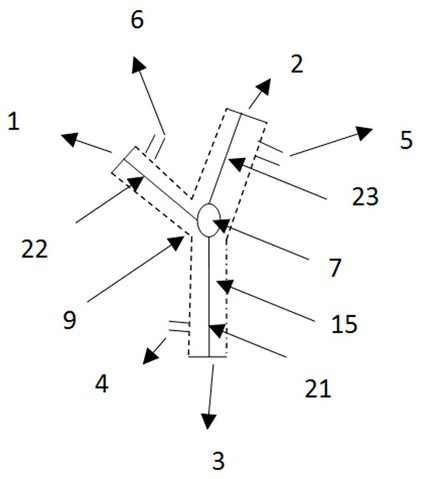

Y-shaped heat exchanger and reactor with heat exchange device

A technology of heat exchangers and reactors, applied in the direction of indirect heat exchangers, heat exchanger types, chemical instruments and methods, etc., can solve problems such as retention, safety hazards, and inability to completely empty, so as to reduce water hammer and ensure Effective recovery and loss avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] When in use: the mixed gas enters the heat exchange tube B 22 from the gas inlet 1, enters the gas-liquid separation chamber 7 after heat exchange, the non-condensable gas is discharged through the gas outlet 2, and the condensate flows into the reactor 11 or the recovery kettle 12 through the reflux port 3 . The heat exchange medium enters the Y-shaped heat exchanger 10 from the heat exchange medium inlet 4 , and the heat exchange medium flows out from the heat exchange medium outlets 5 and 6 .

Embodiment 2

Embodiment 3

[0024] The process flow form of the Y-shaped heat exchanger 10 is not limited to the above-mentioned process flow, and the related processes using the Y-shaped heat exchanger are all included.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com