Double-turntable full-automatic detection machine and detection method thereof

An automatic detection and detection machine technology, applied in sorting and other directions, can solve the problems of high production cost, low detection efficiency, poor detection consistency, etc., to reduce labor intensity and improve detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

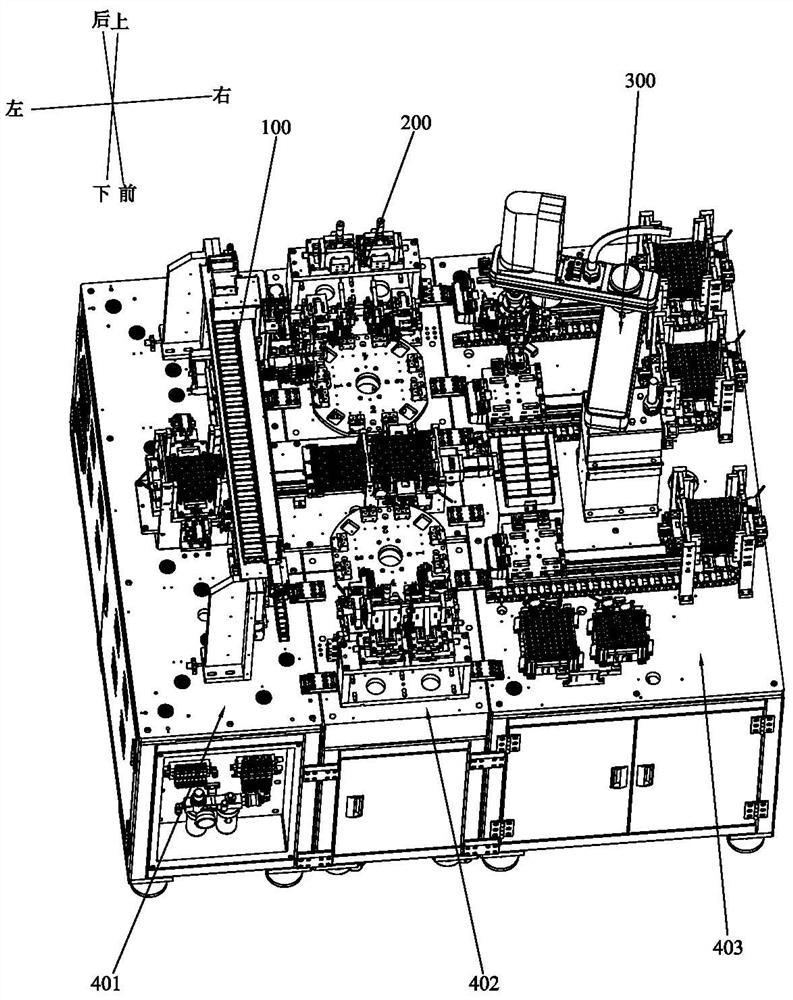

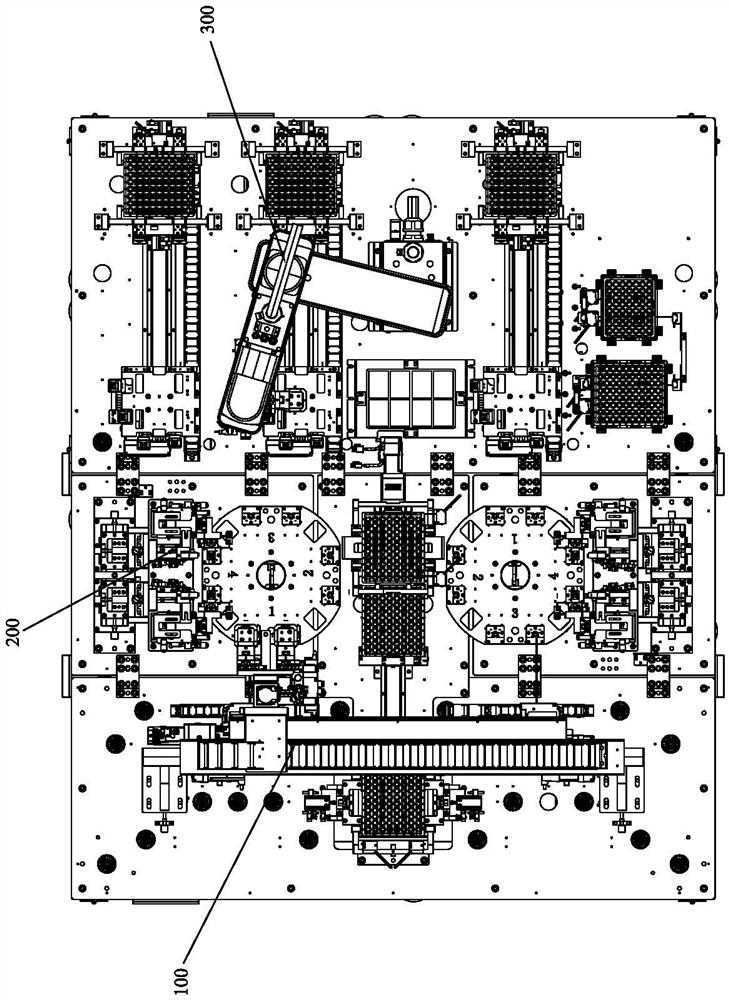

[0065] Please refer to Figure 1 to Figure 18 As shown, it shows the specific structure of the embodiment of the present invention.

[0066] A double turntable fully automatic testing machine, comprising a testing machine and an automatic feeding system 100, an automatic testing system 200, and an automatic unloading system 300 arranged on the testing machine;

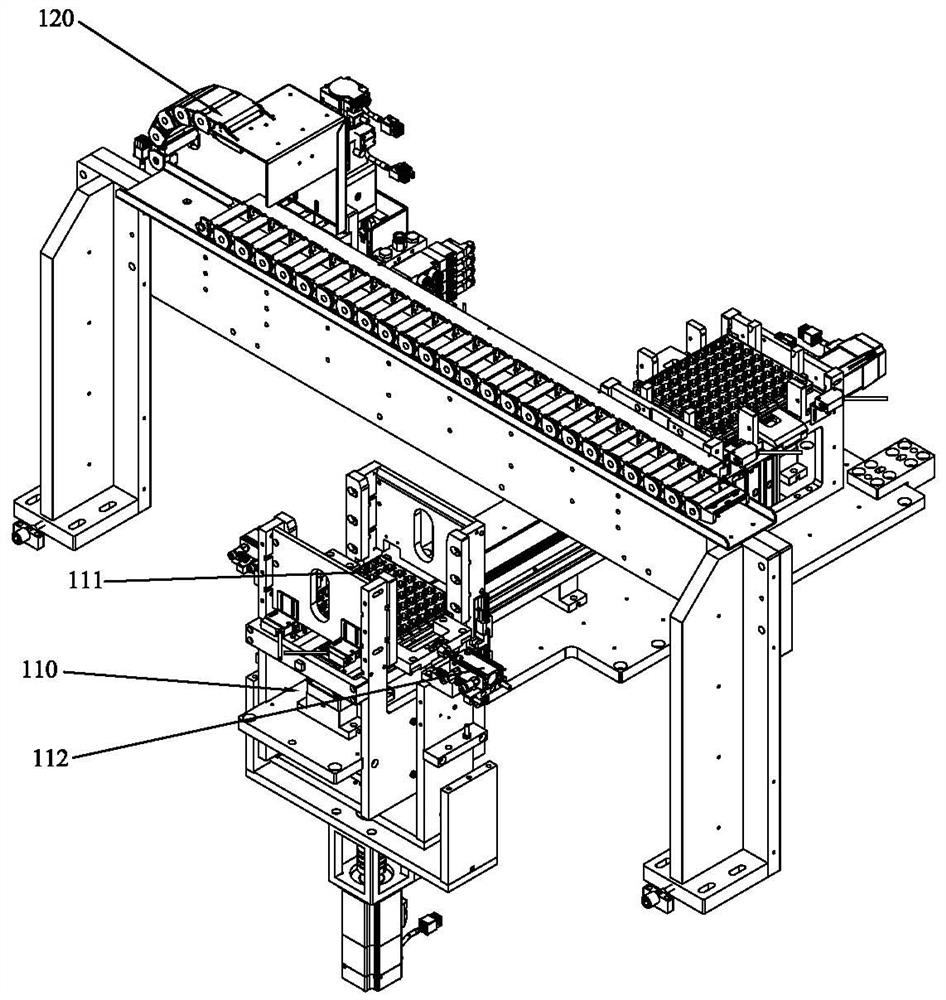

[0067] The automatic feeding system 100 has a feeding mechanism 110 and a feeding mechanism 120. The feeding mechanism 110 has a feeding bin 111. The feeding mechanism 120 has a feeding chuck 121 and is used to control the movement of the feeding chuck 121. The feeding chuck moving device;

[0068] The automatic detection system 200 has a first detection station and a second detection station, both of which are provided with a turntable 220 and a detection mechanism 210, and the detection mechanism 210 is installed on one side of the turntable 220; and, the turntable 220 A loading jig 221 is installed on it;

[0069...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com