Impeller

An impeller and fan blade technology, which is applied to the components of pumping devices for elastic fluids, non-variable volume pumps, machines/engines, etc., can solve the problem of large residual stress, large force on the hub disk and leaf stem, and potential safety hazards. and other problems, to achieve the effect of eliminating hidden safety hazards, small installation size and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

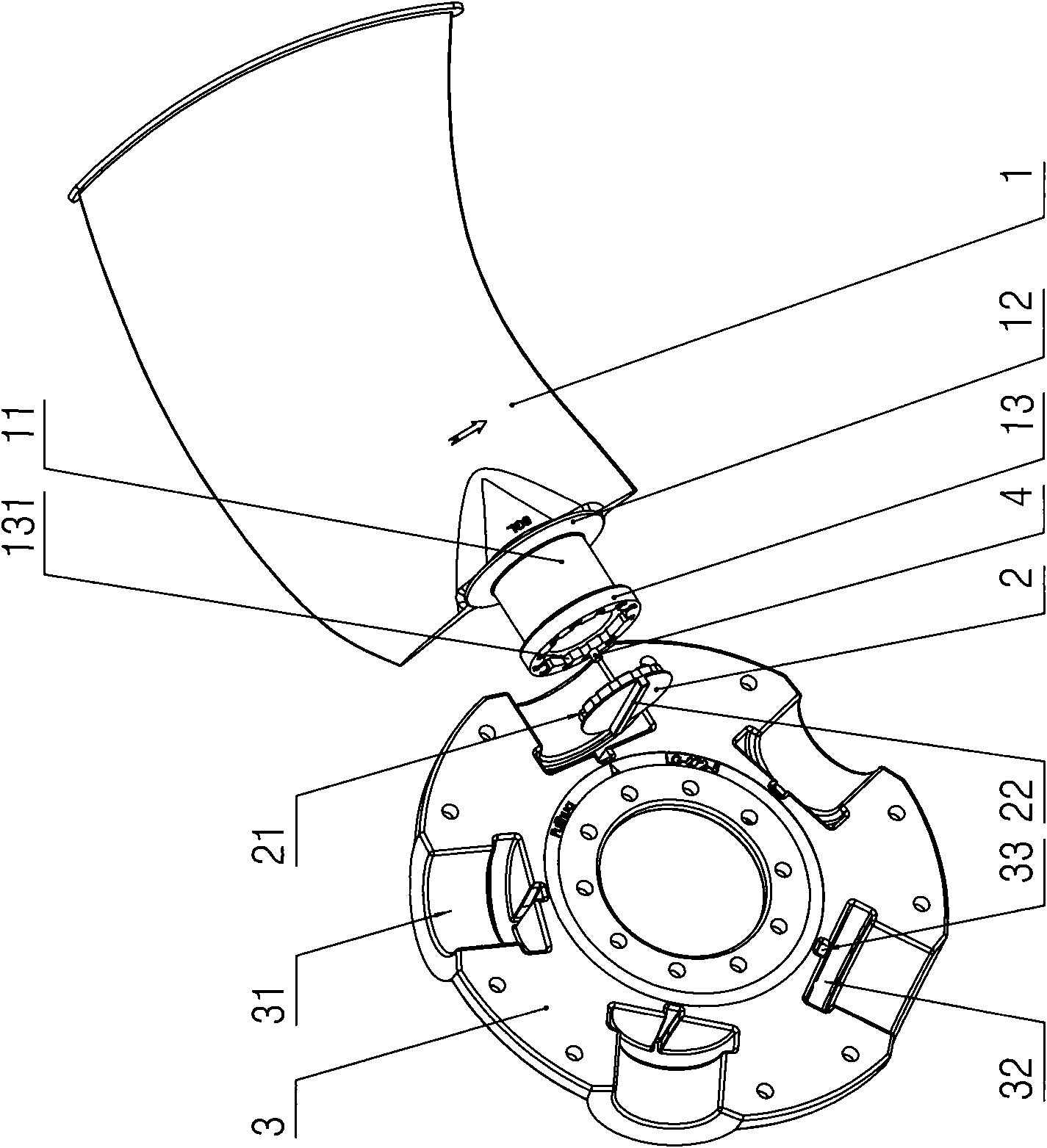

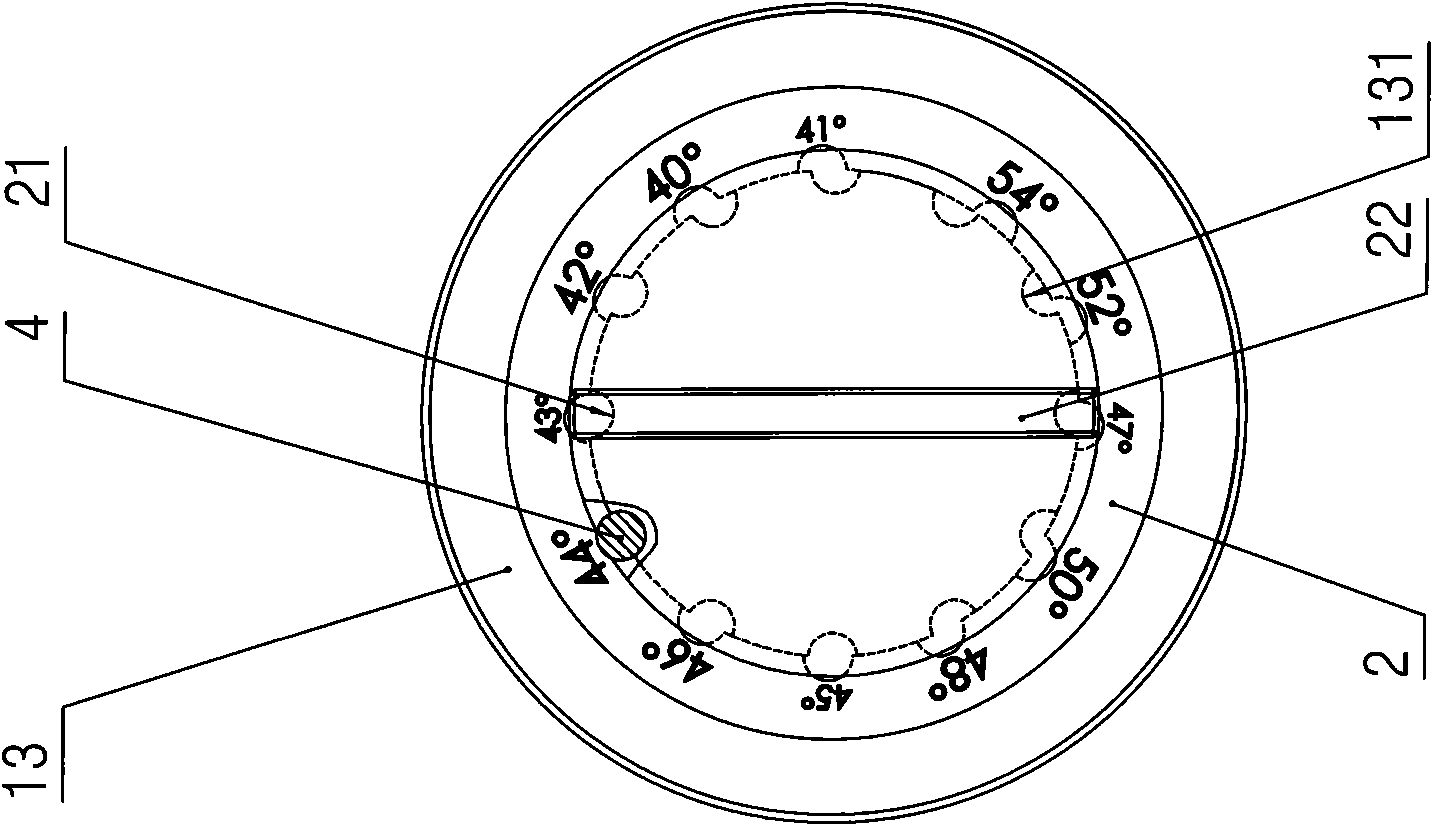

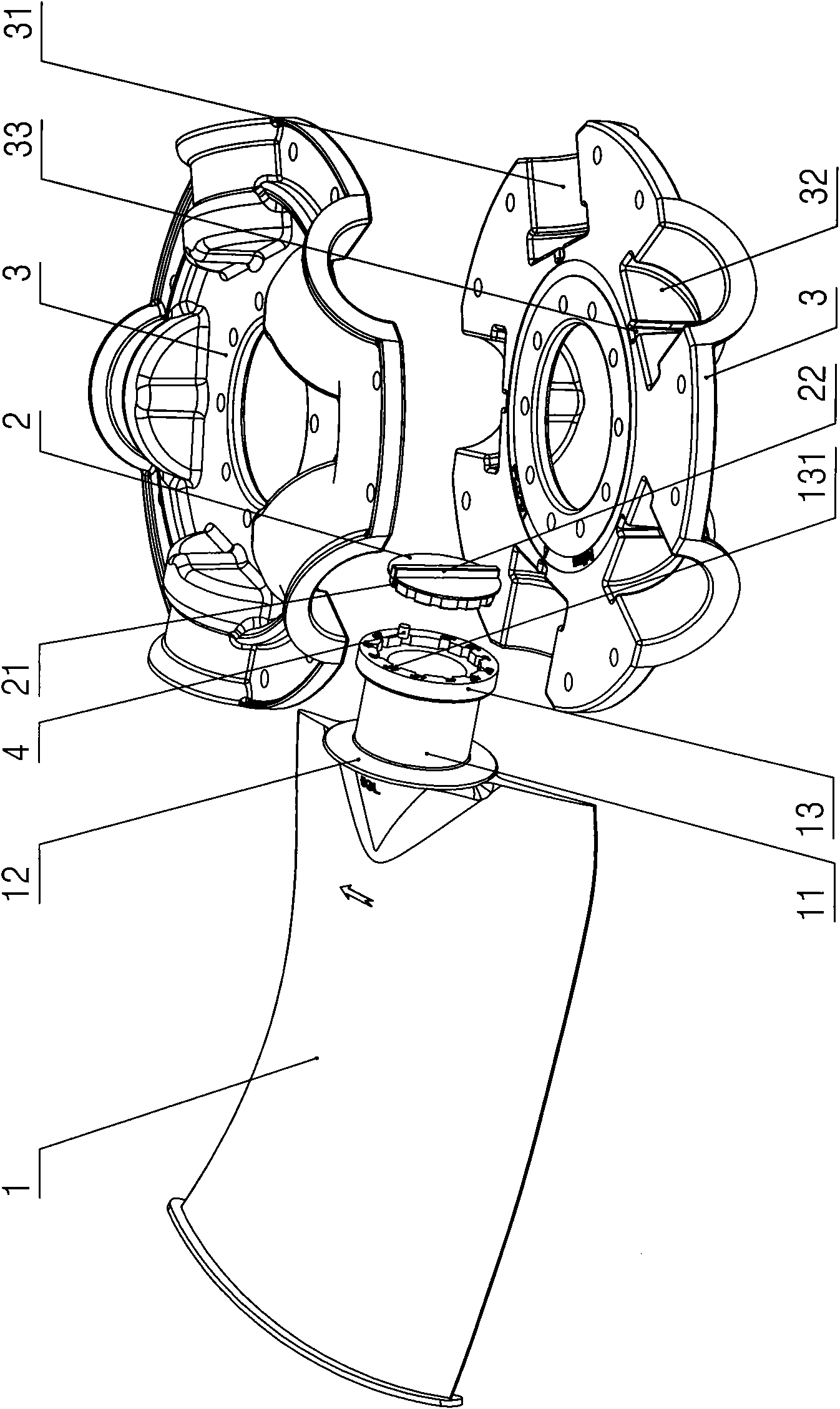

[0014] Such as figure 1 , image 3 As shown, the impeller of the present invention includes: a pair of hub discs 3, five fan blades, five positioning discs 2 and five straight pins 4, each fan blade includes: The petiole at the root, each petiole includes: a cylindrical support arm 11 and positioning edges 12 and positioning seats 13 provided with both sides of the support arm 11, forming a similar I-shaped wheel structure, such as figure 2 As shown, the outer edge of the inner end surface of the positioning disc 2 is provided with twelve equal-diameter inner semi-cylindrical grooves 21, the outer end surface of the positioning disc 2 is provided with a positioning key 22, and the end surface of the positioning seat 13 A placement cavity that matches the positioning disc 2 is provided, and an outer semi-cylindrical groove 131 corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com