Low-shake low-noise water-hammer-free check valve

A low-noise, check valve technology, applied in the field of low-vibration, low-noise, no water hammer check valves, can solve problems such as external leakage, increased valve weight, and local strength reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

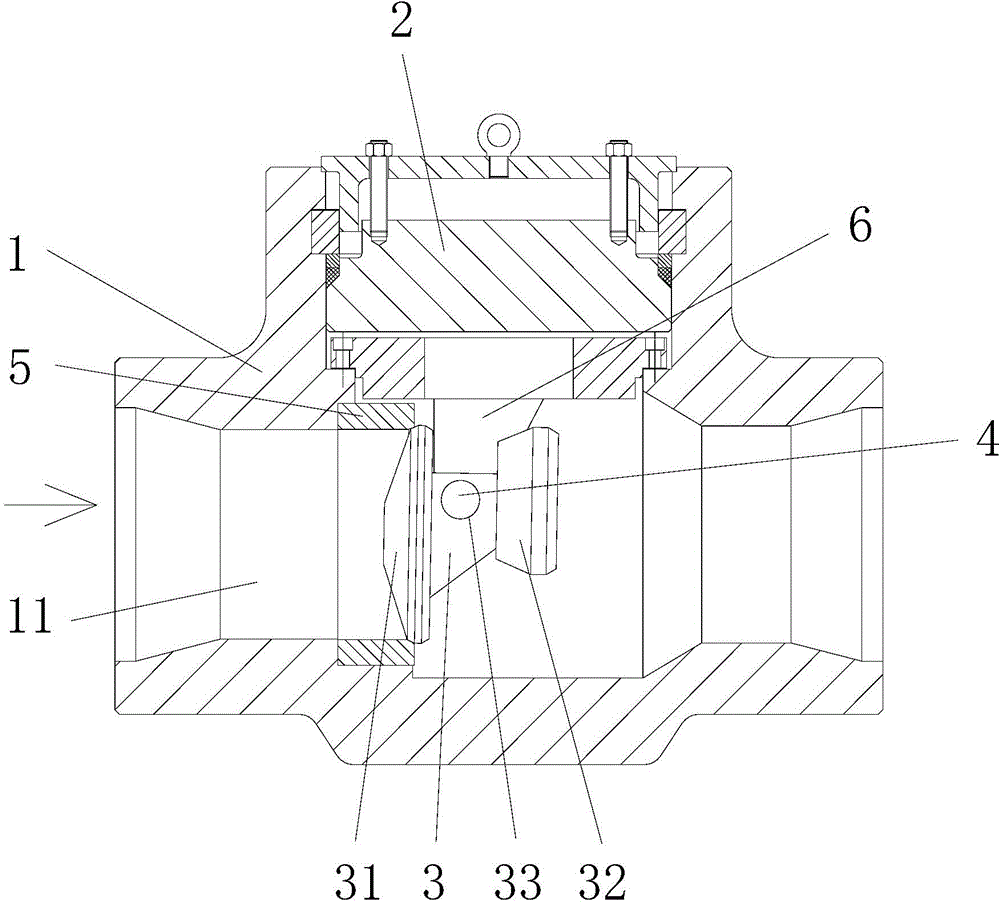

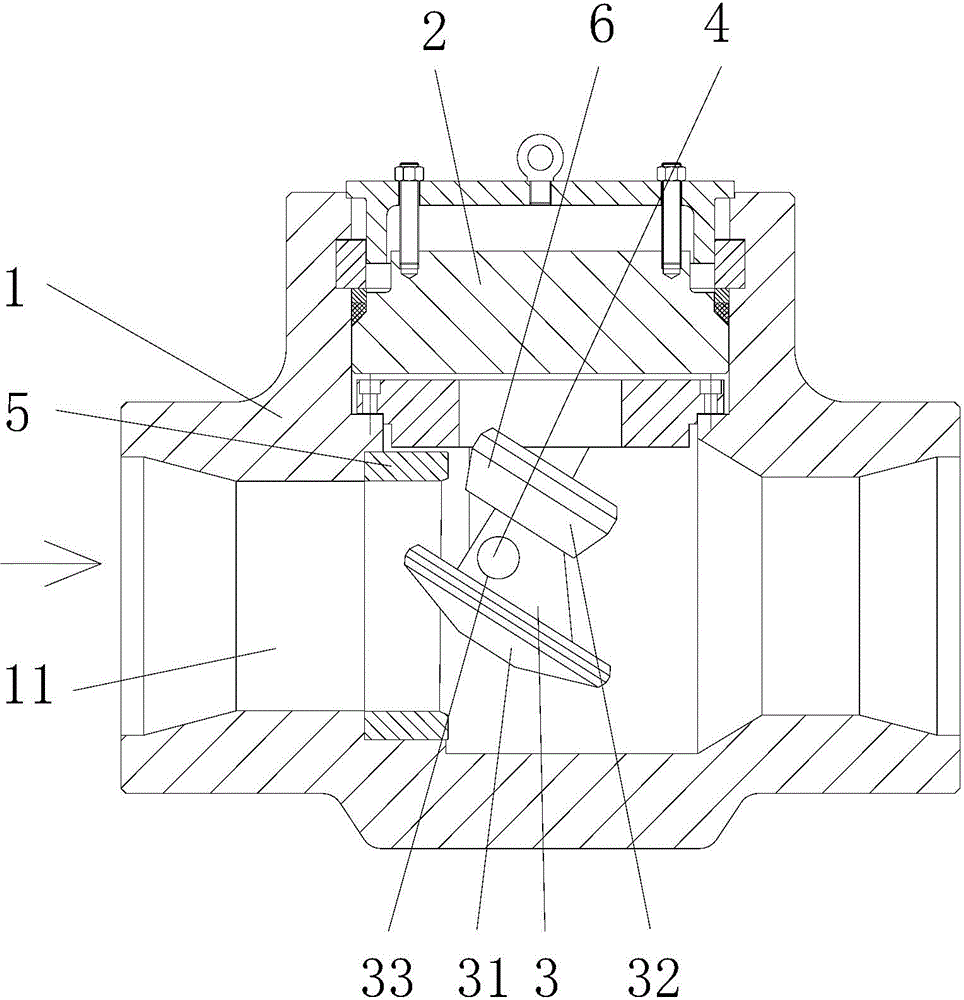

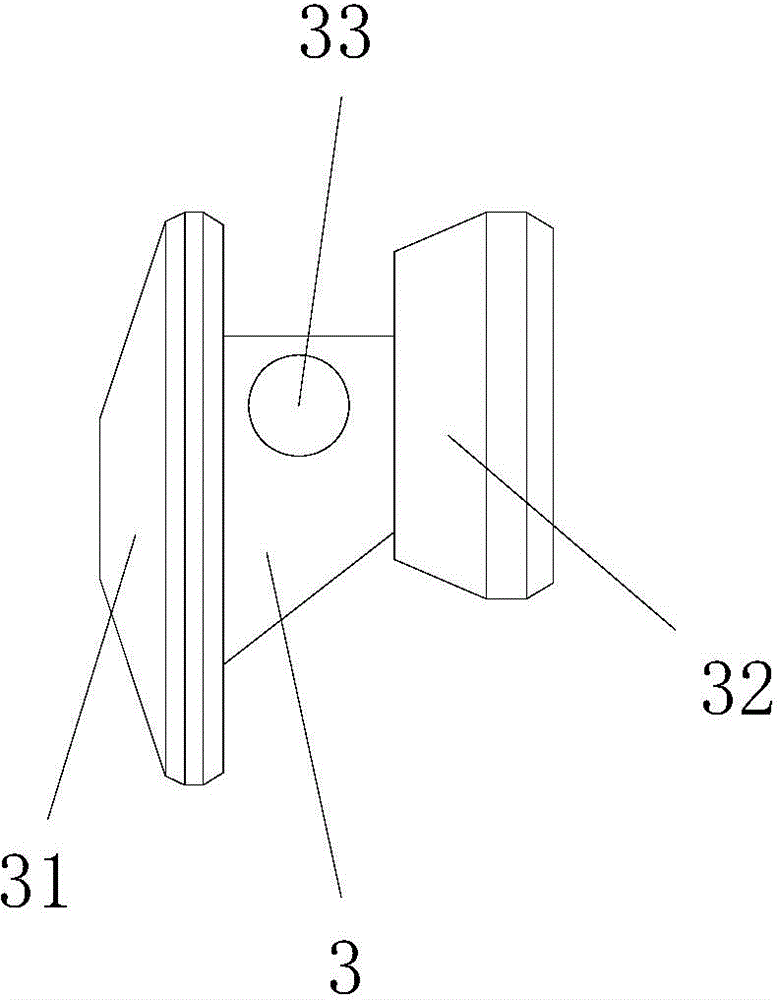

[0026] In further embodiments of the present invention, please continue to refer to Figure 1 to Figure 3 As shown. The shaft hole 33 is located between the sealing device 31 and the gravity balance device 32, and the gravity balance device 32 plays a role of torque adjustment when the check valve is opened and closed.

[0027] In a further embodiment of the present invention, the shaft hole 33 is an eccentric hole. Taking a preferred embodiment as an example, the centerline of the shaft hole 33 is located above the centerline of the channel 11 of the valve body 1 .

[0028] In a further embodiment of the present invention, a valve seat 5 is installed in the passage 11 of the valve body 1 , and the sealing surface of the sealing device 31 can form a seal with the valve seat 5 .

[0029] In a further embodiment of the present invention, the sealing surface of the sealing device 31 is conical, and the sealing surface of the sealing device 31 and the valve seat 5 are conically s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com