Programmable micro-valve device and control method for micro-flow transportation by using programmable micro-valve device

A micro-valve and micro-fluid technology, which is used in laboratory containers, chemical instruments and methods, laboratory utensils, etc., can solve the problems of leakage between the micro-valve and the micro-channel, and achieves a solution that facilitates organic integration and solves leakage problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

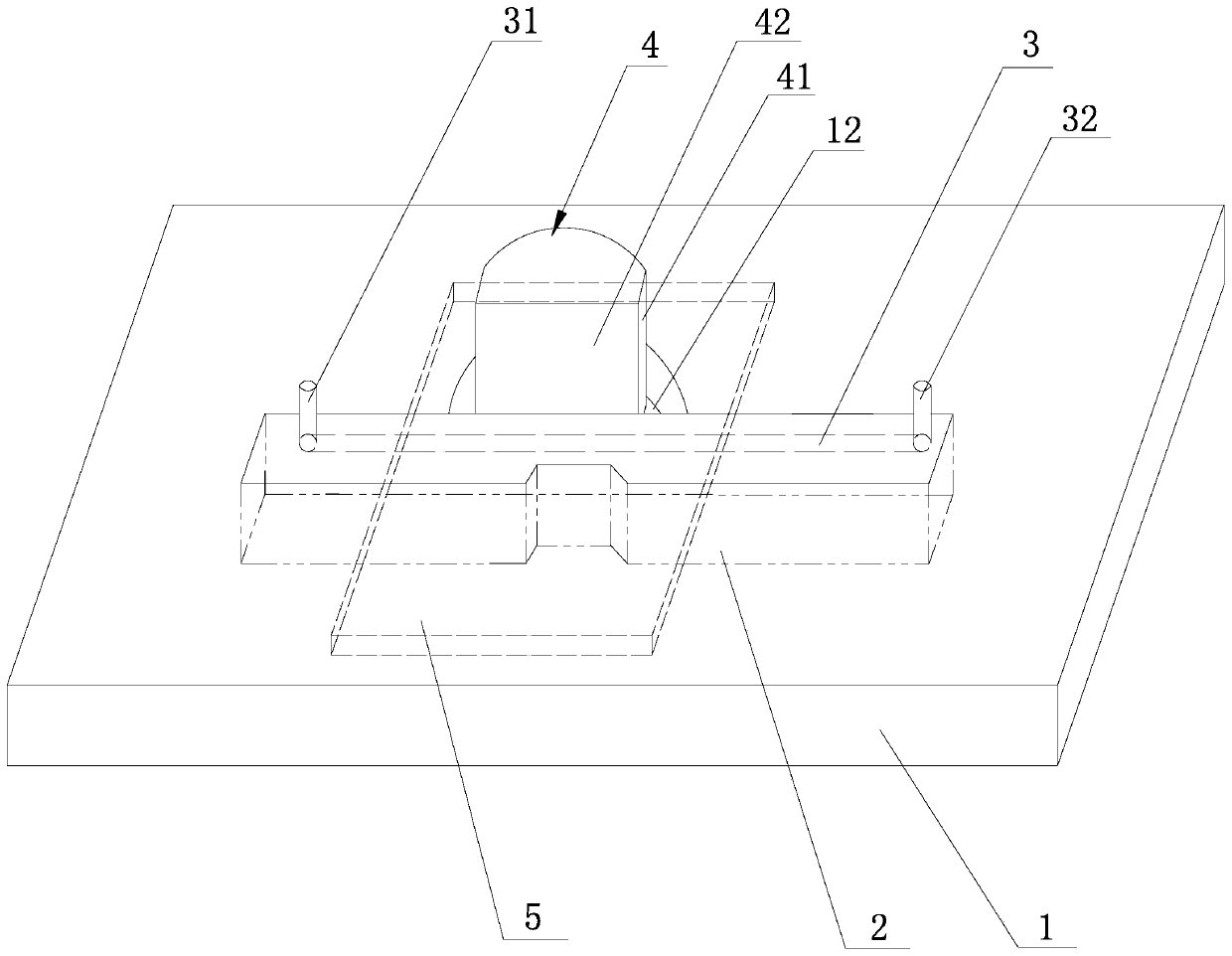

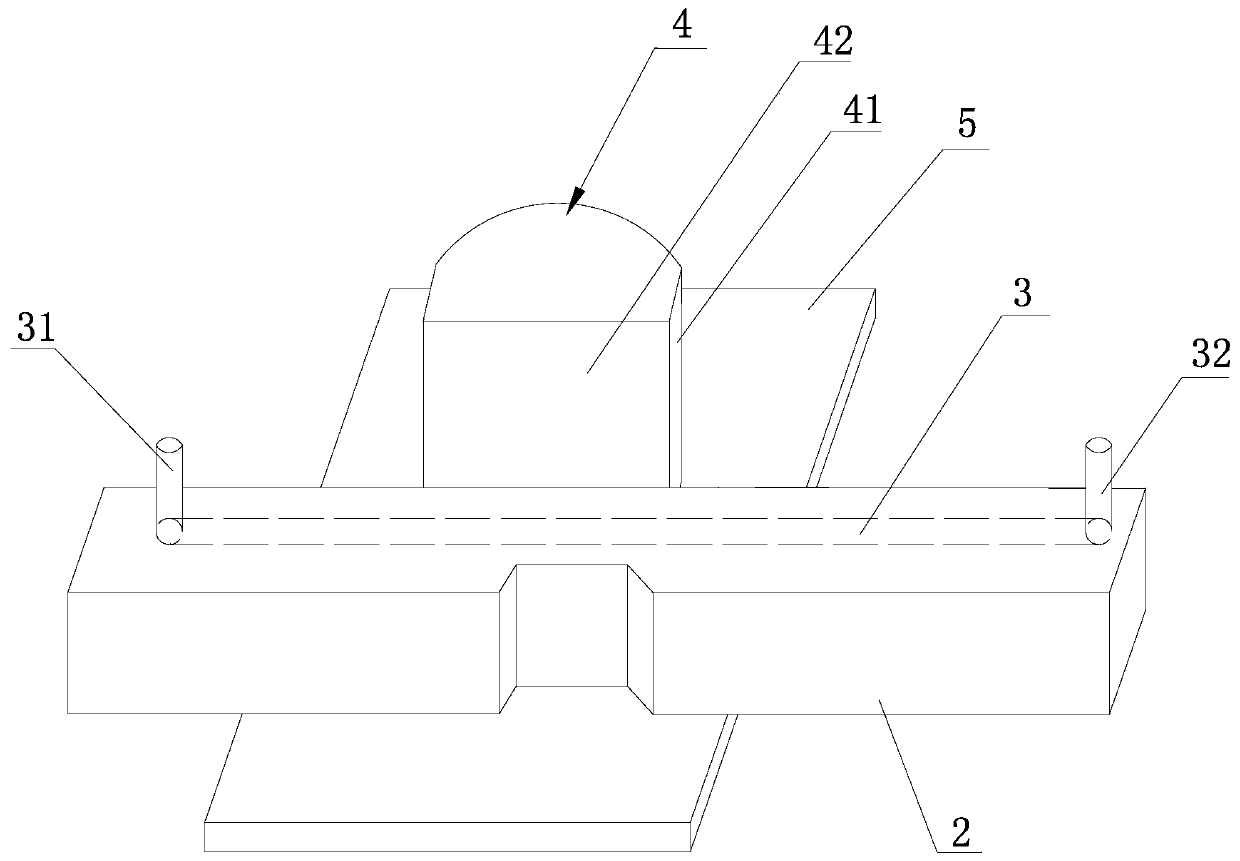

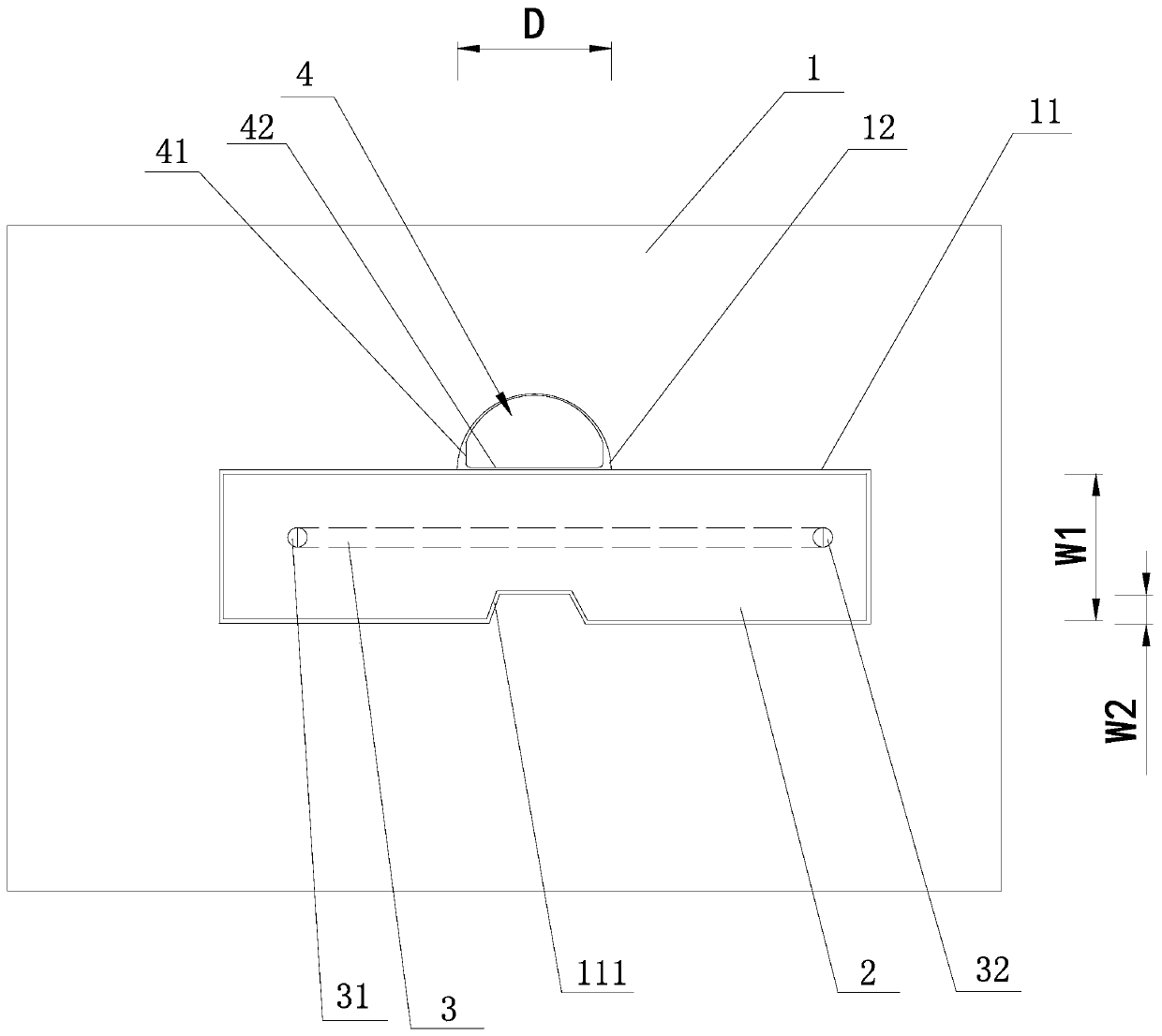

[0022] A programmable microvalve device proposed in this embodiment, as shown in the figure, includes a printed circuit board 1, and the printed circuit board 1 is hollowed out up and down with a concave part 111 on one side in the width direction. A rectangular hole 11 and a shaft hole 12, the shaft hole 12 is close to the other side of the width direction of the rectangular hole 11 and communicates with the rectangular hole 11, the position of the shaft hole 12 is directly opposite to the position of the concave part 111, the rectangular hole 11 is embedded with a PDMS cured body 2 that is compatible with the rectangular hole 11. The PDMS cured body 2 is provided with a microchannel 3 along the length direction, and a rotating rod 4 is vertically placed in the shaft hole 12. The rotating rod 4 is initially When the microchannel 3 is unblocked, the programmable microvalve device is in the open state; the rotating rod 4 is rotated 90 degrees to squeeze the PDMS solidified body ...

Embodiment 2

[0029] This embodiment proposes a control method for microfluidic transport using the programmable microvalve device of Embodiment 1, which includes the following steps:

[0030] The microfluid is injected through the inlet 31 of the microchannel 3, and the microfluid flows towards the outlet 32 of the microchannel 3; if the operator decides to close the programmable microvalve device, the operator rotates the rotating rod 4 clockwise or counterclockwise to make it Rotate 90 degrees, at this time the side plane 41 of the rotating rod 4 is in contact with one side in the width direction of the PDMS cured body 2, the rotating rod 4 squeezes the PDMS cured body 2, and the concave part 111 is facing the semi-cylindrical hole, that is, rotates The side plane 41 of the rod 4 faces the protruding part corresponding to the concave part 111 on the printed circuit board 1. Under the action of the rotating rod 4 and the protruding part on the printed circuit board 1, the deformation of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com