Condensed Water Discharge System for Reducing Water Hammer

A discharge system and water hammer technology, applied in the direction of steam traps, mechanical equipment, etc., can solve the problems of complex actual working conditions, water hammer phenomenon, pipeline damage, etc., to improve the drainage function, increase the processing capacity, and flexibly match Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

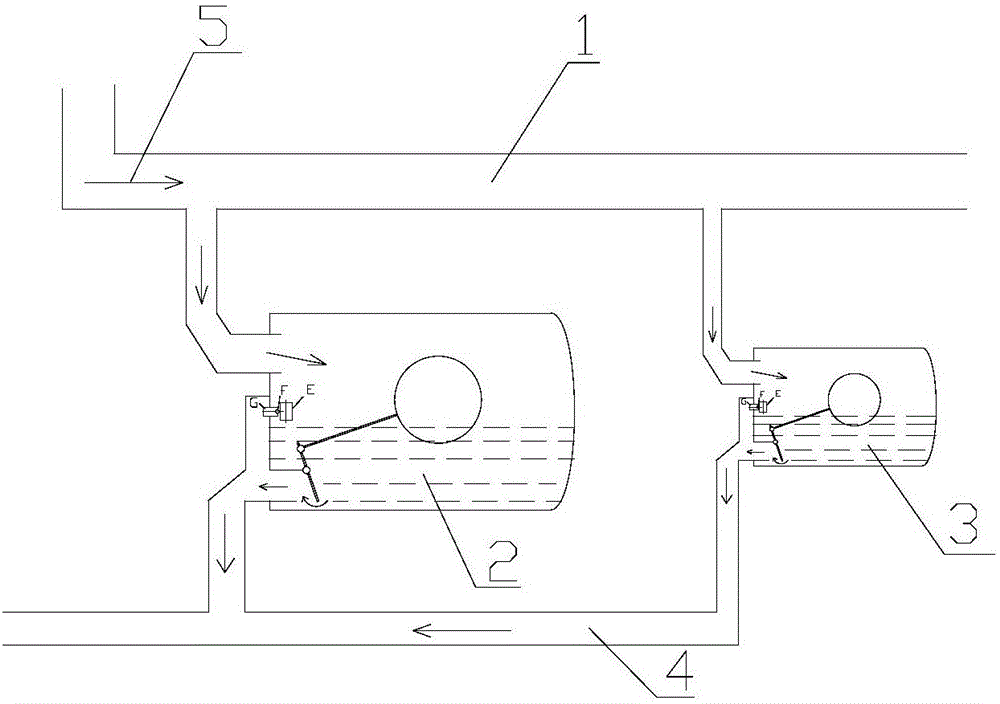

[0023] A condensate drainage system for reducing the occurrence of water hammer, used for condensate drainage of heat exchangers, such as figure 1 As shown, it includes a controller, a pre-valve condensate pipe 1 used to connect with the heat exchanger, two float traps arranged in parallel on the pre-valve condensate pipe 1 and connected with each float trap respectively. The condensed water pipeline 4 behind the valve is provided with a control valve at the condensed water inlet of each ball float trap, and the control valve is connected with the controller by communication. The two ball float traps are the large diameter ball float trap 2 and the small diameter ball float trap 3. The valve seat of the large diameter float trap 2 is composed of an upper valve seat and a lower valve seat. Double valve seat, the valve seat of the small diameter ball float trap 3 is a single valve seat, the condensate pipe 1 in front of the valve is set horizontally, the condensation of the larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com