Noise-reducing and water-hammer-effect-reducing long-handle welding type valve ball and ball valve manufactured by valve ball

A water hammer effect and welding technology, applied in the field of valve body components, can solve the problems of damaged equipment and industrial pipelines, large noise and vibration of ball valves, and achieve the effect of reducing water hammer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the drawings:

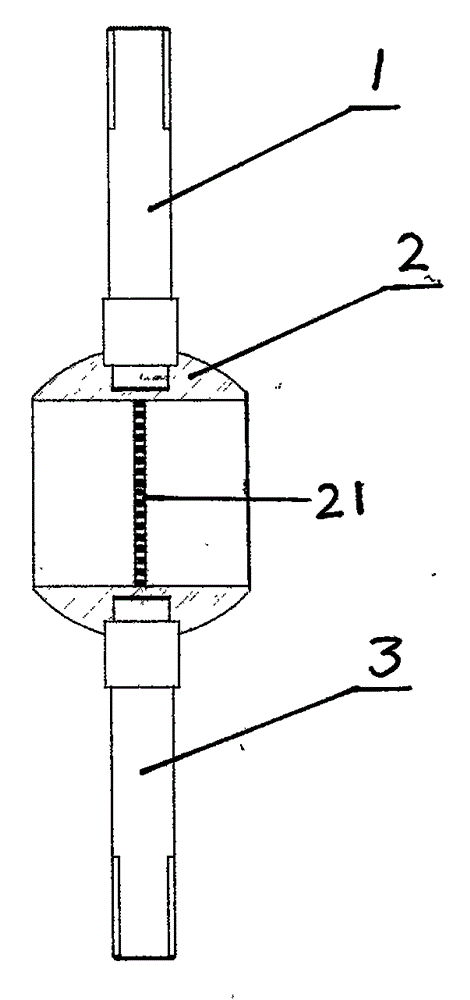

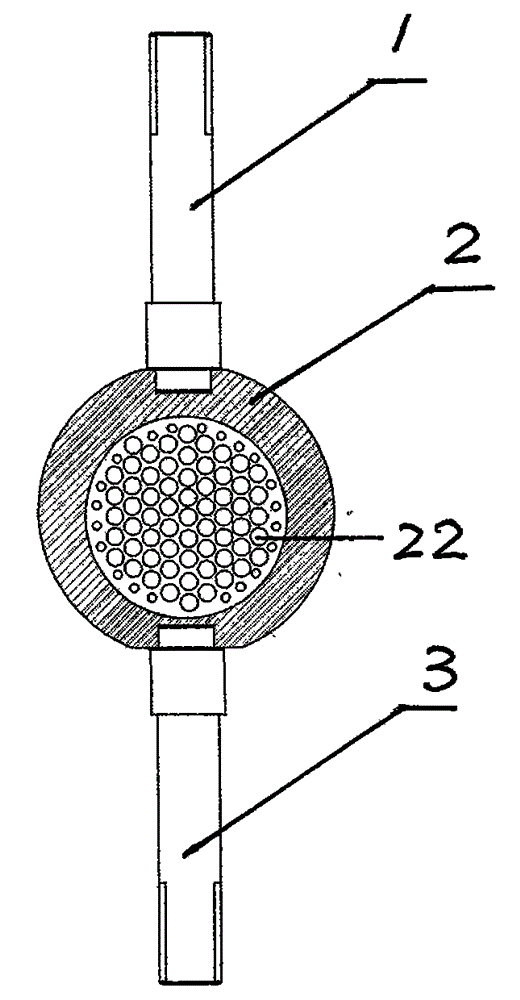

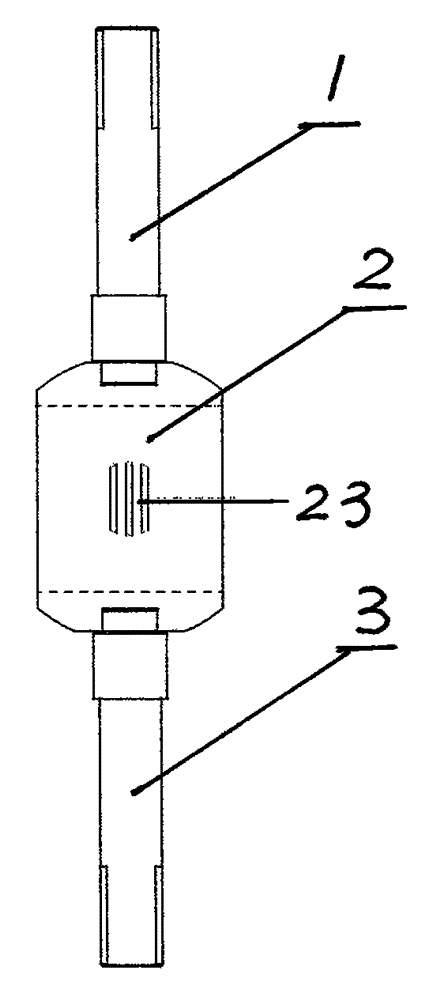

[0015] Such as figure 1 , figure 2 , image 3 As shown, a long-handled welded symmetrical valve ball for noise reduction and water hammer reduction includes a first valve stem 1, a valve ball 2, a second valve stem 3. The first valve stem 1, the second valve stem 3 are welded to the valve On the ball 2, and the first valve stem 1 and the second valve stem 3 are symmetrical and equal in length, it is characterized in that a noise reduction plate 21 is welded in the flow passage of the valve ball 2, and the noise reduction plate 21 is provided with a number of noise reduction holes 22 The non-sealing surface of the valve ball 2 is provided with a diversion groove 23.

[0016] Further, the guide groove 23 is three parallel grooves.

[0017] A ball valve made of a long-handled welded symmetrical valve ball with noise reduction and water hammer effect reduction, comprising a valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com