Pre-fixing abrasive and water jet united cutting tooth type roller of coal mining machine

A technology of pre-mixing abrasives and shearer drums, which is applied to cutting machinery, earthwork drilling and mining, etc., can solve the problems of reduced mining efficiency, shortened service life, and weak cutting ability of pure water jets, so as to improve mining efficiency, Effect of reducing tool wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

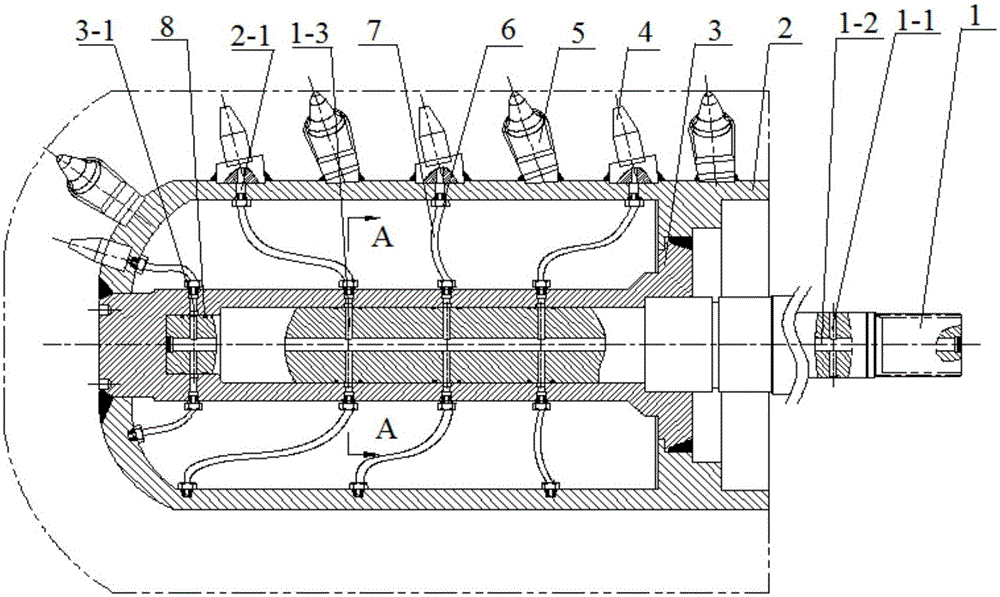

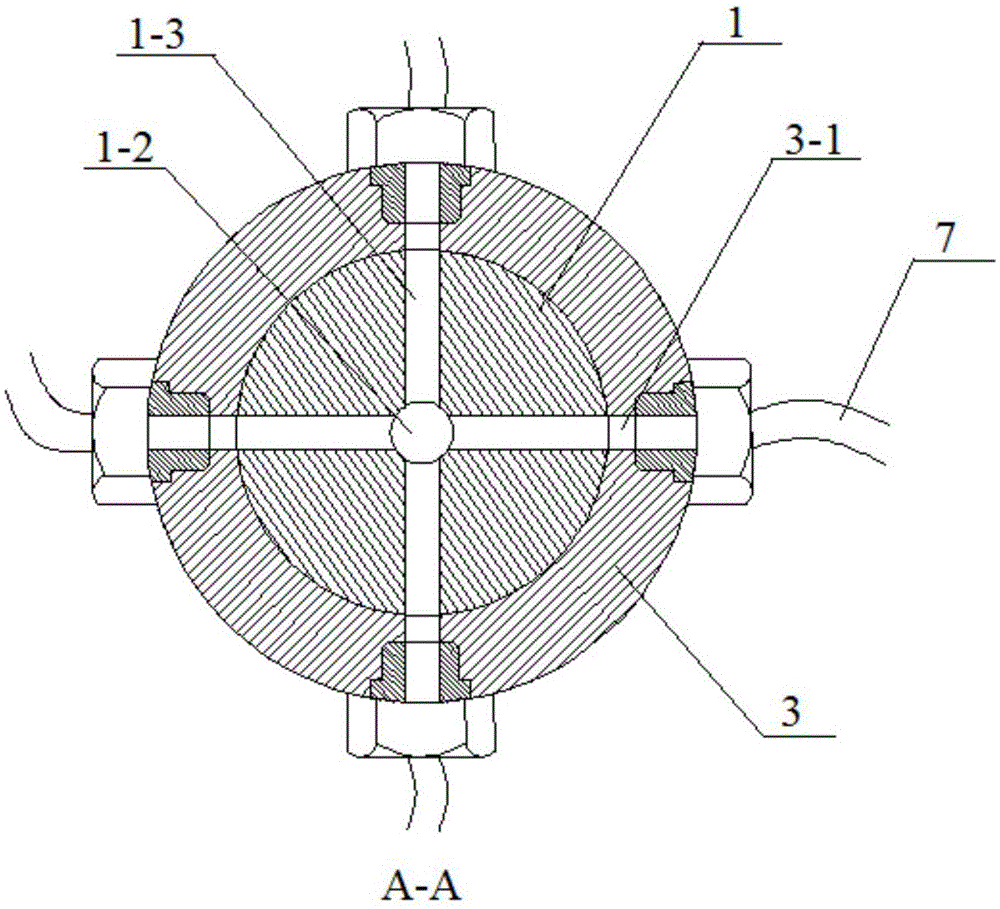

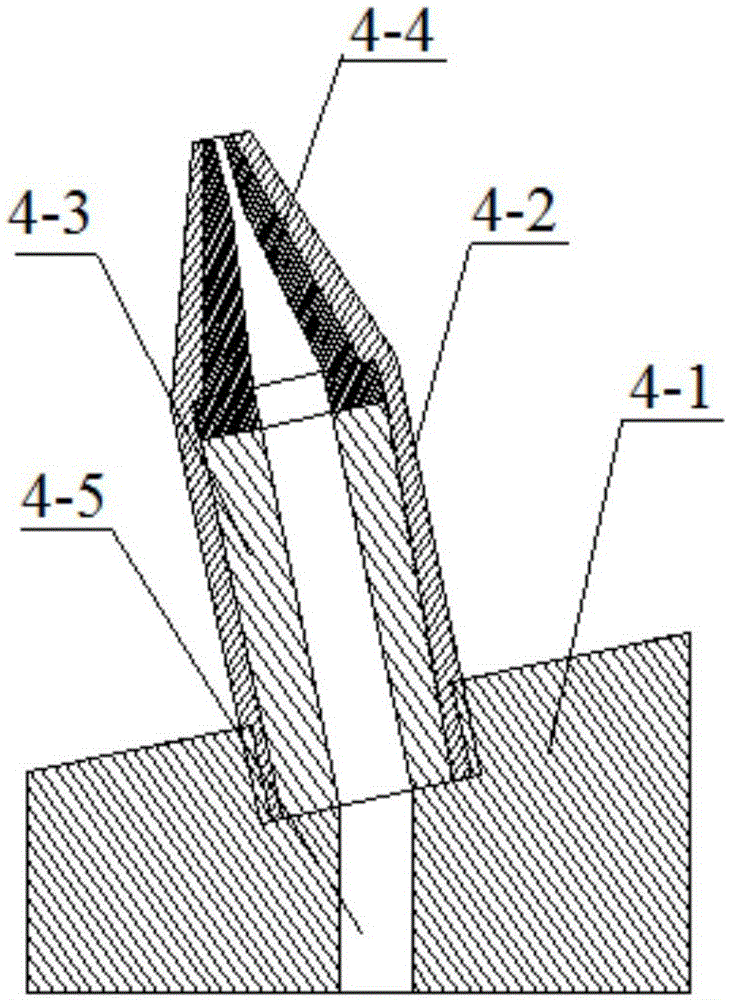

[0020] figure 1 As shown, the pre-mixed abrasive water jet combined pick shearer drum of the present invention is mainly composed of a cutting shaft 1, a cylinder body 2, a core sleeve 3, a nozzle assembly 4, a pick 5, a threaded joint 6 and a high-pressure soft Tube 7 constitutes. The cylinder body 2, the core sleeve 3, the nozzle assembly 4, and the pick 5 are all connected by welding, and the cutting shaft 1 is connected with the core sleeve 3 through a spline to drive the entire cutting head to work. 1 and the core sleeve 3 are provided with a plurality of leak-proof sealing rings 8 . The cylinder body 2 is provided with a core sleeve 3 fixed on the cutting shaft 1 , and the core sleeve 3 is welded to both ends of the cylinder body 2 inner cavity. The cylinder body 2 is sleeved on the outer periphery of the core sleeve 3, and the front and rear en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com