Liquid gasification burner

A burner and liquid technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of unfavorable combustion exhaust gas emission, inconvenient processing and maintenance, complex internal structure, etc., and achieve good social and ecological benefits, processing and maintenance Convenient, compact and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

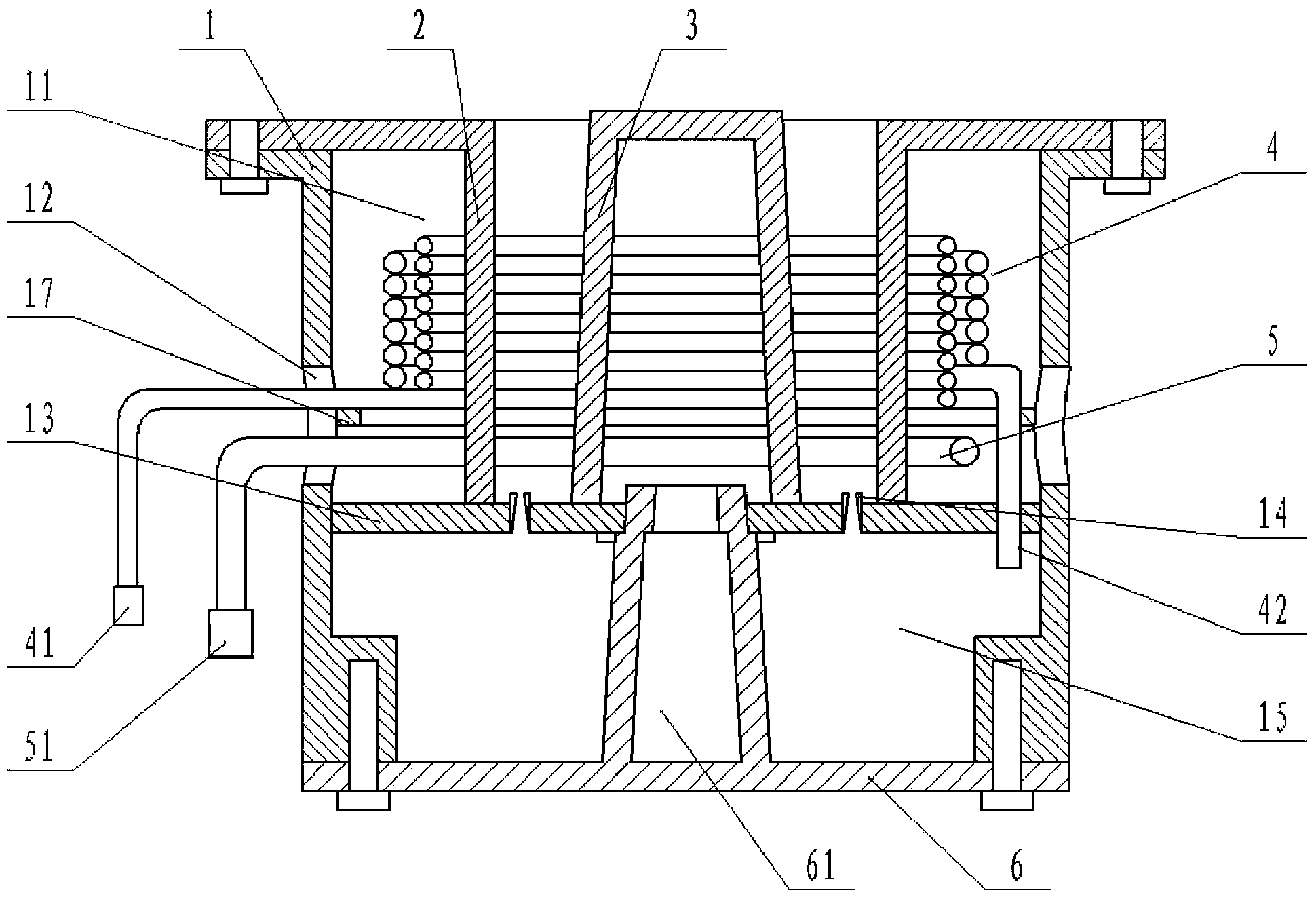

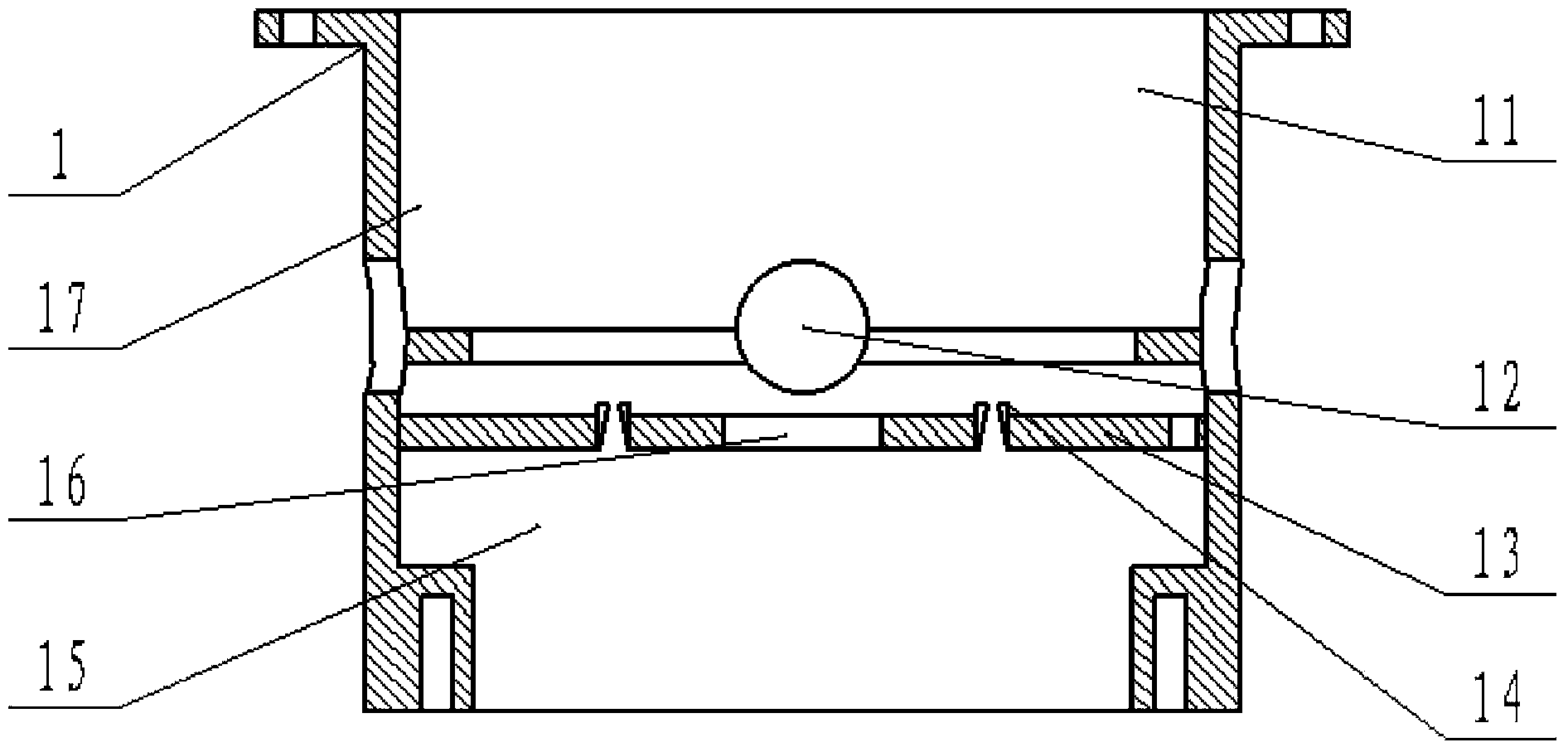

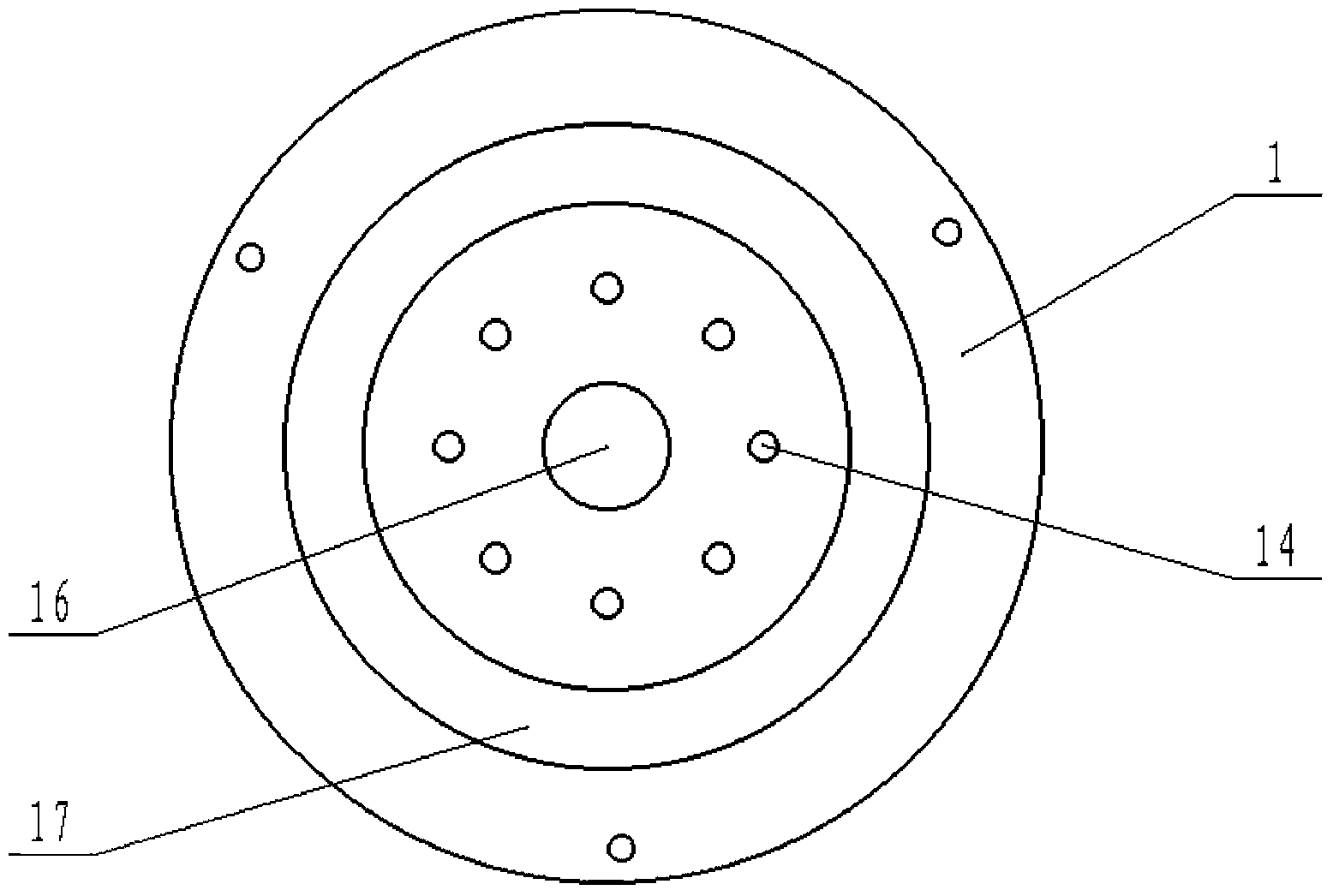

[0027] A liquid gasification burner, comprising a furnace body 1, an outer gas distribution cover 2, an inner gas distribution cover 3 and a base 6, the furnace body 1 is divided into upper and lower layers through a partition 13, the upper layer is a furnace 11, and the lower layer is a The gasification chamber 15 and the furnace 11 are provided with four air inlet holes 12 and a flange 17 for fixing the gasification coil 4 on the four walls of the furnace body 1 . The furnace 11 is provided with an outer gas distribution hood 2 , an inner gas distribution hood 3 , a preheating coil 5 and a gasification coil 4 . The outer gas distribution hood 2 is placed in the furnace 11, and the outer gas distribution hood 2 is fixedly connected to the upper end of the furnace body 1 with bolts; the inner gas distribution hood 3 is placed in the middle of the furnace 11. Small combustion-supporting holes 8 are evenly arranged on the four walls of the lower end of the outer layer gas distri...

Embodiment 2

[0032] A liquid gasification burner, comprising a furnace body 1, an outer gas distribution cover 2, an inner gas distribution cover 3 and a base 6, the furnace body 1 is divided into upper and lower layers through a partition 13, the upper layer is a furnace 11, and the lower layer is a The gasification chamber 15 and the furnace 11 are provided with 6 air inlet holes 12 and a flange 17 for fixing the gasification coil 4 on the four walls of the furnace body 1 . The furnace 11 is provided with an outer gas distribution hood 2 , an inner gas distribution hood 3 , a preheating coil 5 and a gasification coil 4 . The outer gas distribution hood 2 is placed in the furnace 11, and the outer gas distribution hood 2 is fixedly connected to the upper end of the furnace body 1 with bolts; the inner gas distribution hood 3 is placed in the middle of the furnace 11. Small combustion-supporting holes 8 are evenly arranged on the lower walls of the outer layer gas distribution hood 2 and t...

Embodiment 3

[0037] A liquid gasification burner, comprising a furnace body 1, an outer gas distribution cover 2, an inner gas distribution cover 3 and a base 6, the furnace body 1 is divided into upper and lower layers through a partition 13, the upper layer is a furnace 11, and the lower layer is a The gasification chamber 15 and the furnace 11 are provided with 8 air inlet holes 12 and a flange 17 for fixing the gasification coil 4 on the four walls of the furnace body 1 . The furnace 11 is provided with an outer gas distribution hood 2 , an inner gas distribution hood 3 , a preheating coil 5 and a gasification coil 4 . The outer gas distribution hood 2 is placed in the furnace 11, and the outer gas distribution hood 2 is fixedly connected to the upper end of the furnace body 1 with bolts; the inner gas distribution hood 3 is placed in the middle of the furnace 11. Small combustion-supporting holes 8 are evenly arranged on the four walls of the lower end of the outer layer gas distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com