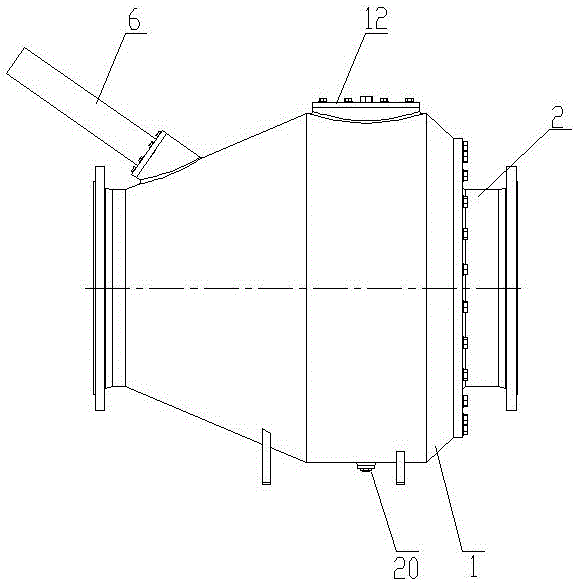

High-performance silent slow-closing check valve

A high-performance, check valve technology, applied in the direction of functional valve type, valve details, control valve, etc., can solve the problems of damage to the sealing pair, high noise, and only the entire valve can be replaced, so as to reduce water hammer and water head The effect of small loss and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

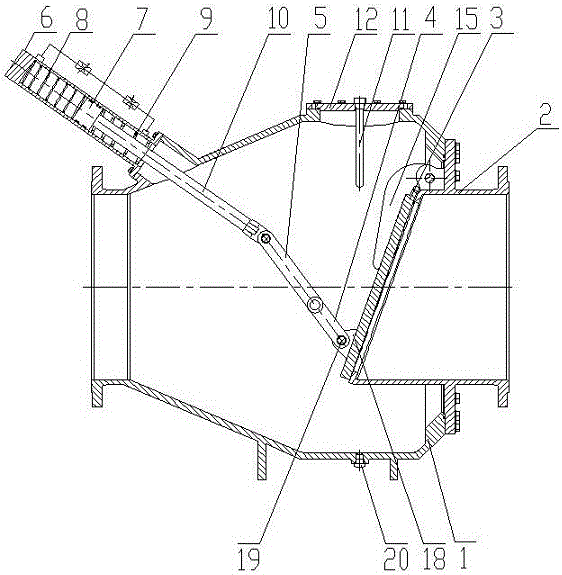

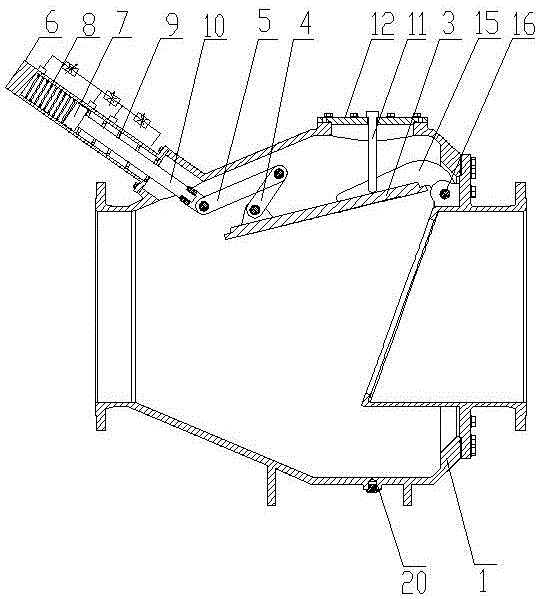

[0018] Embodiment 1: A high-performance silent slow-closing check valve, including a valve body 1, a valve seat 2 and a valve disc 3, a valve body channel is arranged in the valve body, and both sides of the valve seat are detachably fixedly connected with the valve body 1. The central part of the valve seat extends into the passage of the valve body inside the valve body. The cross-section of the matching surface of the central part of the valve seat and the disc is an inclined plane so that the disc is inclined when the disc is sealed. A connecting rod 4, one end of the first connecting rod is connected with the second connecting rod 5, the side of the valve body away from the valve seat is provided with a cylinder 6, the cylinder is provided with a piston 7, the cylinder The first spring 8 and the second spring 9 are respectively arranged on both sides of the length direction in the body and the first spring and the second spring are respectively located on both sides of the...

Embodiment 2

[0019] The difference between Embodiment 2 and Embodiment 1 is that an inspection port is provided on the side of the radial valve body located in the passage of the valve body. on the top cover.

Embodiment 3

[0020] Embodiment 3 differs from Embodiment 1 in that: the wire diameter of the first spring is larger than that of the second spring or the wire diameter of the second spring is larger than the first spring or the wire diameters of the first spring and the second spring are equal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com