third structure of the present invention; Figure 20 yes Figure 19 The three-dimensional structure schematic diagram of the deflector shown when viewed from another angle.

[0063] This embodiment is basically the same as Embodiment 1, the difference is: see Figure 19 and Figure 20 , the deflector main body 311 is radially provided with two to six concave liquid inlet grooves 315 at its liquid inlet end, and the liquid inlet grooves 315 and the liquid outlet channels in the deflector main body 311 313 connected. At the liquid inlet end, there is no longer a pillar 314 protruding in the axial direction for supporting the restrictor 32 . This embodiment only relies on the deformation of the flow restrictor 32 in different degrees under different water pressures, and adjusts the gap size of each l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com