Compressor input shaft sealing structure

A technology of sealing structure and input shaft, applied in the field of compressors, can solve the problems of increased maintenance cost, waste of manpower, low maintenance efficiency, etc., and achieve the effects of reducing maintenance cost, saving manpower and improving sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

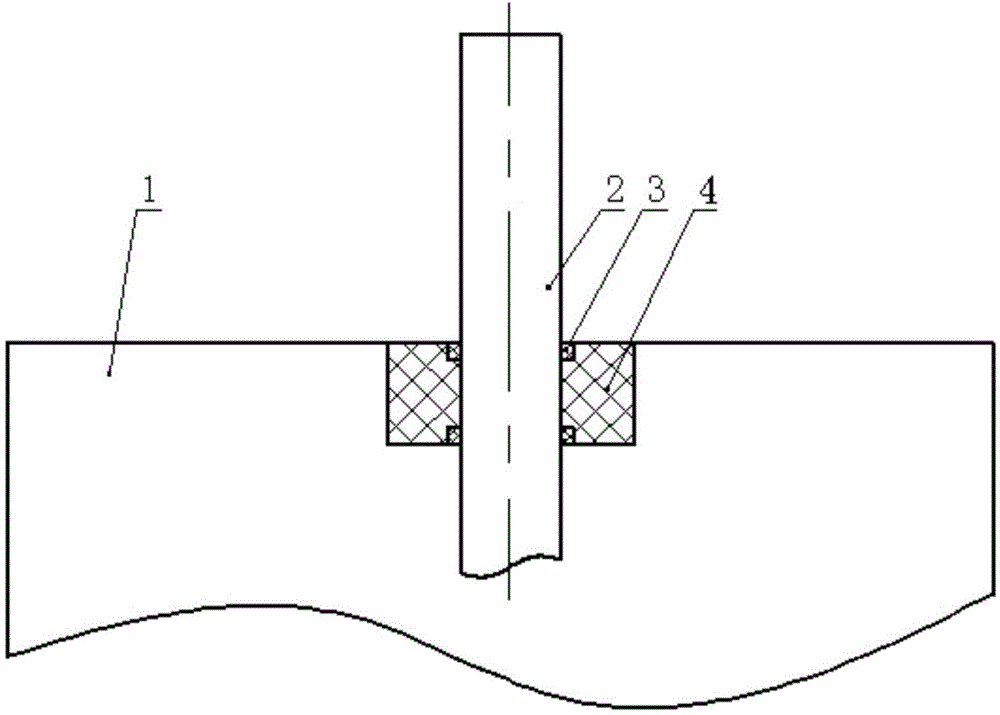

[0015] A compressor input shaft seal structure, such as figure 1 As shown, it includes a compressor body 1 and an input shaft 2, which is installed on one side of the compressor body.

[0016] The innovation point of the present invention is:

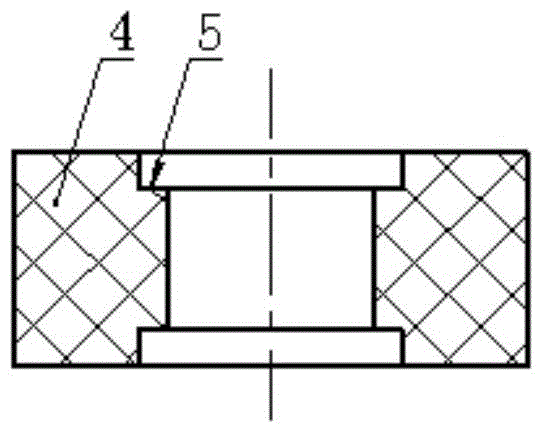

[0017] A shaft sleeve 4 is coaxially sealed between the input shaft and the compressor body, and the structure of the shaft sleeve is as follows: figure 2 As shown, the upper and lower end surfaces of the shaft sleeve are respectively formed with an annular groove 5 for accommodating the sealing ring 3 .

[0018] In this embodiment, the sleeve is made of polytetrafluoroethylene.

[0019] Advantage effect of the present invention is:

[0020] The invention effectively improves the sealing effect o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com