Carbon roaster control system with combustion assistance function and implementation method of system

A carbon roasting furnace and control system technology, applied in furnace control devices, furnaces, furnace components, etc., can solve the problems of inaccurate temperature control in the preheating zone of the roasting furnace, failure to burn out combustibles, waste of resources, etc., and achieve control The method is clear and reasonable, the utilization rate is improved, and the effect of avoiding the waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

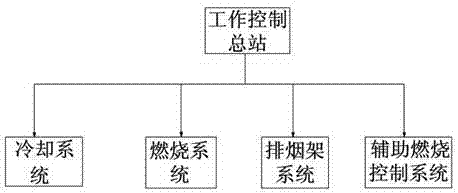

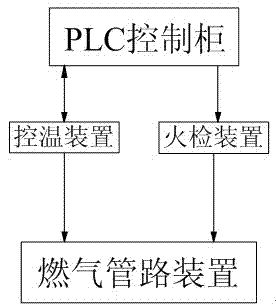

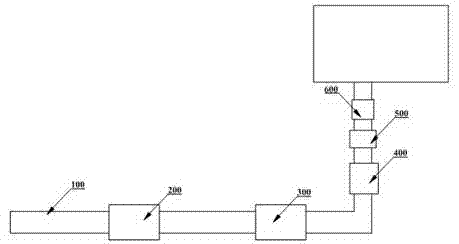

[0039] like figure 1 As shown, the present invention includes a working control station, a combustion system, an auxiliary combustion control system, a smoke rack system and a cooling system. All systems are connected to the work control central station through the industrial Ethernet bus, which coordinates and controls all the systems. Among them, the combustion system is used to ignite the fuel fed into the heating chamber of the roaster, so that it The carbon products in the roaster are roasted; the auxiliary combustion control system is used to feed natural gas and mix with the combustibles discharged to the fire channel from the carbon products placed in the preheating chamber of the roaster, and burn them; the smoke exhaust rack system is used to control the combustion smoke The flow direction of the gas; and the cooling system is used to control the cooling air entering the roasting furnace to exchange heat with the roasted carbon products, thereby cooling the products....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com