Seal rotary ball valve with anti-loose press ring and valve seat capable of floating in single direction

A technology of rotary ball valve and valve seat, which is applied in the direction of the cock including the cut-off device, the operation/release device of the valve, and the details of the valve, which can solve the problems of large shape, two-way sealing, and difficulty in manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

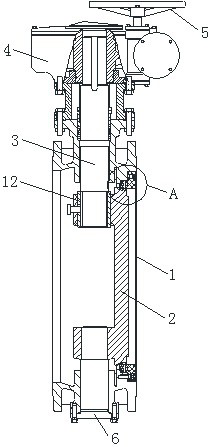

[0018] Such as figure 1 with 2 As shown, the present invention includes a valve body 1 and a valve plate 2, the valve plate 2 is located inside the valve body 1, a valve stem 3 is installed inside the valve body 1, and a driving device 4 is installed on the upper part of the valve body 1 , the top of the driving device 4 is equipped with a handwheel 5, the upper end of the valve stem 3 is connected to the driving device 4, the lower end of the valve stem 3 is connected to the upper end of the valve plate 2, and the bottom end of the valve body 1 A sealing base 6 is fixedly installed;

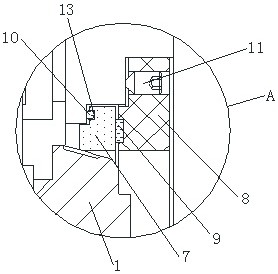

[0019] A valve seat 7 is arranged inside the valve body 1, and the valve seat 7 is located on the top of the valve plate 2. A pressure ring 8 is embedded in one side of the valve body 1, and the pressure ring 8 is located on the top of the valve seat 7. On the outside, the side of the valve seat 7 close to the pressure ring 8 is fixedly connected with a first sealing ring 9, and the first seal...

Embodiment 2

[0022] Such as figure 1 with 2 As shown, the present invention includes a valve body 1 and a valve plate 2, the valve plate 2 is located inside the valve body 1, a valve stem 3 is installed inside the valve body 1, and a driving device 4 is installed on the upper part of the valve body 1 , the top of the driving device 4 is equipped with a handwheel 5, the upper end of the valve stem 3 is connected to the driving device 4, the lower end of the valve stem 3 is connected to the upper end of the valve plate 2, and the bottom end of the valve body 1 A sealing base 6 is fixedly installed;

[0023] A valve seat 7 is arranged inside the valve body 1, and the valve seat 7 is located on the top of the valve plate 2. A pressure ring 8 is embedded in one side of the valve body 1, and the pressure ring 8 is located on the top of the valve seat 7. On the outside, the side of the valve seat 7 close to the pressure ring 8 is fixedly connected with a first sealing ring 9, and the first seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com