Plug-socket integrated connector with board-to-board butting compatibility function

A technology of compatible boards and connectors, which is applied in the direction of connection, parts of connection devices, fixed/insulated contact components, etc., can solve problems such as vertical misalignment and misalignment between equipment and modules, high-precision tolerances, and large volume of finished products, etc., to achieve Effective shielding of information transmission, reduction of high-precision tolerances, and the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

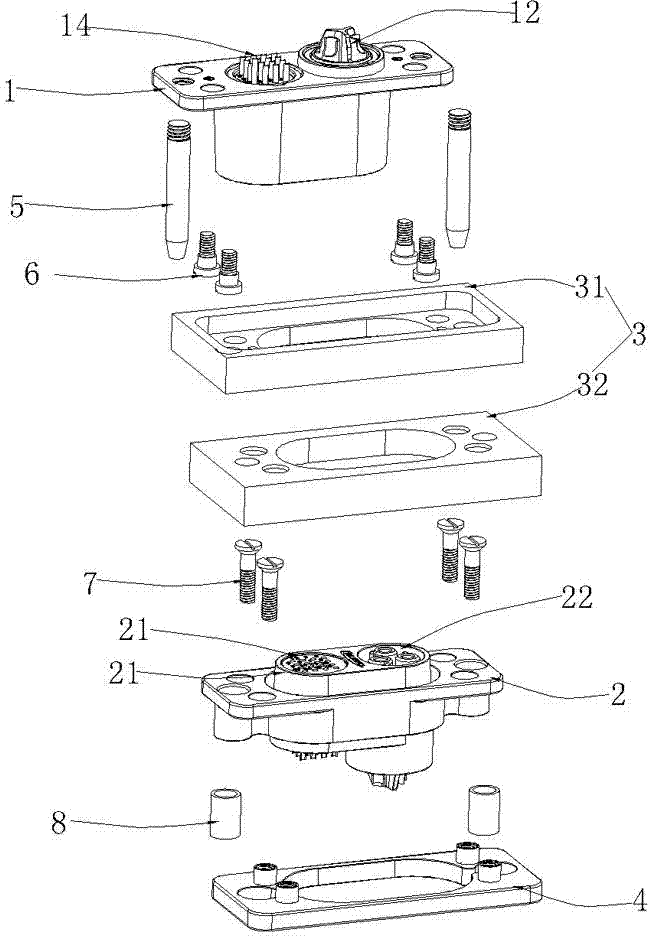

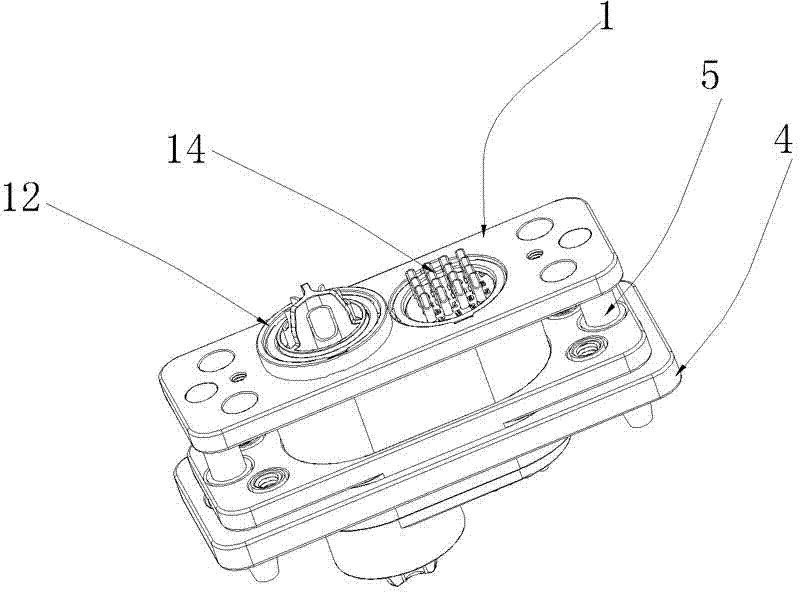

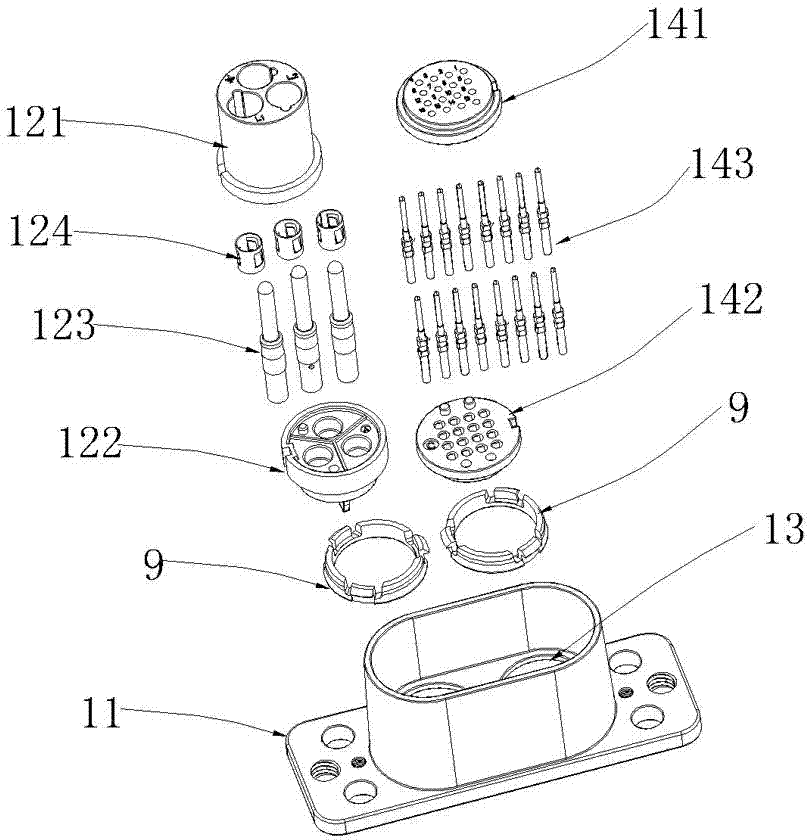

[0058] see Figure 1-4 , the plug and socket integrated connector compatible with board-to-board docking provided by the present invention includes a plug 1, a socket 2, a box body 3, a movable plate 4 for correcting the installation position between the plug 1 and the socket 2, and a plurality of The guide post 5 is symmetrically distributed and used to guide and correct the position between the plug 1 and the socket 2. The bottom end of the plug 1 penetrates the box body 3 and is fixedly connected to the socket 2, and the bottom end of the socket 2 is plugged into the movable plate 4. One end of a plurality of guide posts 5 is fixed on both sides of the plug 1, and the other end passes through the through holes on both sides of the box body 3 and the socket 2 in turn and is inserted on both sides of the movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com