Coating device of battery sealing agent

A technology of coating device and sealing agent, which is applied to the device and coating of the surface coating liquid, which can solve the problems of low production efficiency, piston fluctuation, glue breaking, etc., and achieve high production efficiency, guarantee sealing, and reliability good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

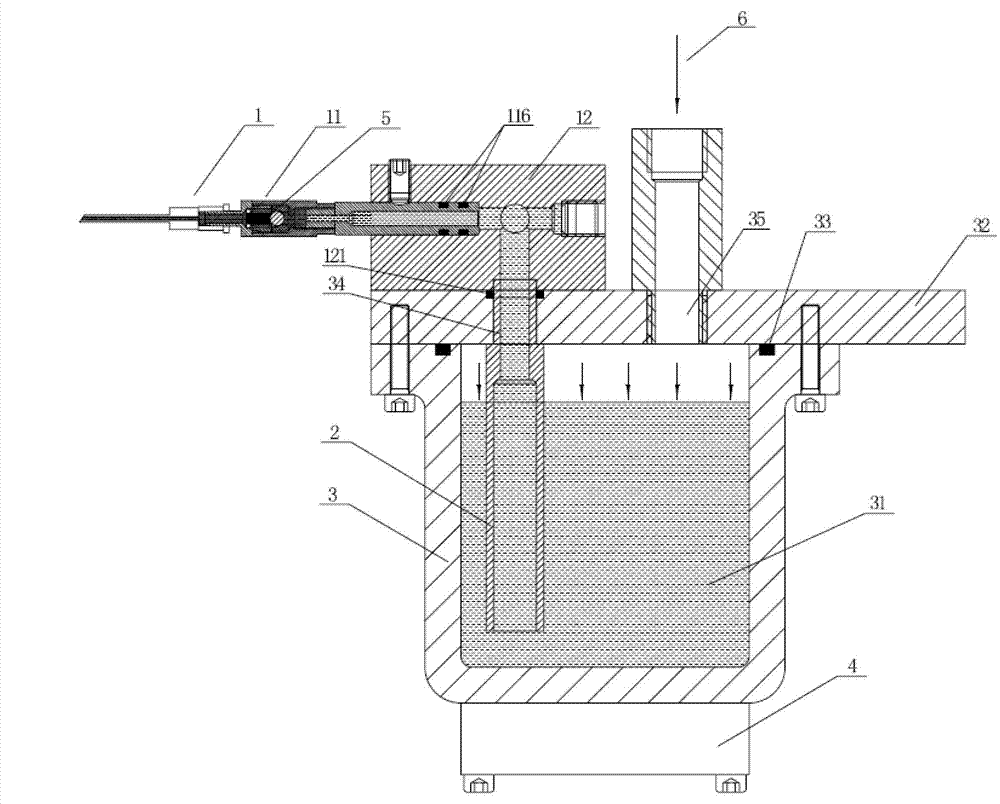

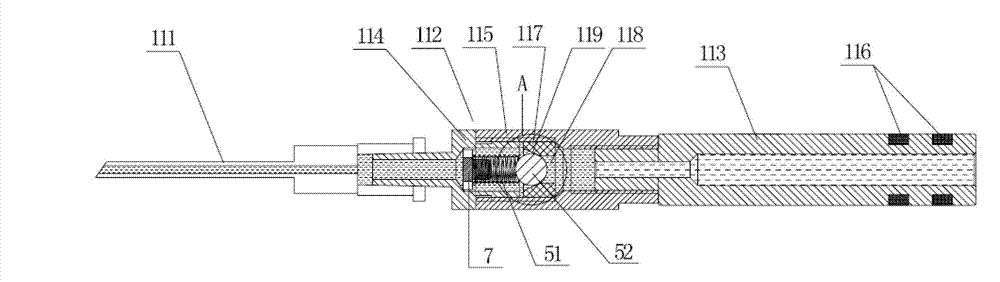

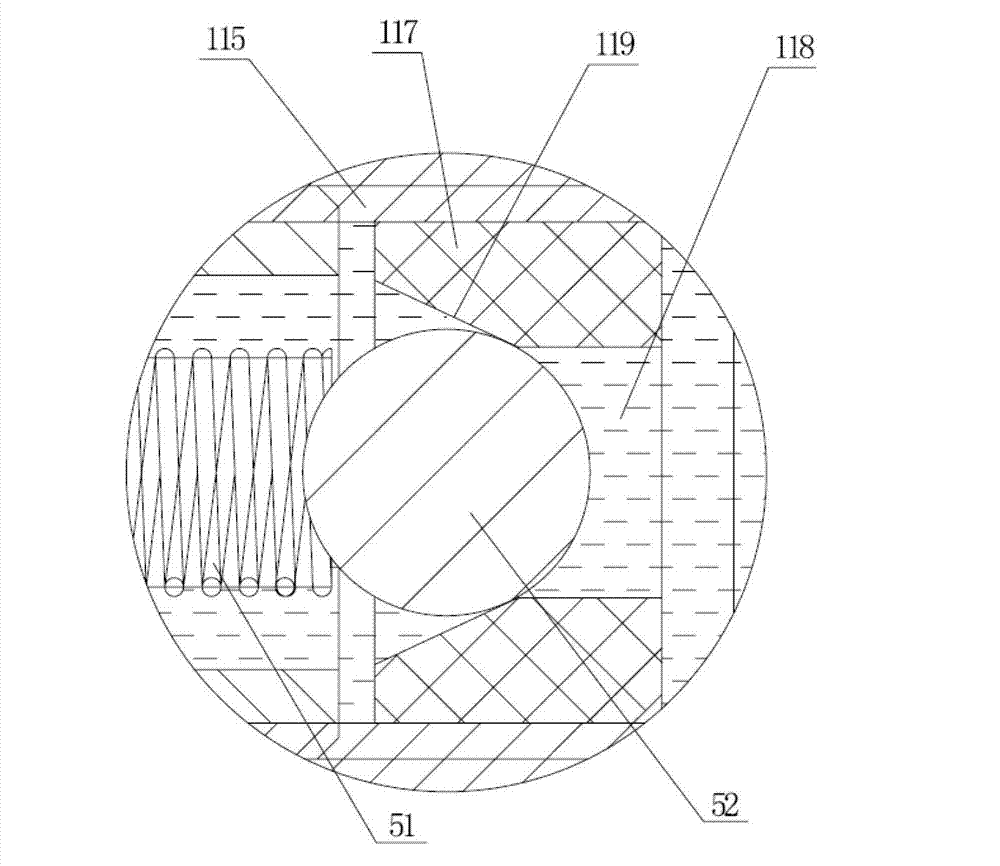

[0020] As shown in the figure, a battery sealing agent coating device includes a coating mechanism 1, an agent tube 2, an agent tank 3, and an electric heating aluminum plate 4 arranged at the bottom of the agent tank 3; the agent tank 3 is filled with a sealing agent agent 31; the upper end of the agent cylinder 3 is fixed on the agent cylinder mounting plate 32, the upper end of the agent cylinder 3 is provided with a third sealing ring group 33, and the agent cylinder mounting plate 32 is provided with a first through hole 34 and a second through hole Hole 35, the agent tank 3 communicates with the compressed air 6 through the second through hole 35; the coating mechanism 1 includes a spray needle assembly 11, and the spray needle assembly 11 is made up of a needle head 111, a needle seat 112 and a needle tail 113, and the needle seat 112 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com