Process for manufacturing DC waterproof pump controlling valve with small water hammer

A manufacturing process and control valve technology, applied in pump control, components of pumping devices for elastic fluids, non-variable pumps, etc., can solve the problems of water hammer reduction and long time consumption, and achieve water hammer Reduced, reasonable process, and the effect of protecting the water pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

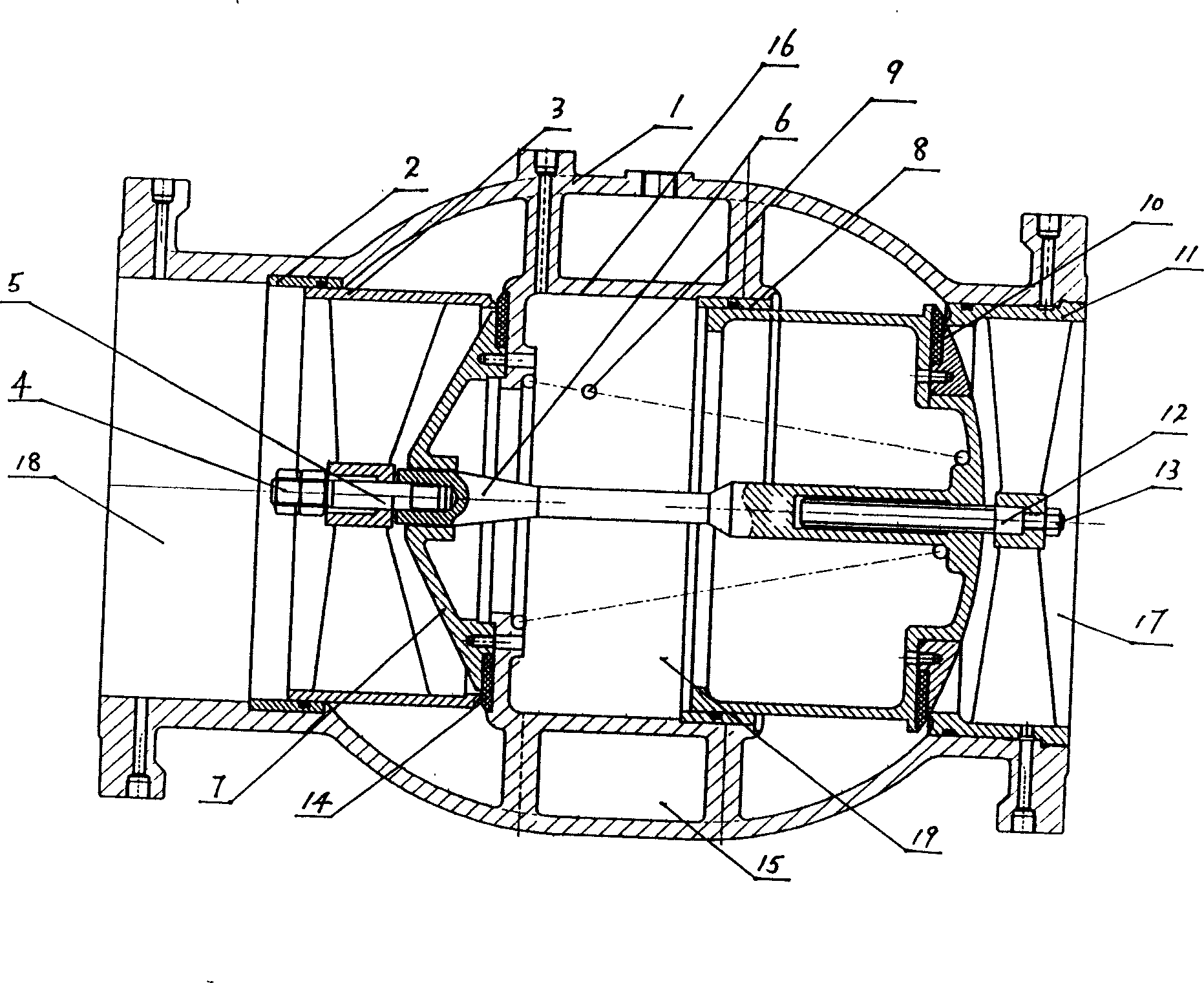

[0008] A manufacturing process of a direct-flow water pump control valve with small water hammer mainly includes the following steps: a tapered shaft and connecting bolts are provided between the outlet valve disc and the inlet valve disc, and are connected by nuts. The structure of the straight-line water pump control valve with small water hammer produced by the present invention will be further described in detail below in conjunction with the accompanying drawings. Referring to the accompanying drawings, it is a direct-flow water pump control valve with small water hammer. The valve body 1 is provided with an inlet port 17 and an outlet port 18. The inlet port 17 is provided with an inlet valve seat 11. The inlet valve seat 11 and the inlet valve disc 10 form a In the first level of sealing, the inlet disc 10 is set in the valve inner sleeve 16 on the valve body 1, the inlet valve disc sleeve 8 is set between the inlet valve disc 10 and the valve inner sleeve 16, and the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com