Ultralow-temperature high-bearing bidirectional sealing device

A two-way sealing, high load-bearing technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of short life of the shaft hole sealing structure, short life of the sealing structure, poor processing technology, etc., and achieve low cost and simple assembly , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to improve the pressure adaptability of the existing shaft hole sealing structure and improve its ultra-low temperature characteristics, the present invention provides an ultra-low temperature and high-load bidirectional sealing device. The partial structure of the moving shaft hole seal can be used, which can improve the sealing performance of the existing common ultra-low temperature structures that require shaft hole sealing, and can work in a larger pressure range and can also be used at lower temperatures.

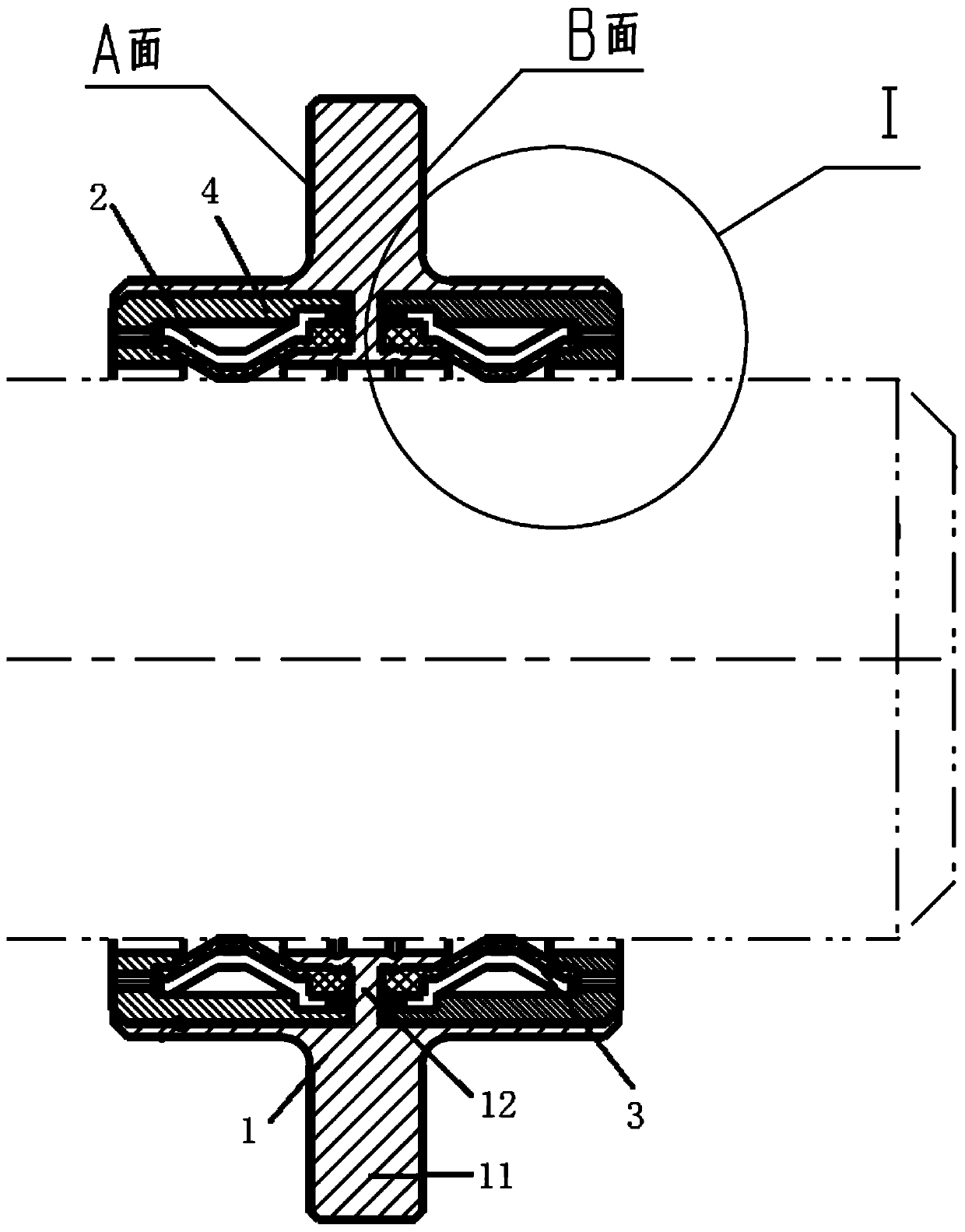

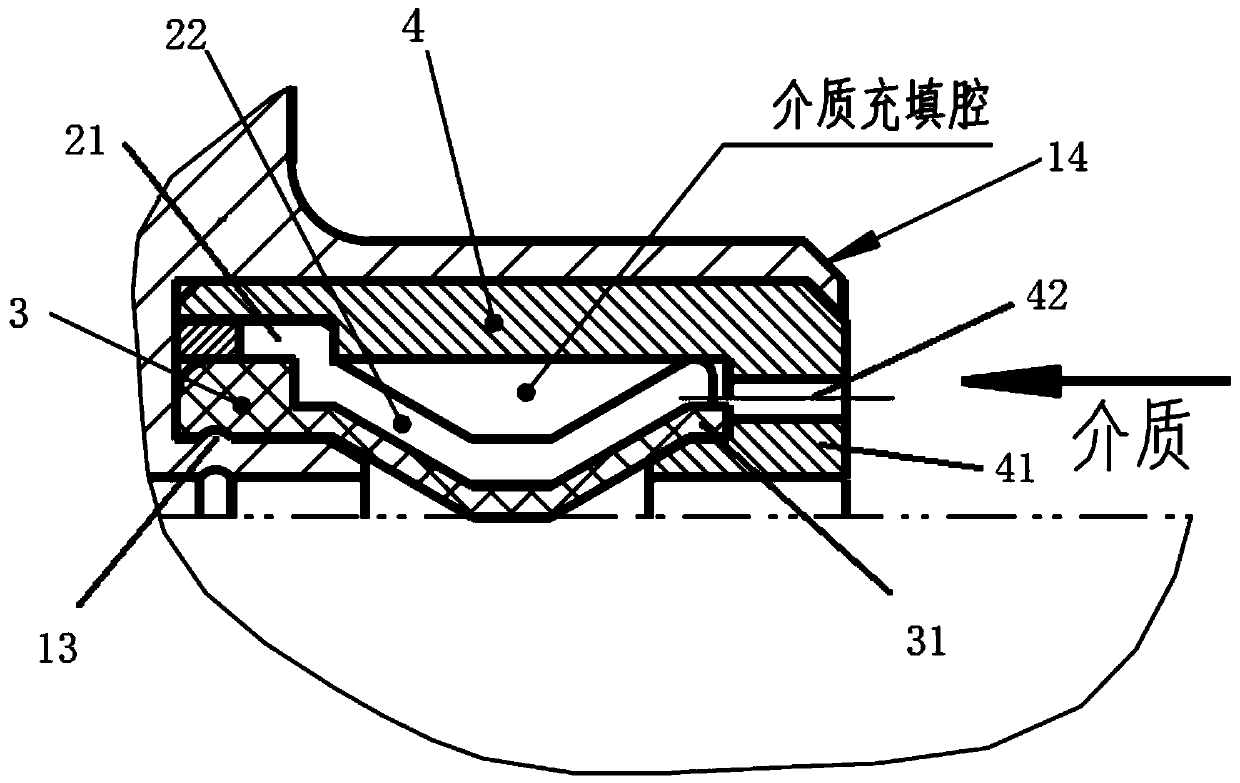

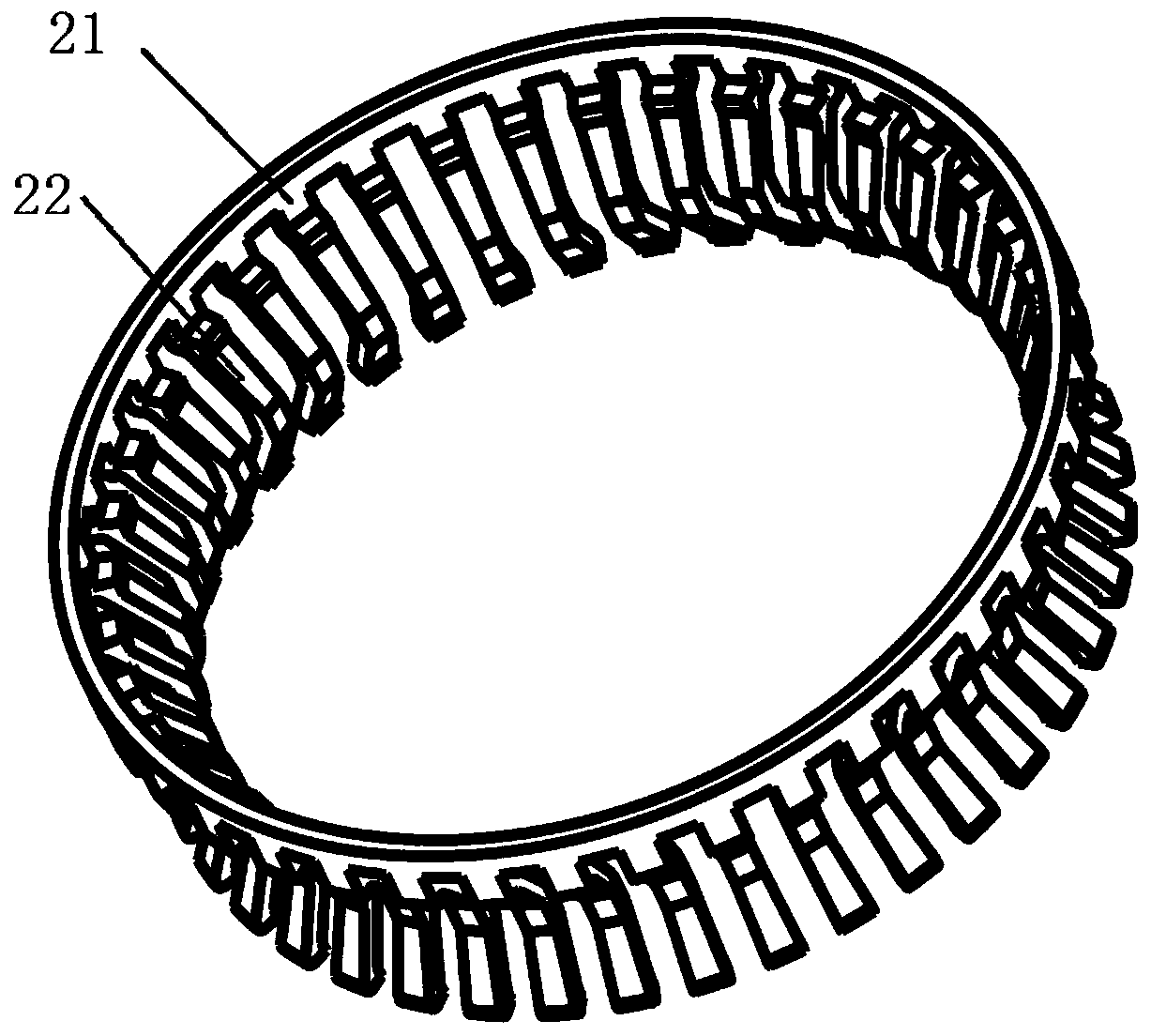

[0019] like Figure 1 to Figure 3 As shown, the ultra-low temperature and high load-bearing bidirectional sealing device provided by the present invention includes a sealing frame 1 and two sets of dynamic sealing units. The dynamic sealing unit includes a spring sheet 2, a plastic ring 3 and a pressing sleeve 4; the sealing frame 1 is a sleeve structure, an annular sealing plate 11 is provided on the outer end surface of the sleeve, and the two end su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com