Steering engine for underwater vehicle

A technology of underwater vehicles and steering gears, which is applied in directions such as rudder steering and steering. It can solve the problems of difficult to meet the requirements of shock and vibration resistance, large size of steering gears, and long response time, and achieve compact structure, reliable mechanical support and The connection and the effect of small moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

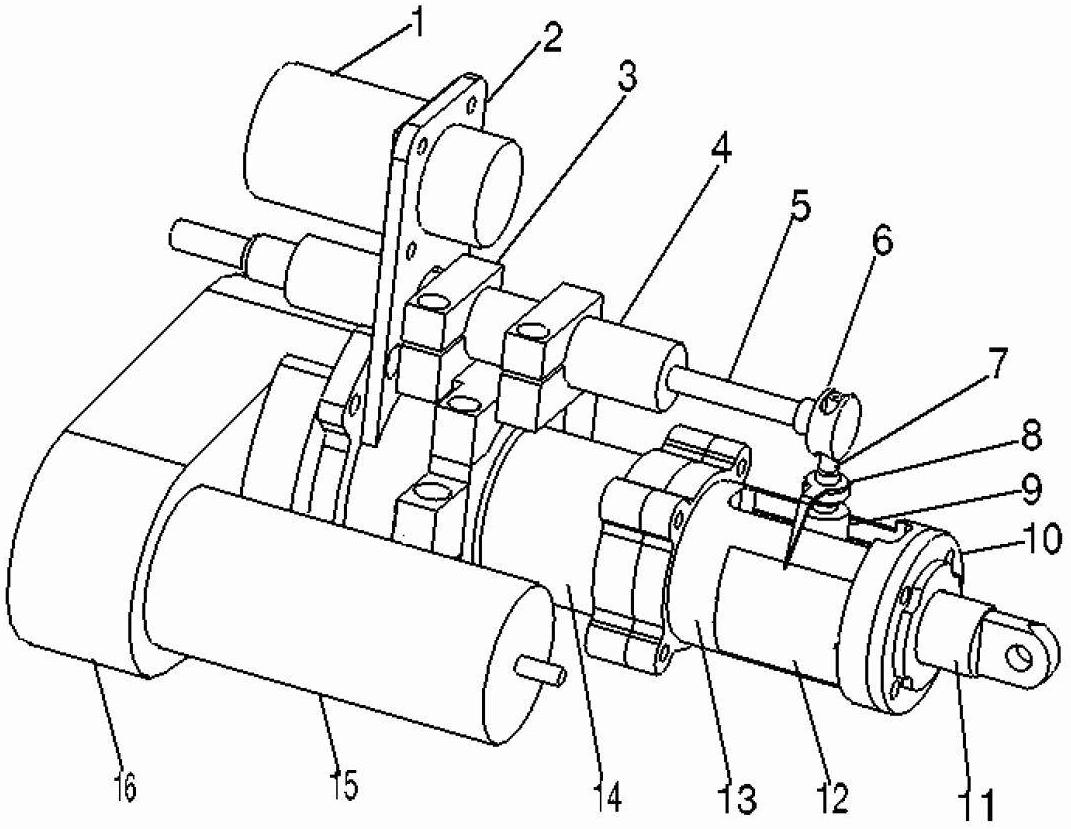

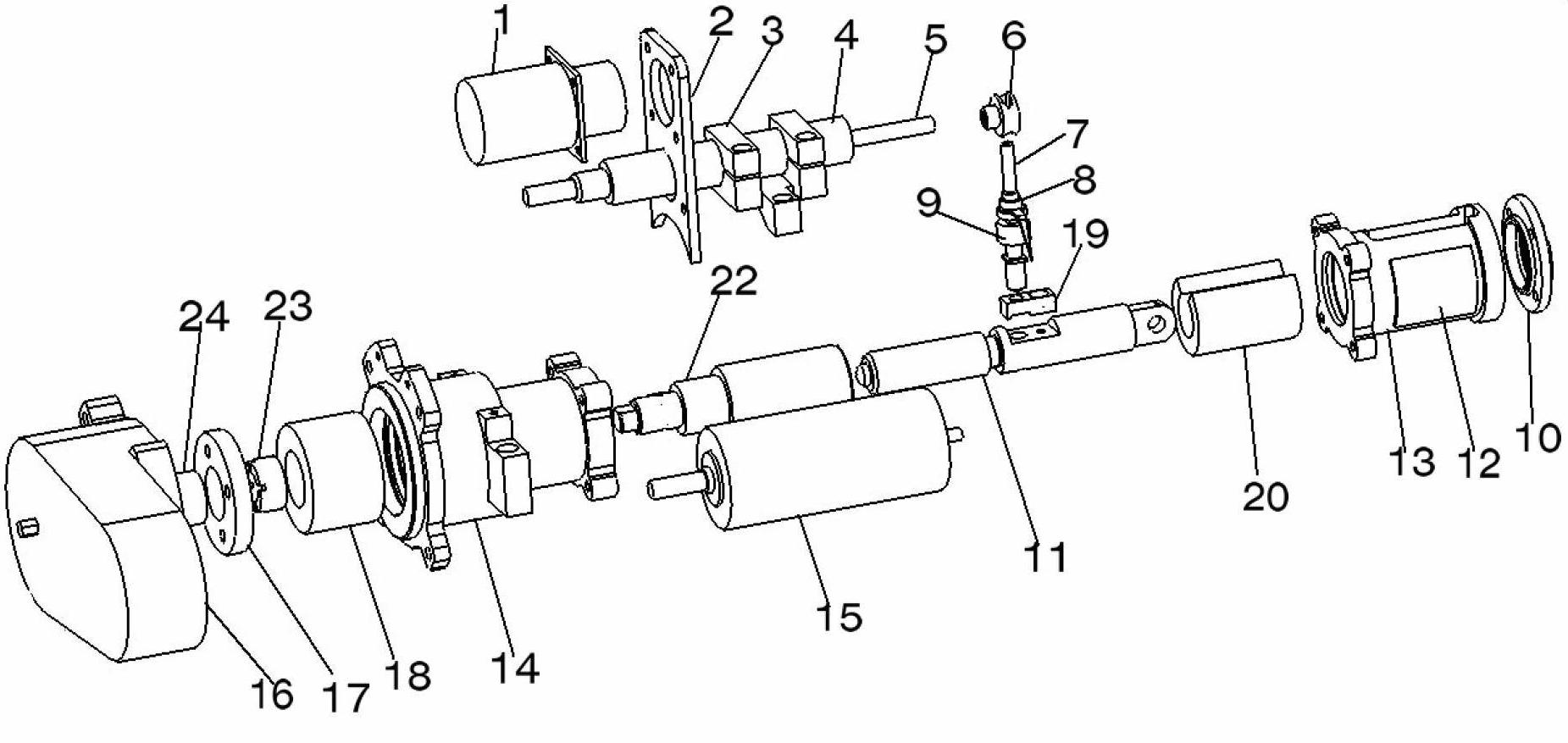

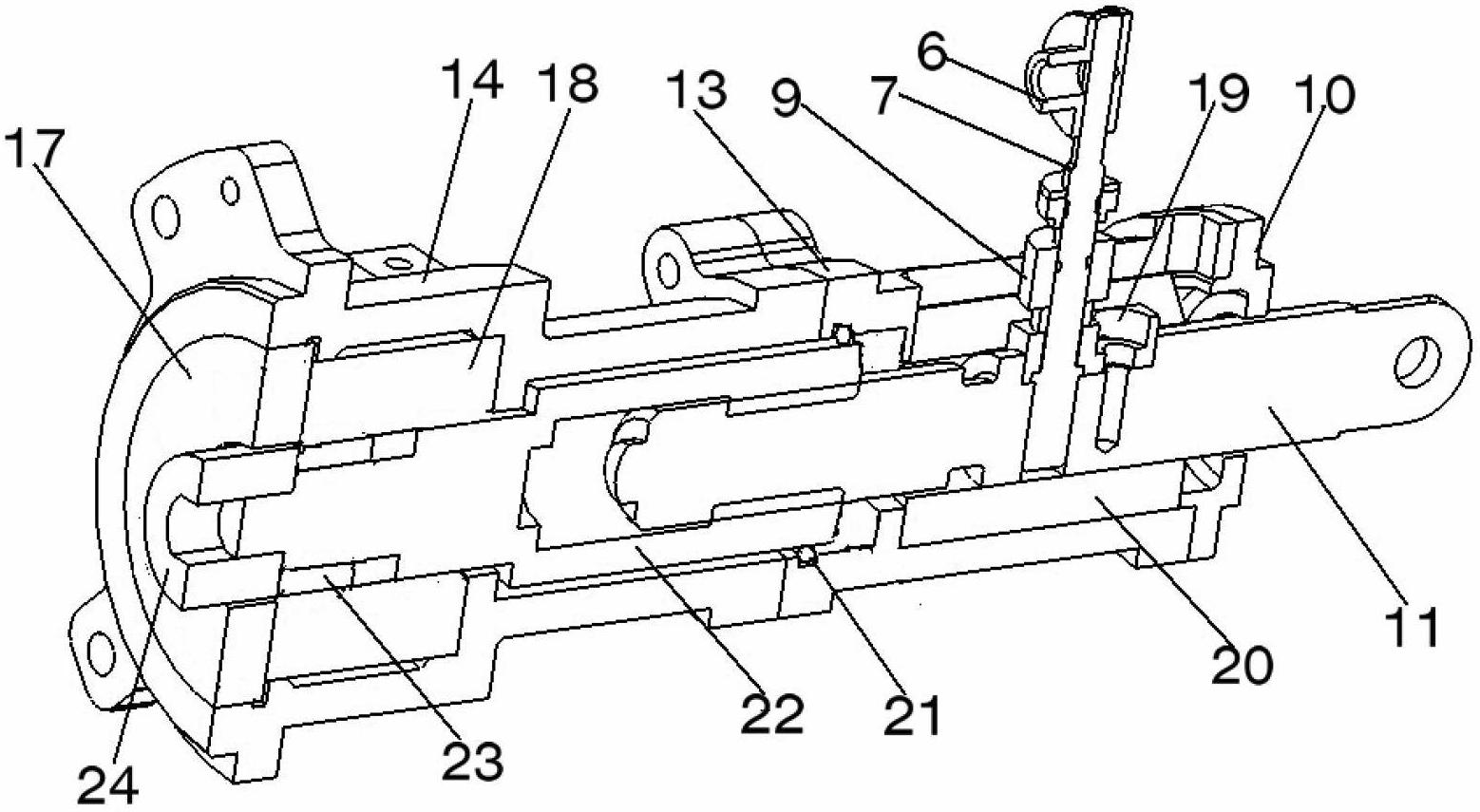

[0052] This embodiment is a steering gear for an underwater vehicle, including a connector 1, a DC motor 15, a reducer 16, a guide sleeve housing 13, a bearing housing 14, a screw nut mechanism and a position feedback assembly. and:

[0053] The lead screw and nut mechanism includes a lead screw 11 , a linear bearing 20 , a driving nut 22 and a stroke insert 19 . Wherein, the linear bearing 20 is sleeved on the lead screw 11 , and the through groove on the circumference of the linear bearing 20 corresponds to the installation groove of the position feedback component on the lead screw 11 . The driving nut 22 is also sleeved on the threaded end of the lead screw 11 . The stroke insert 19 is fixed in the position feedback component mounting groove on the lead screw 11 . The position feedback assembly includes a connecting rod 7 , a guide bearing 9 , a pointer 8 , a guide rod 5 , a sensor mounting seat 3 , a connector mounting plate 2 , a position sensor 4 and a connecting nut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com