Sleeve valve

A sleeve valve and outer cylinder technology, which is applied in the direction of valve device, engine seal, engine components, etc., can solve the problems of ineffective two-way sealing and easy outflow.

Active Publication Date: 2012-09-26

JIANGSU TIANYU ENVIRONMENTAL PROTECTION GRP CO LTD

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

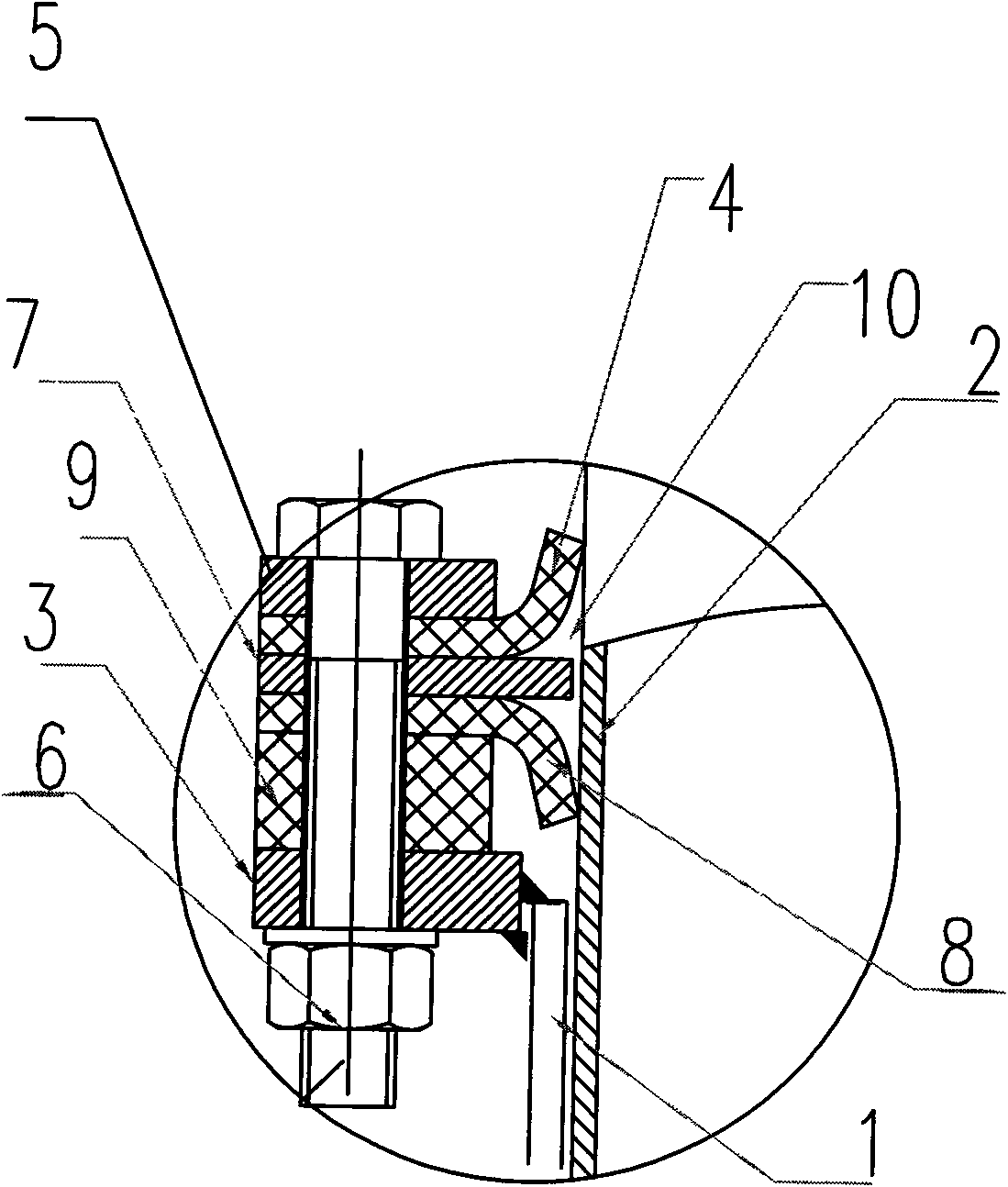

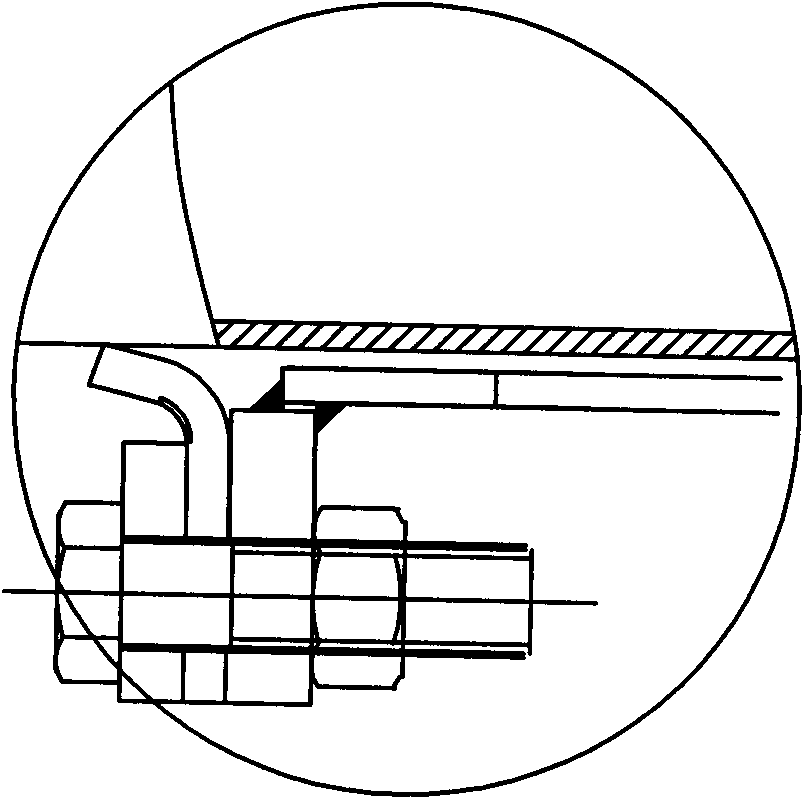

As shown in Figure 3, the sleeve valve sealing device in the prior art has only one sealing ring with an upwardly bent inner edge, so it can only prevent the outside water from entering the inner cavity of the sleeve, and the water in the inner cavity of the sleeve is easy to flow out. Can not effectively achieve two-way sealing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

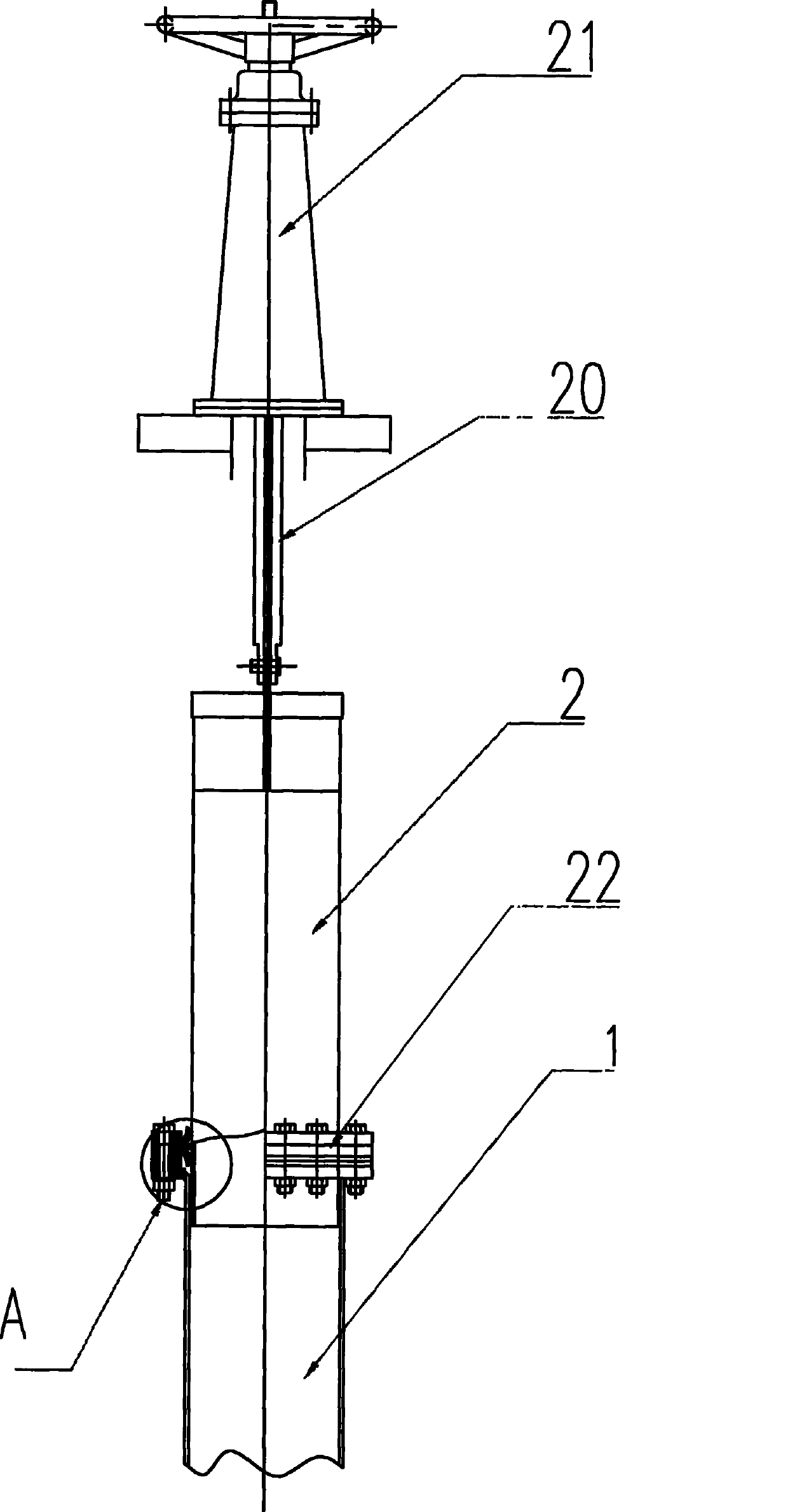

The invention relates to a sleeve valve, which comprises an outer barrel (1) and an adjustment barrel (2) which can relatively slide up and down in the outer barrel (1), wherein a sealing device consisting of a flange (3), an upper sealing ring (4) of which the inner edge is upwards bent and a pressing plate (5) is arranged at the end of the outer barrel (1); and a lower sealing ring (8) of which the inner edge is downwards bent is arranged between the upper sealing ring (4) and the flange (3). An oil storage tank can store more lubrication oil, and the sealing effect is relatively good.

Description

technical field The invention relates to a valve, in particular to a sleeve valve. Background technique Sleeve valve, also known as lifting valve, is generally used in the sedimentation tank mud discharge well to discharge mud outside the pool. Because its structure is an inner and outer telescopic sleeve, it can also be used to adjust the water level in the water distribution well or the water outlet well, such as a single-pipe dredger Mud discharge, air flotation water discharge, etc., are generally made of carbon steel or stainless steel. However, since the lift pump is usually installed in the water distribution well, when the lift pump needs to be repaired for some reason, the sleeve valve is required to have a two-way sealing function, which can not only prevent water from flowing backward, but also prevent the water in the secondary settling tank from leaking into the drain. In the mud well, maintenance personnel can maintain the lift pump on the spot in the mud well...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16J15/16F16K51/00

Inventor 严成喜杨如峰沙淘马田华孔勇

Owner JIANGSU TIANYU ENVIRONMENTAL PROTECTION GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com