Mortar vehicle for concrete and asphalt

A cement asphalt and mortar truck technology, which is applied to cement mixing devices, mixing operation control, clay preparation devices, etc. Emulsion feeding, proportioning and other issues, to achieve the effect of compact structure, elimination of precipitation and material segregation, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

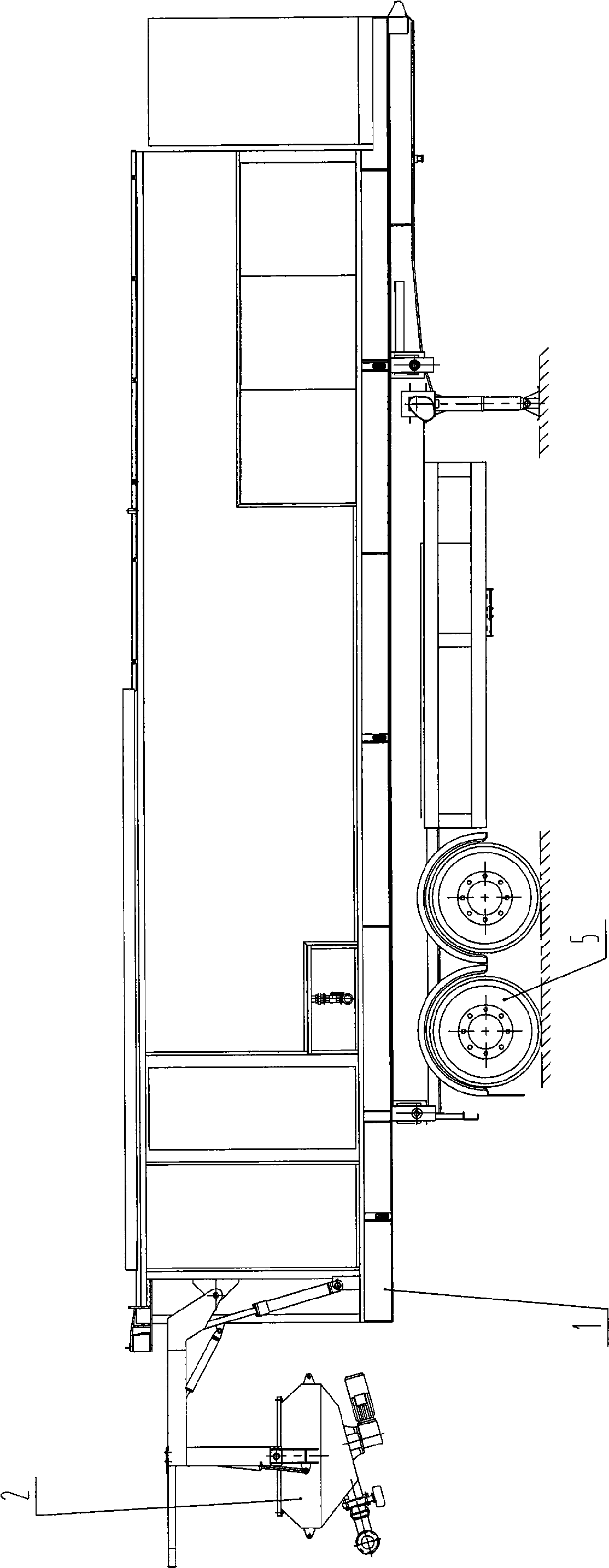

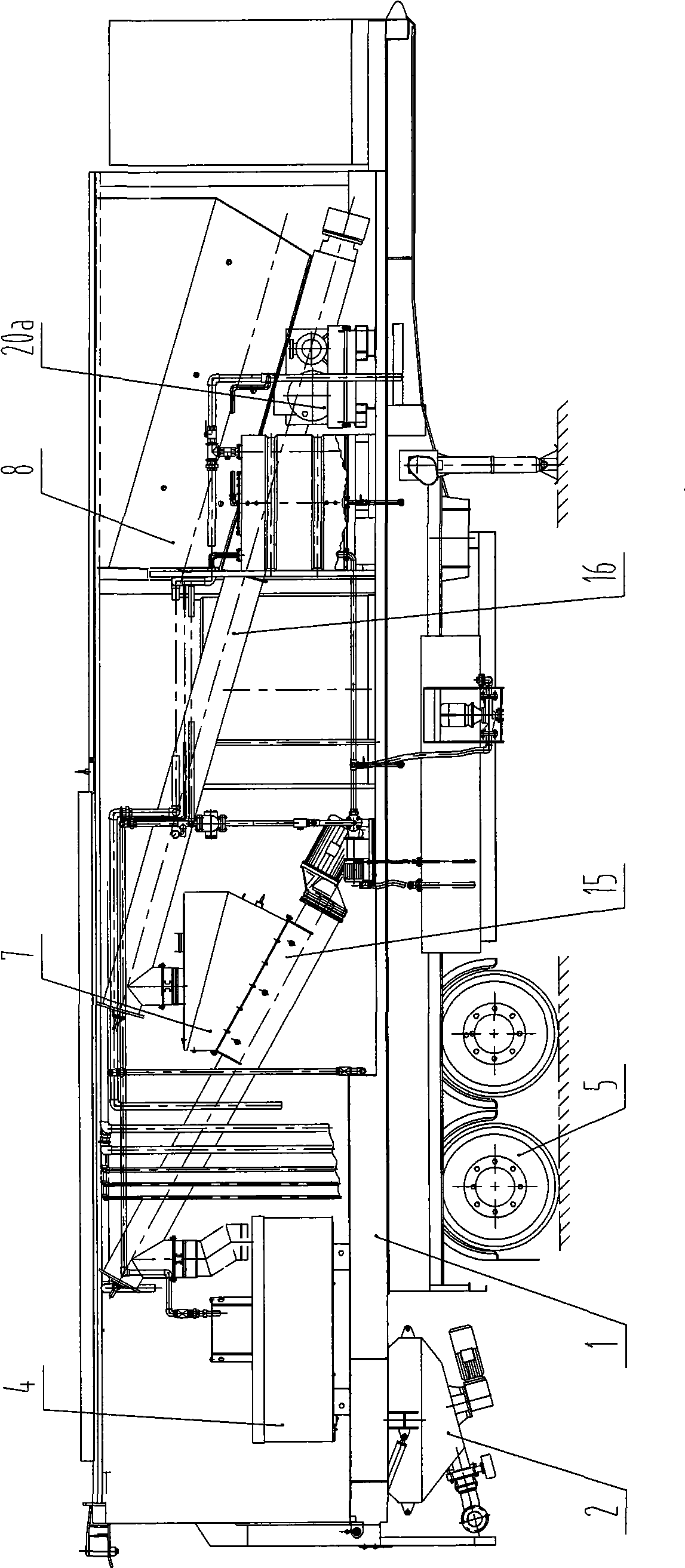

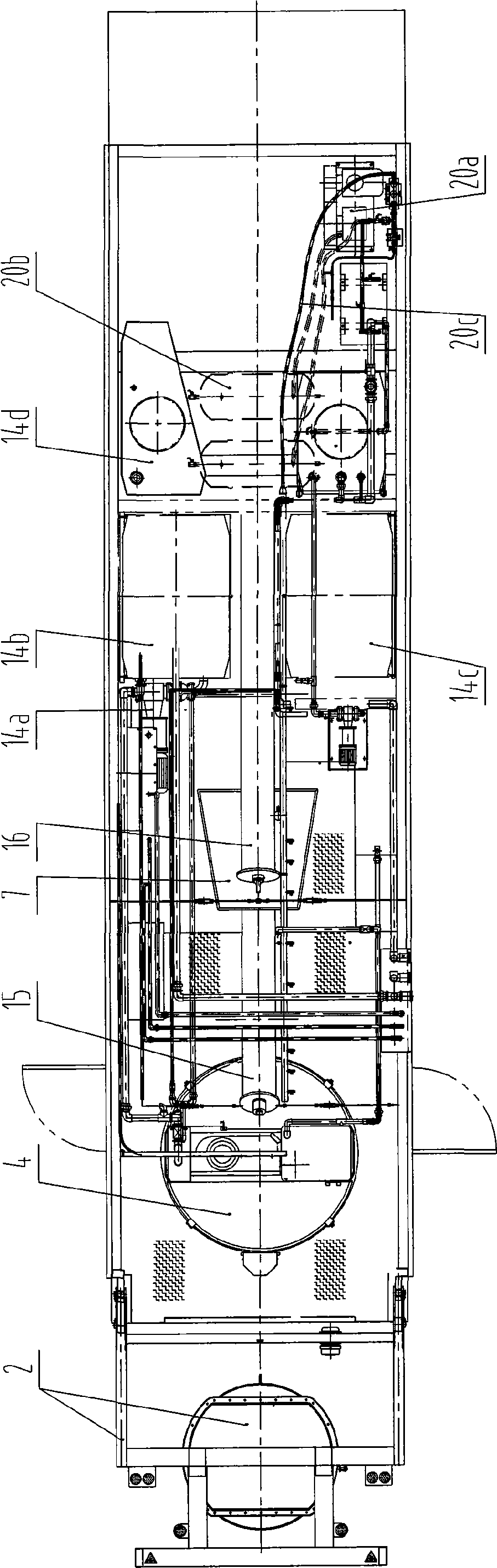

[0056] Such as figure 1 , figure 2 , image 3 Shown, a kind of cement asphalt mortar truck of the present invention, it comprises chassis 5 and the top that is installed on the chassis 5, and top is the closed compartment that is made of outer wall board, and the top of top is provided with top cover assembly. The bodywork includes dry powder weighing and feeding assembly, asphalt metering and feeding assembly, water metering and feeding assembly, admixture metering and feeding assembly, P emulsion metering and feeding assembly, mixing host assembly 4, mortar filling board Assembly, power system, control system and necessary auxiliary systems. Dry powder weighing and feeding assembly, asphalt metering and feeding assembly, water metering and feeding assembly, admixture metering and feeding assembly, P emulsion metering and feeding ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com