Instant liquefied fuel gasifying combustion stove

A liquid fuel, combustion furnace technology, applied in the direction of liquid heating fuel, heating fuel, household stove/stove, etc., can solve the problems of liquid leakage, high pressure, bad, etc., achieve uniform fire distribution, improve thermal efficiency, and good heating effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

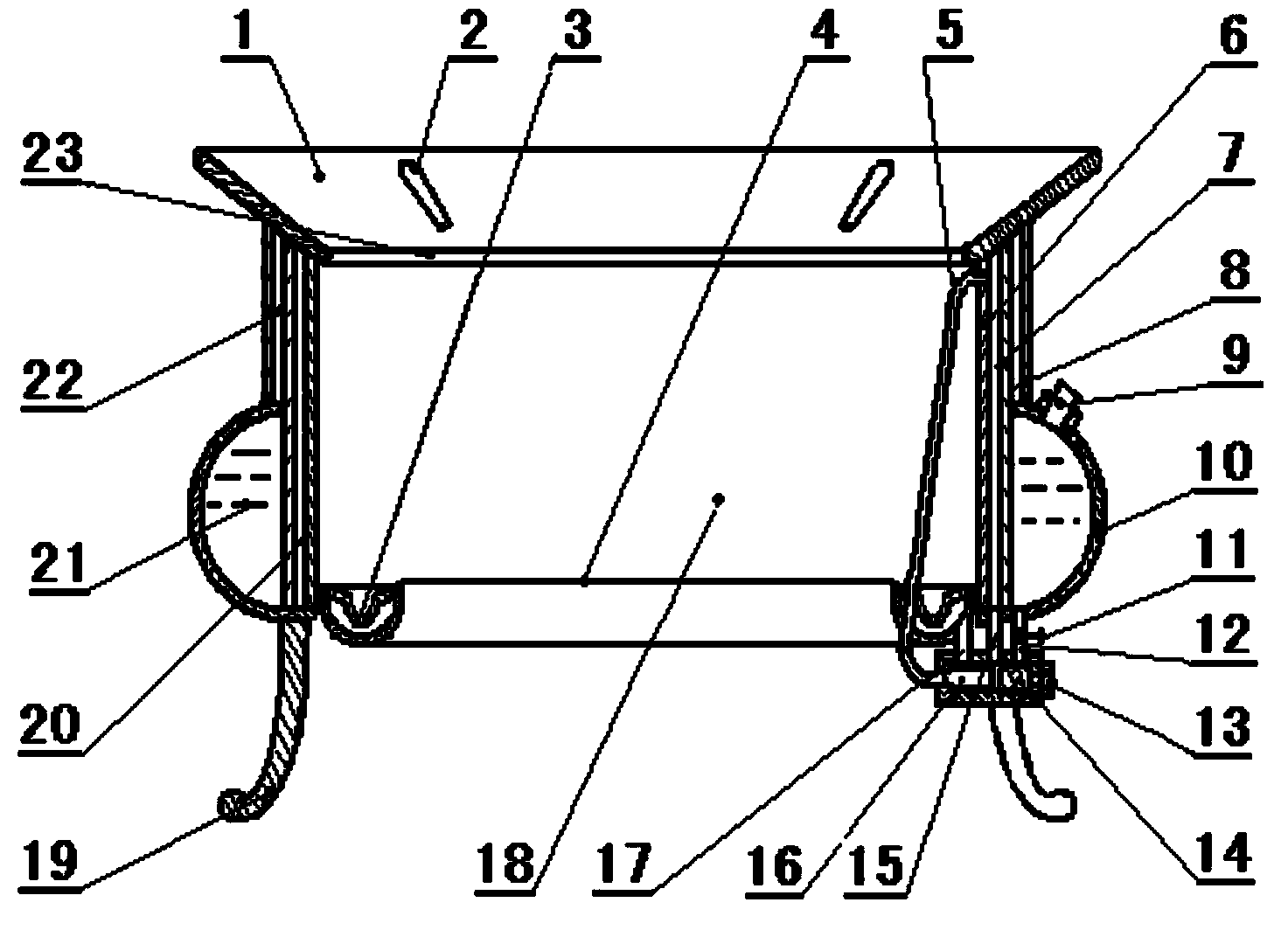

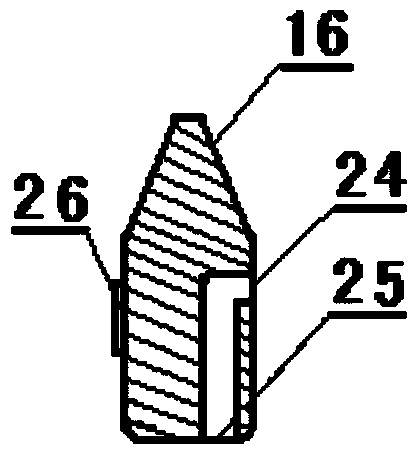

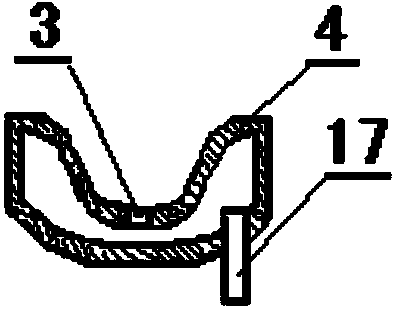

[0029] A small liquid fuel instant gasification combustion furnace, characterized in that: the setting includes: a furnace base 1, a combustion tank ring pipe 4, a gas supply pipe 5, a heat transfer layer 6, a gas-liquid interlayer 7, an insulation layer 8, and a liquid supply ring groove 10. Liquid and gas control valve 13 and stove foot 19; the heat transfer layer 6 is the innermost layer of the combustion furnace, and the heat transfer layer 6 is connected with the combustion groove ring pipe 4 to form a combustion chamber 18; the gas-liquid The interlayer 7 is the middle layer of the combustion furnace, and the gas-liquid interlayer 7 and the heat transfer layer 6 constitute the gasification chamber 20; the insulating layer 8 is the outermost layer of the combustion furnace, and the insulating layer 8 and the gas-liquid interlayer 7 constitute Gas insulation chamber 22; said liquid supply ring groove 10 is arranged on the outer wall of the lower section of gas-liquid interl...

Embodiment 2

[0038] A medium-sized liquid fuel instant gasification combustion furnace, characterized in that: the setting includes: a furnace base 1, a combustion tank ring pipe 4, a gas supply pipe 5, a heat transfer layer 6, a gas-liquid interlayer 7, an insulation layer 8, and a liquid supply ring groove 10. Liquid and gas control valve 13 and stove foot 19; the heat transfer layer 6 is the innermost layer of the combustion furnace, and the heat transfer layer 6 is connected with the combustion groove ring pipe 4 to form a combustion chamber 18; the gas-liquid The interlayer 7 is the middle layer of the combustion furnace, and the gas-liquid interlayer 7 and the heat transfer layer 6 constitute the gasification chamber 20; the insulating layer 8 is the outermost layer of the combustion furnace, and the insulating layer 8 and the gas-liquid interlayer 7 constitute Gas insulation chamber 22; said liquid supply ring groove 10 is arranged on the outer wall of the lower section of gas-liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com