Ultra-low-temperature top entry ball valve and assembly method thereof

An ultra-low temperature, installed technology, applied to valve details, valve devices, cocks including cut-off devices, etc., can solve problems such as shortening the service life of packing and the entire valve ball, unreasonable valve body structure settings, and condensed water ingress, etc., to achieve Simple structure, long service life, and increased sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

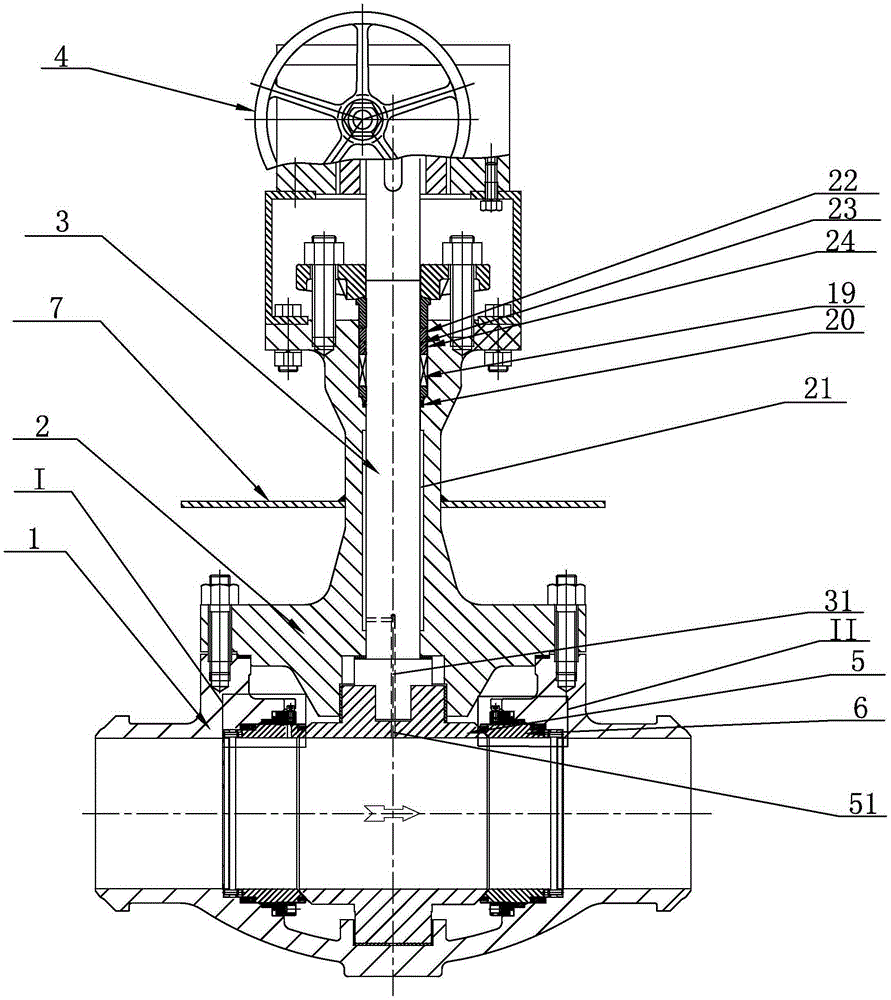

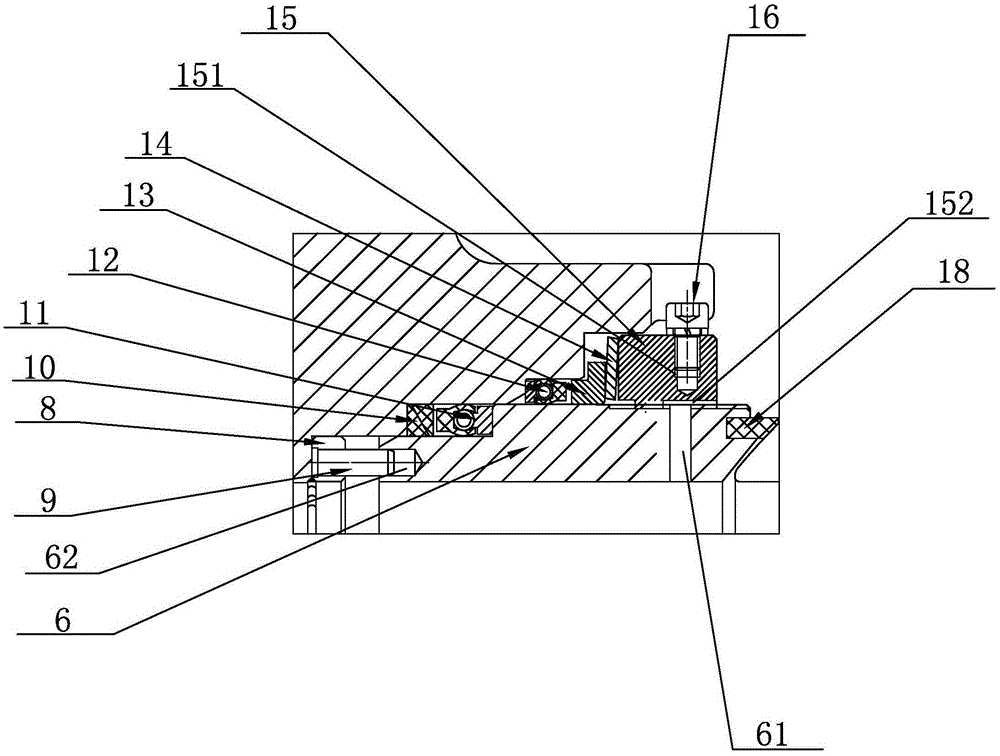

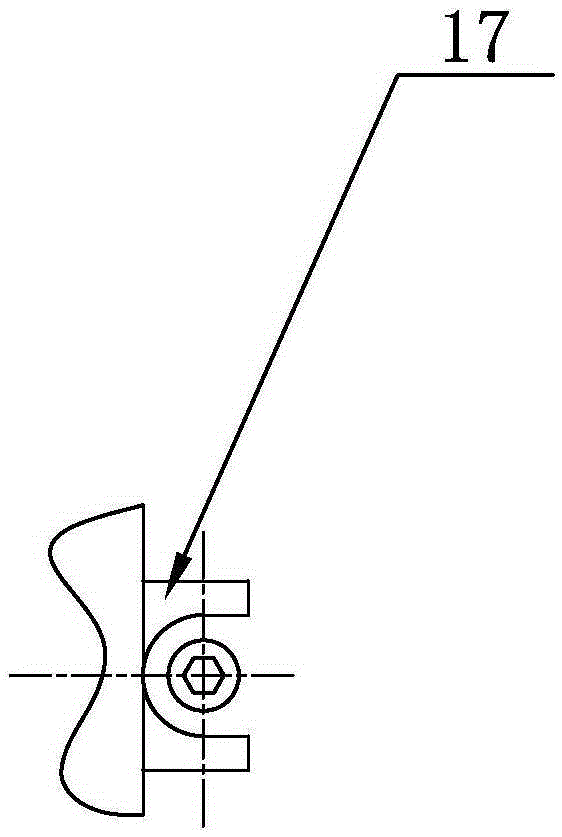

[0018] see figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , an ultra-low temperature top entry ball valve disclosed in the present invention, comprising a valve body 1, a valve cover 2, a valve stem 3 and an operating mechanism 4, the valve cover 2 is detachably connected to the valve body 1, and the valve body of the valve body 1 A valve ball 5 and a valve seat 6 are arranged in the middle cavity, and the lower end of the valve stem 3 passes through the valve cover 2 to connect with the valve ball 5. The valve cover 2 is welded with a drip plate 7, and the valve cover 2 is provided with The steam chamber 21, the valve stem 3 is provided with a first pressure relief hole 31, the valve ball 5 is provided with a second pressure relief hole 51, the steam chamber 21, the first pressure relief hole 31 and the second pressure relief hole 51 connected; between the inner wall surface of the valve body 1 and the valve seat 6, a positioning ring 8, a positioning pin 9, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com