Bidirectional sealing strip and oil-immersed transformer with same

An oil-immersed transformer, bidirectional sealing technology, applied in transformer/inductor casing, transformer/inductor cooling, transformer/inductor components, etc., can solve problems such as sealing failure, transformer failure, and airtight container suction, etc., to achieve The effect of solving the leakage problem, improving the service life and working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

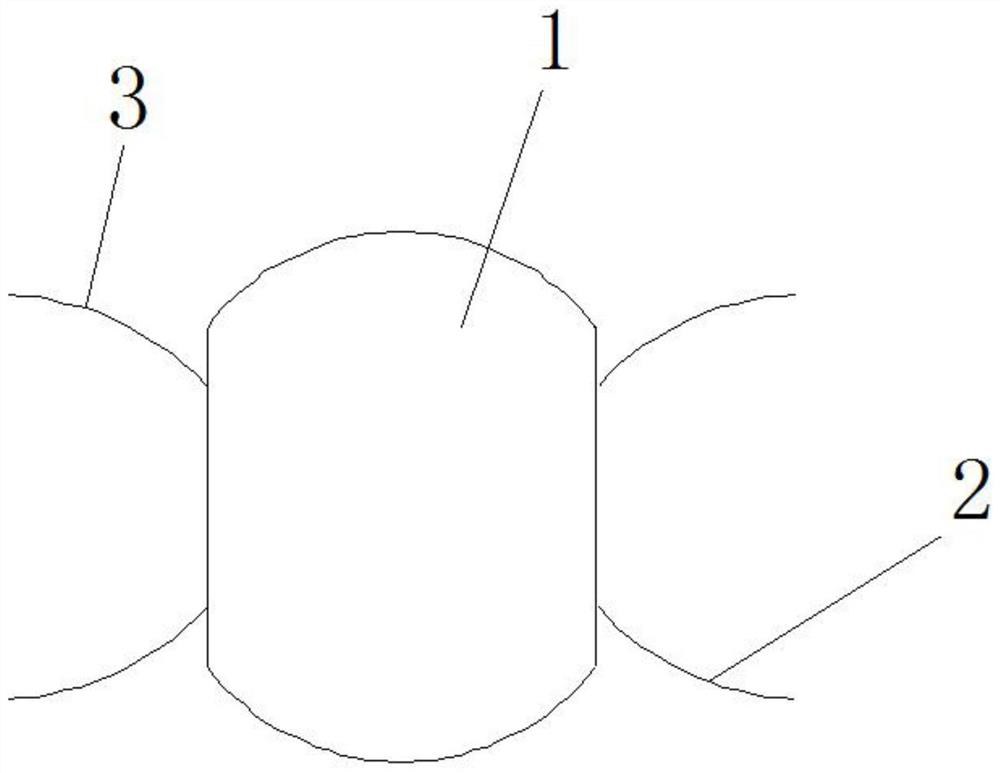

[0027] Such as figure 1 As shown, a two-way sealing strip includes a sealing strip body 1, and a forward elastic sealing portion 3 and a reverse elastic sealing portion 2 are respectively extended on both sides of the sealing strip body 1.

[0028] Preferably, both the forward elastic sealing portion 3 and the reverse elastic sealing portion 2 are arc-shaped sealing portions 2 .

[0029] Preferably, the outer layers of the sealing strip body 1 , the forward elastic sealing portion 3 and the reverse elastic sealing portion 2 are all provided with UV-resistant and oil-resistant coatings.

[0030] Preferably, both the forward elastic sealing part 3 and the reverse elastic sealing part 2 are arc-shaped sealing parts 2 are integrally formed of silicone material through an injection molding machine.

[0031] Compared with the existing technology, the present invention has the following advantages: the bidirectional sealing strip of this patent can realize bidirectional sealing. Un...

Embodiment 2

[0033] An oil-immersed transformer with a two-way sealing ring, including a transformer oil tank, a transformer box edge is welded on the top of the transformer oil tank, an upper cover plate is fixed above the transformer box edge, an insulator is arranged on the top of the upper cover plate, and an insulator is arranged on the top of the transformer box edge. There is a block groove at the top, and a sealing groove for installing a two-way sealing ring is opened on the inner side of the block groove at the top of the transformer box edge. The sealing ring includes a sealing ring body 1 and positive elastic seals on both sides of the sealing ring body 1 Part 3 and reverse elastic sealing part 2, the shape of the sealing groove corresponds to the shape of the two-way sealing ring.

[0034] Preferably, a sealing gasket is glued and connected in the block groove.

[0035] Preferably, both the forward elastic sealing portion 3 and the reverse elastic sealing portion 2 are C-shape...

Embodiment 3

[0040] An anti-leakage fully sealed transformer, including a transformer oil tank cover and a transformer oil tank body, and also includes:

[0041] The first two-way sealing ring, the first two-way sealing ring is arranged at the junction of the transformer oil tank body and the transformer oil tank cover, and the two sides of the first two-way sealing ring are respectively extended with a forward elastic sealing part 3 and a reverse elastic sealing part 2;

[0042] The second two-way sealing ring, the second two-way sealing ring is arranged at the junction of the transformer low-voltage bushing and the transformer oil tank cover, and the positive elastic sealing part 3 and the reverse elastic sealing part 2 are respectively extended on both sides of the third two-way sealing ring;

[0043] The third two-way sealing ring, the third two-way sealing ring is arranged at the connection between the transformer high-voltage bushing and the transformer oil tank cover, and the two sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com