Pneumatic seal ring with irregularly-shaped cross section

A pneumatic sealing and special-shaped cross-section technology, which is applied in the direction of engine sealing, engine components, fluid pressure actuators, etc., can solve the problem that the grease on the sealing working surface cannot be maintained, and achieve the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

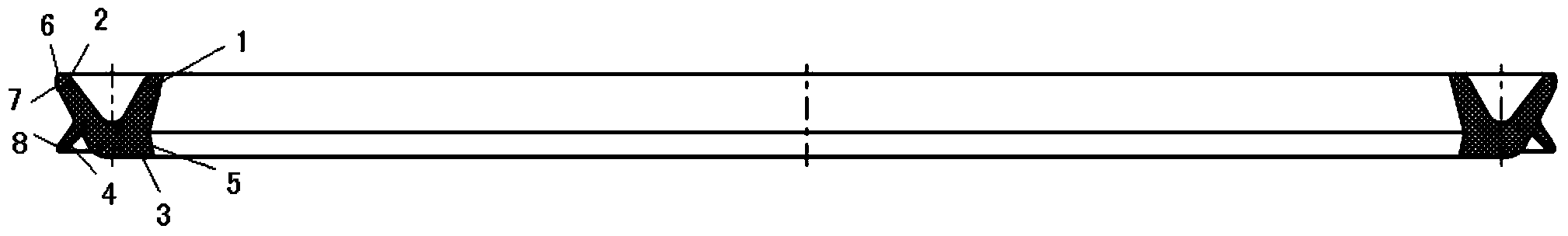

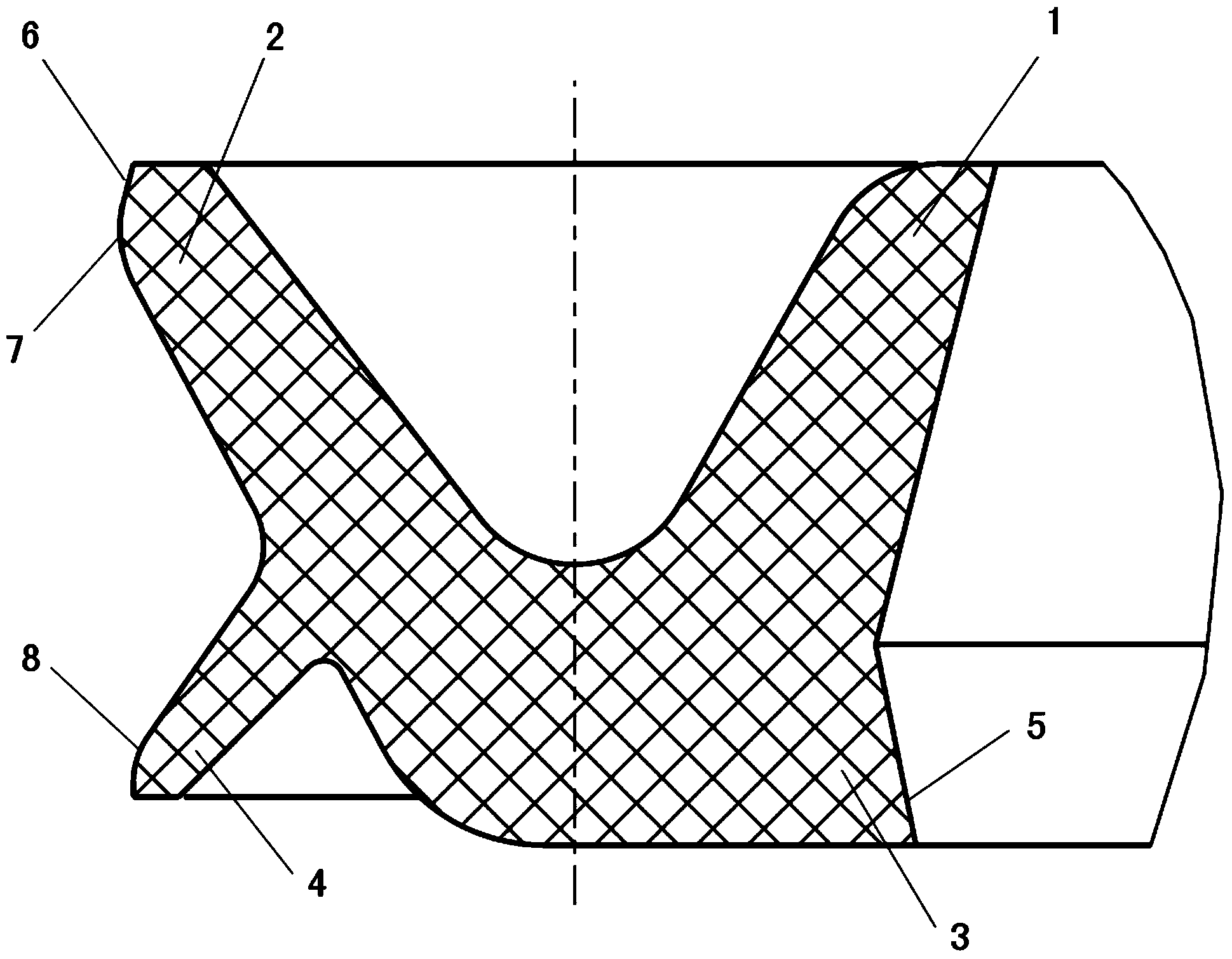

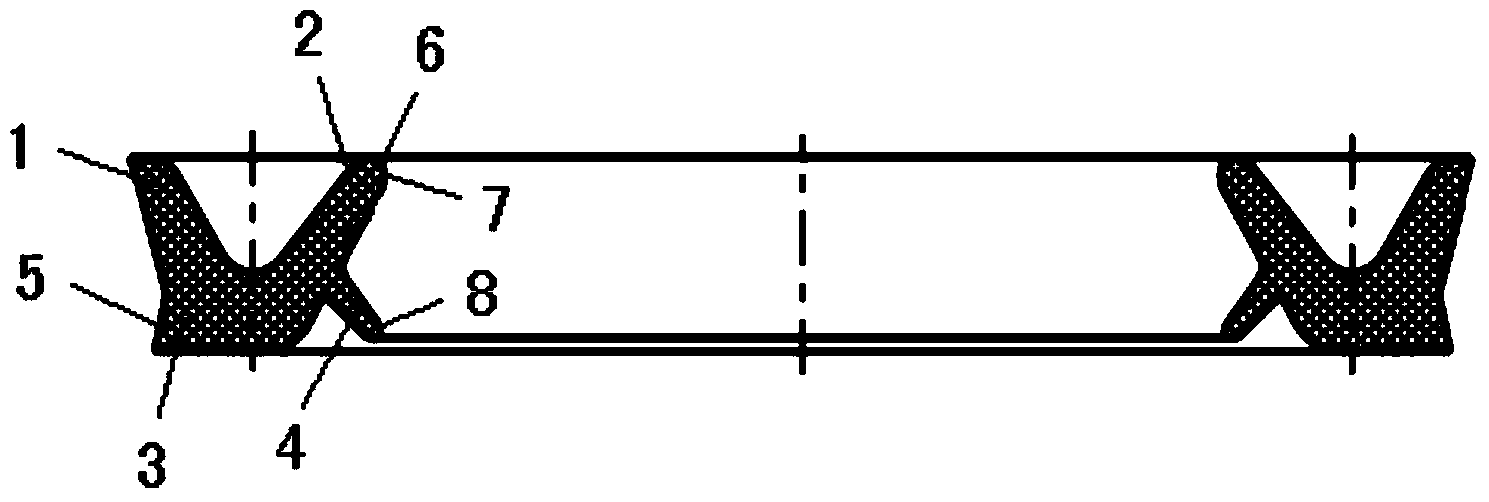

[0016] Such as Figure 1 ~ Figure 4 As shown, the present invention provides a special-shaped cross-section pneumatic sealing ring for pistons and piston rods, which includes a sealing lip 1 , a primary sealing lip 2 , a sealing ring root 3 and a secondary sealing lip 4 integrally injected. A groove is formed between the sealing lip 1 and the main sealing lip 2 for fixing a pneumatic sealing ring with a special-shaped section. The root part 3 of the sealing ring is located at the lower part of the sealing lip 1, and the end 5 of the root part 3 of the sealing ring is inclined to the installation groove of the piston or piston rod, so that the two-way sealing on one side of the installation groove can be realized. The end 6 of the main sealing lip 2 is upturned and does not contact the inner wall of the piston cylinder or the outer wall of the piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com