Valve control type energy recovery unit device

An energy recovery and unit device technology, which is applied in seawater treatment, permeation/dialysis water/sewage treatment, etc., can solve the problems of high switching frequency, difficulty in automatic opening and closing, low efficiency of hydraulic turbine energy recovery devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

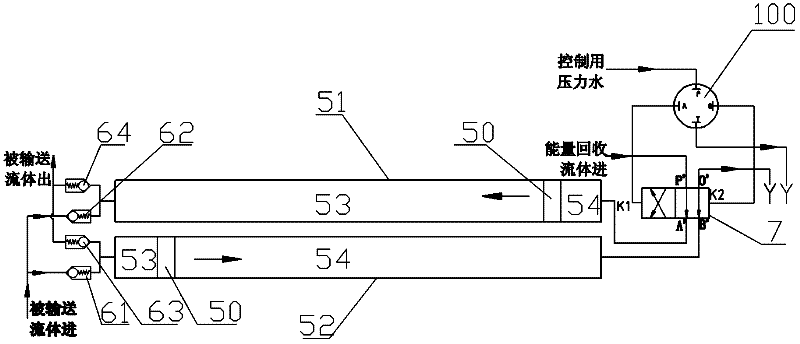

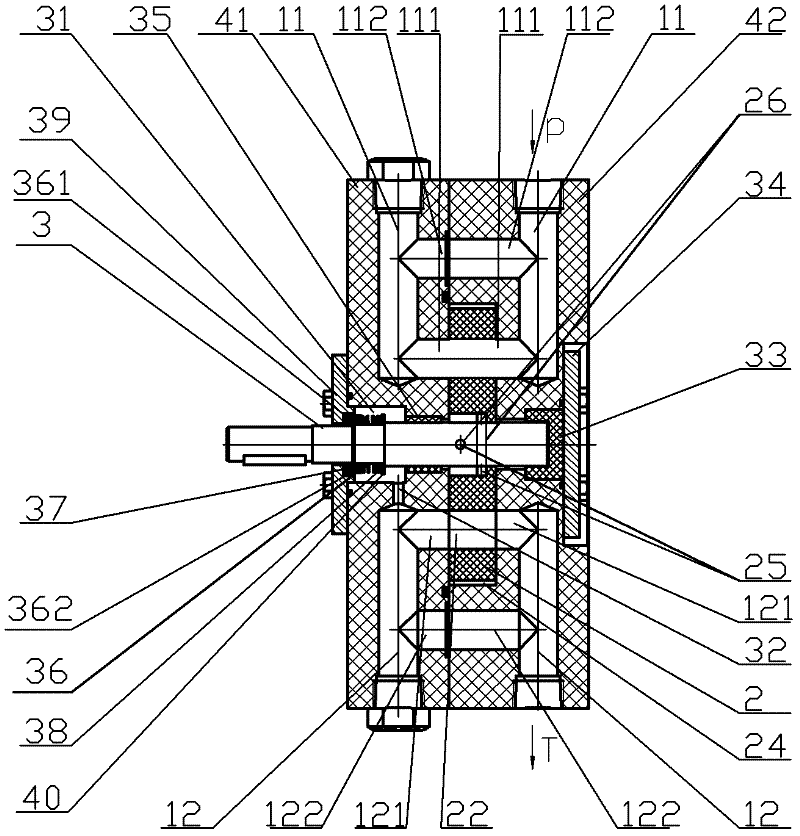

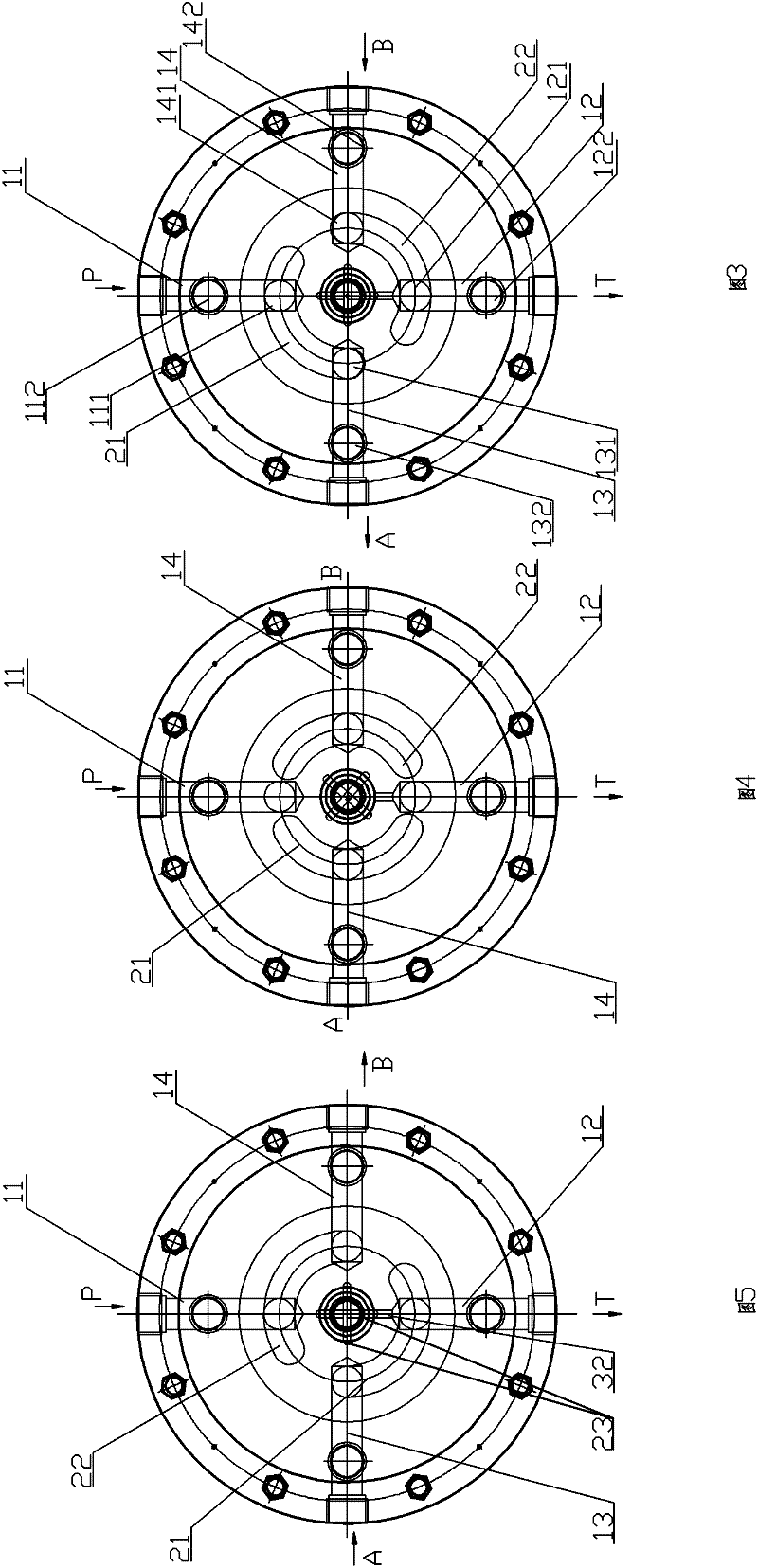

[0068] Embodiment 1, with reference to Figure 1-5 .

[0069] The present invention includes a pressure exchange tube group, the pressure exchange tube group has two pressure exchange tubes 51, 52, and the pressure exchange tube group is equipped with four one-way valves 61, 62, 63, 64 and one two-way valve. A four-way linear slide valve 7; each pressure exchange tube has a built-in free piston 50, and the pressure exchange tube is divided into two working chambers, which are the fluid working chamber 53 and the energy recovery fluid working chamber 54;

[0070] The four one-way check valves are equally divided into two groups, the directions of the two groups of one-way valves are opposite, and one group of one-way valves 61 and 62 are used as low-pressure fluid suction valves of the energy recovery device, and the low-pressure fluid is transported Fluid, such as low-pressure seawater to be desalinated; another set of one-way valves 63, 64 are used as high-pressure outlet va...

Embodiment 2

[0094] Embodiment 2, with reference to attached Figure 6-11 .

[0095] The present invention includes three sets of parallel pressure exchange tube groups, the pressure exchange tube groups have two pressure exchange tubes 51, 52, and each set of pressure exchange tube groups is equipped with four one-way valves 61, 62, 63, 64 and One three-position four-way linear slide valve 7; each pressure exchange tube has a built-in free piston 50, and the pressure exchange tube is divided into two working chambers, which are respectively the working chamber 53 for the fluid to be delivered and the working chamber 54 for the energy recovery fluid ;

[0096] The four one-way check valves are equally divided into two groups, the directions of the two groups of one-way valves are opposite, and one group of one-way valves 61 and 62 are used as low-pressure fluid suction valves of the energy recovery device, and the low-pressure fluid is transported Fluid, that is, low-pressure seawater th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com