Double-crank slide block type heavy duty vehicle rear protector

A slider-type, heavy-duty vehicle technology, applied in vehicle parts, transportation and packaging, vehicle safety arrangements, etc., can solve the problems of high cost, insufficient use effect, difficult promotion, etc., and achieve low cost, light weight, strong strength. promotional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

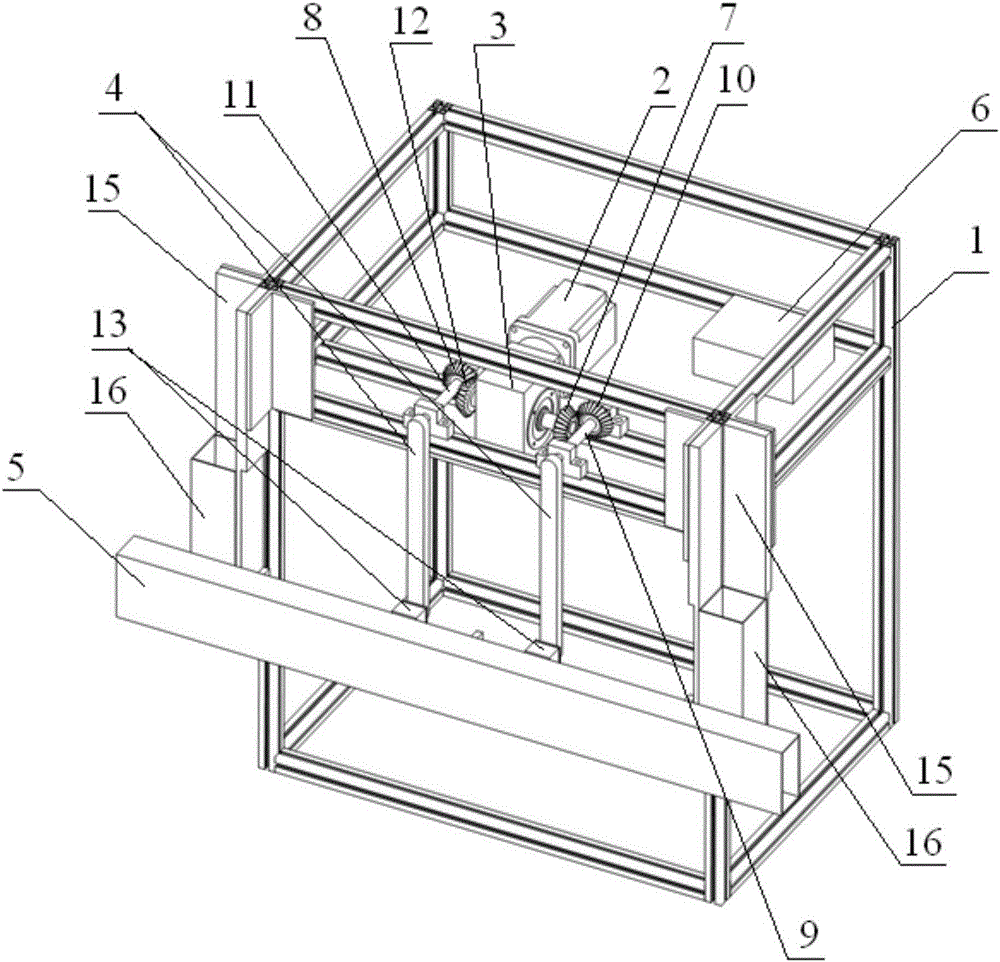

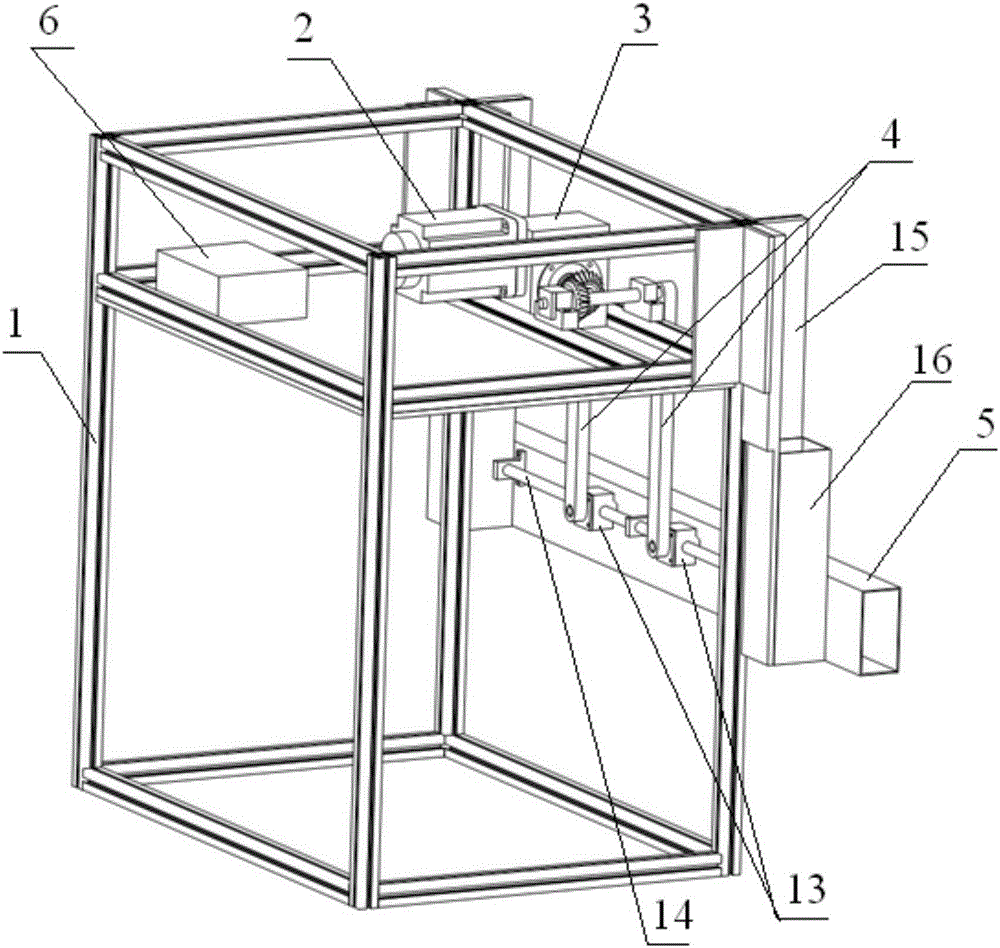

[0020] see figure 1 with figure 2 Shown:

[0021] The double-crank slider type heavy-duty vehicle rear protection device provided by the present invention includes a frame body 1, a drive motor 2, a reducer 3, a crank 4, a bumper 5 and a controller 6, wherein sliding devices are provided on both sides of the frame body 1 , the two ends of the bumper 5 are fixed on the sliding device, and the bumper 5 can slide up and down along both sides of the frame body 1 through the sliding device. The two ends of the output shaft of the reducer 3 are respectively provided with a first bevel gear 7 and a second bevel gear 8, wherein the first bevel gear 7 meshes with the third bevel gear 10 at the rear end of the first transmission shaft 9, The second bevel gear 8 meshes with the fourth bevel gear 12 at the rear end of the second transmission shaft 11, and two cranks 4 are provided, and the upper ends of the two cranks 4 are respectively fixed on the front ends of the first transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com