Novel bidirectional sealing sleeve

A two-way sealing and sealing sleeve technology, applied in the direction of engine sealing, air-filled/oil-filled cable accessories, mechanical equipment, etc., can solve the problems of unguaranteed sealing, randomness, and different sizes, and reduce oil leakage. hidden dangers, improve product quality, and facilitate safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be clearly and completely described below through specific embodiments.

[0021] In the existing technology, when the product needs to be sealed in both the axial and radial directions, it can only be sealed separately in the radial and axial directions, and there is no way to use a sealing ring to simultaneously achieve radial and axial bidirectional sealing.

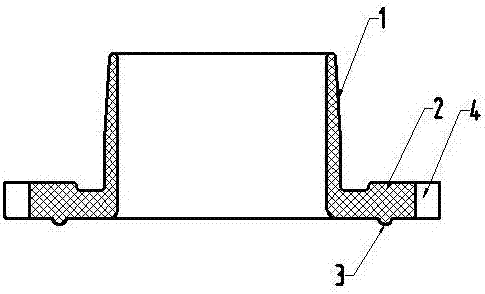

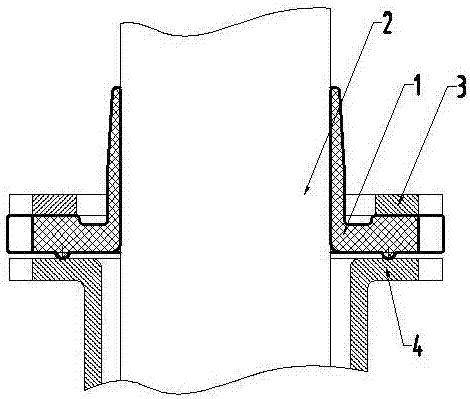

[0022] And a kind of novel two-way seal sleeve of the present invention, as figure 1 As shown, the seal sleeve body 1 is included, and the seal sleeve body 1 includes an axial seal 11 and a radial seal 12 that are connected to each other and have elasticity; the axial seal 11 and the radial seal 12 are integrally formed; the The axial seal 11 is a cylindrical casing, which tightly hugs the surface of the cable insulation shielding layer 2 to form an axial seal; the radial seal 12 is an annular gasket; the annular gasket passes through the sealing The flange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com