Fuel truck nozzle

A refueling gun and fuel technology, applied in special distribution devices, packaging, distribution devices, etc., can solve the problems of limited peak pressure of water hammer and inconspicuous extension time, prolong the closing time, reduce the phenomenon of water hammer, Impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

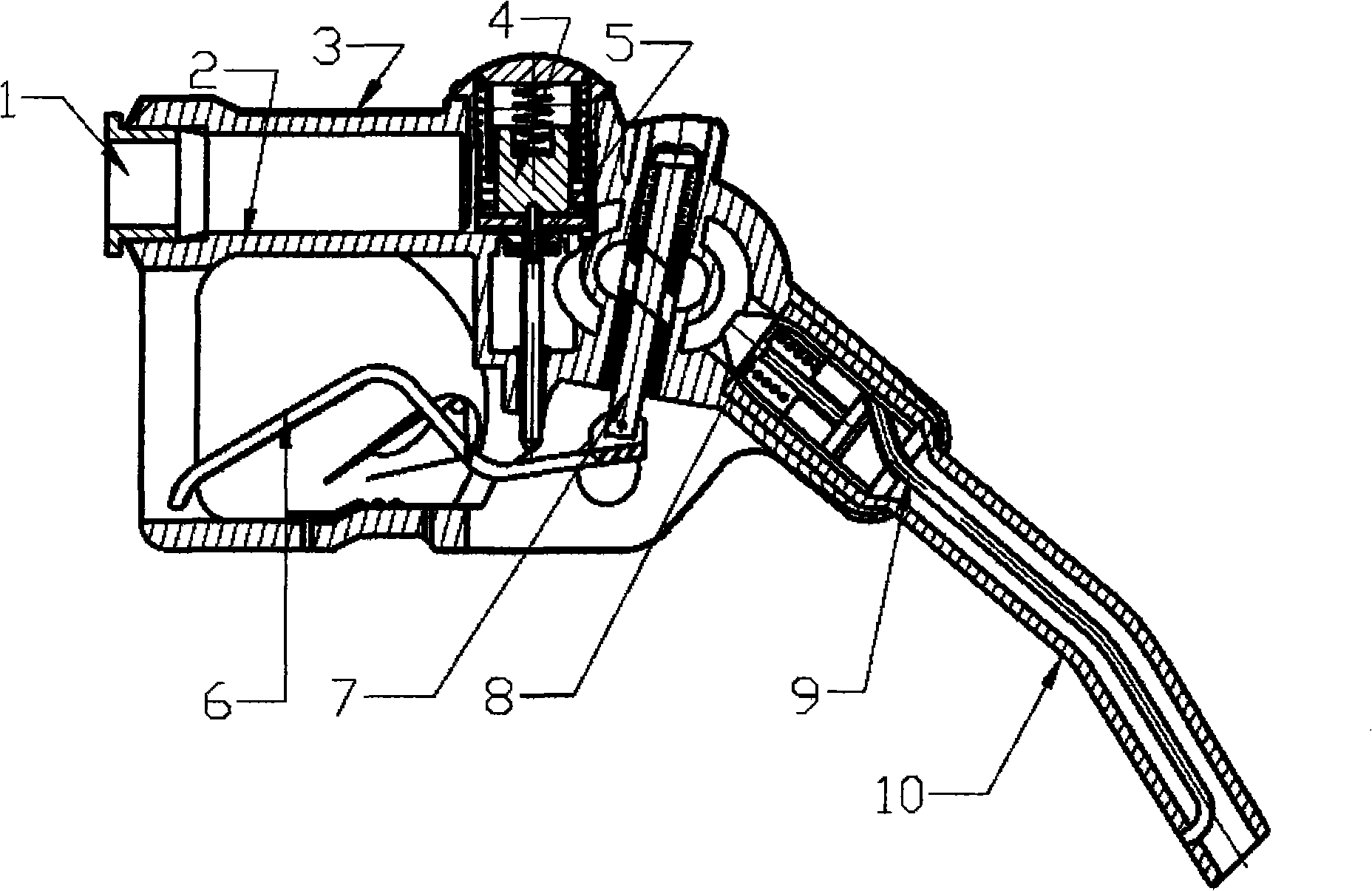

[0026] Such as figure 1 As shown, the fuel oil refueling gun of the present invention is composed of gun body 2, gun body cover 3, control valve 4, oil inlet pipe 1, control handle 6, ejector rod 5, self-control lever 7, vacuum valve 8, oil outlet pipe 10, vent pipe 9 and so on.

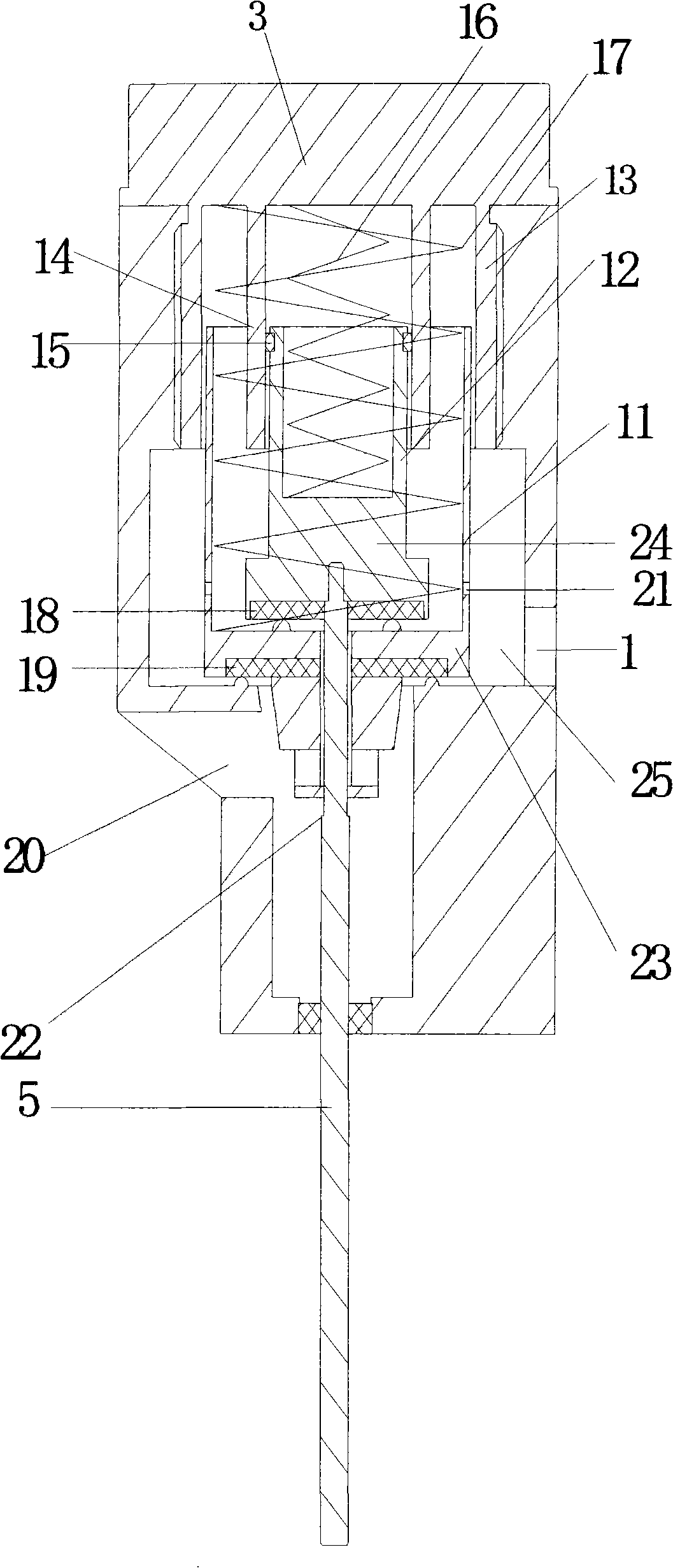

[0027] Such as figure 2 As shown, the gun body cover 3 is fixedly connected with the gun body 2 through threads, and the control valve 4 is arranged on the lower side of the gun body cover 3 and placed between the oil inlet 25 and the oil outlet 20 in the oil inlet pipe 1, and the outlet The oil port 20 communicates with the oil outlet pipe 10, and the control valve 4 includes a main valve and an auxiliary valve located in the main valve and installed concentrically with the main valve; The main valve body 11 and the main valve spring 17 at both ends are respectively offset against the main valve 23 at the bottom of the gun body cover 3 and the main valve body 11; and the auxiliary valve spring 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com