Assisted constant valve

A valve core and valve body technology, applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems of large water impulse, not suitable for large valve applications, and cannot be gradually reduced, so as to achieve the effect of automatic pressure adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In the following embodiments, the auxiliary constant valve is opened when the valve stem is rotated counterclockwise as an example for illustration.

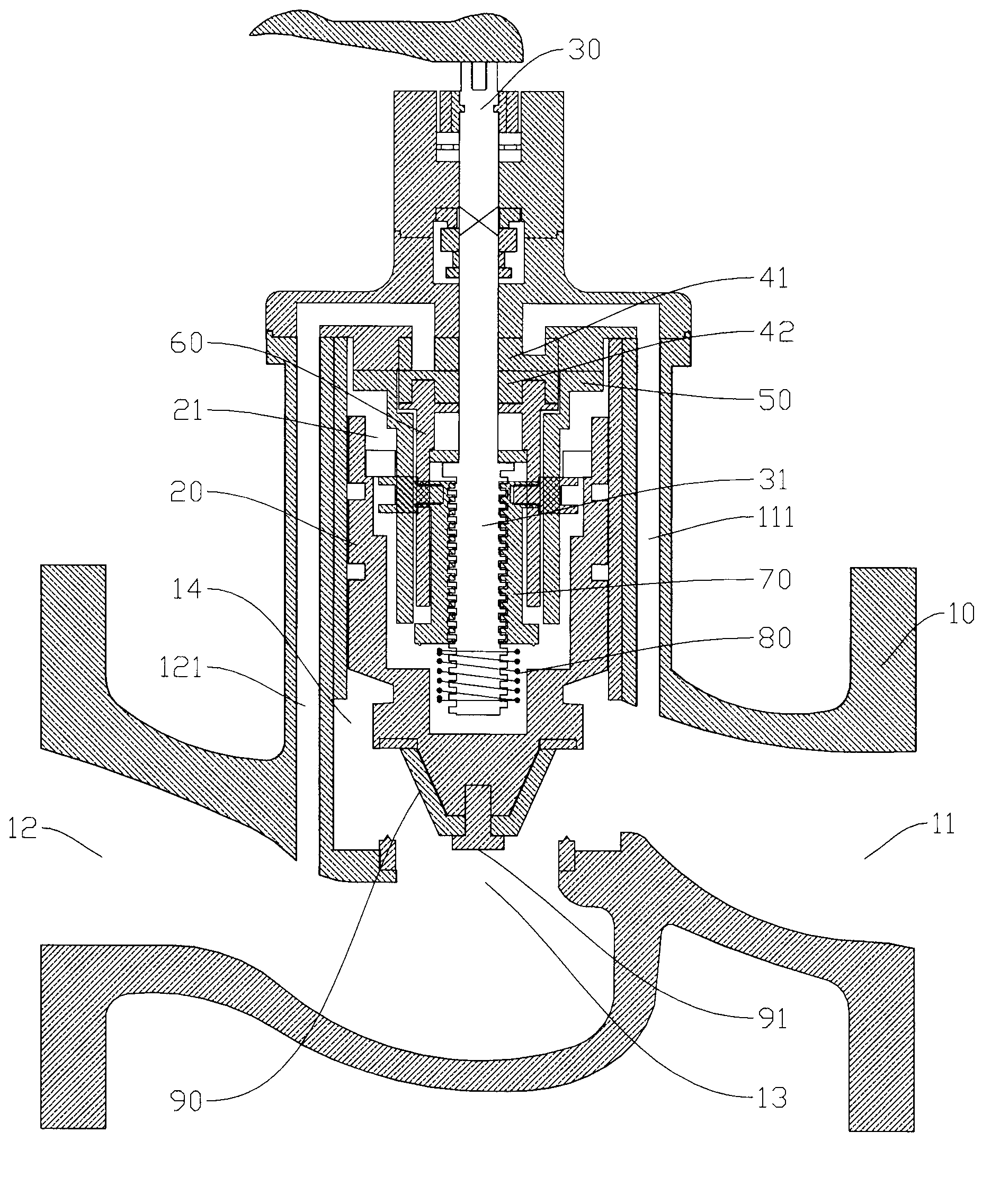

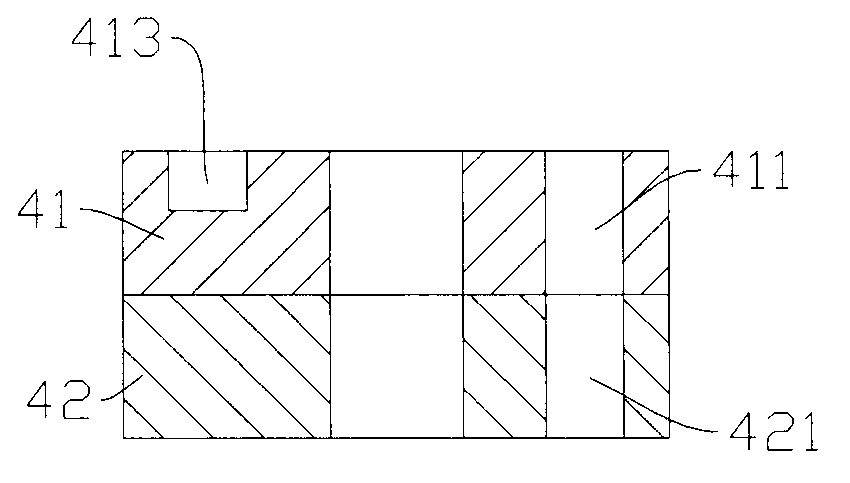

[0043] Examples, see Figure 1 to Figure 8 Shown: auxiliary constant valve, including valve body 10, valve core 20, fixed piece 41, rotating piece 42, valve stem 30 and other components. in:

[0044] The valve body 10 is provided with an inner chamber 14, a first water channel 111, a second water channel 121, and a water inlet 11 and a water outlet 12 connected through the connection port intercepting surface 13, and the lower end of the first water channel 111 communicates with the water inlet 11, A lower end of the second water channel 121 communicates with the water outlet 12 .

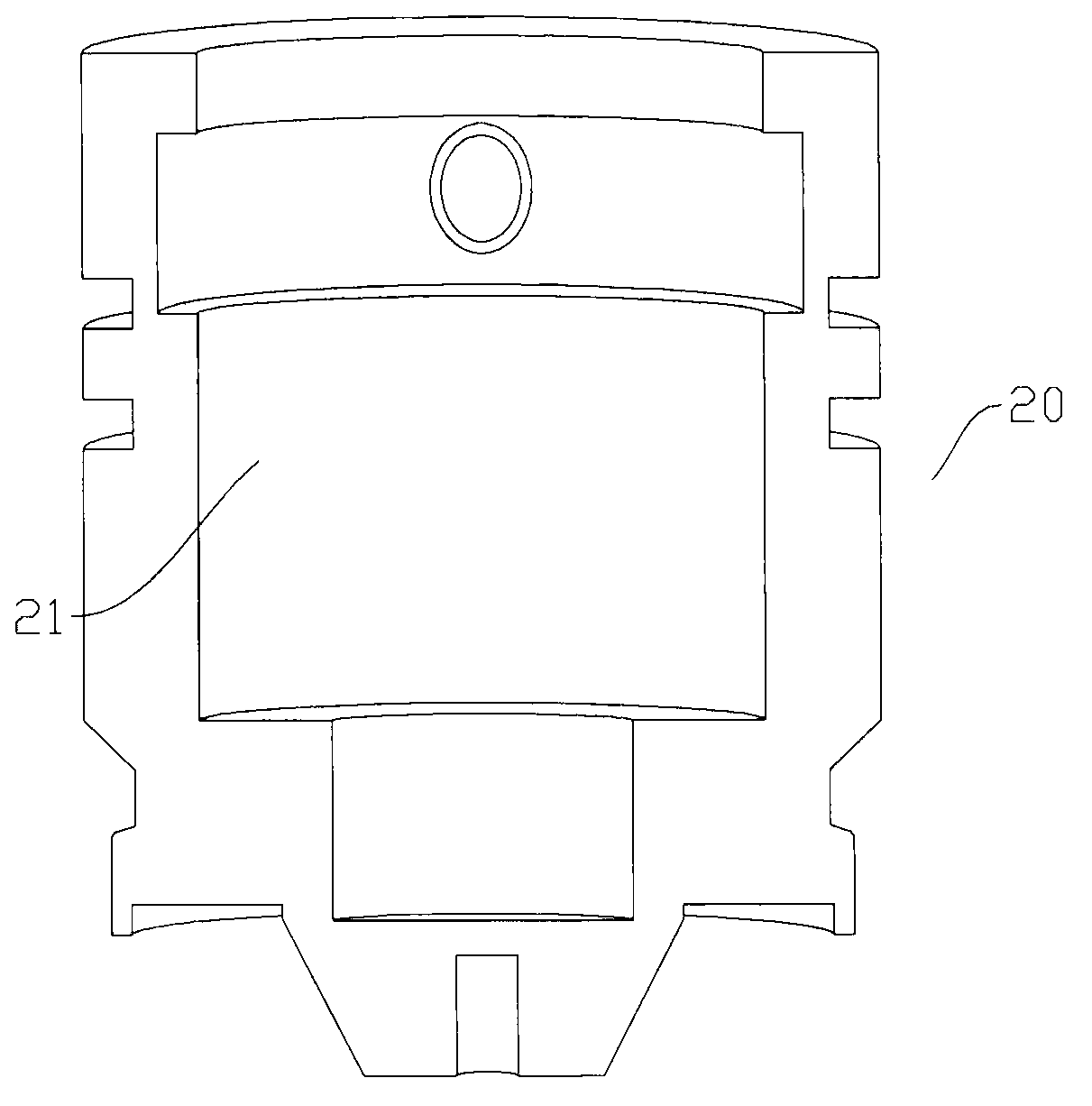

[0045] The valve core 20 is located in the inner chamber 14 and the lower part of the valve core 20 is matched with the connection port intercepting surface 13 . That is to say, the lower end of the spool 20 opens or blocks the cut-off surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com