Multi-chip intelligent mounting equipment and using method thereof

A multi-chip, intelligent technology, applied in the manufacturing of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of large footprint, insufficient speed, poor integration, etc., to reduce the equipment footprint , Easy to operate, ensure the effect of placement quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

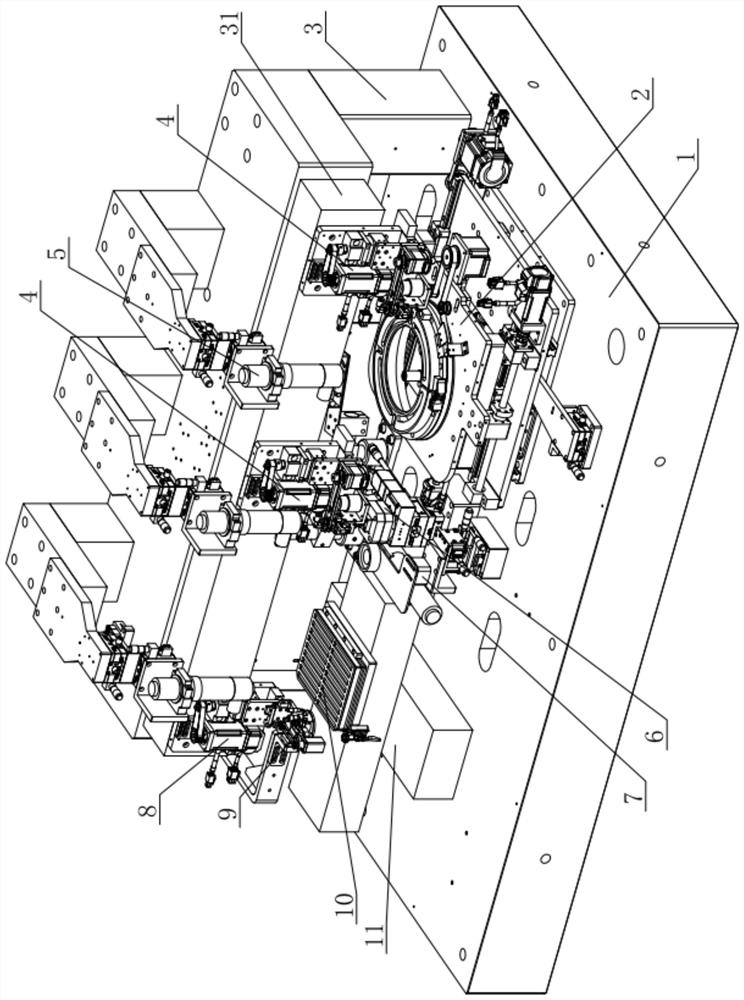

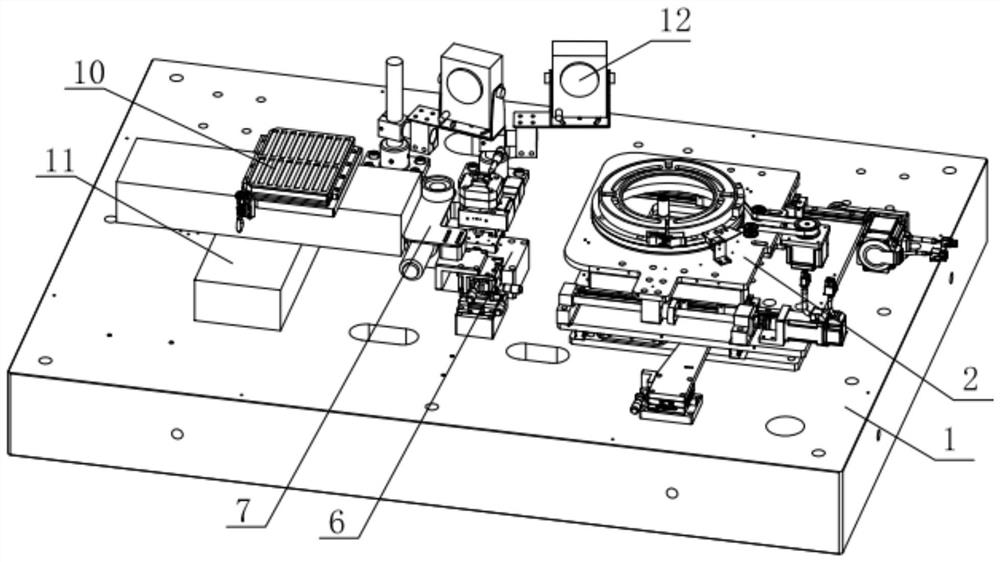

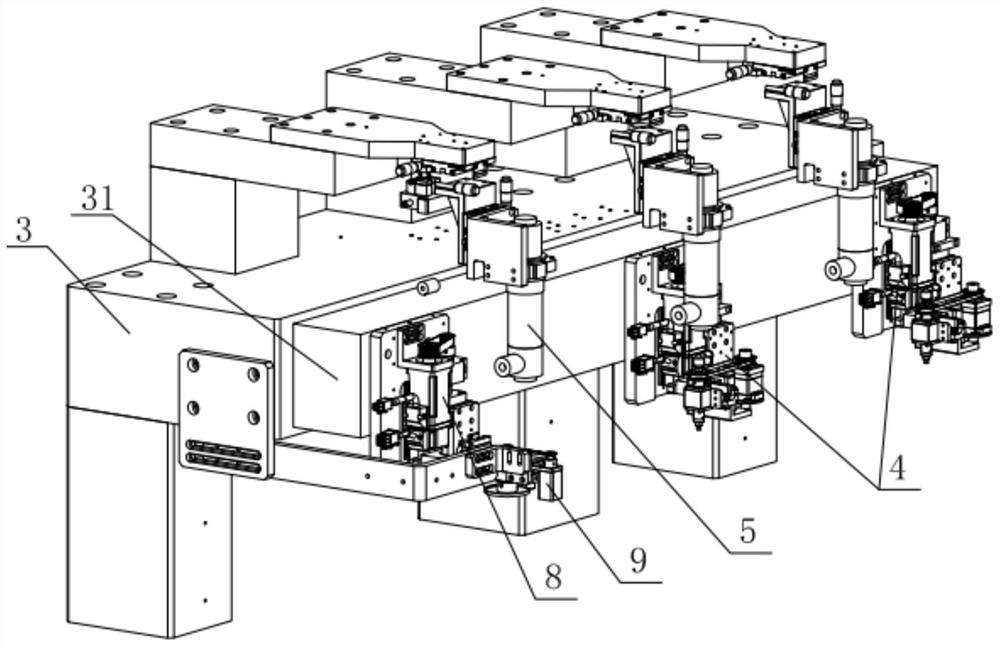

[0059] Such as figure 1 , figure 2 and image 3 As shown, the multi-chip intelligent placement equipment of this embodiment includes a working platform 1, on which a loading area 2, a preset platform 6 and a loading area 10 are arranged in sequence along the Y-axis direction, and are located in the loading area 2. A support frame 3 is installed on the working platform 1 outside the preset platform 6 and the end of the blanking area 10, and the front side of the support frame 3 is installed with a Y-direction linear guide rail 31 along the length direction, and the Y-direction linear guide rail 31 is moved and installed There is a welding head assembly 4, and a gluing assembly 8 is installed on the Y-direction linear guide rail 31 above the unloading area 10; multiple groups of camera assemblies 15 are installed on the top of the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com