Anti-tensile high-voltage electric box hose coupler

A high-voltage electric box and hose joint technology, which is applied in the direction of cable joints, hose connection devices, pipes/pipe joints/pipe fittings, etc., can solve the problems of poor overall effect, general sealing performance, and increased maintenance frequency, and achieve The effect of safe and reliable use, perfect overall function and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

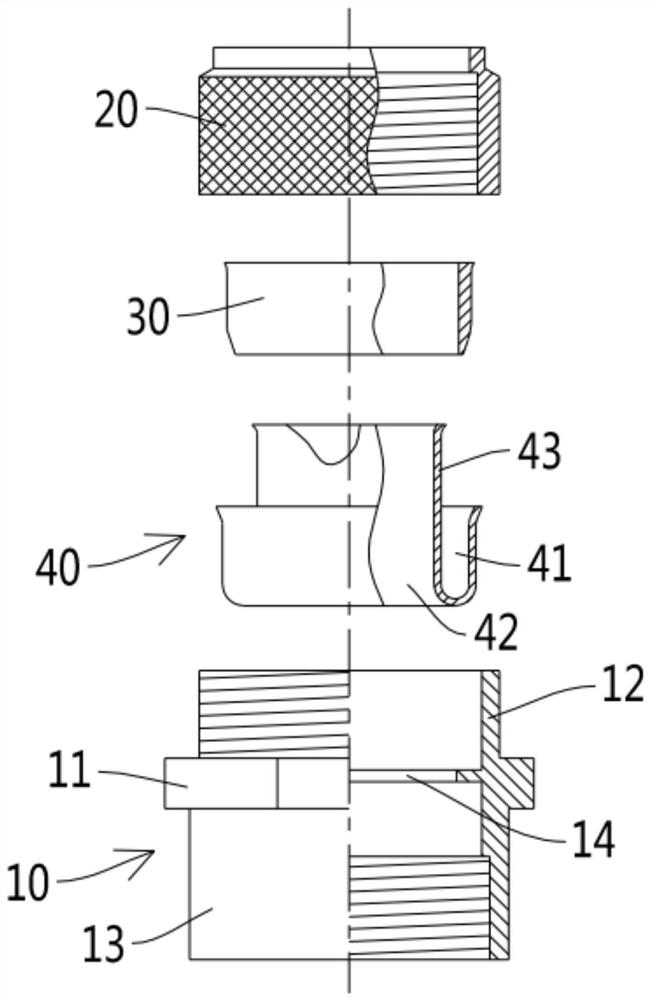

[0021] see Figures 1 to 3 As shown, a kind of tension-type high-voltage electrical box hose joint involved in this embodiment includes a main radial pipe 10 with a first knob part 11 at the waist, and one end of the main radial pipe 10 has a threaded outer surface. The first connecting end 12, the other end of the main web 10 has a second connecting end 13 with an internal thread on the inner surface, the first connecting end 12 is threadedly connected with a tightening nut 20, and the tightening nut 20 and the first coupling end 12 are provided with a clamping ring 30 and a hose sheath 40, the hose sheath 40 is embedded in the first coupling end 12, and the hose sheath 40 includes an outer bowl 41 , The bottom of the outer bowl 41 is provided with a bowl mouth 42 , and a bowl pipe 43 extends from the bowl mouth 42 , and the clamping snare 30 is on the bowl pipe 43 and embedded in the outer bowl 41 .

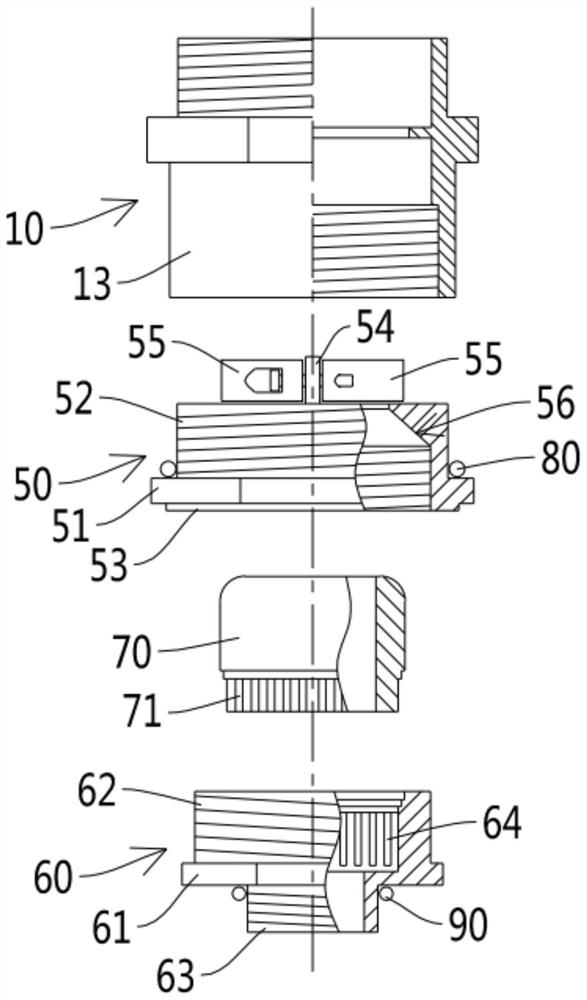

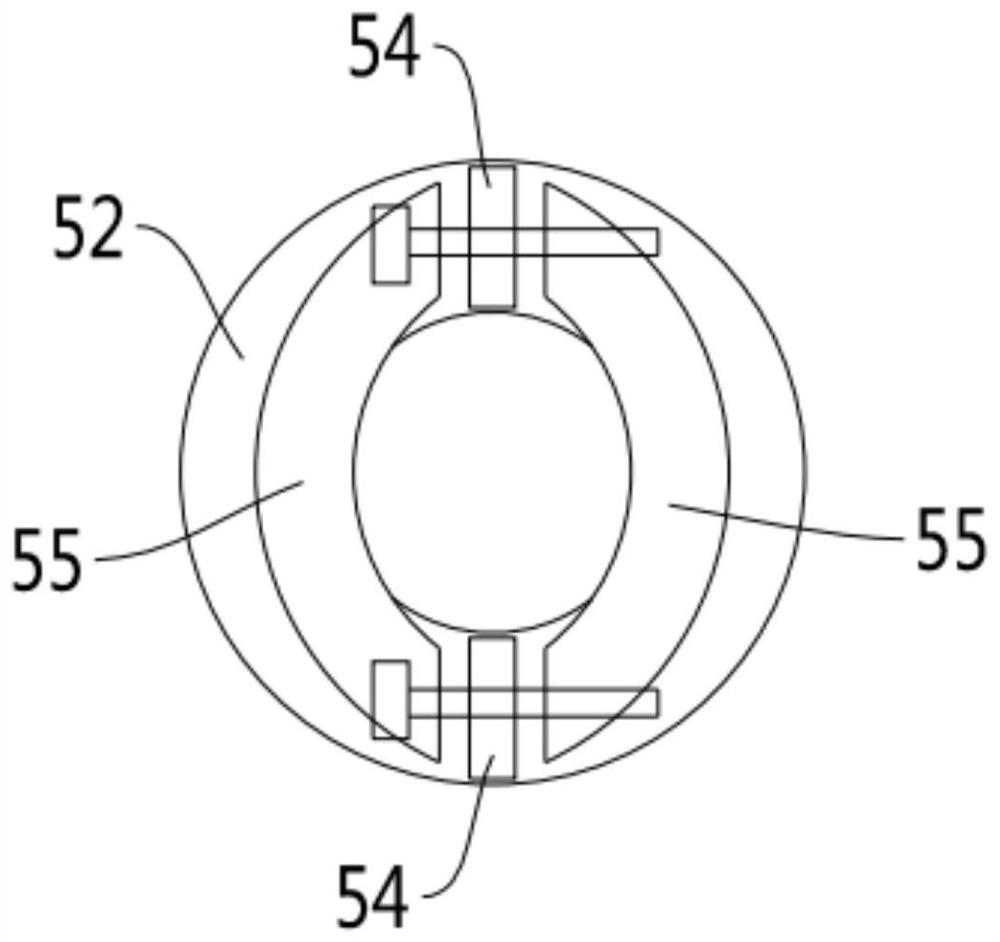

[0022] Further, the second coupling end 13 is threadedly connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com