Automobile wire harness fixing support

A technology for fixing brackets and automotive wiring harnesses, which is applied to vehicle components, electrical components, circuits or fluid pipelines, etc. It can solve the problems of unsatisfactory installation reliability and accuracy of wiring harnesses, and achieve convenient disassembly, improved efficiency, and improved reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments thereof.

[0022] All of the following drawings are only convenient for explaining the basic teaching of the present invention, and the number, position, relationship, and size extension of the components that constitute the preferred embodiment will be described in the accompanying drawings. After reading and understanding the teaching of the present invention The associated change implementation is within the skill of the industry. In addition, changes in precise dimensions and dimensional ratios to accommodate specific strength, weight, strength, and similar requirements are common knowledge in the art after reading and understanding the teachings of the present invention.

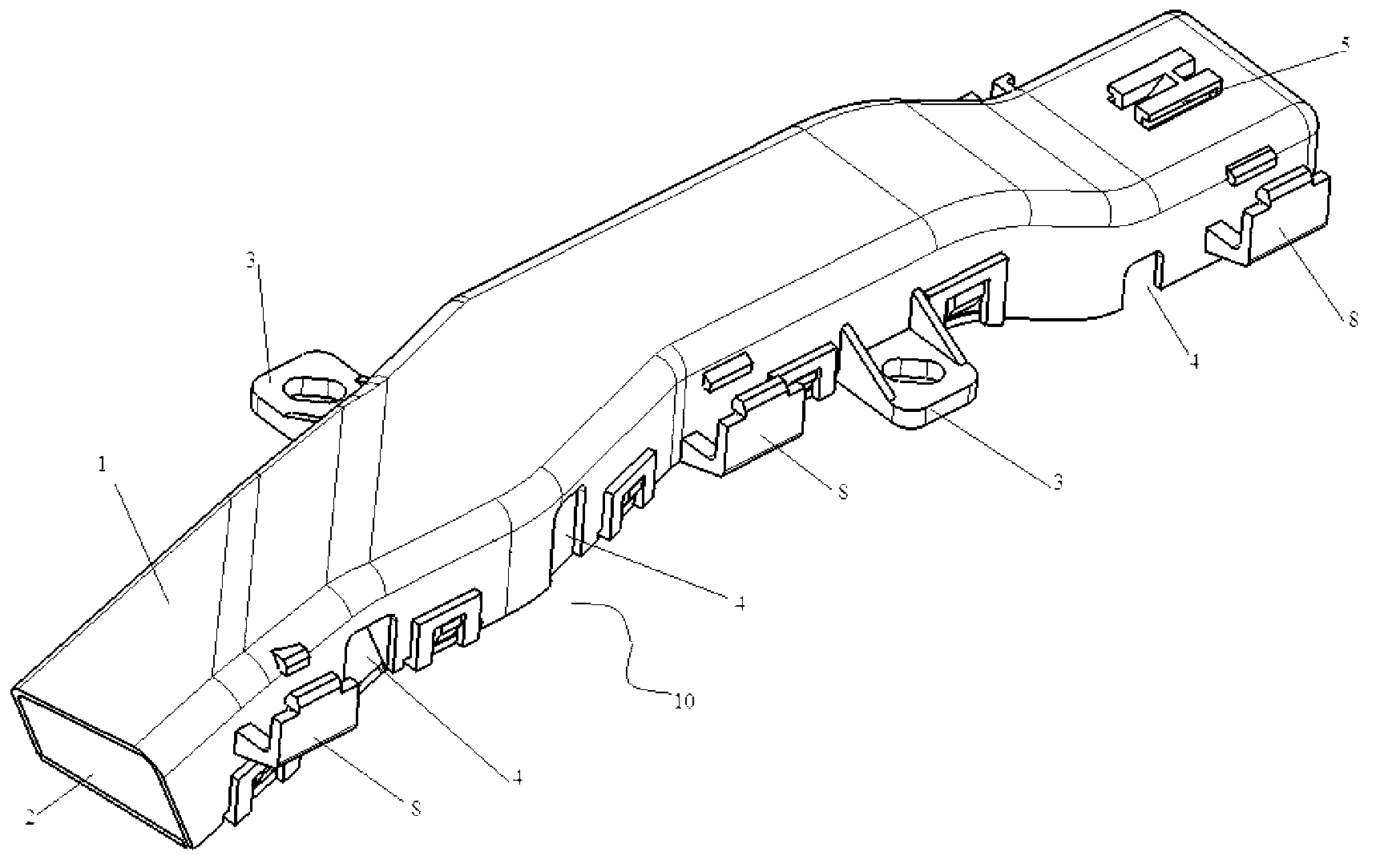

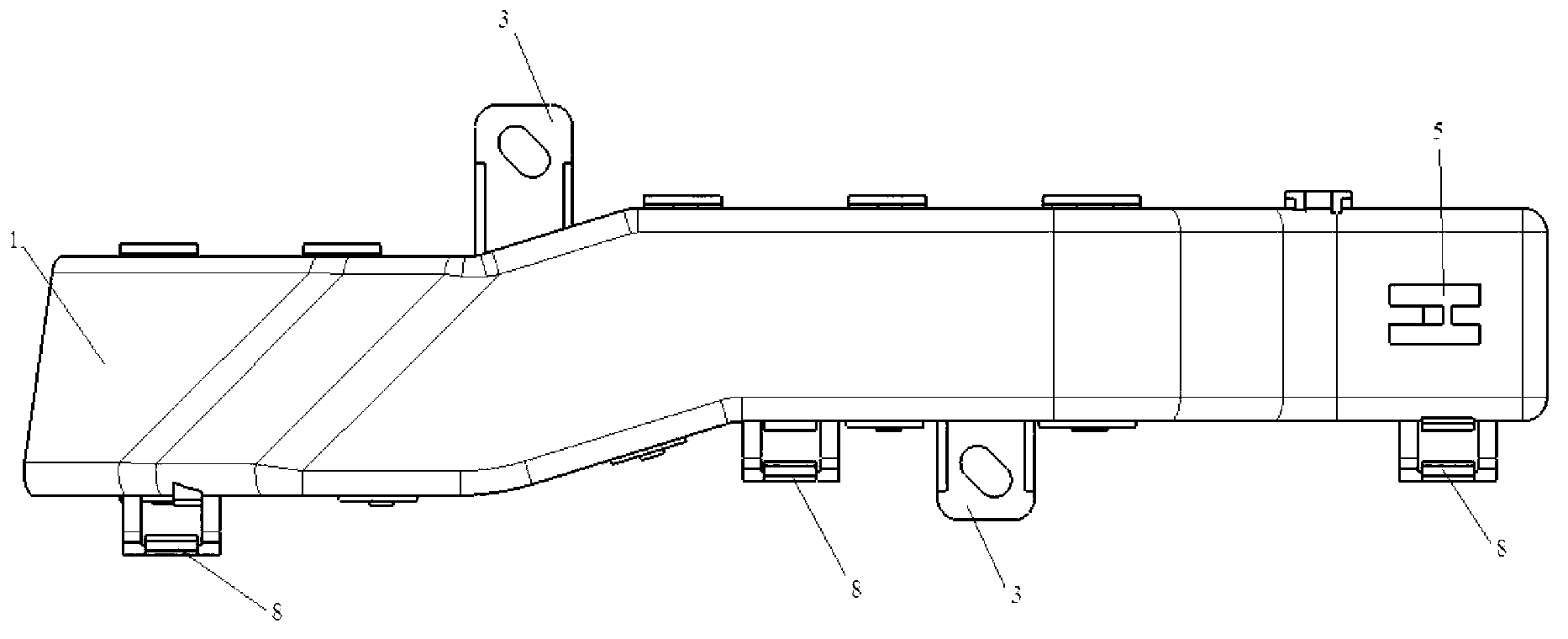

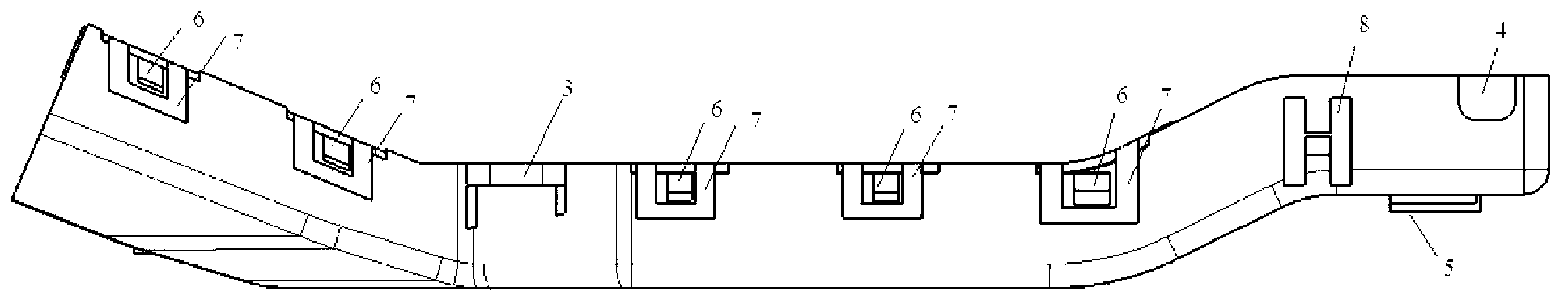

[0023] Such as figure 1 As shown, a fixed bracket for automobile wiring harness includes a bracket body 10 composed of an upper frame 1 and a lower frame 2; wherein, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com