Water hammer prevention method for medium plate quenching machine

A quenching machine, steel plate technology, applied in quenching devices, heat treatment equipment, furnaces, etc., can solve problems such as water pressure fluctuations, and achieve the effect of reducing water hammer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

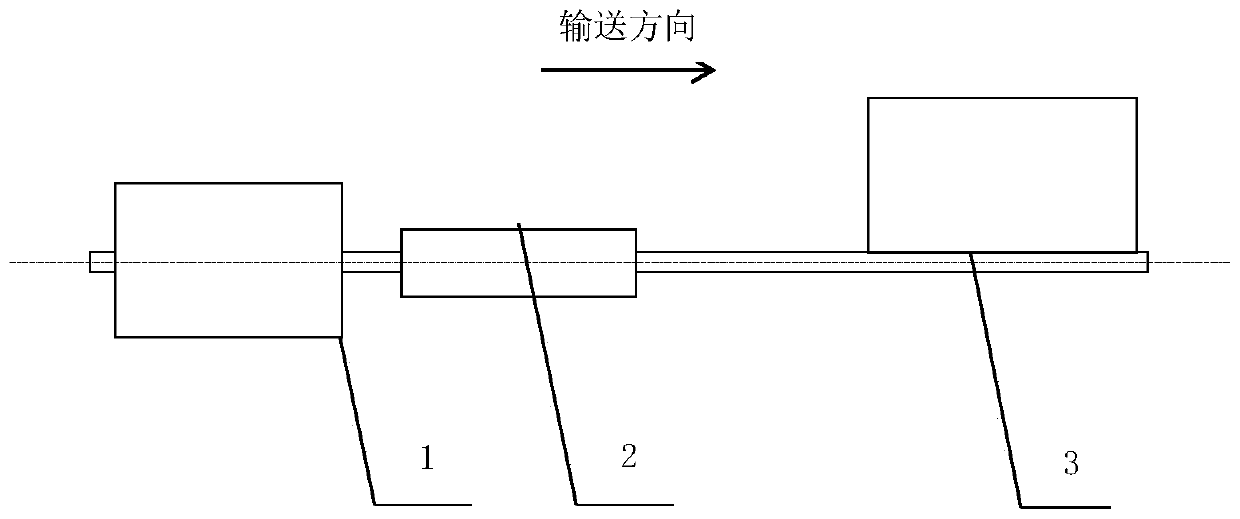

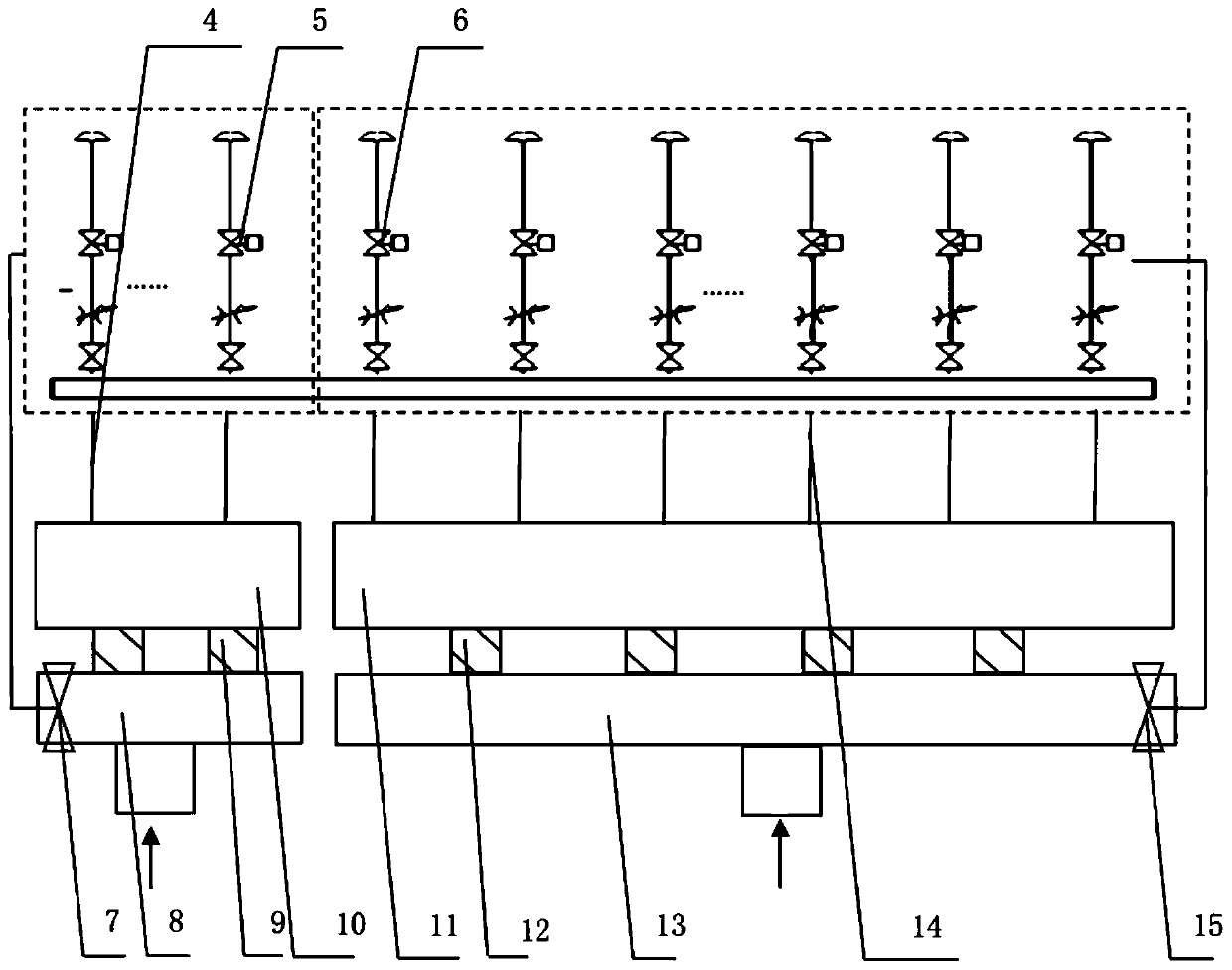

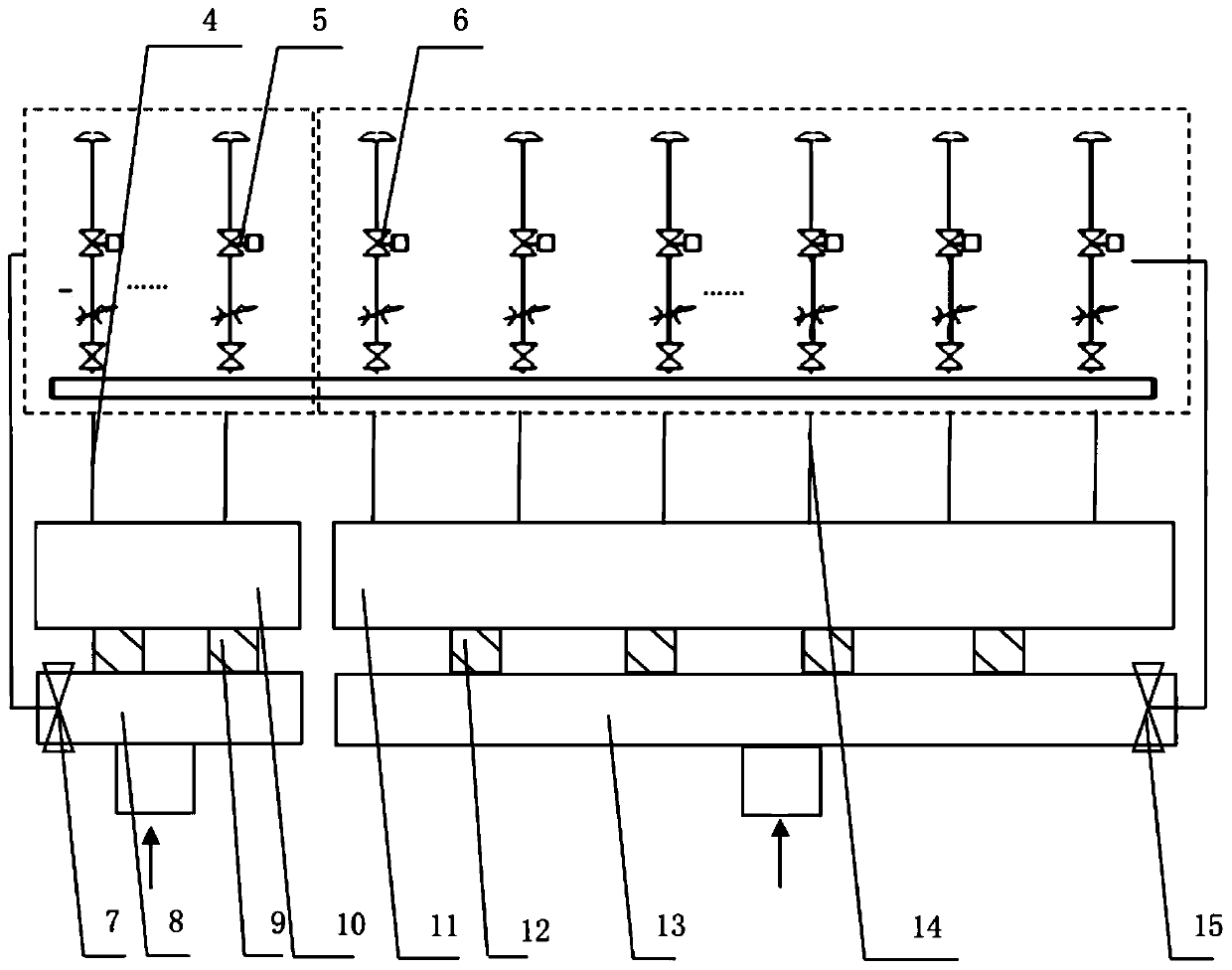

[0041] Take the quenching process of NM400 steel plate with a thickness of 30mm as an example. The length of the steel plate is 20m. figure 1 The application technology of the quenching process of the arranged quenching machine is taken as an example to further describe the process method. attached figure 1The first zone of the roller hearth heating furnace heats the steel plate to 900°C, and the steel plate is sent to the attached figure 1 Quenching to 50°C in zone 2 of the quenching machine, and the quenched steel plate is sent to the attached figure 1 Cooling bed zone 3. Among them, there are 4 groups of high-pressure section coolers and they are fully opened, and the attached diameter is DN800. figure 2 The water supply main pipe 8 of the high pressure section will have a flow rate of 4200m 3 0.8MPa high-pressure water per hour passes through two attachments with a diameter of DN600 figure 2 The branch bellows 9 of the high-pressure section is sent to the attached ...

Embodiment 2

[0043] Take the normalized cooling process for the production of 60mm thick Q390 steel plate as an example. The length of the steel plate is 18m. figure 1 The application technology of the normalized cooling process of the arranged quenching machine is taken as an example to further describe its process method. attached figure 1 The first zone of the roller hearth heating furnace heats the steel plate to 850°C, and the steel plate is sent to the attached figure 1 The 2nd zone of the quenching machine is normalized and cooled to 610°C, and the steel plate after normalized cooling is sent to the attached figure 1 Cooling bed zone 3. Among them, the coolers in the high-pressure section are not open and empty, and the coolers in the low-pressure section have a total of 18 groups and are fully opened. Attached with a diameter of DN800 figure 2 The flow rate of the low-pressure section water supply main pipe 13 is 4800m 3 / h of 0.4MPa low-pressure water through four attachments...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com