Patents

Literature

154results about How to "Suitable for production applications" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

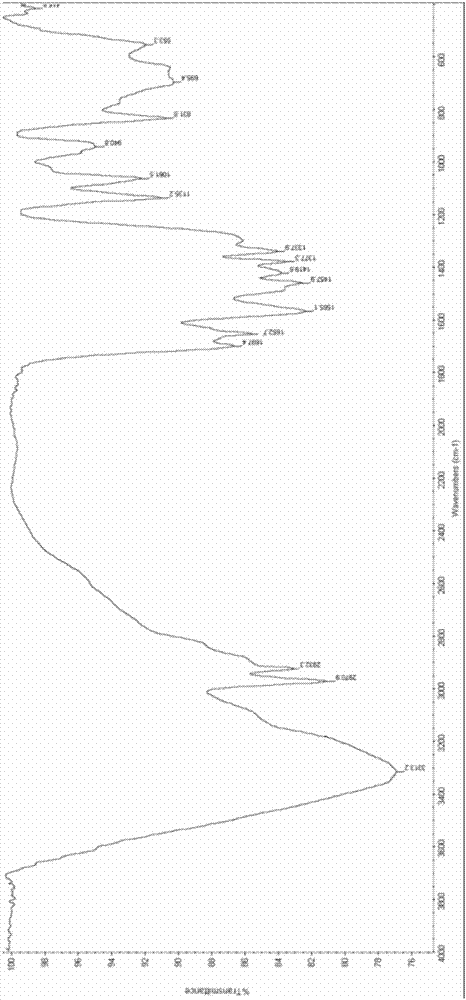

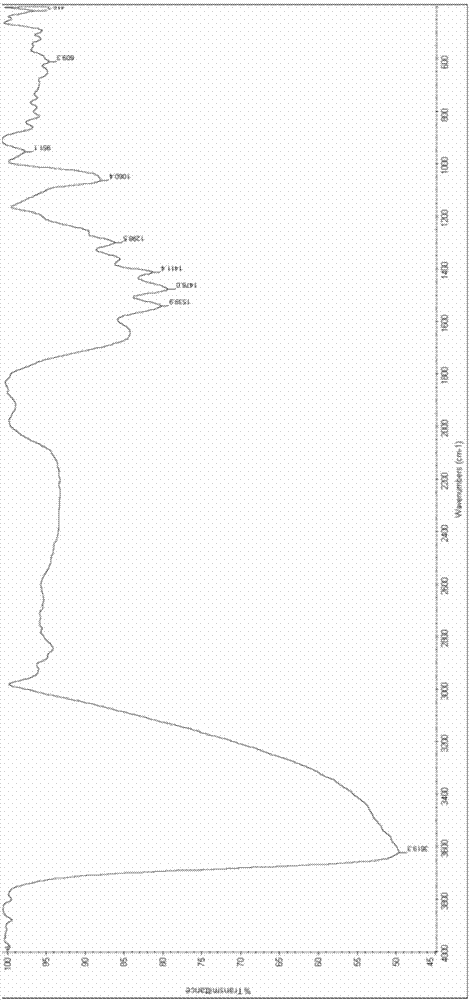

Synthetic method for agomelatine

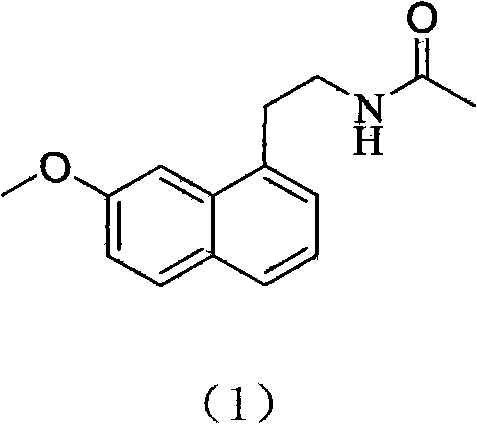

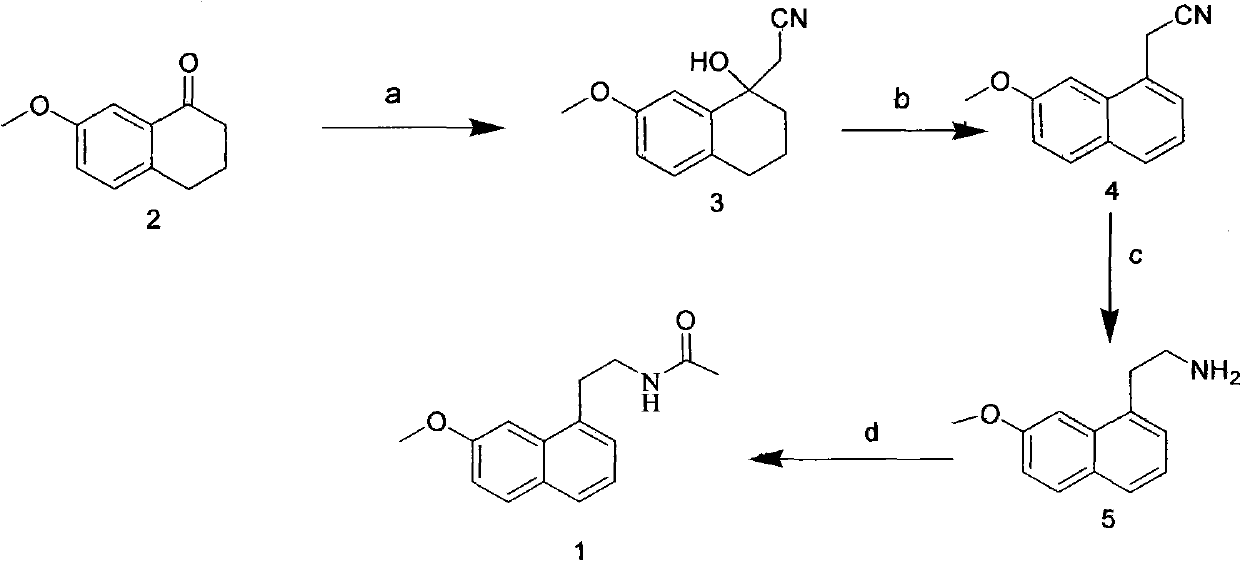

InactiveCN101792400AHigh reaction yieldMild reaction conditionsOrganic compound preparationCarboxylic acid amides preparationButyl lithiumEthylamines

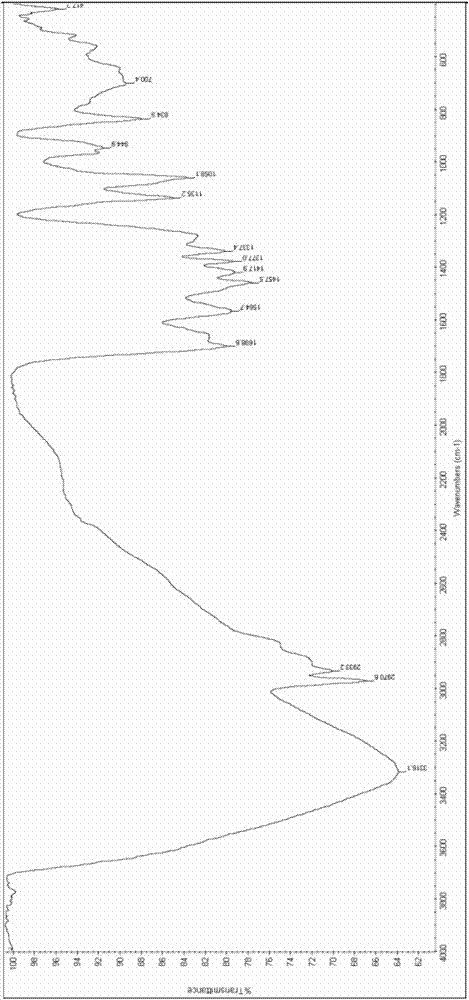

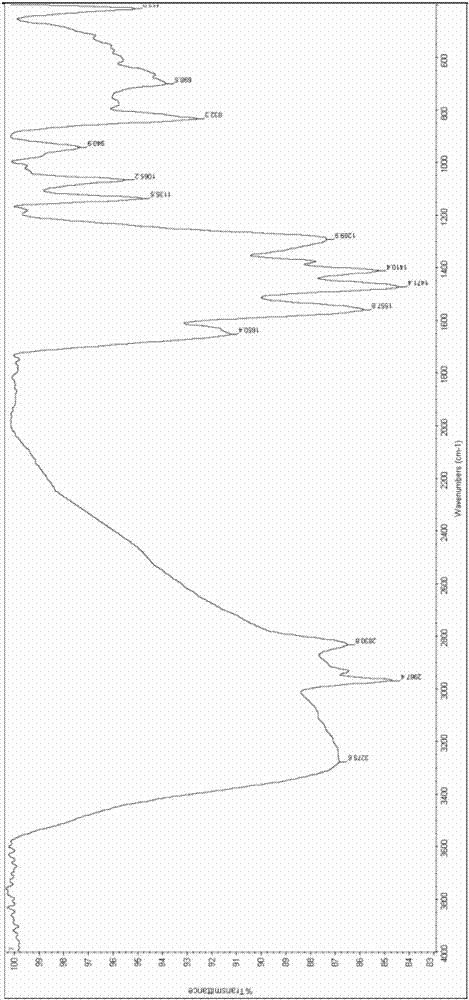

The invention relates to a synthetic method for agomelatine. The method comprises the following steps: reacting 7-methoxy-1-tetralone (2) serving as a raw material with acetonitrile under the action of n-butyl lithium to obtain 1-hydroxy-7-methoxy-1,2,3,4-tetralin-1-naphthyl acetonitrile (3); then uniformly mixing the compound (3) and acetic acid solvent or toluene, adding dichloro dicyano benzoquinone into the mixture for reacting at the temperature of between 50 and 150 DEG C for 4 to 20 hours to obtain a compound (4); adding the compound (4) into uniformly mixed solution of lithium aluminum hydride and tetrahydrofuran for reacting at the temperature of between 0 and 60 DEG C for 5 to 24 hours to obtain (7-methoxy-1-naphthyl) ethylamine (5); and finally uniformly mixing the compound (5)and triethylamine or naphthyridine, and adding acetylchloride into the mixture for reacting at the temperature of between 0 and 25 DEG C for 1 to 5 hours to obtain the agomelatine (1). The synthetic method for the agomelatine of the invention has the advantages of high yield, low cost, high controllability, simple processing after the reaction and environment protection and is suitable for industrial production of the melatonin antidepressant.

Owner:EAST CHINA NORMAL UNIVERSITY

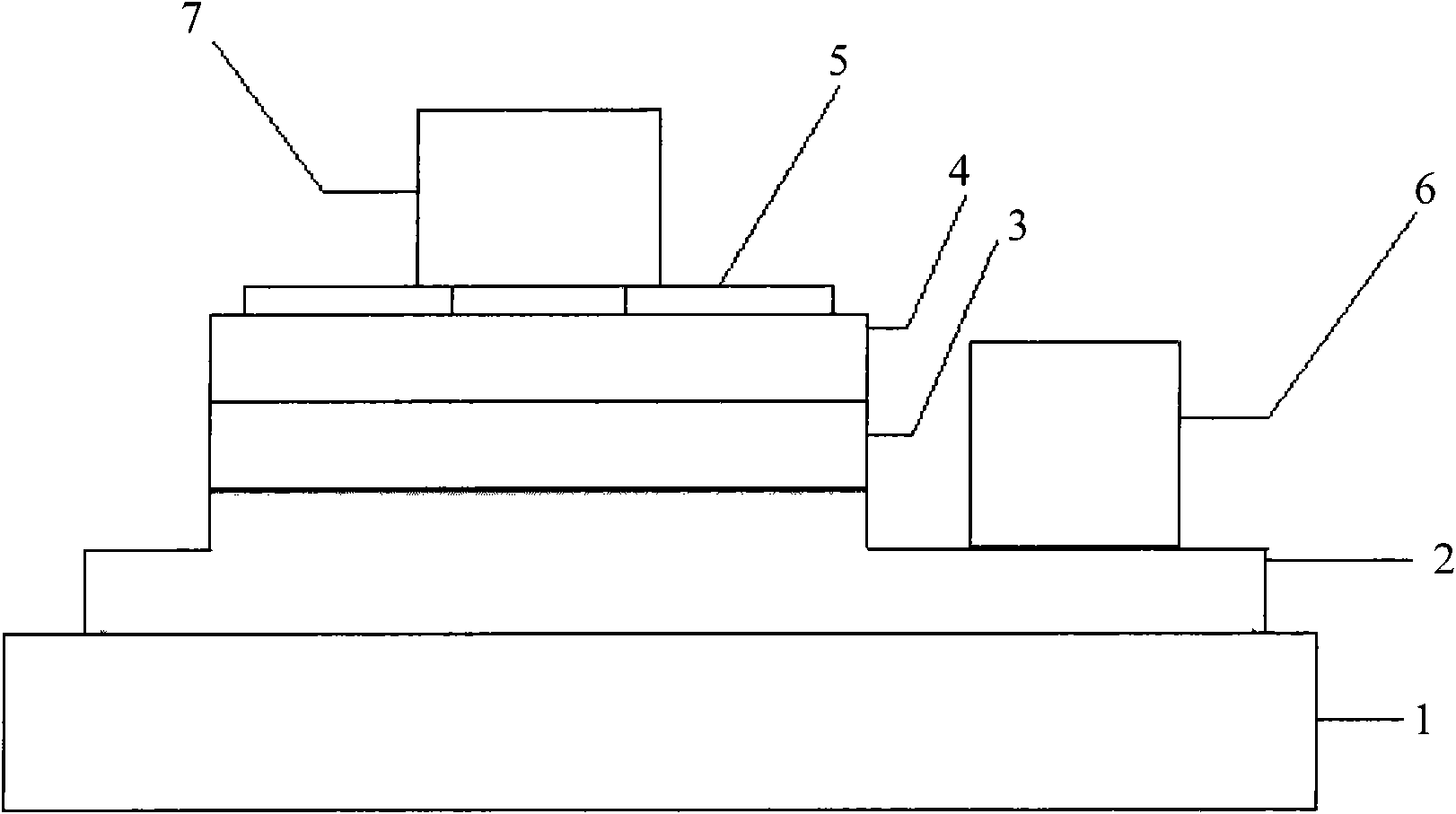

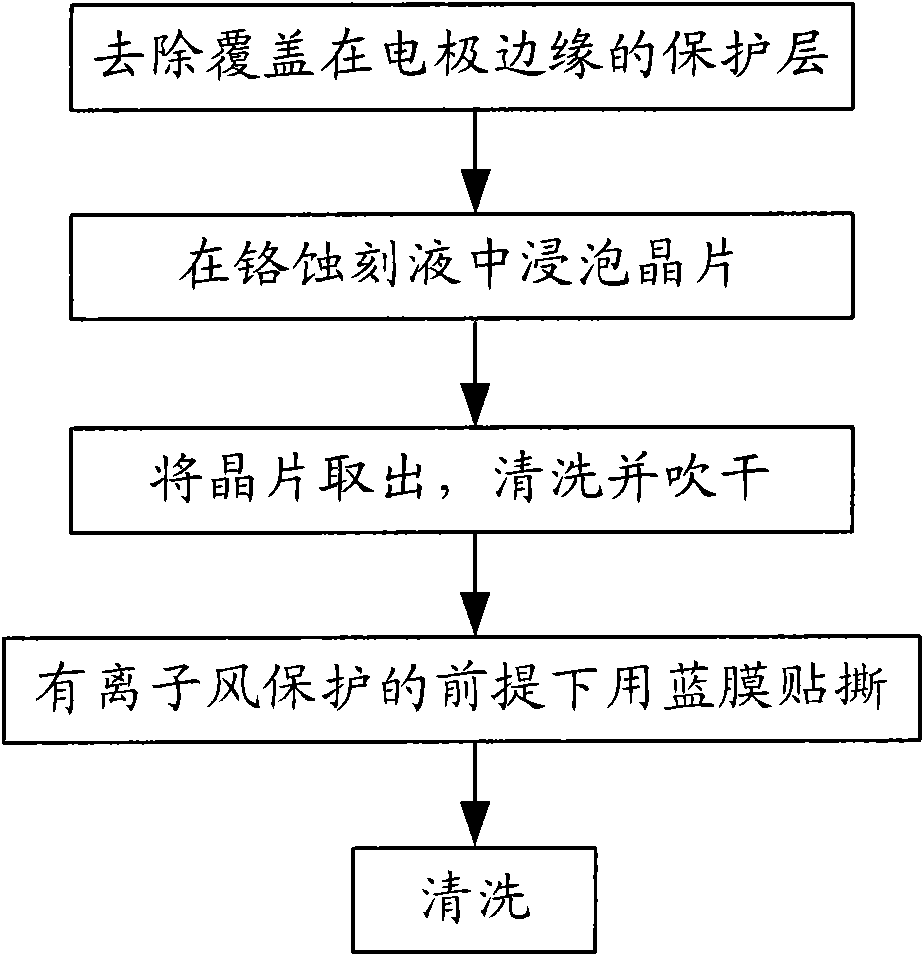

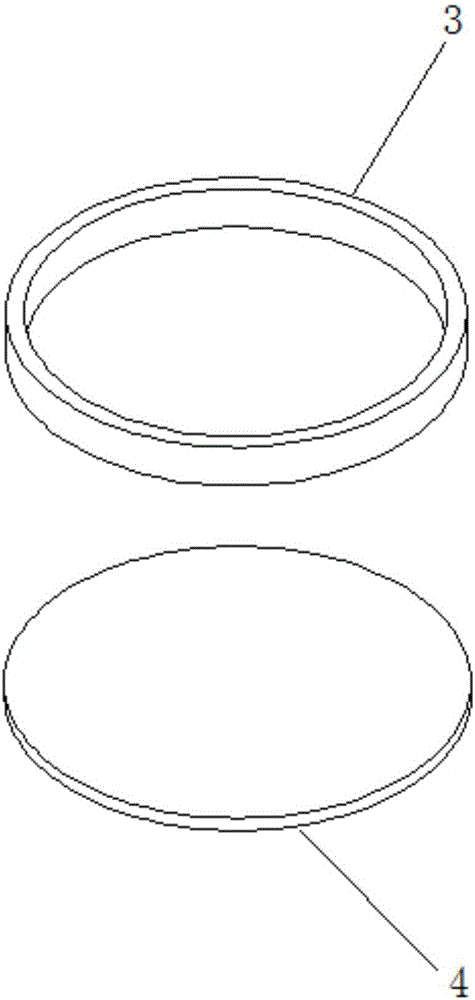

Method for removing light-emitting diode (LED) chip electrode

InactiveCN101944562AEfficient removalHigh selectivitySemiconductor devicesIndium tin oxideLight-emitting diode

The invention discloses a method for removing an LED chip electrode, which comprises the following steps of: removing a protective layer covered on the edge of the LED chip electrode; immersing the chip in chrome etching liquid after the protective layer is removed; taking the immersed chip out, washing and drying by air; and adhering a blue membrane or a white membrane on the surface of the air dried chip and then peeling the blue membrane or the white membrane off. The method provided by the invention has very high selectivity, exerts no influences on the other parts of the LED chip structure and retains the conventional indium tin oxide (ITO) layer.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

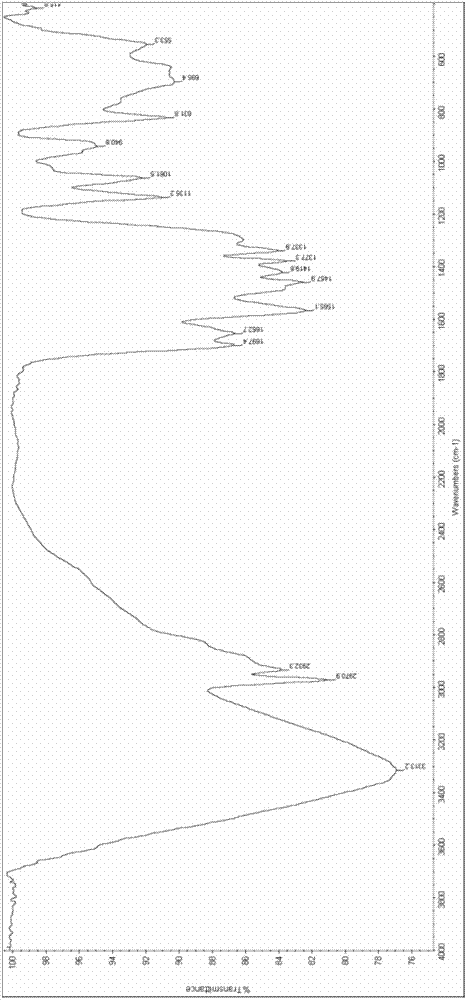

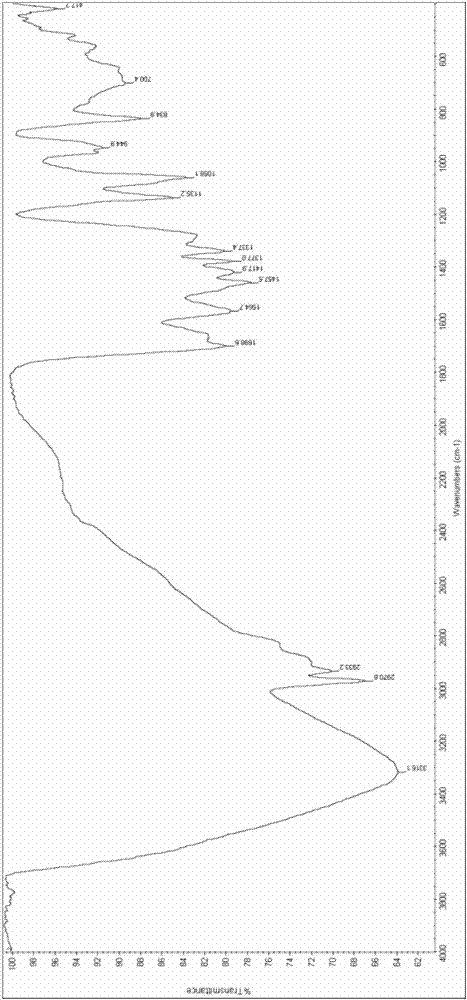

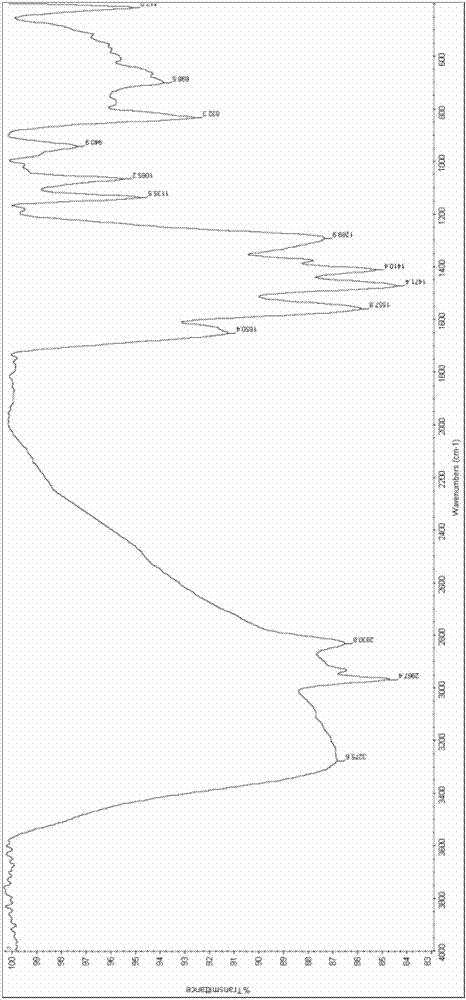

Organic amine salt compound with negative ion as CO2 donor and application thereof as foaming agent

ActiveCN107089927AAppropriate decomposition temperatureImprove performanceCarbamic acid derivatives preparationOrganic compound preparationFoaming agentChemical compound

Owner:SHANDONG UNIV OF TECH

Water-based self-drying casting paint, and preparation method and application method

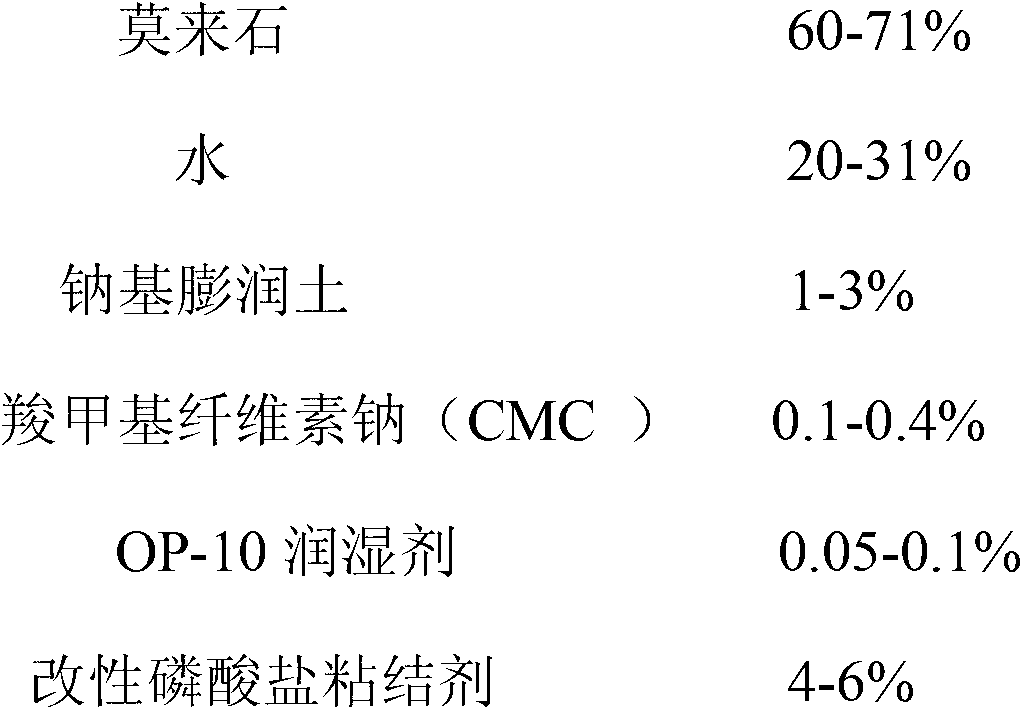

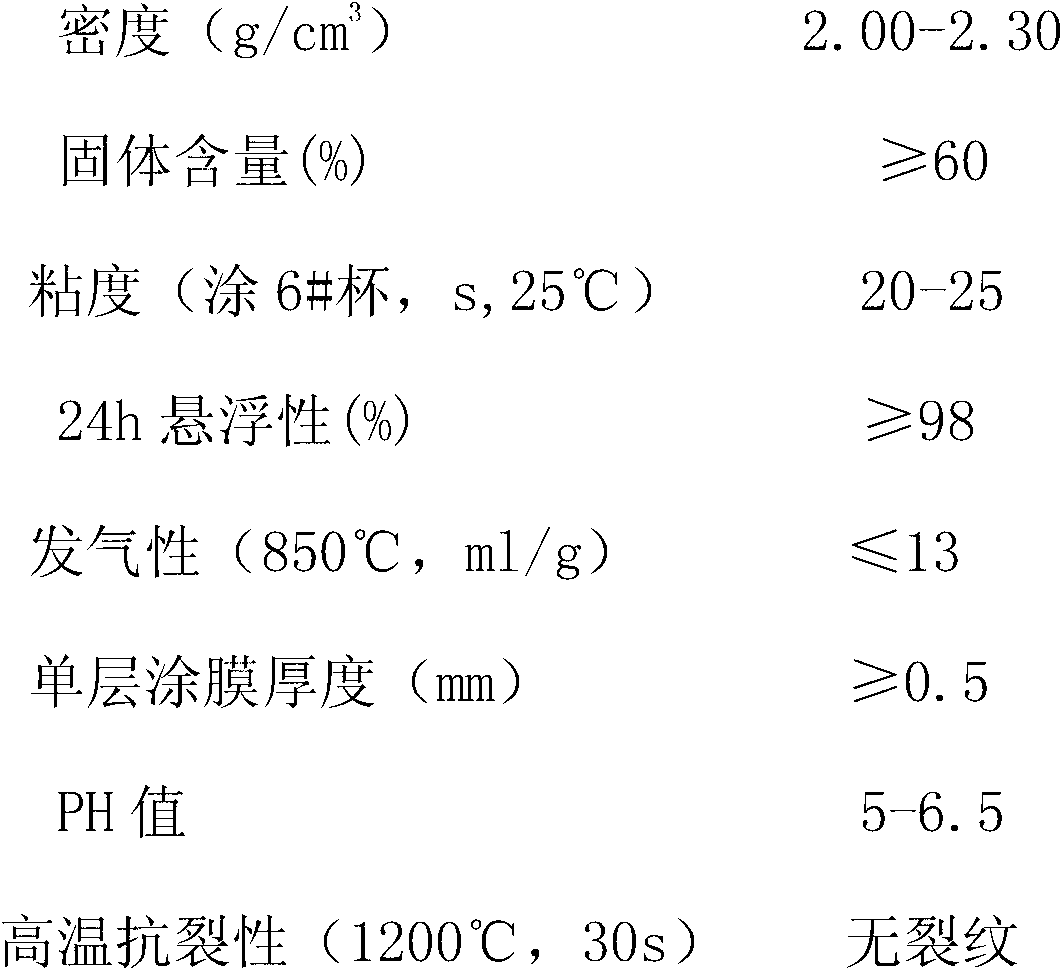

InactiveCN103223458ATightly boundImprove rheologyFoundry mouldsFoundry coresWater basedSodium Bentonite

The invention provides a water-based self-drying casting paint, and a preparation method and an application method. According to the invention, 1-3% of sodium-based bentonite and water 1-1.5 times the weight of bentonite are uniformly stirred with high speed; the mixture is added in a sealed container and is subjected to standing, where the mixture is sufficiently wetted and activated, such that a liquid A is prepared; 0.1-0.4% of sodium carboxymethyl cellulose is dispersed by using ethanol with a concentration no lower than 95% according to a weight ratio of 1:1; water with an amount 30-50 times that of the mixture is added; the mixture is uniformly stirred and is subjected to standing and sufficient initiation; the mixture is mixed with the liquid A; the obtained mixture is stirred with a proper amount of water; a composite suspension is prepared by grinding by using a colloid mill; the suspension is mixed and grinded with 60-71% of mullite, 0.05-0.1% of a wetting agent, and 4-6% of a modified phosphate binder, such that a pasty paint is prepared; and the pasty paint is diluted by using water, such that the paint is obtained. After a reaction with an alcohol-based paint comprising magnesia powder, the paint can be self-dried. Therefore, cost of independent use of an alcohol-based paint or a water-based paint is greatly reduced, and the influence to the environment is greatly ameliorated.

Owner:HUBEI UNIV OF TECH

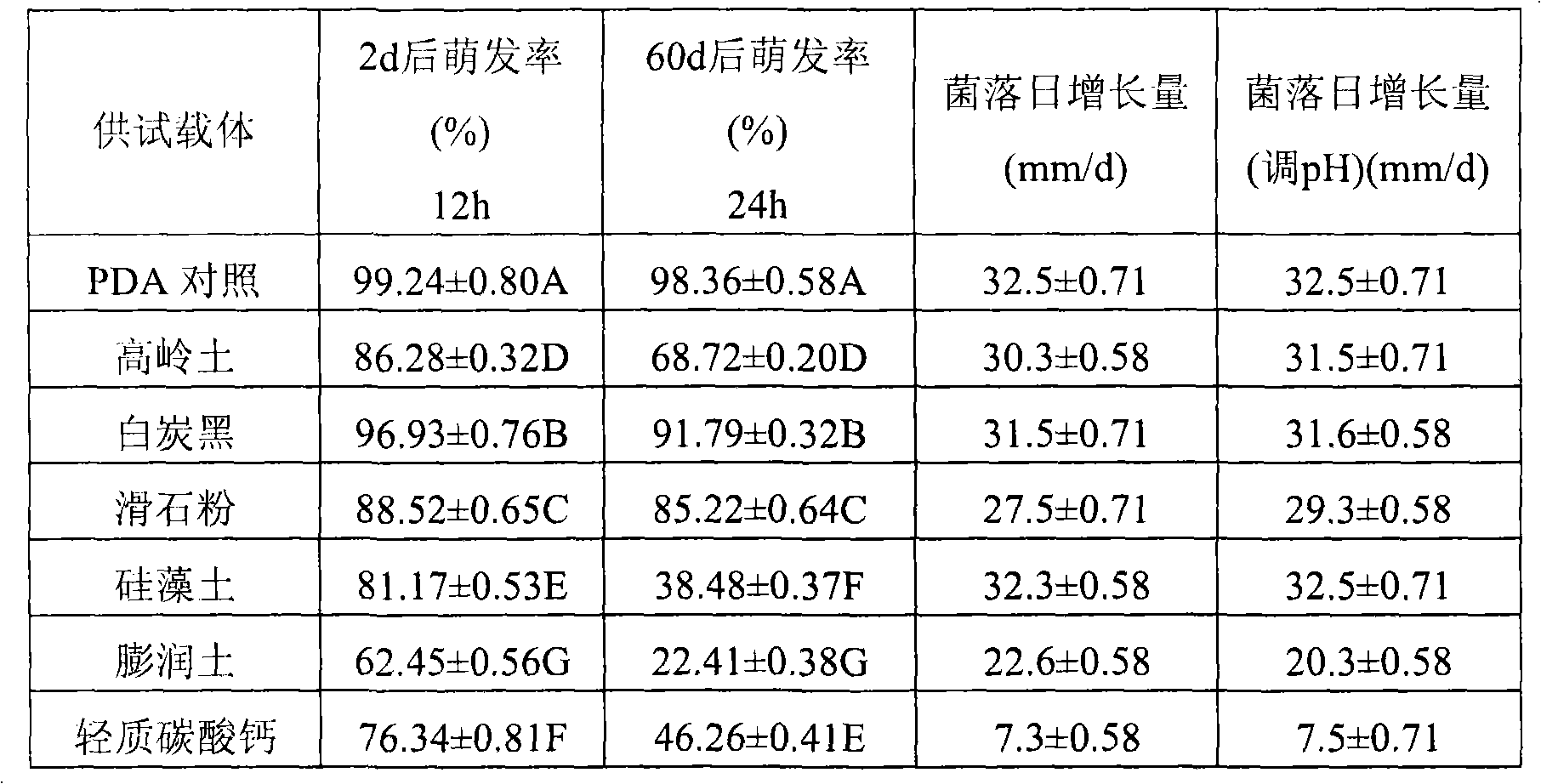

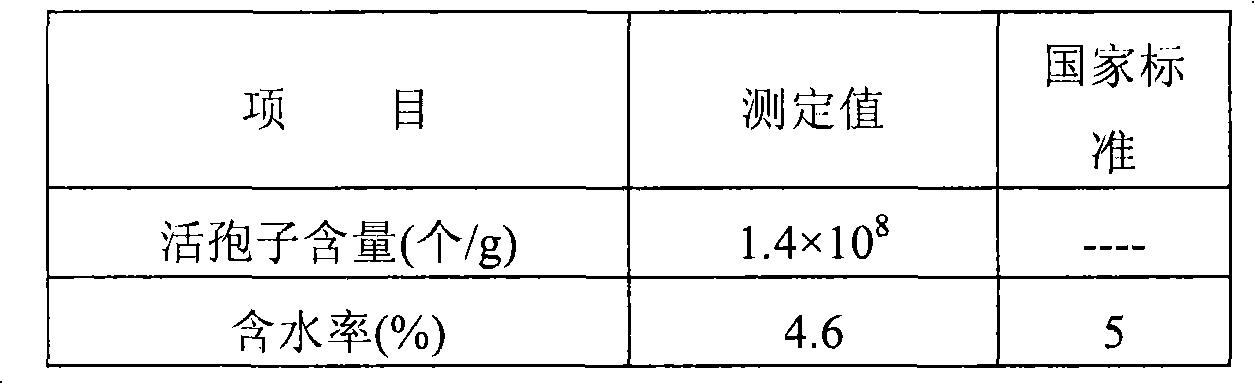

Bacillus spore and trichoderma chlamydospore compound preparation and preparation method and application thereof

ActiveCN102027998APromote plant growthImprove fertilizer use efficiencyBiocidePlant growth regulatorsTrichodermaBacillus spores

The invention provides a compound preparation for controlling plant diseases. The compound preparation consists of a bacillus spore and a trichoderma chlamydospore. The invention also provides a method for preparing the compound preparation and application of the compound preparation.

Owner:EAST CHINA UNIV OF SCI & TECH

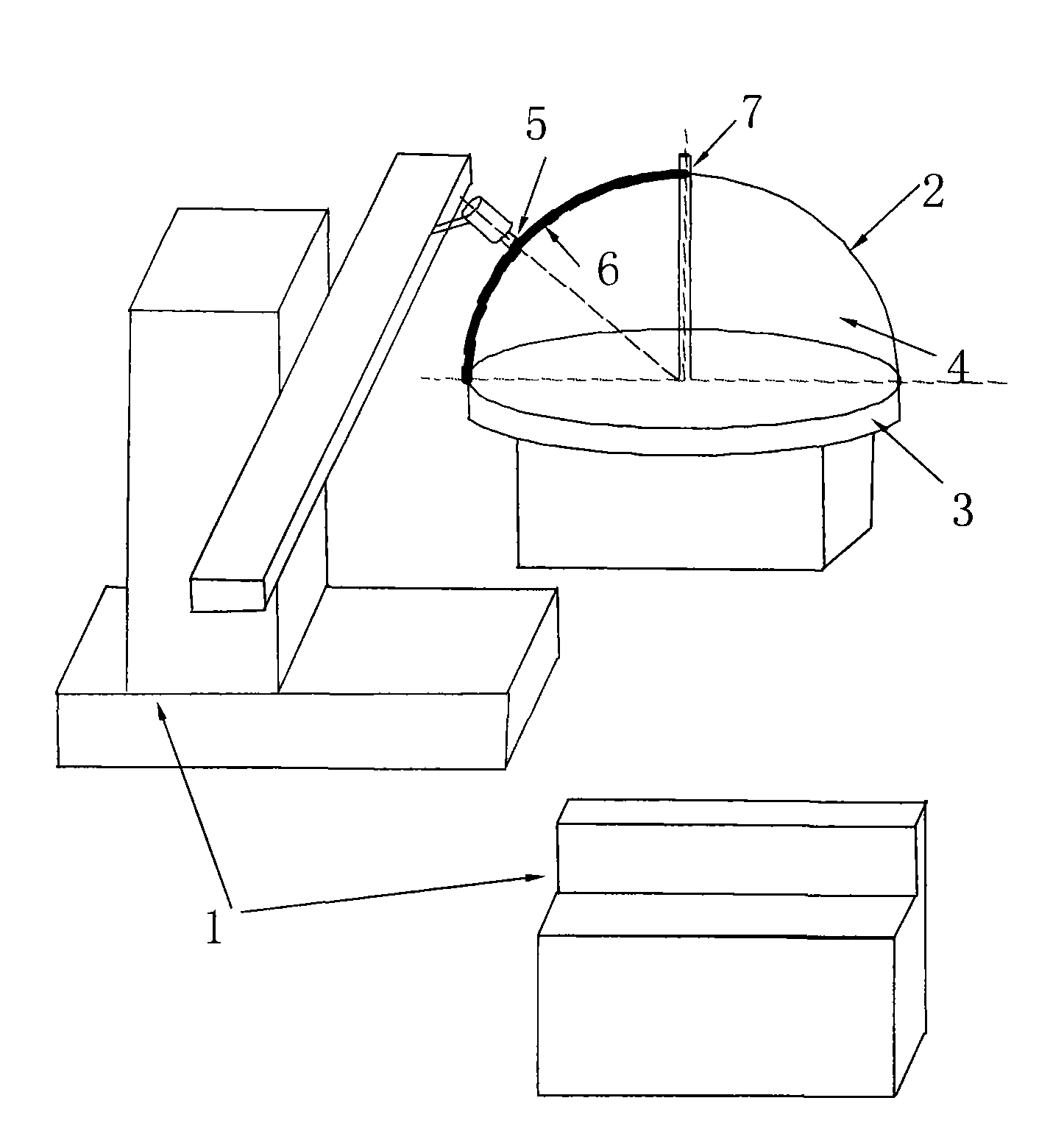

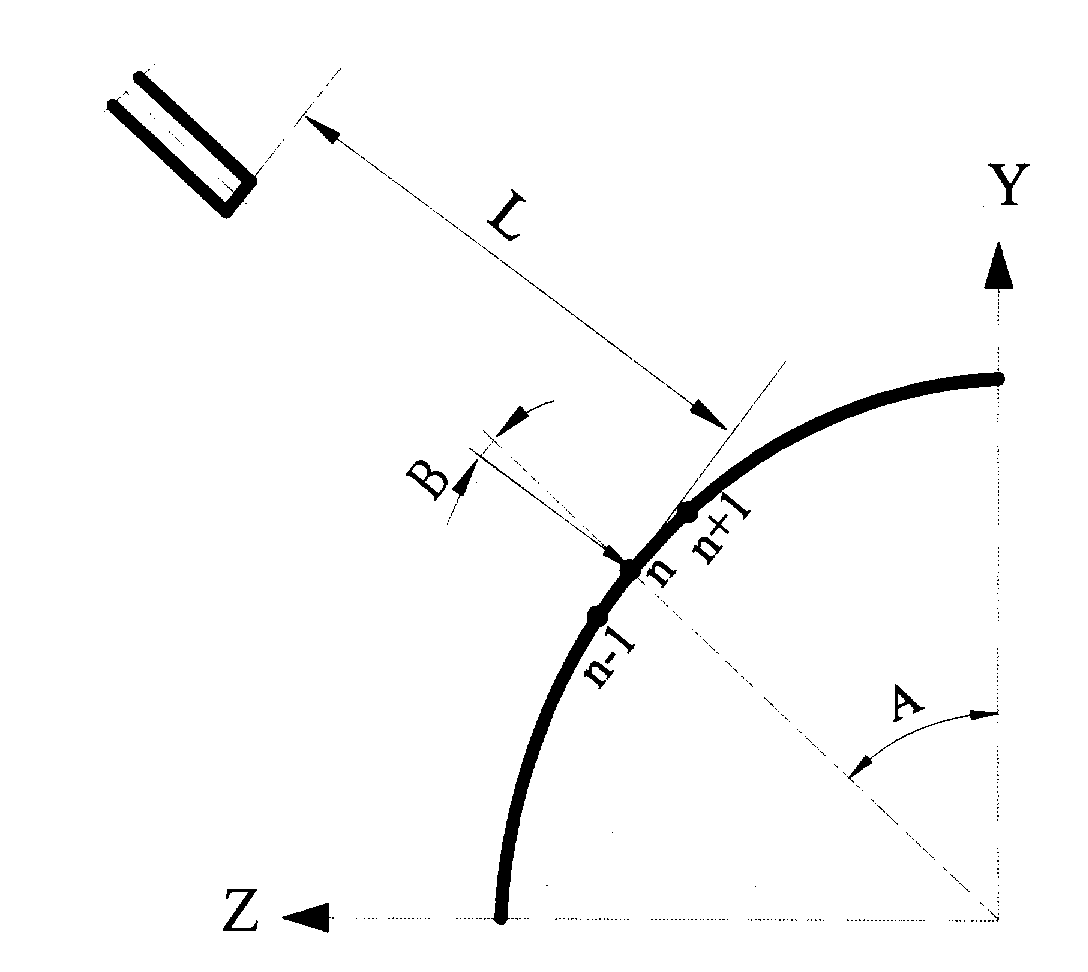

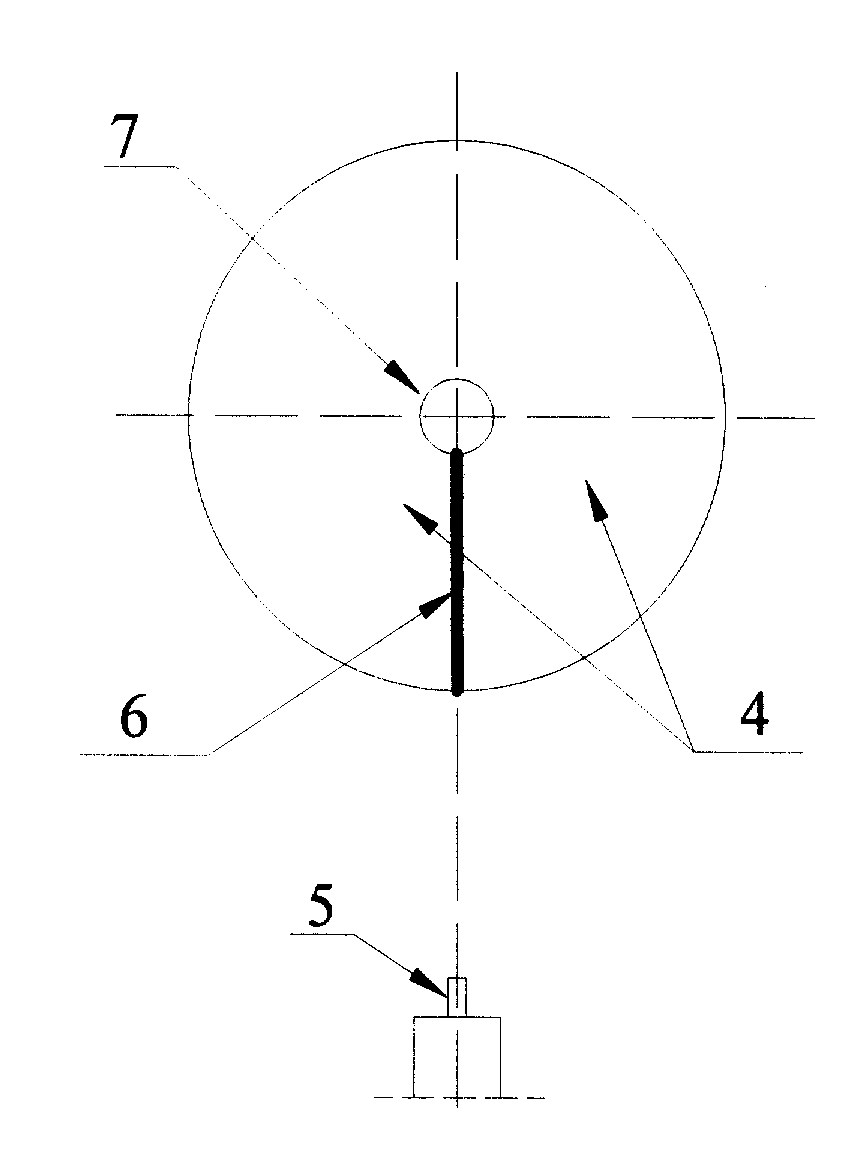

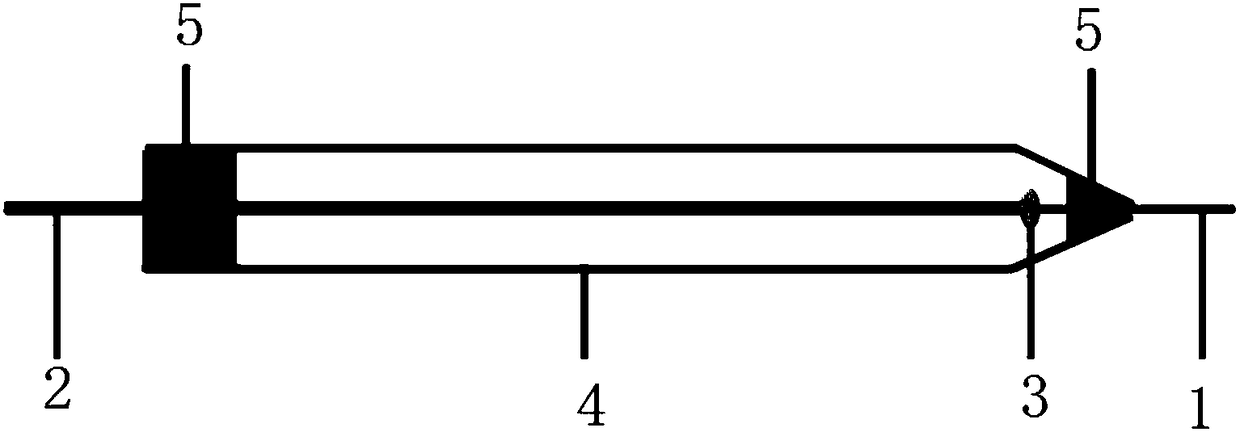

Numerical control stirring friction welding system and welding method thereof

InactiveCN101612689AImprove welding precisionEasy to centerNumerical controlNon-electric welding apparatusEngineeringFriction stir welding

The invention discloses a numerical control stirring friction welding system, which comprises a numerical control stirring friction welder [1] provided with control software, wherein a main shaft of the numerical control stirring friction welder [1] is provided with a stirring head [5]; a welding fixture [2] is arranged on a rotating platform [3]; the shaft center of the welding fixture is the same as that of a central shaft [7] of the rotating platform [3]; and a welding structure member [4] is arranged on the welding fixture [2]. The invention also discloses a welding method for the system, which comprises the following steps: 1, the compiling of numerical control programs; 2, system debugging; 3, assembly; 4, system centration; 5, the set of welding parameters; and 6, system zero restoring. The numerical control stirring friction welding system solves the problems of the welding of space curve welding seams and plane two-dimensional welding seams, and has the advantages of high welding precision, simple and convenient operation, and the like.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

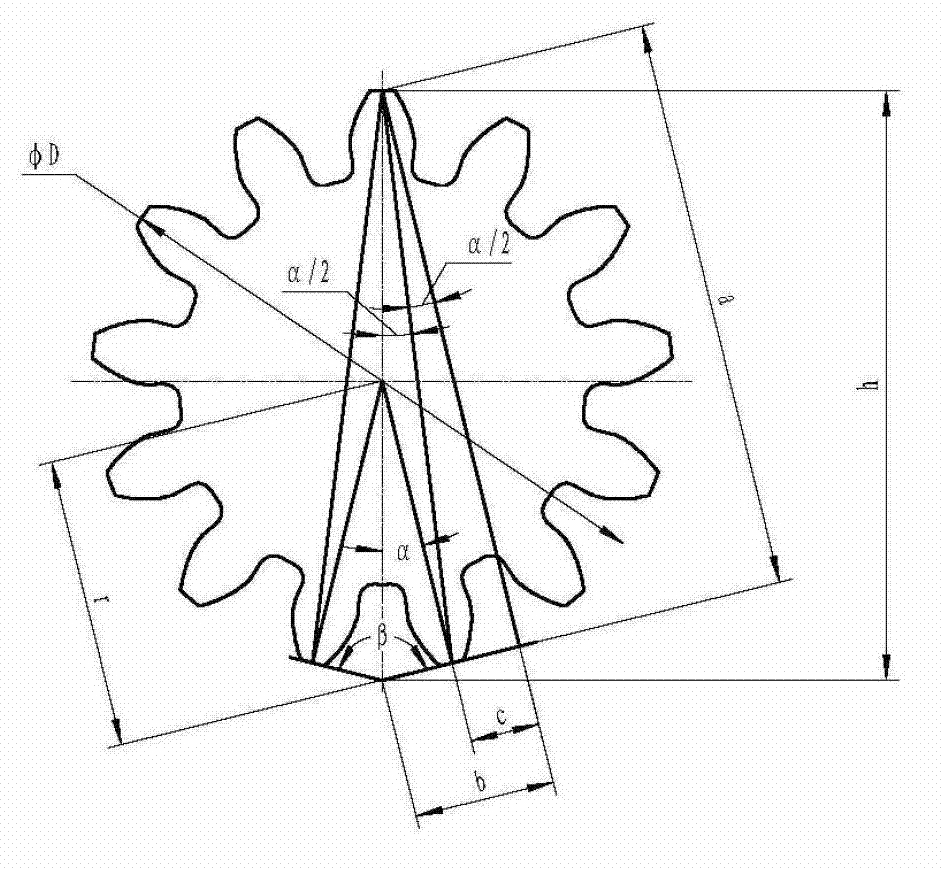

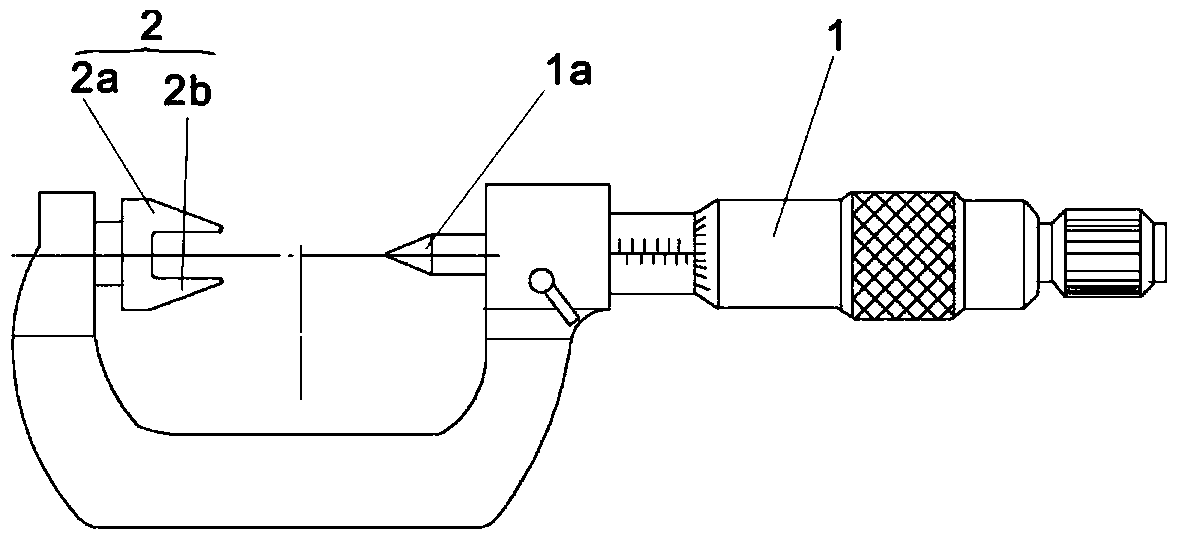

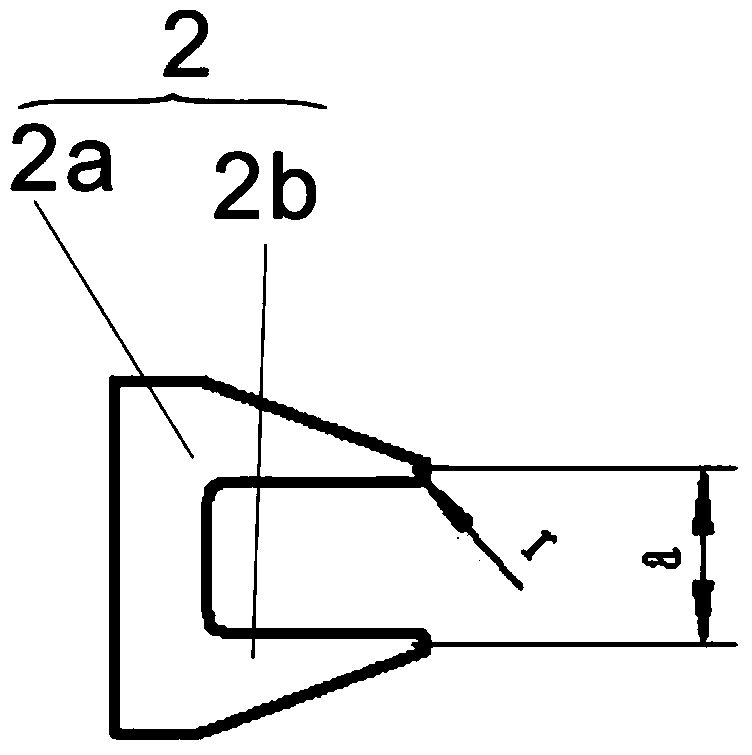

Measuring method and measuring equipment of large diameter of odd number gear or spline

InactiveCN103033115ASolve the problem of rapid measurementReduce manufacturing costMechanical diameter measurementsMeasuring equipmentGreek letter alpha

The invention discloses a measuring method and measuring equipment of the large diameter of an odd number gear or a spline. The large diameter of the odd number gear or the spline, namely the h value, is measured according to the following formula: r is the radius of an external circle of the odd number gear or the spline, alpha is 180 degrees / Z, and Z is the tooth number of the odd number gear. The measuring method and the measuring equipment can solve the fast measurement problem of the odd number gears and spines of various specifications on a production site, have the advantages of being low in production cost, convenient and fast, and are particularly suitable for production application.

Owner:JIANGSU SUN WAY GRP FEIDA CO LTD

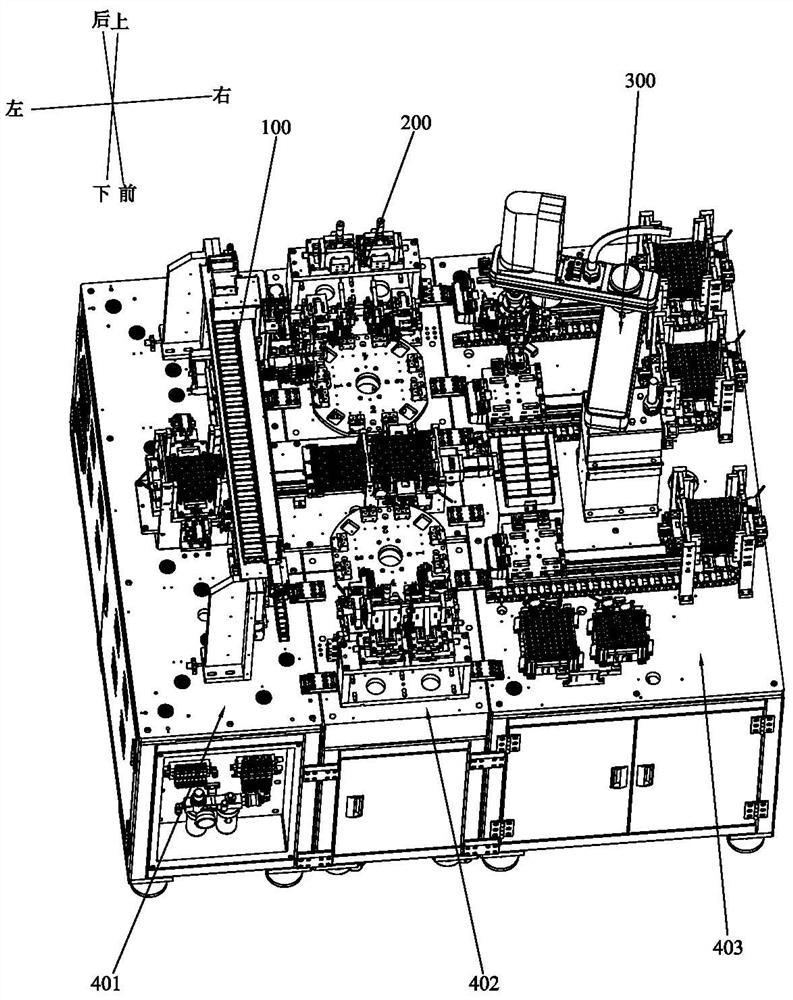

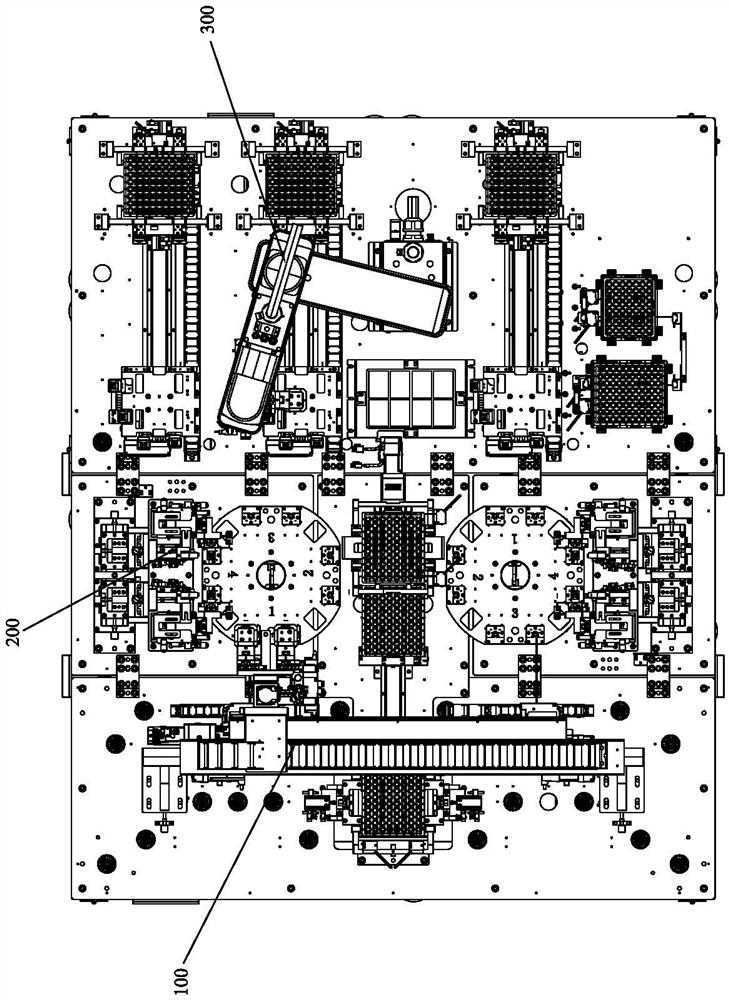

Double-turntable full-automatic detection machine and detection method thereof

PendingCN112517417AReduce labor intensityImprove detection efficiencySortingControl engineeringProcess engineering

The invention discloses a double-turntable full-automatic detection machine and a detection method thereof. The double-turntable full-automatic detection machine comprises a detection machine and an automatic feeding system, an automatic detection system and an automatic discharging system which are arranged on the detection machine. The automatic feeding system is provided with a feeding mechanism and a feeding chuck. The automatic detection system is provided with a first detection station and a second detection station which are each provided with a turntable and a detection mechanism. Eachturntable is provided with a loading jig. The automatic discharging system is provided with a discharging chuck. The feeding chuck grabs products from the feeding mechanism and places the products inthe loading jigs on the turntables, the first detection station and the second detection station detect the products on the corresponding turntables, and after detection is completed, the dischargingchuck grabs the products in the loading jigs and places the products in corresponding good product areas or defective product areas according to detection results to complete discharging. Therefore,compared with the prior art, the double-turntable full-automatic detection machine has the advantages that the automation degree is higher, and the detection efficiency is multiplied.

Owner:皓星智能装备(东莞)有限公司

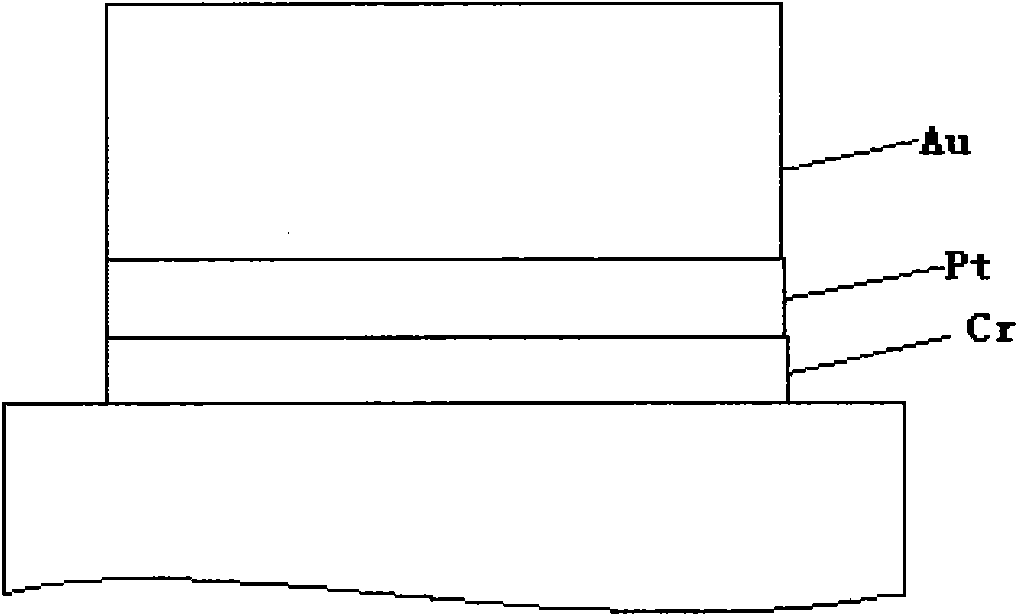

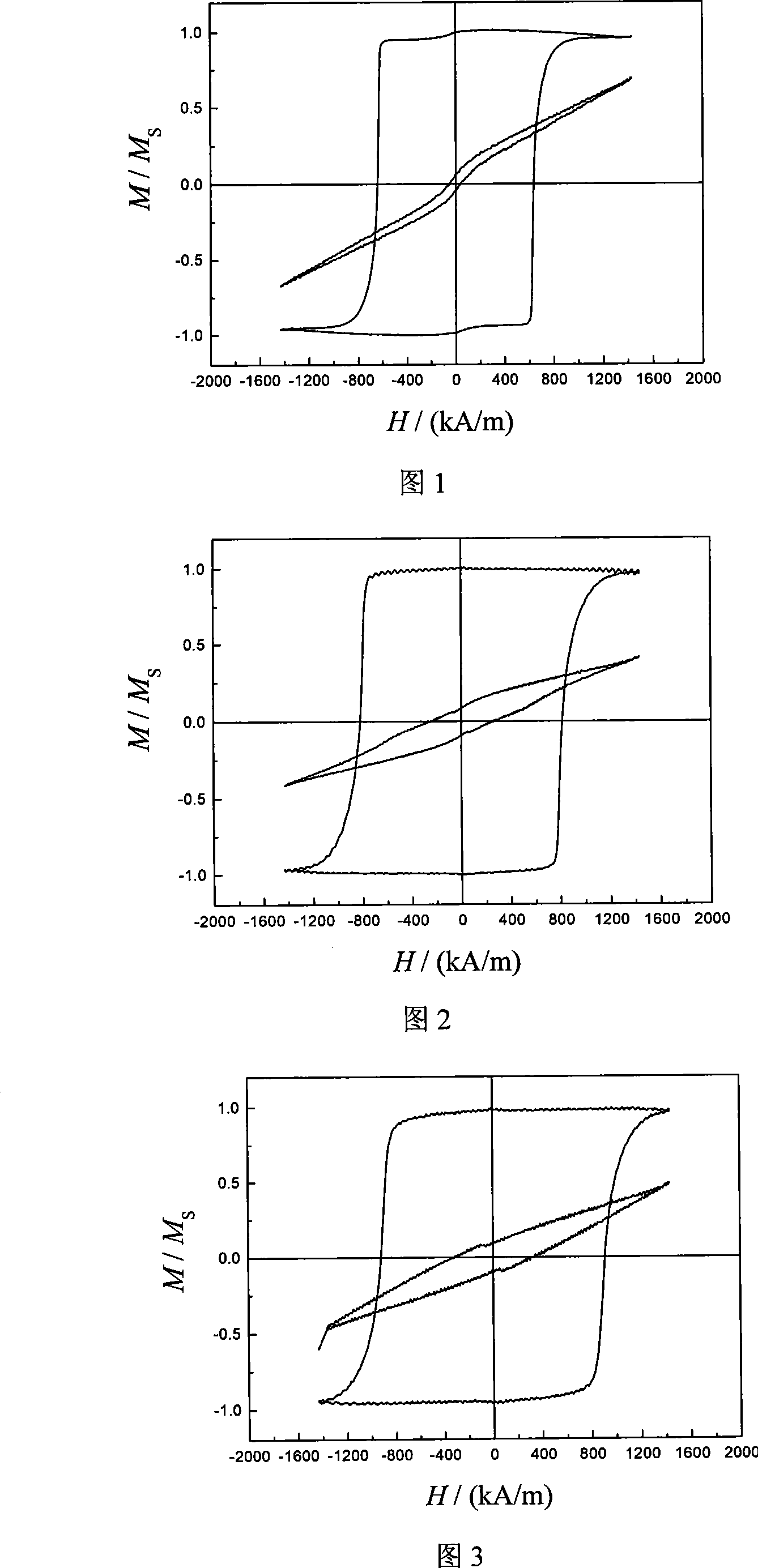

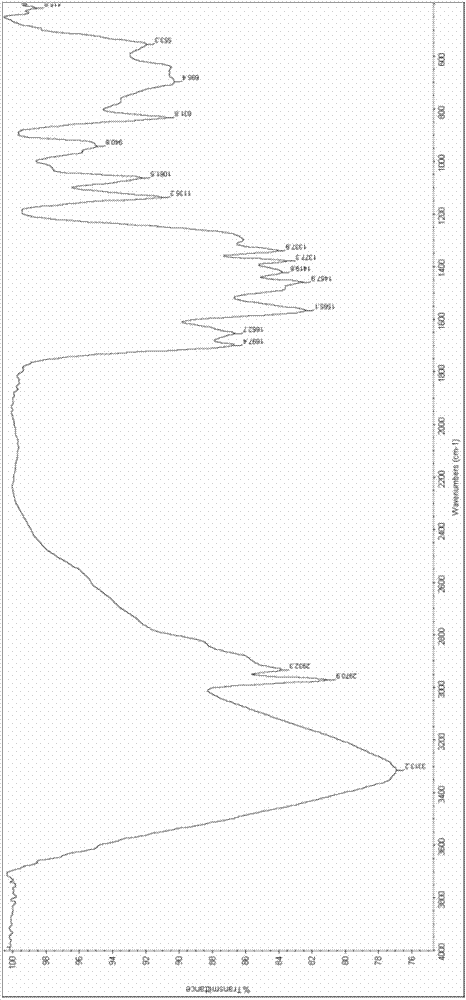

A preparation method for ultra-high density perpendicular magnetic recording medium

InactiveCN101217041AIncreasing the thicknessReduce thicknessCoating by sputteringRoom temperatureSingle crystal substrate

The invention provides a preparation method used for ultra-high density perpendicular magnetic recording medium. A multilayer film [FePt (5-20) / Au (2.5-7)] 5-10 deposits on a heated MgO (001) single crystal substrate by utilizing the Magnetron Sputtering method. The temperature of the substrate is 100-450 DEG C, background pressure in the sputtering chamber is 1*10<-5>-7*10<-5>Pa, and argon pressure is 0.9-1.6 Pa when sputtering. After deposition, the film is cooled to the room temperature and then put into a vacuum annealing furnace for heat treatment with the annealing temperature is 470-700 DEG C, the annealing time is 20m-4 h, and the background pressure in the annealing furnace is 2*10<-5>-7*10<-5>Pa. The prepared L10-FePt film is characterized in vertically alignment, superior magnetic property and particle size smaller than 10nm, and is suitable for ultra-high density perpendicular magnetic recording medium. The method has the advantages of low cost, easy preparation and suitability for industrial application.

Owner:UNIV OF SCI & TECH BEIJING

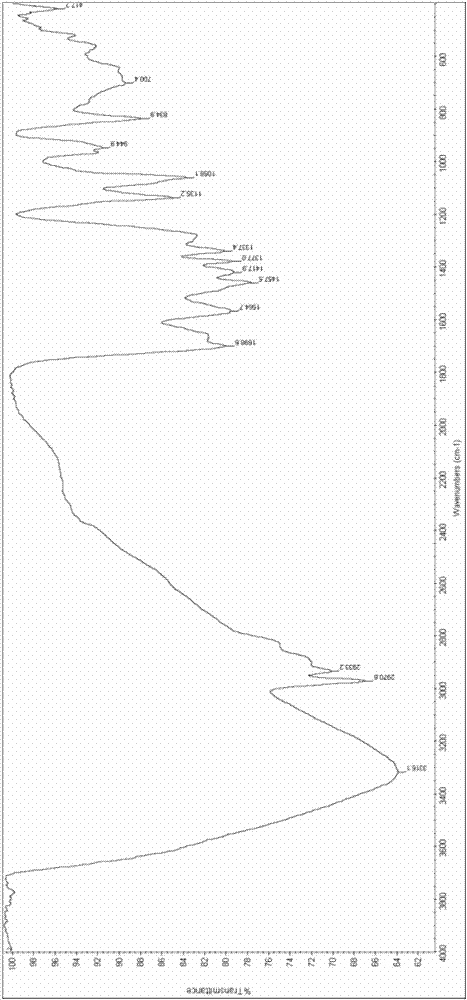

Formic acid organic amine salt compound and application thereof as foaming agent

ActiveCN107089916AAppropriate decomposition temperatureImprove performanceOrganic compound preparationCarboxylic acid salt preparationFoaming agentAlcohol

The invention discloses a formic acid organic amine salt compound with the following general formula (I) A<n->[B<m+>]p. In the formula (I), A<n-> is formate; B<m+> is or comprises ammonium ion and / or organic amine B positive ion; m=1-10; 0<p<=n / m; the formula (I) compound has at least one hydroxyalkyl connected with an N atom, that is to say, has an alcohol amine residue. The compound can be a polyurethane foaming agent or polystyrene foaming agent or polyvinyl chloride foaming agent.

Owner:BUTIAN NEW MATERIAL TECH CO LTD

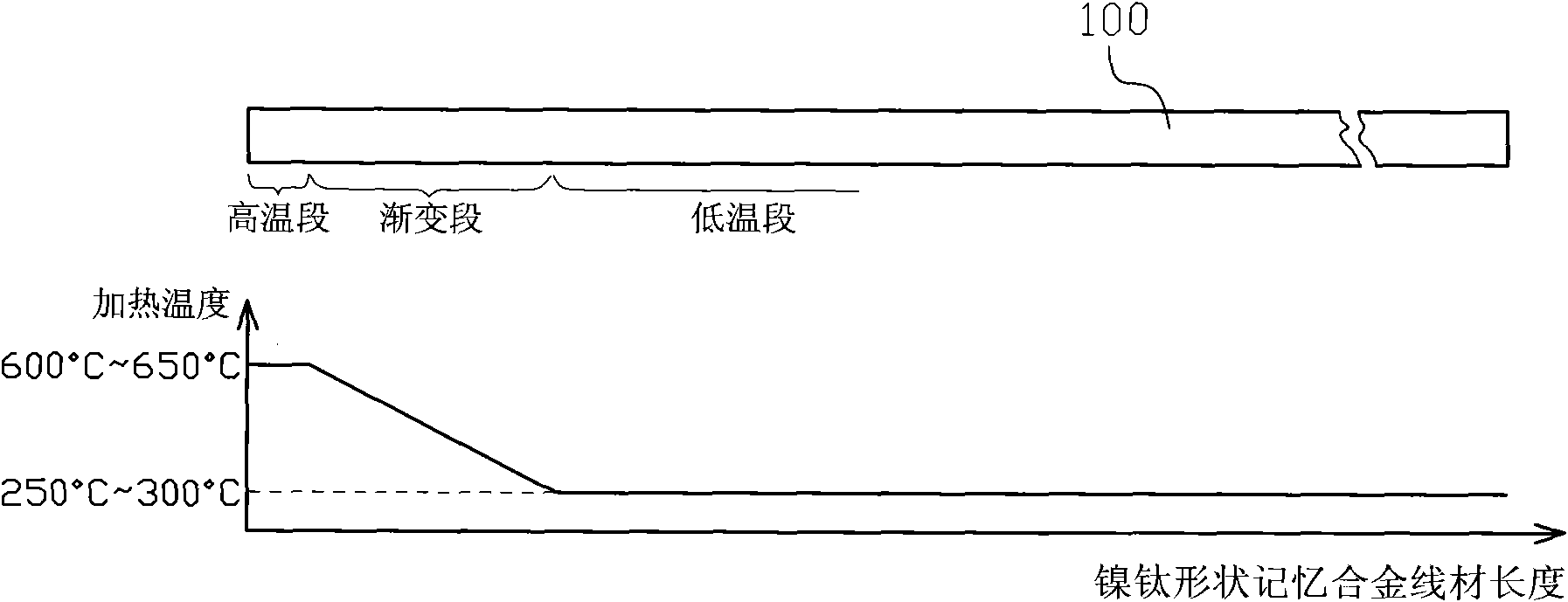

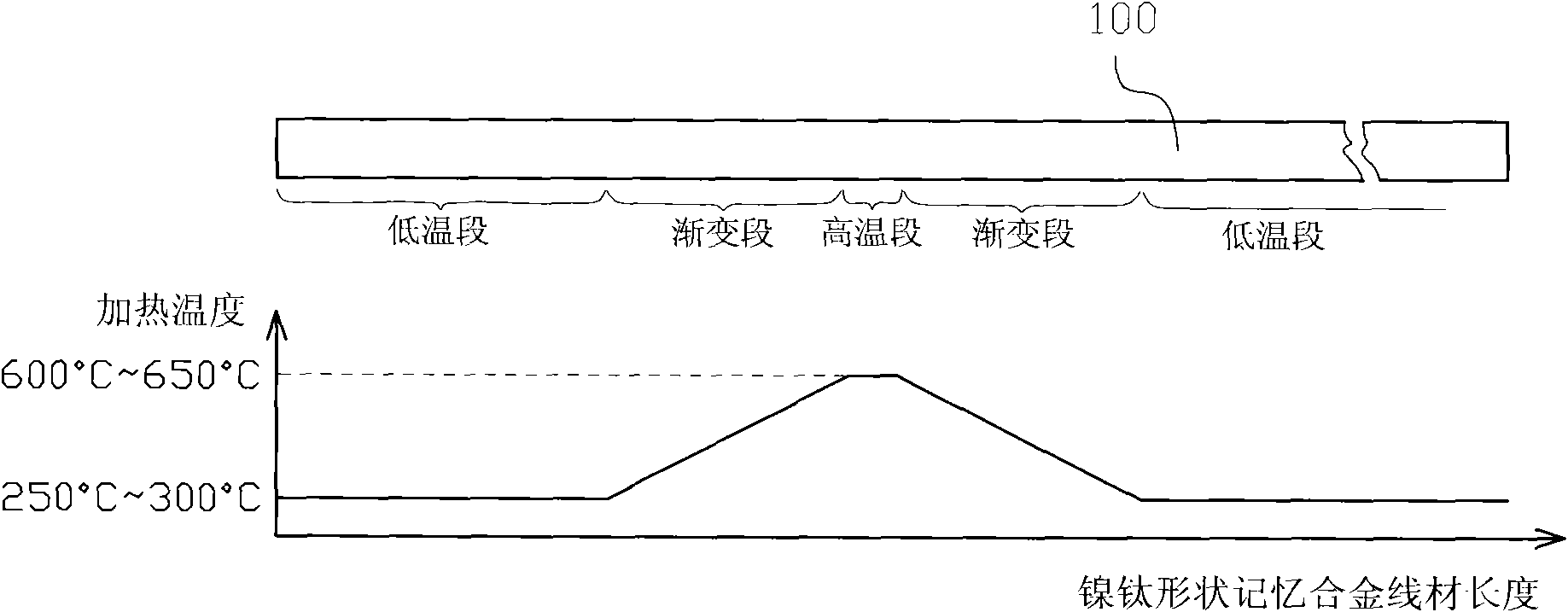

Heat-treatment method and equipment for nickel-titanium shape memory alloy

InactiveCN101665894ALow costReduce process stepsIncreasing energy efficiencyHeat treatment process controlAlloyTitanium

The invention provides a heat-treatment method and an equipment for nickel-titanium shape memory alloy, relating to a method for preparing nickel-titanium shape memory alloy wire with functional continuous gradients. The method comprises the steps of preheating the nickel-titanium shape memory alloy wire, placing the nickel-titanium shape memory wire in a tuner pyrosphere of a high-frequency induction heating machine which forms continuous heating temperature with different temperature gradients due to gradual change of fire of the pyrosphere, heating, keeping temperature and annealing for a specified time. The equipment is characterized in that a plurality of tuner pyrospheres of the high-frequency induction heating machine are assembled into a pyrisphere group coaxially; all pyrispheresare gradually equidifferent to form the heating temperature of continuous different temperature gradients. Alternatively, the tuner pyrosphere of the high-frequency induction heating machine is enwound as spiral coils; and the alloy wire is heated under continuous different temperature gradients by the gradual change of pyrosphere diameter or pyrosphere pitch or the combination of the diameter andthe pitch. The heat-treatment equipment is special, simple, convenient and practical, the process step is few, the time is short, the efficiency is high, and the heat-treatment equipment is applicable to the production and application of high-class nickel-titanium shape memory alloy glasses frame part.

Owner:深圳市欧帝光学有限公司

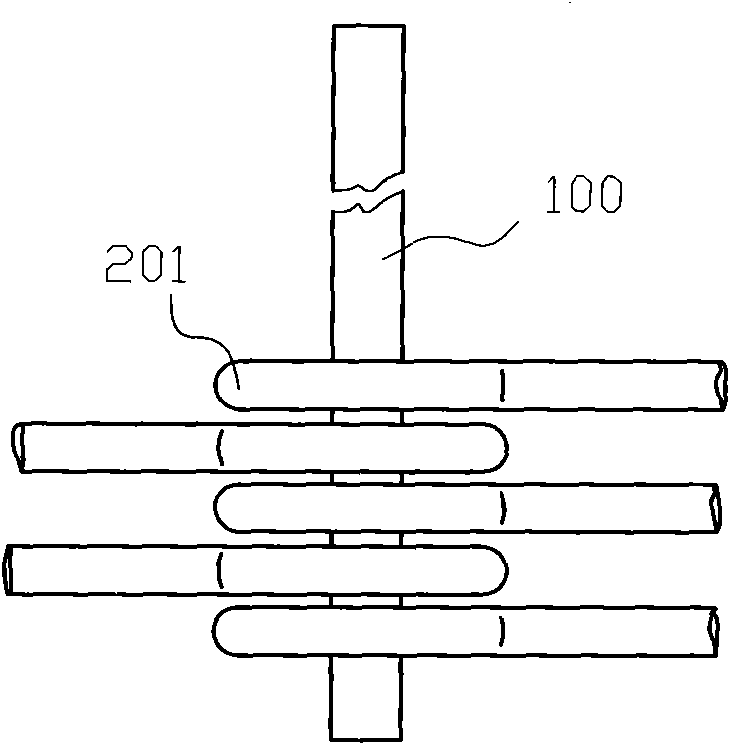

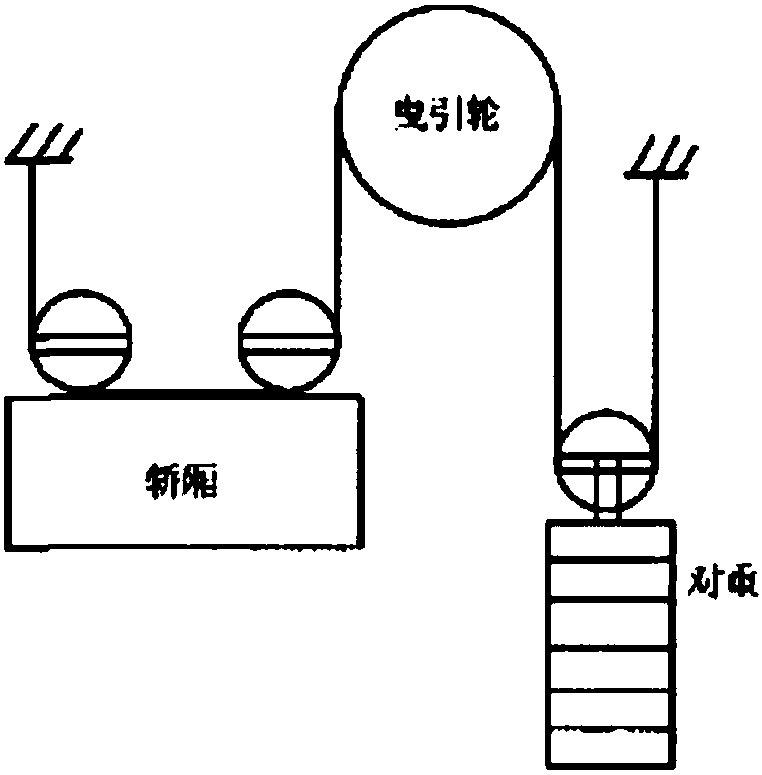

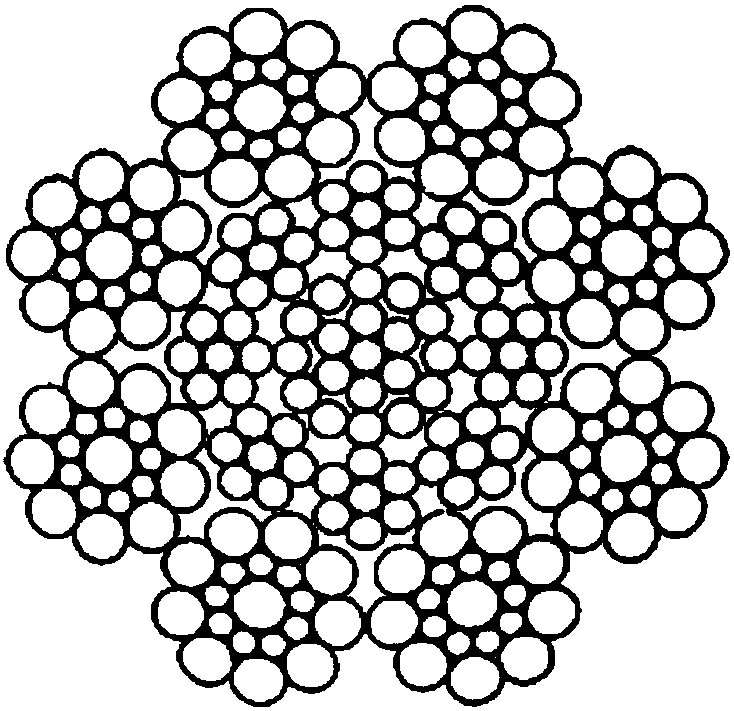

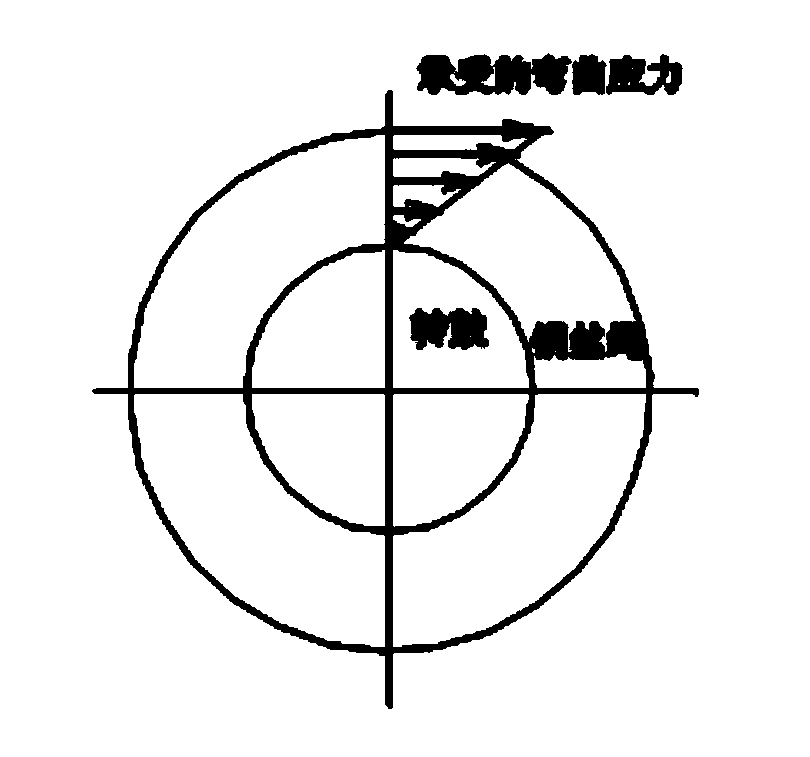

Method for producing high-speed mute and durable steel wire ropes for elevators

The invention belongs to the field of application of steel for steel wire ropes, in particular to a method for producing high-speed mute and durable steel wire ropes for elevators. The steel for the steel wire ropes comprises the chemical components in mass percentage: 0.64-0.69% of C, 0.10-0.30% of Si, 0.30-0.60% of Mn, at most 0.020% of P, at most 0.010% of S and the balance of Fe and unavoidable impurities, wherein the target mass percentage of a part of chemical components is as follows: 0.65% of C, 0.50% of Mn and 0.15% of Si; and the size of the impurities is controlled by below 8mu m. The method comprises the following steps: (1) descaling and drawing a steel wire rod prepared from the steel components for the first-time annealing, drawing again for the second-time annealing, then drawing to obtain steel wires, wherein the drawing pass after the second-time annealing is 6, and finally standing the steel wires to form a semi-finished product of steel wire rope for elevators; (2)plastic-coating the semi-finished product of steel wire rope for elevators to form a flat ribbon, wherein the thickness of the flat ribbon is 3mm, and thus obtaining the high-speed mute and durable steel wire rope for elevators. The steel wire rope for elevators produced by the method has the advantages of high strength, muteness, durability, and the method has a simple process and is suitable forproduction application.

Owner:武汉钢铁有限公司

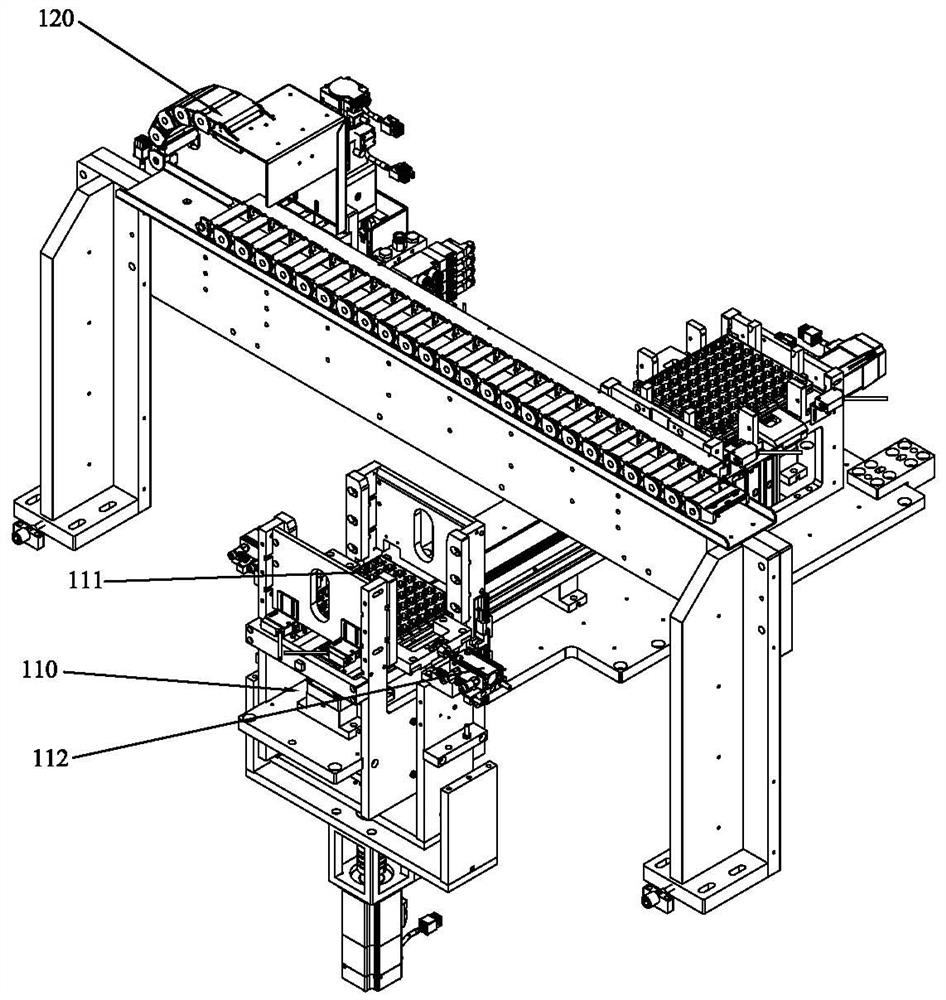

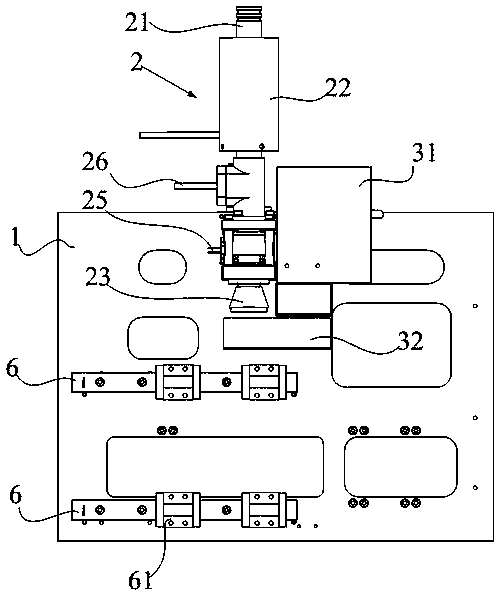

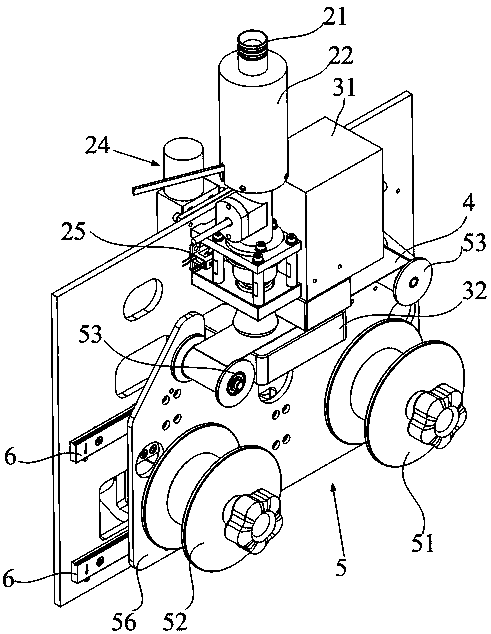

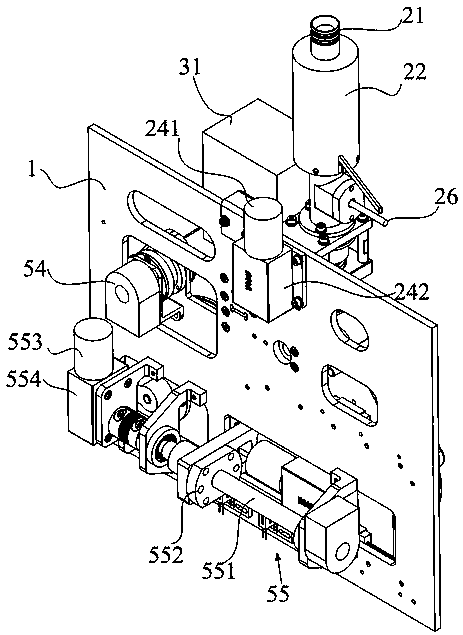

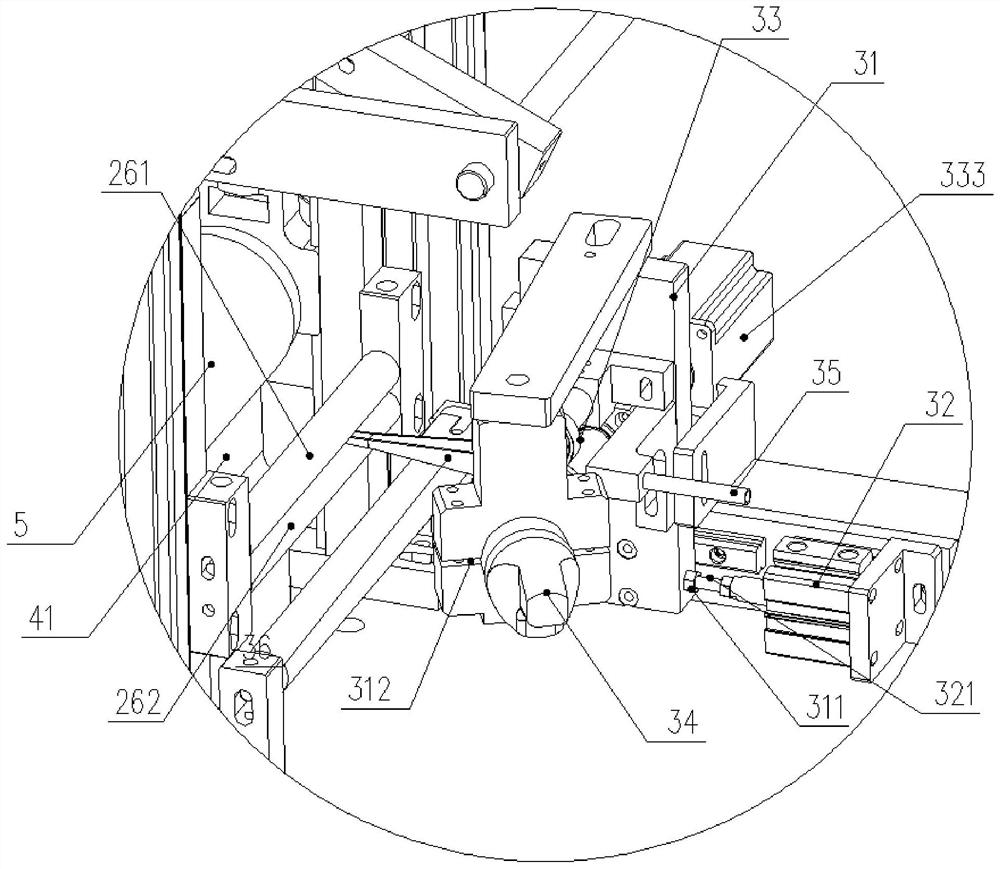

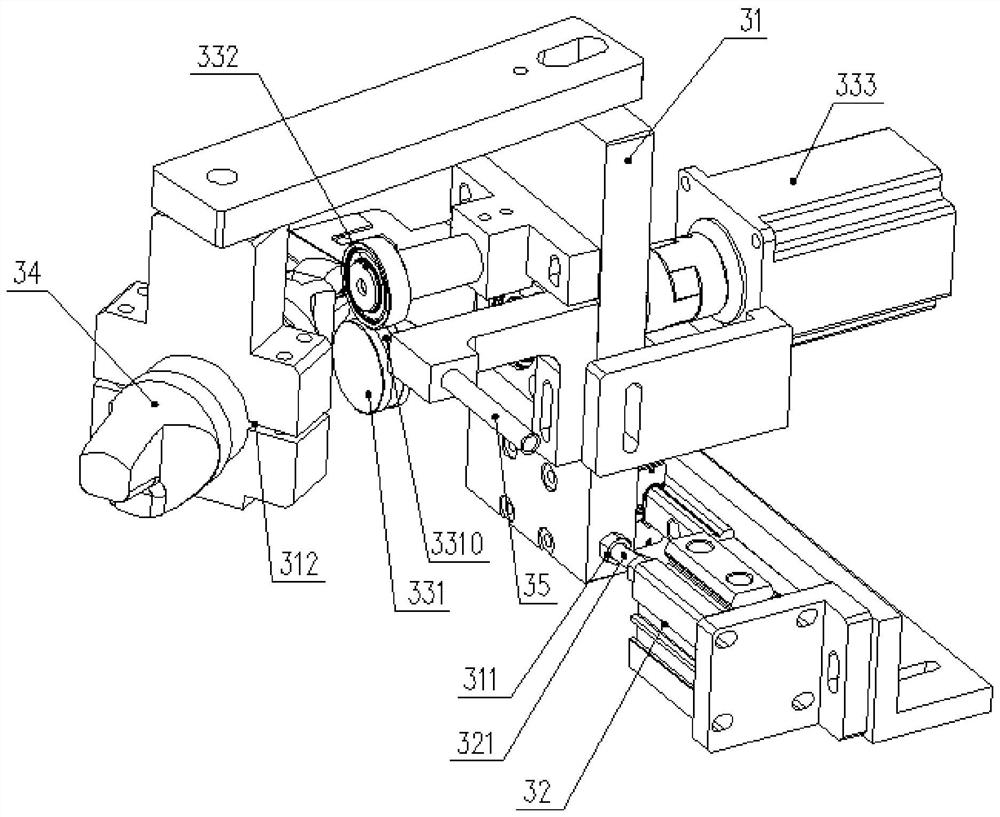

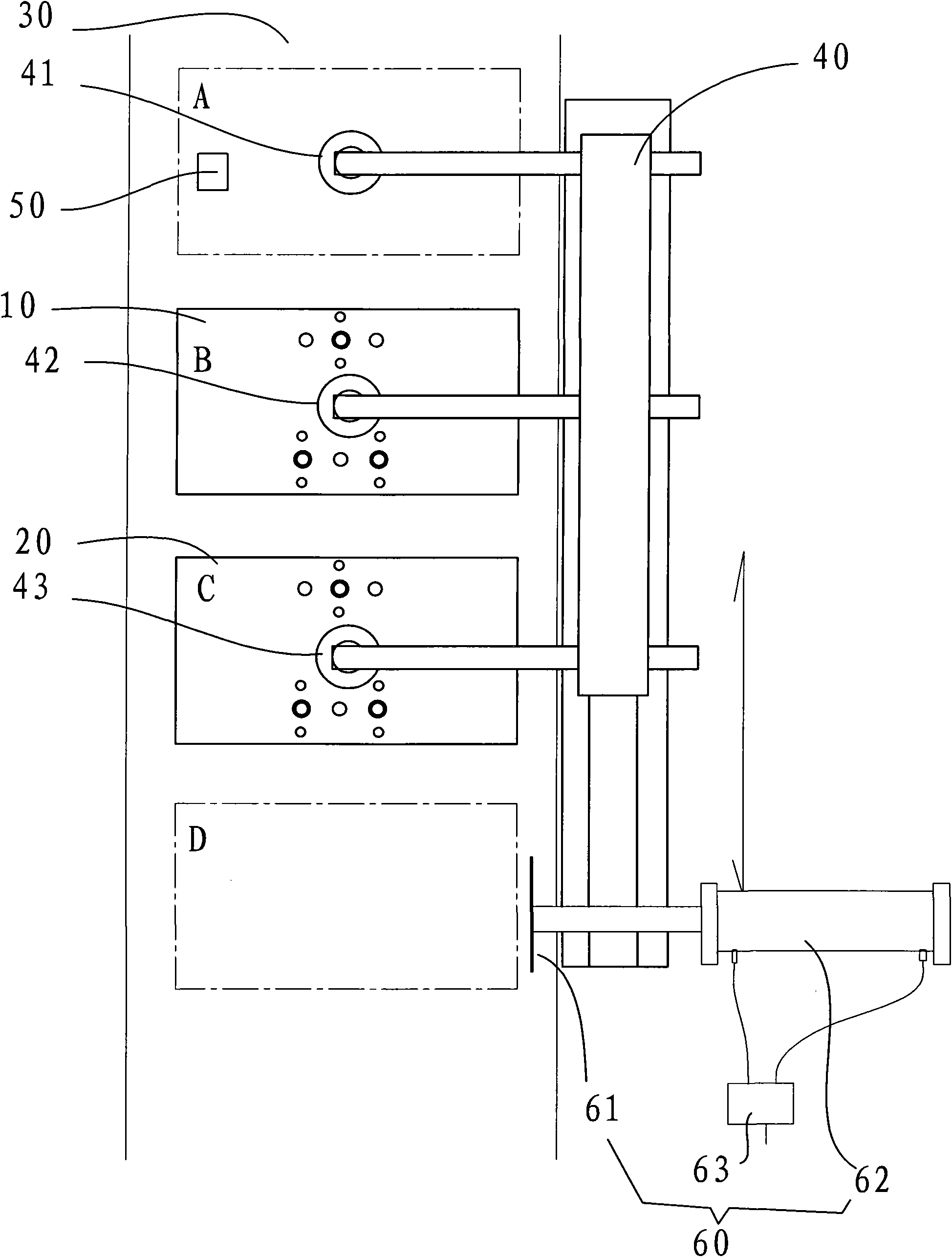

Paper feeding mechanism internally moving type double-station particulate matter monitoring device

PendingCN108152181AMove quickly and preciselyNot easy to break paperParticle suspension analysisPaper tapePulp and paper industry

The invention provides a paper feeding mechanism internally moving type double-station particulate matter monitoring device. The device comprises a sampling mechanism, a detecting mechanism and a paper feeding mechanism, the sampling mechanism comprises a sampling tube, the upper end of the sampling tube is connected with a cutter, and the lower end of the sampling tube is connected with an enrichment nozzle; a measuring mechanism comprises a beta ray emitting source and a beta ray photomultiplier tube; the paper feeding mechanism is mounted on guide rails and driven by a moving driving mechanism to move left and right along the guide rails; the paper feeding mechanism comprises a fixing plate, a paper placing wheel, a paper collecting wheel and two guiding wheels are mounted on the fixingplate, and the paper collecting wheel is driven by a paper tape drive mechanism to rotate. According to the double-station particulate matter monitoring device, paper tapes move in one direction, andas long as the paper tapes between the paper collecting wheel and a paper conveying wheel have proper winding tightness, a paper pressing wheel is not needed to press the paper tapes. The movement ofthe paper tapes between sampling stations depends on the overall movement of the paper feeding mechanism, the movement is fast and accurate, paper is unlikely to break, and monitoring of the concentration of particulate matter can be continuously performed for a long time.

Owner:QINGDAO ZHONGRUI INTELLIGENT INSTR

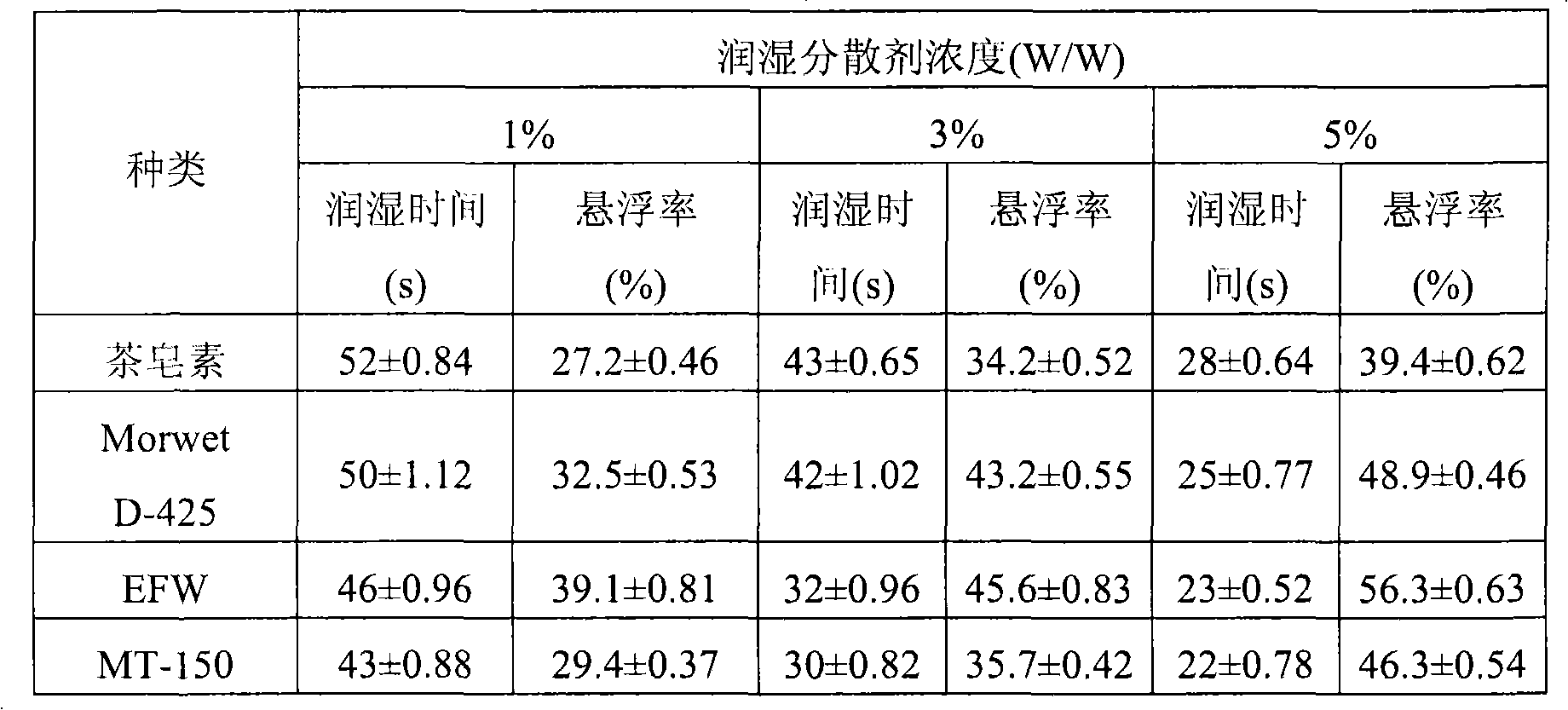

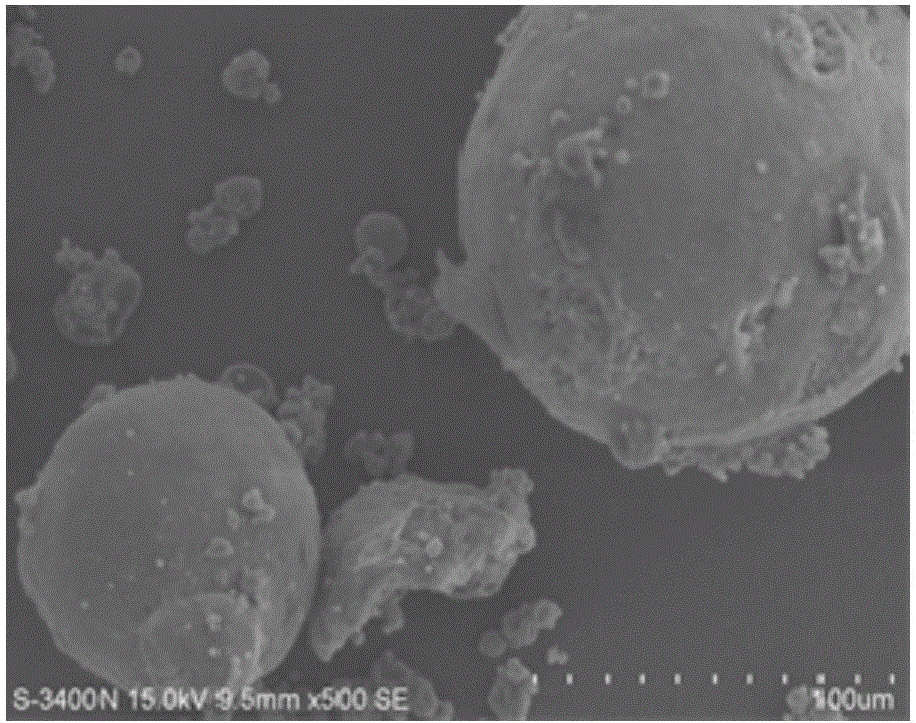

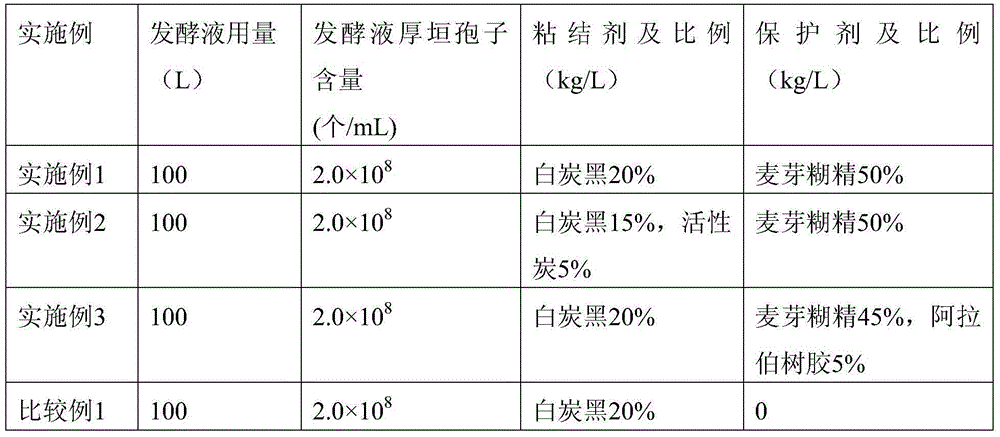

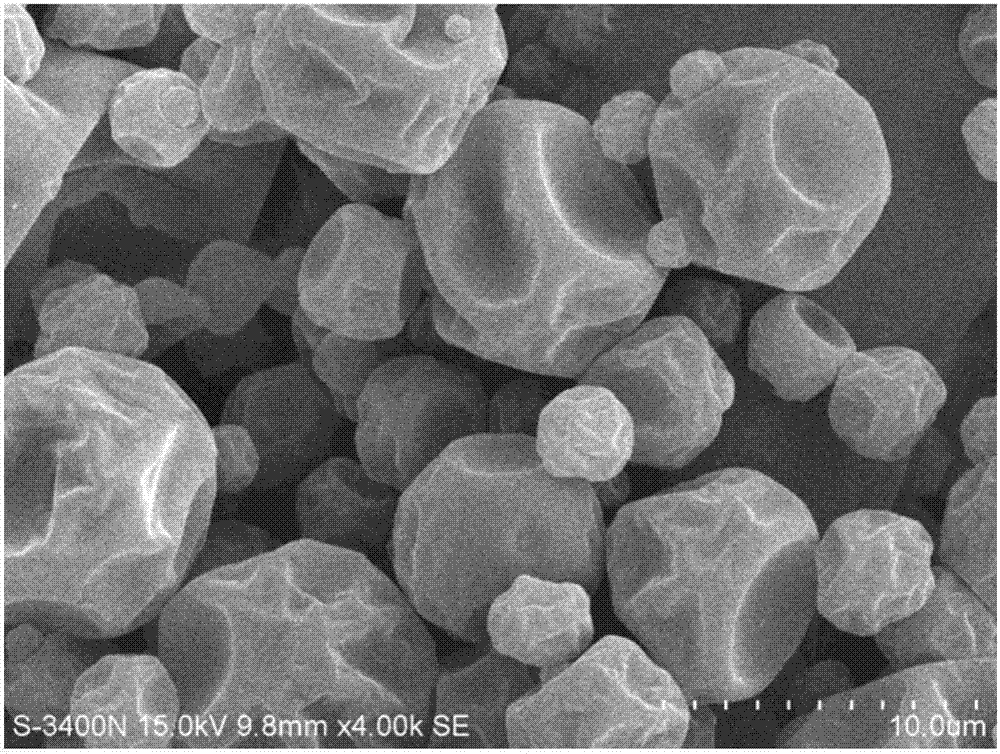

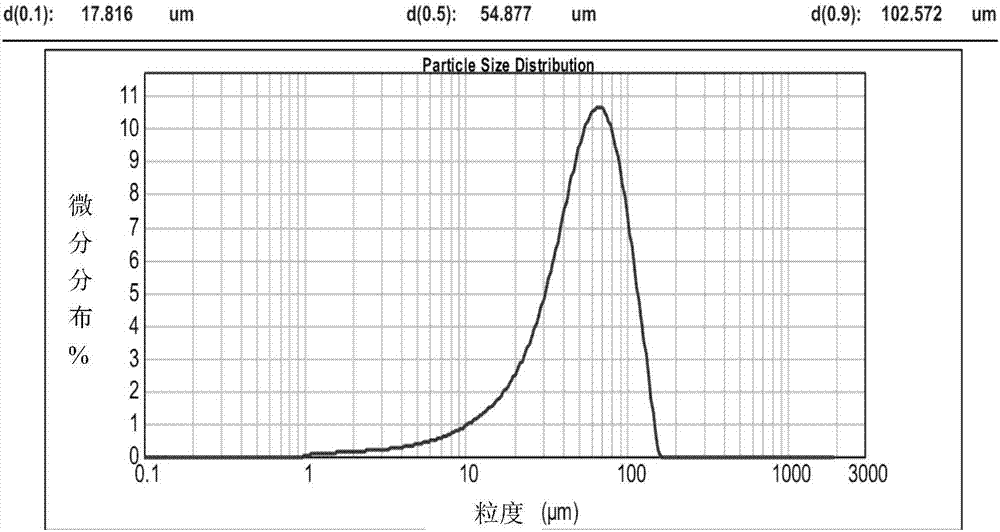

Trichoderma sp. chlamydospore microcapsule and its preparation method and use

The invention discloses a trichoderma sp. chlamydospore microcapsule for preventing and treating plant diseases. The trichoderma sp. chlamydospore microcapsule comprises trichoderma sp. chlamydospores, a binder and a protective agent. The preparation method comprises 1, providing a trichoderma sp. chlamydospore fermentation liquor and 2, mixing the trichoderma sp. chlamydospore fermentation liquor, the binder and the protective agent and carrying out spray drying to obtain the microcapsule preparation. The trichoderma sp. chlamydospore microcapsule can be used for preventing and treating plant soil borne diseases and especially has effects of preventing and treating crucifer clubroot and grape gray mold rot. Compared with a conidiospore preparation produced by the traditional method, the trichoderma sp. chlamydospore microcapsule has strong vitality and adverse resistance, has more functions and is suitable for production and application. The trichoderma sp. chlamydospore microcapsule solves the problems of a short shelf life of the existing trichoderma sp. biopesticide, large scale production infeasibility of the existing trichoderma sp. biopesticide and dust in application and production.

Owner:EAST CHINA UNIV OF SCI & TECH

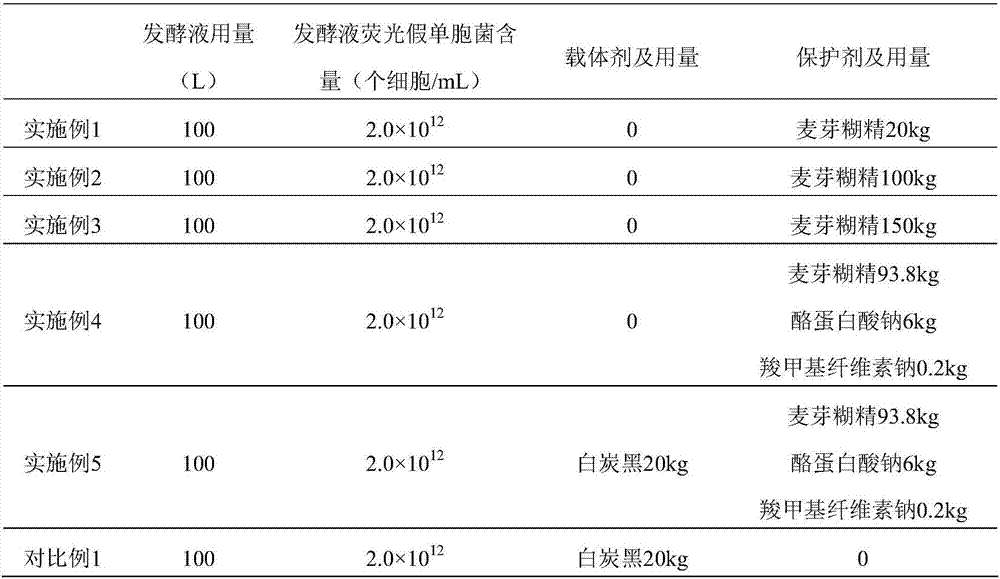

Microcapsule for preventing and treating plant diseases as well as preparation method and application of microcapsule

ActiveCN107873704ADisease controlControl bacterial wiltBiocideFungicidesSodium CaseinatePseudomonas fluorescens

The invention discloses a microcapsule for preventing and treating plant diseases. The microcapsule contains pseudomonas fluorescens, a protective agent and a carrier; and the protective agent is selected from one or two or more of maltodextrin, sodium caseinate and sodium carboxymethyl cellulose. The invention further discloses a preparation method and application of the microcapsule. The microcapsule containing the pseudomonas fluorescens is formed by using liquid fermentation to produce the pseudomonas fluorescens serving as an effective component and organically compounding the carrier, the protective agent and the pseudomonas fluorescens. The microcapsule disclosed by the invention can be used for preventing and treating various plant soil-borne diseases and particularly has a bettereffect for preventing and treating vegetable bacterial wilt and plant wilt; in addition, compared with a living bacterial preparation produced by using a traditional method, the microcapsule has stronger vitality and stress tolerance as well as more effects and functions and is more suitable for production application. The problems that large-scale production cannot be realized and dust is generated in production and application processes due to short shelf life and high death rate during processing of a current biopesticide containing the pseudomonas fluorescens are solved.

Owner:EAST CHINA UNIV OF SCI & TECH

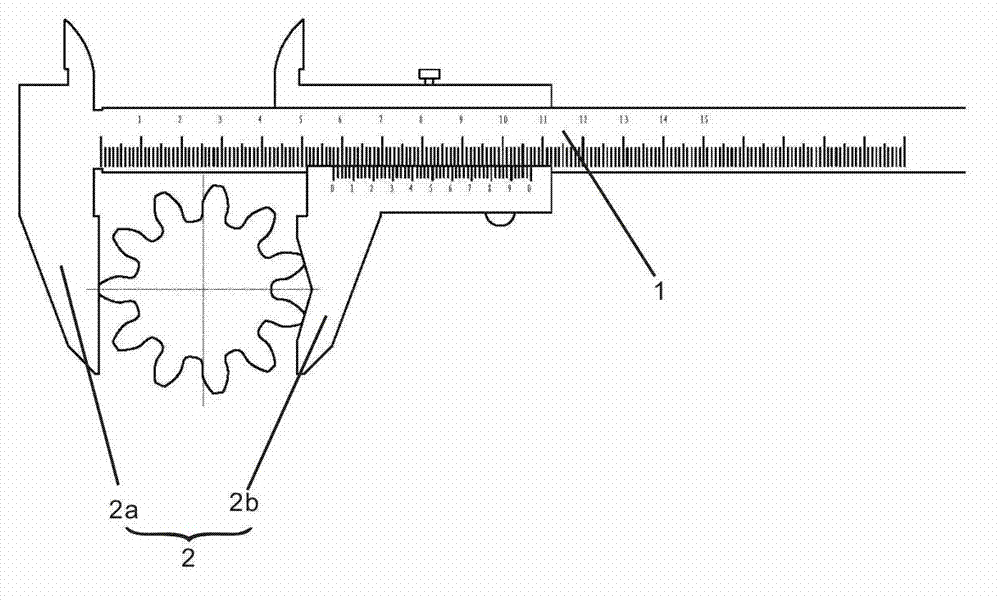

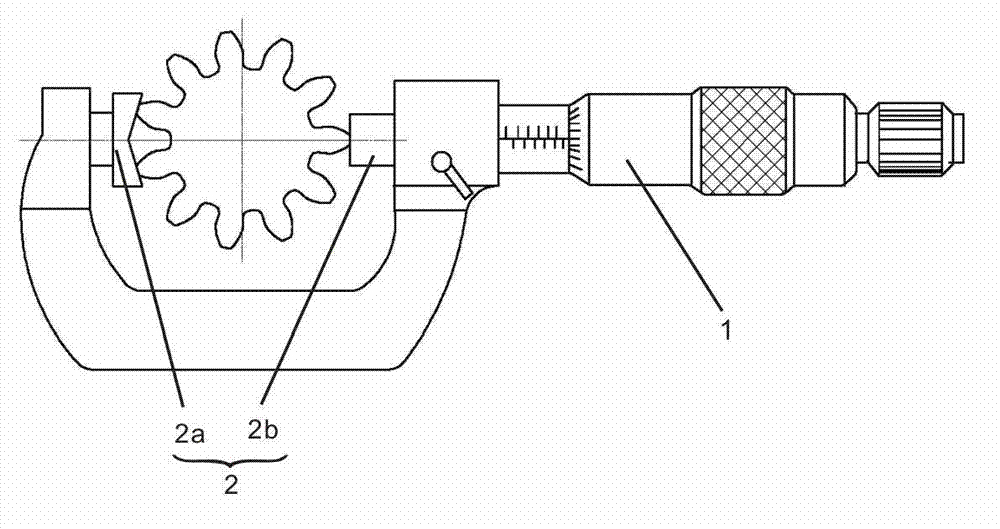

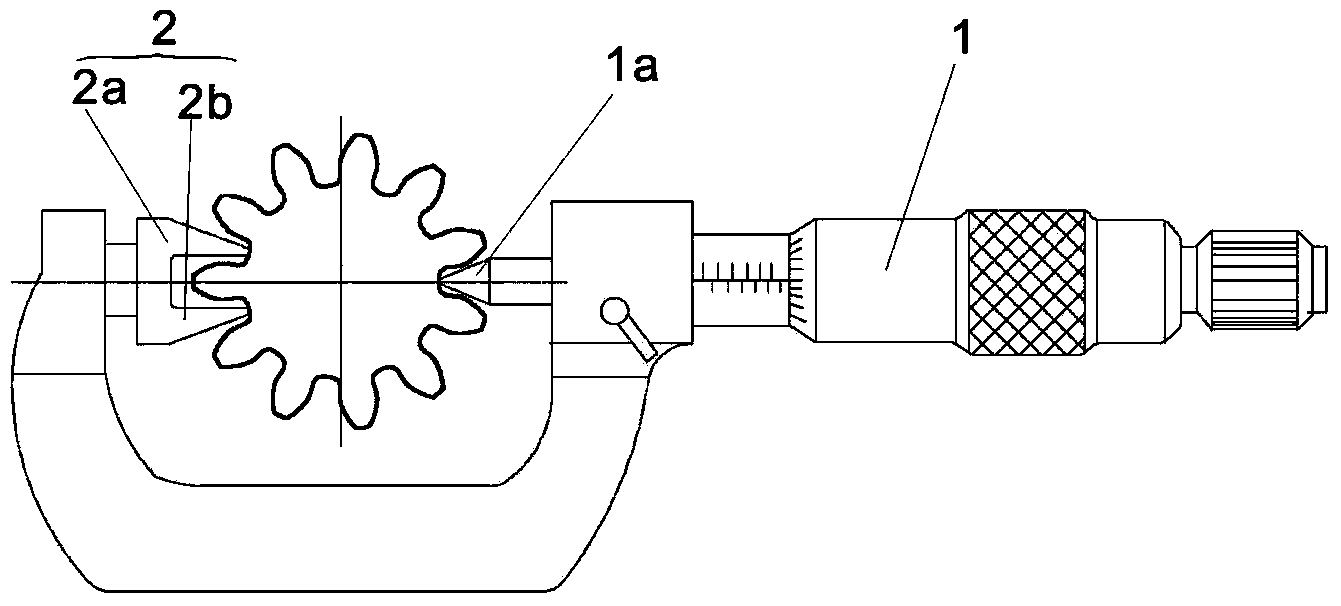

Measurement apparatus used to measure gear diameter and measurement method thereof

InactiveCN103353269ASolve the problem of rapid measurementReduce manufacturing costMechanical diameter measurementsFast measurementMeasurement device

The invention discloses a measurement apparatus used to measure a gear diameter and a measurement method thereof. The measurement apparatus comprises a main scale component and a measurement component. The main scale component comprises a first measurement terminal. The measurement component comprises a second measurement terminal and a third measurement terminal. An end portion of the second measurement terminal is an arc. The end portion of the third measurement terminal is the arc which has an equal diameter with the diameter of a circle where the arc of the end portion of the second measurement terminal is located. By using the apparatus of the invention, a rapid measurement problem of the odd number of the gear with various kinds of types, large and small diameters of a spline on a production field can be solved. The apparatus and the method of the invention possess advantages that production cost is low, convenient and fast and so on. The apparatus and the method are very suitable for production and applications.

Owner:JIANGSU SUN WAY GRP FEIDA CO LTD

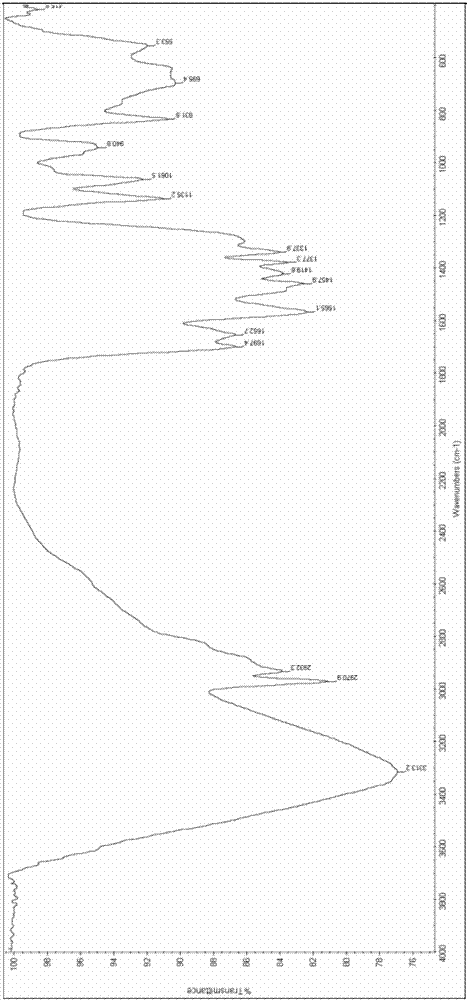

Novel carbon fiber microelectrode and preparation method thereof

InactiveCN108490052AImprove electrochemical performanceHigh yieldMaterial analysis by electric/magnetic meansFiberCarbon fibers

The invention belongs to the technical field of microelectrode preparation and relates to a novel carbon fiber microelectrode and a preparation method thereof. The novel carbon fiber microelectrode comprises carbon fiber wires and copper wires. One end of the carbon fiber wire and one end of the copper wire are connected and cured by a conductive adhesive. The cured carbon fiber wire-copper wire is sleeved by a glass capillary with a tip at one end. The thick end of the glass capillary and the copper wire are fixed through a short wax column. The gap between the tip end of the glass capillaryand the carbon fiber wire are sealed through a short wax column. Wax oil is used as a simple and efficient sealant. The carbon fiber microelectrode with good electrochemical performances can be prepared without a complicated instrument. The novel carbon fiber microelectrode has the characteristics of good sealing effects, high yield, no pollution, good electrochemical performance, etc. The carbonfiber microelectrode has no pollution to an analysis sample, good stability and high reproducibility, utilizes cheap and easily available raw materials, is prepared through simple processes and is suitable for mass production.

Owner:CHONGQING UNIV OF ARTS & SCI

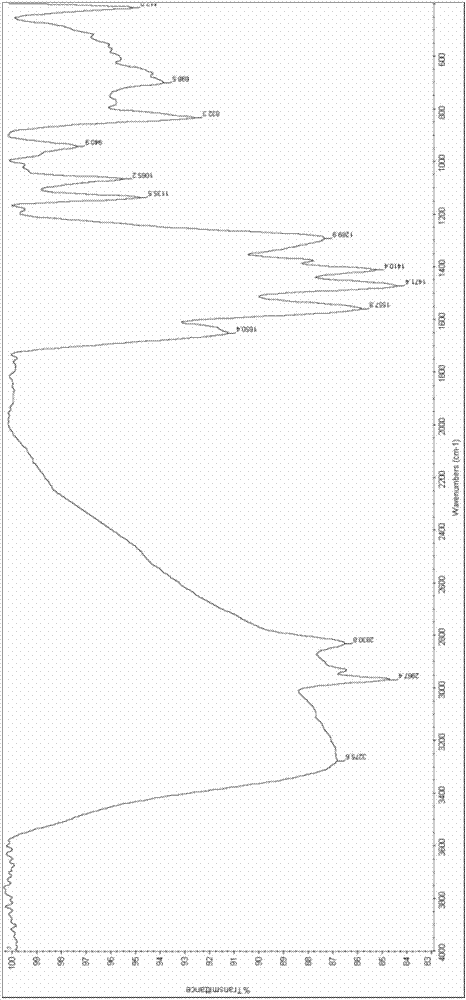

Hydrazino-alcohol amine salts compound and preparation method and application thereof

The invention relates to a hydrazino-alcohol amine salt compound with a general formula (I) as shown in the specification. In an An-[Bm+] p(I) formula, An- is a negative ion which is used as a CO2 donor and has -n valent, wherein n=1, 2 or 3, Bm+ is or comprises an ammonium ion, a hydrazine ion and / or an organic amine B positive ion, m= 1-10, p is greater than 0 and smaller than or equal to n / m, and An- is selected from one or more of the following negative ions: (a) amino formate or hydrazino-formate, (b) carbonate, (c) formate, (d) bicarbonate, (e) organic single carbonate, (f) organic polyamino formate, (g) original formate, or (h) organic polycarbonate, and at least one of An- and Bm+ comprises hydrazine and / or comprises hydrazino or substituted hydrazino. The compound in the general formula (I) is provided with at least one hydroxyalkyl which is connected with an N atom, namely, the compound is provided with alkylol amine residue. The hydrazino-alcohol amine salt compound can be used as a polyurethane foaming agent, and most of foaming agents can be used as a polystyrene foaming agent or a polyvinyl chloride foaming agent.

Owner:SHANDONG UNIV OF TECH +1

Production method of cylindrotheca clostetium

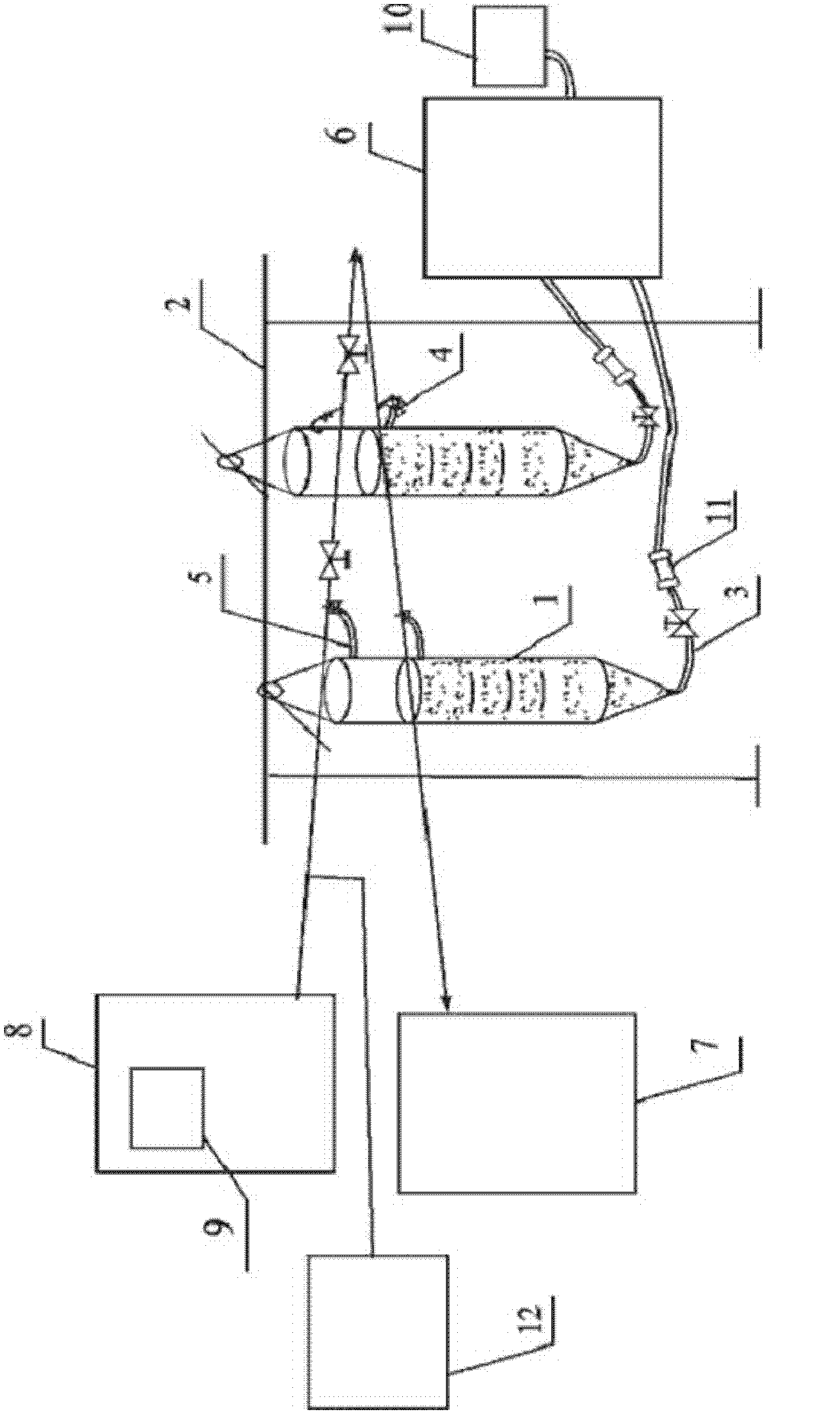

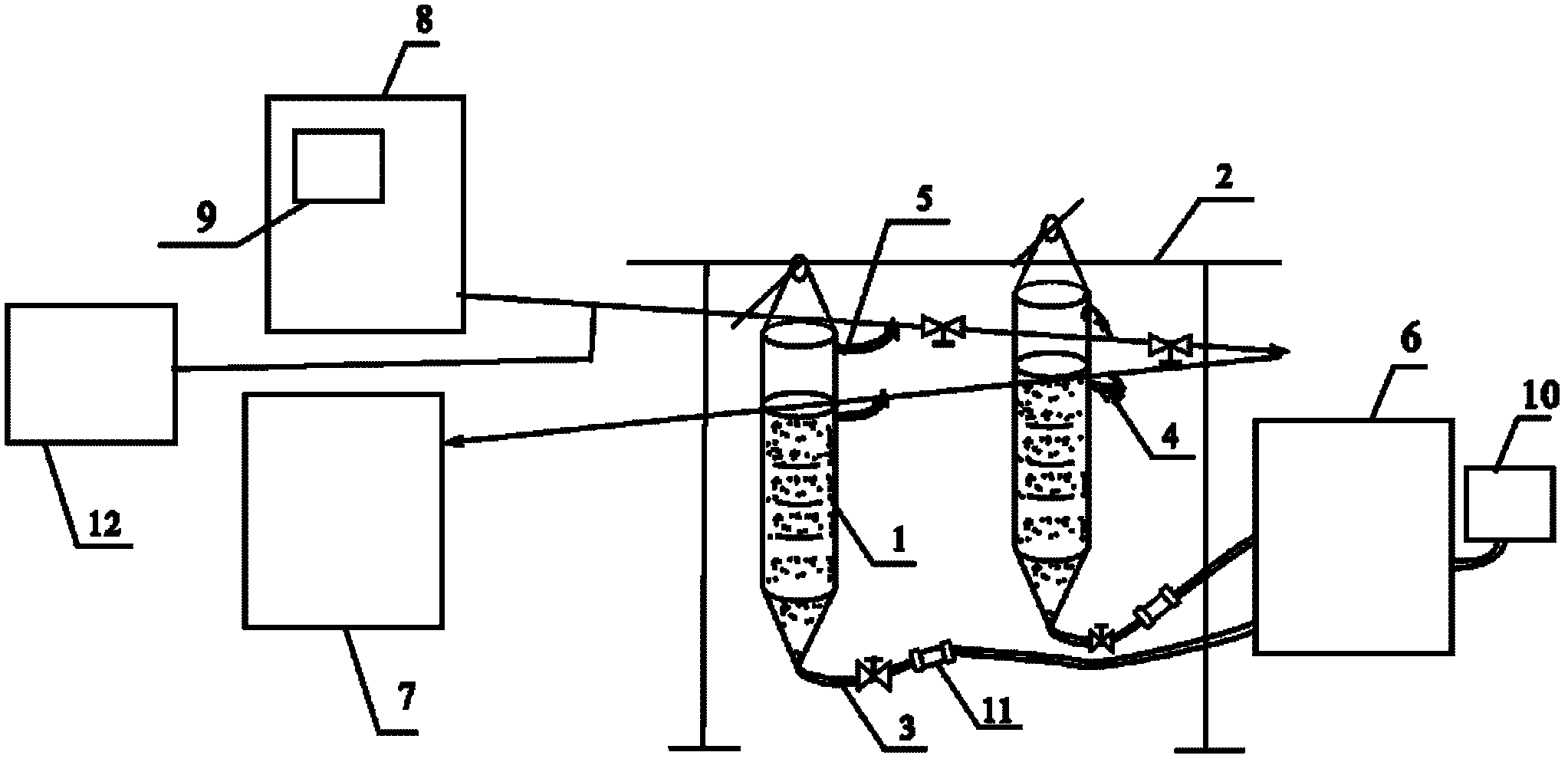

ActiveCN102358885AGrow fastFast growthUnicellular algaeMicroorganism based processesSeawaterPhotobioreactor

A production method of cylindrotheca clostetium comprises the following steps: respectively connecting a culture medium charging system, a material liquid collecting system, and an air supply system with a hanging-bag photo bioreactor so as to form a culture system of cylindrotheca clostetium; adding cylindrotheca clostetium after expansion culture and the culture medium into the reactor; continuously charging the culture medium with a constant flow rate and continuously injecting air; during the culture process, controlling the seawater temperature to be 10 DEG C-35 DEG C, the salinity to be20-30, and the illuminance to be 3000-10000 lx, controlling the pH of the culture medium to be within 7.8-8.4; continuously collecting mature cylindrotheca clostetium under the action of continuous air injection. The invention not only establishes a mature cylindrotheca clostetium expansion culture method, but also establishes a fully-closed continuous culture method of cylindrotheca clostetium based on the established expansion culture method, and has the advantages that the method accords with the physiological characteristics and ecological habits of cylindrotheca clostetium; during cylindrotheca clostetium culture, the whole culture process is clean, continuous, controllable, has high culture efficiency, and is applicable to the characteristics of production application.

Owner:QINGDAO QIHAO NUTRITION TECH

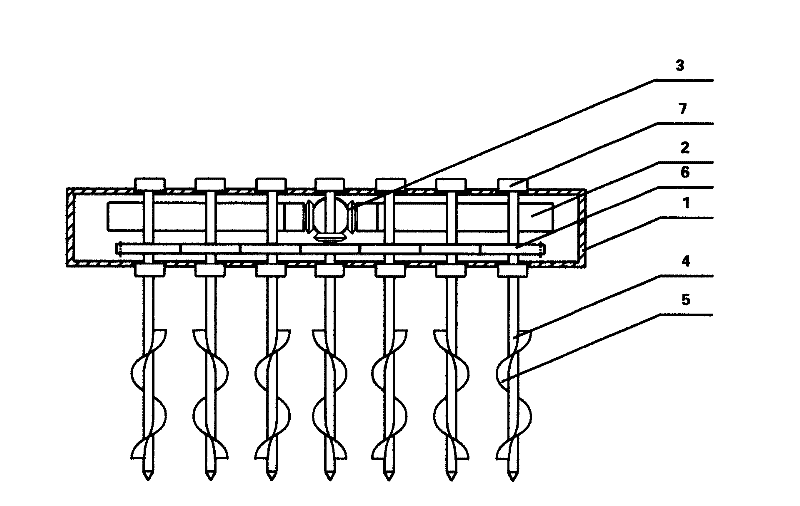

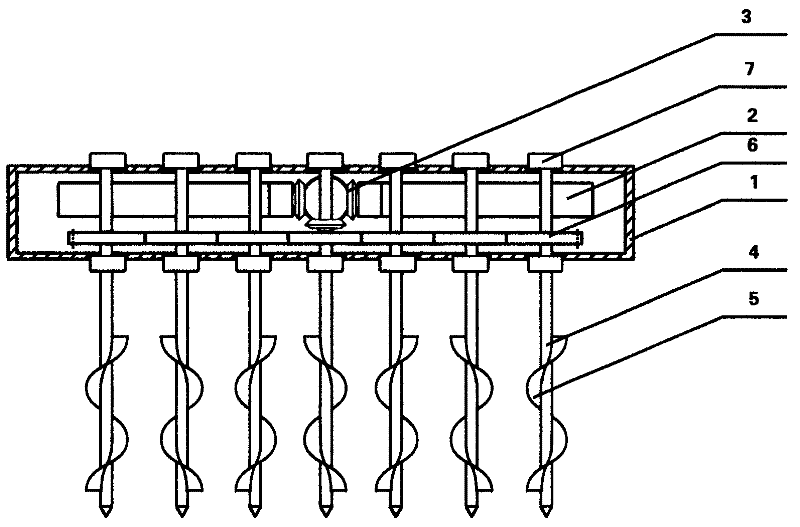

Plow

InactiveCN102197720ASimple structureSuitable for production applicationsTilling equipmentsAgricultural engineering

The invention discloses a plow which relates to the field of agricultural production, in particular to a plow. The invention provides the plow to overcome the deficiencies of poor soil loosening effect and high consumption of the traditional soil loosening method. The plow comprises a driving / vibrating assembly and a spiral body assembly. The plow disclosed by the invention has a simple structure, is easy to popularize, and is suitable for production and application.

Owner:吴小华

Organic alcohol amine salt compound and application thereof serving as foaming agent

The invention discloses an organic alcohol amine salt compound with a general formula (I) of A<n>[B<m+>]p. In the formula (I), A<n> is a negative ion which serves as a CO2 donor and has -n valence, and n is equal to 1, 2 or 3; B<m+> is or includes ammonium ion, hydrazine ion and / or organic amine B positive ion; m is equal to 1 to 10; p is greater than 0 and less than or equal to n / m; the A<n> is selected from one or more of the following negative ions: (a) carbamate or hydrazino-formate; (b) carbonate; (c) formate; (d) bicarbonate radical; (e) organic monocarbonate; (f) organic polycarbamate; (g) original formate; or (h) organic polycarbonate. The compound with the general formula (I) contains 25-95 wt% of salt of alcohol monamine and salt of alcohol diamine. The compounds can serve as polyurethane foaming agents, and most of the foaming agents can serve as polystyrene foaming agents or polyvinyl chloride foaming agents.

Owner:SHANDONG UNIV OF TECH +1

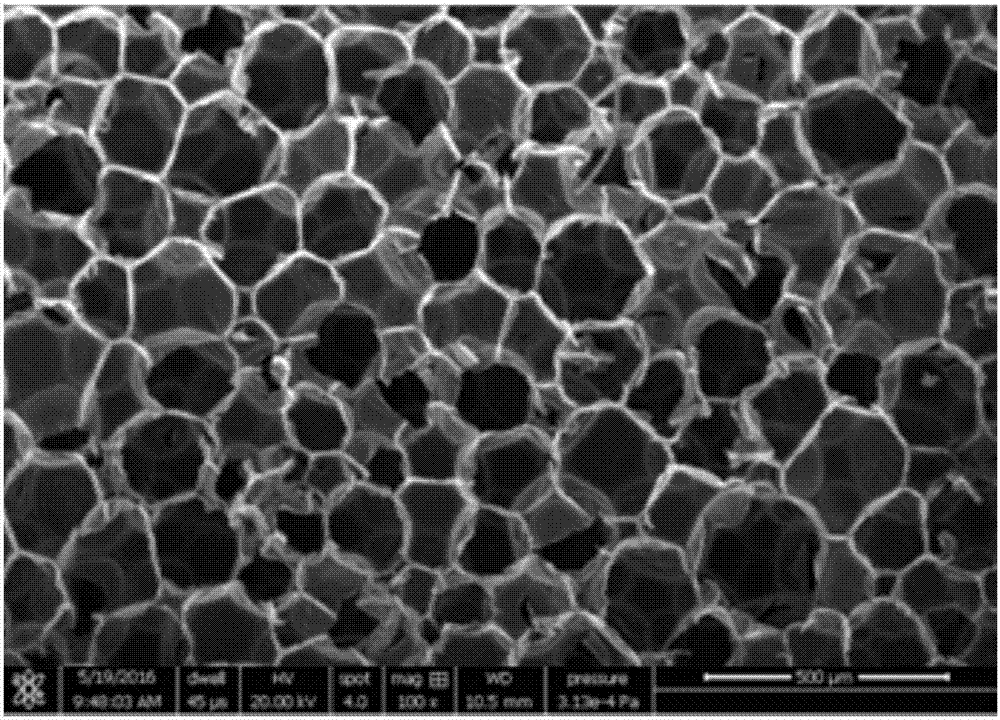

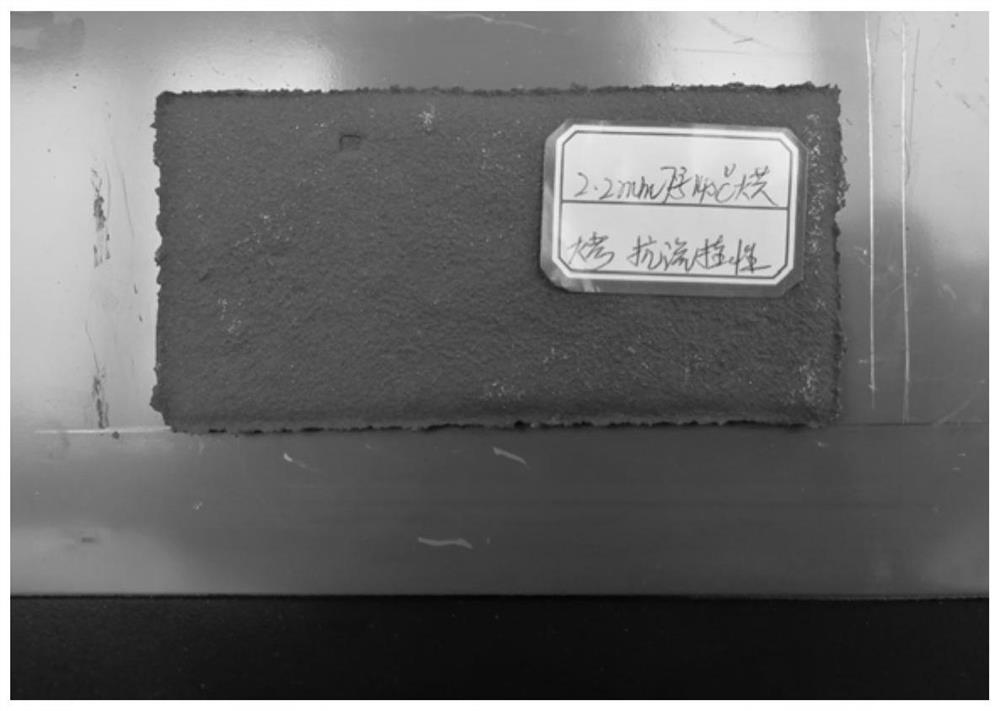

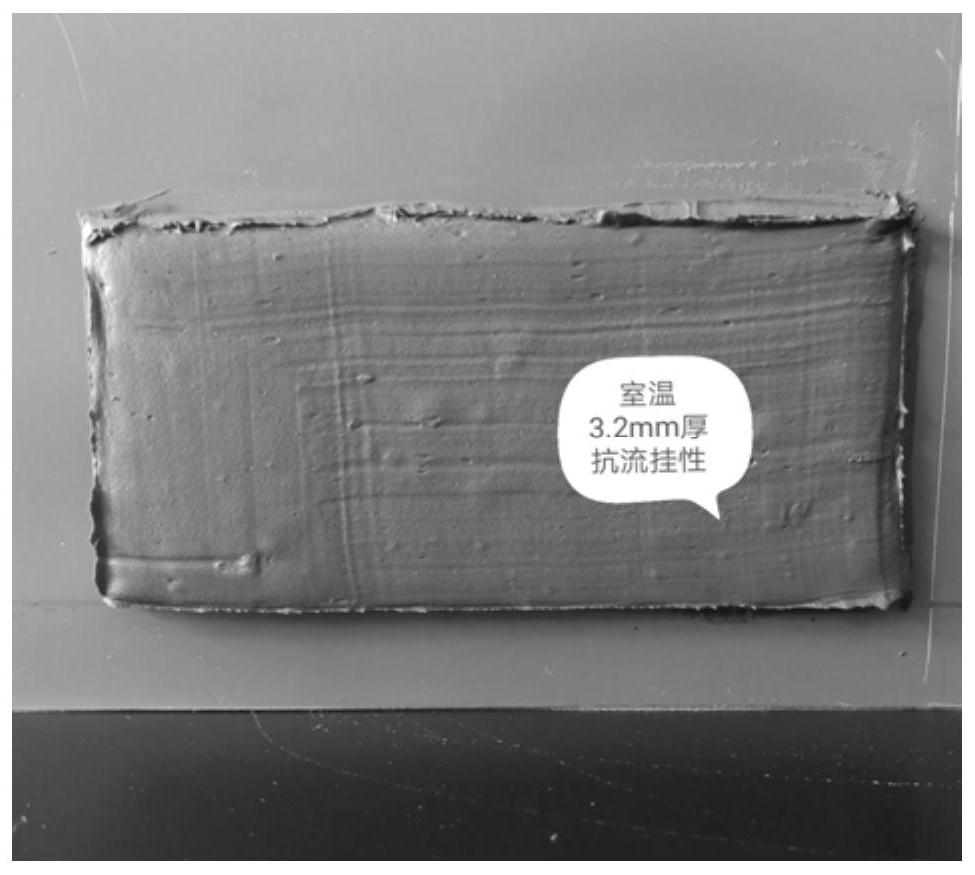

Bakeable thick paste type water-based damping coating for automobile and preparation method of coating

InactiveCN112680047ASuitable for production applicationsImprove high temperature resistanceCoatingsEmulsionPhysical chemistry

A bakeable thick paste type water-based damping coating for an automobile comprises 20-45wt% of water-based acrylic emulsion , 2.5-6 wt% of an auxiliary agent; 5-30 wt% of mica powder; 35-55 wt% of calcium carbonate; 5-35 wt% of a functional filler; and the balance of deionized water. The invention also provides a preparation method of the damping coating, and the method comprises the following steps: sequentially adding the water-based acrylic emulsion, deionized water and assistants under a low-speed stirring condition, regulating the pH value of the system to 8.0-9.0, sequentially adding a functional filler, mica powder and calcium carbonate under a medium-speed stirring condition, uniformly stirring, and stirring under a high-speed stirring condition to obtain the bakeable thick paste type water-based damping coating for the automobile. The damping coating provided by the invention can be directly baked and cured at a high temperature after thick coating (the thickness of a wet film is 2-4.5 mm), has high solid content, a wide temperature range and excellent vibration and noise reduction effects, and can effectively meet the requirements of production and application of an assembly line of an automobile main engine plant.

Owner:重庆德天汽车新材料研究院有限公司

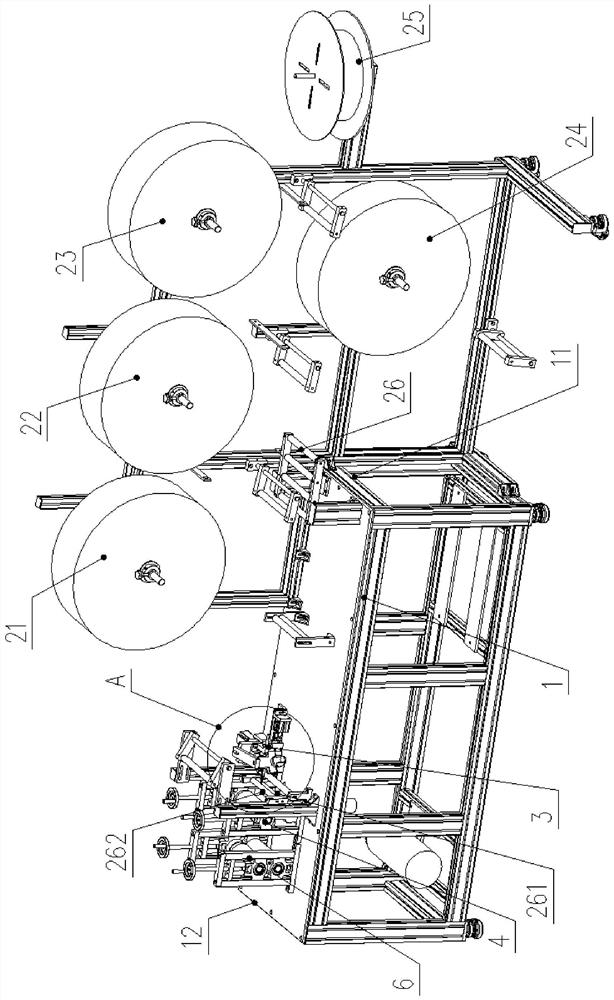

Mask manufacturing method and mask production system applying same

According to the mask piece manufacturing method and the mask production system applying the same, the mask piece manufacturing method comprises the following steps of: S1, outputting mask fabric withat least two layers; S2, outputting the cut nose bridge strip between the two layers of mask fabrics; S3, carrying out welding treatment and cutting treatment on the mask fabric output from each layer and the nose bridge strip, so that the mask fabric is welded and cut into a mask piece part and a waste part, the nose bridge strip is arranged between the mask piece parts, and the mask piece partsand the waste part are in a partial connection state; S4, pressing and leveling treatment is conducted on the mask piece parts; S5, completely separating the mask piece parts from the waste part to obtain a mask sheet product. The mask production system can directly, accurately and efficiently produce mask pieces with built-in nose bridge strips of different specifications through the applicationof the mask piece manufacturing method, and the produced mask pieces have the advantages of being high in welding precision and smooth in state.

Owner:FOSHAN FODA HUAKANG TECH CO LTD

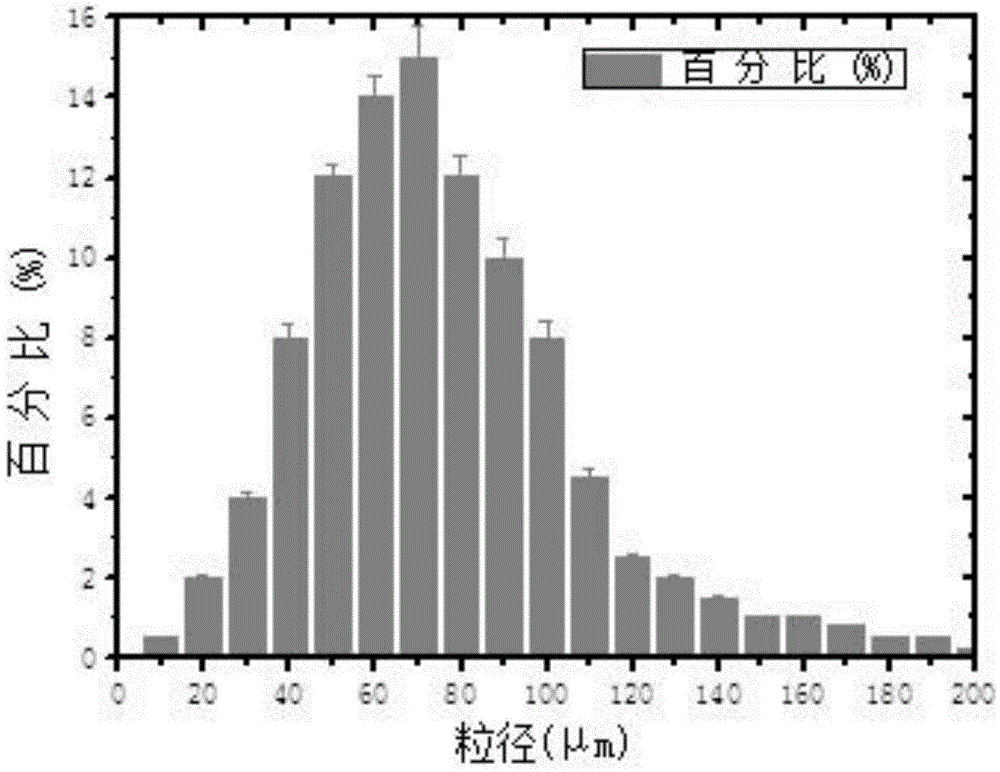

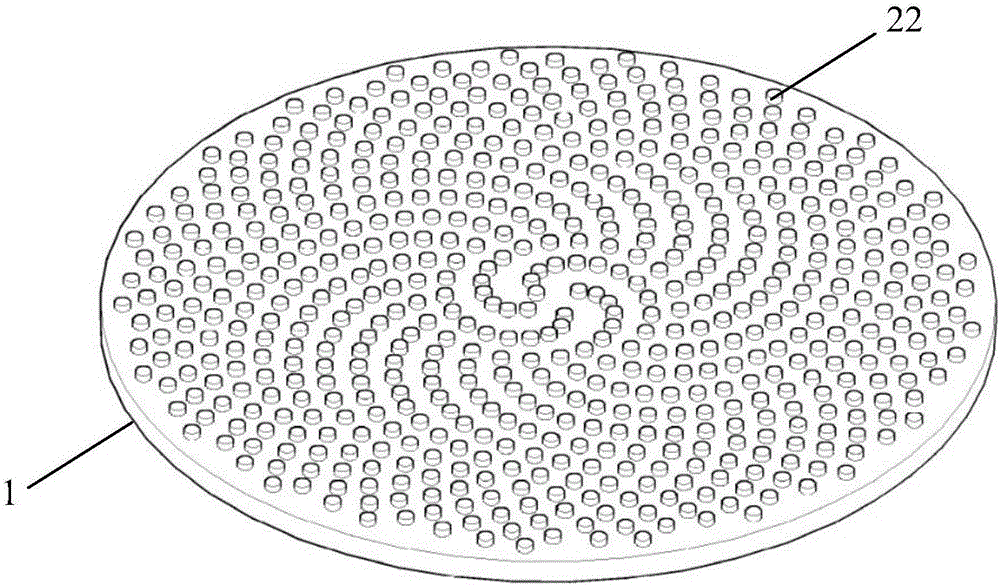

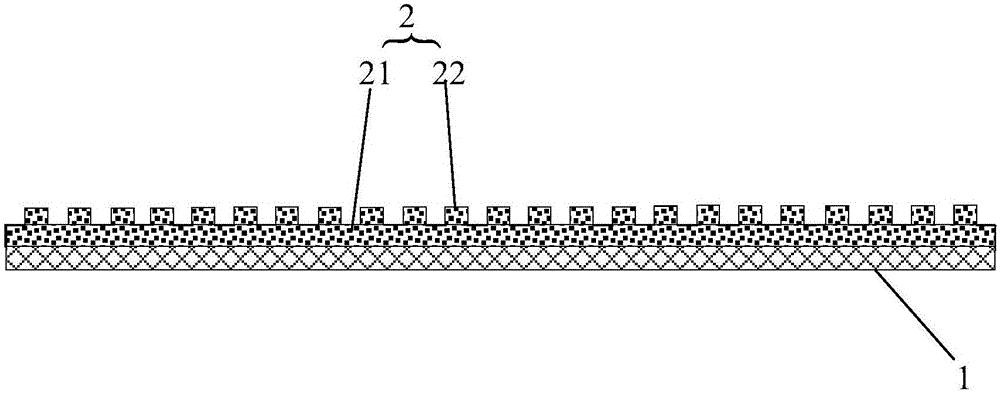

Resin concretion diamond micro-powder phyllotaxy grinding disc and manufacturing method

InactiveCN106378700AAvoid cloggingEven and smooth entryGrinding devicesLapping toolsConcretionMachining process

The invention relates to a resin concretion diamond micro-powder phyllotaxy grinding disc. The grinding disc comprises a resin base layer and a resin-diamond micro-powder working layer, the resin-diamond micro-powder working layer at least partially forms a columnar phyllotaxy structure, and phyllotaxy arrangement of the columnar structure meets a track uniformity theory based on H.Vogel plane phyllotaxy model. The invention further provides a manufacturing method of the above grinding disc. A partially-cured resin base layer is firstly formed; secondly, a partially-cured resin-diamond micro-powder layer is formed on the partially-cured resin base layer; a phyllotaxy pressing plate with above phyllotaxy arrangement cylinder holes is pressed on the resin-diamond micro-powder layer so that the corresponding columnar phyllotaxy structure can be at least partially formed; and finally, curing is carried out. The grinding disc has the effects of being even in grinding track distribution and smooth in cooling liquid flowing, ground scraps formed in the machining process can be discharged in time, the grinding quality and the grinding efficiency can be greatly improved, and the grinding disc is prevented from being blocked. The manufacturing method is simple and practicable.

Owner:HUAQIAO UNIVERSITY

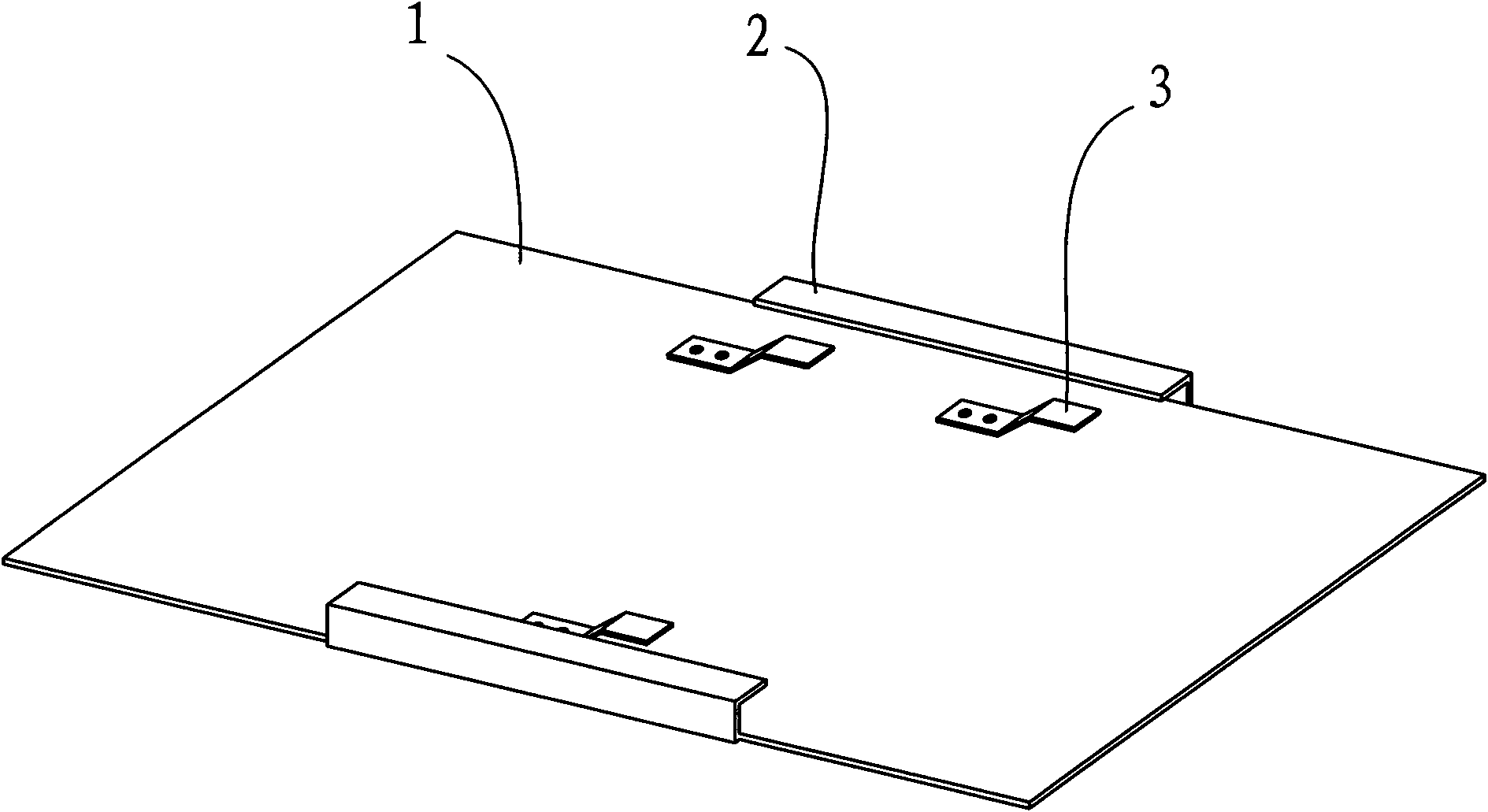

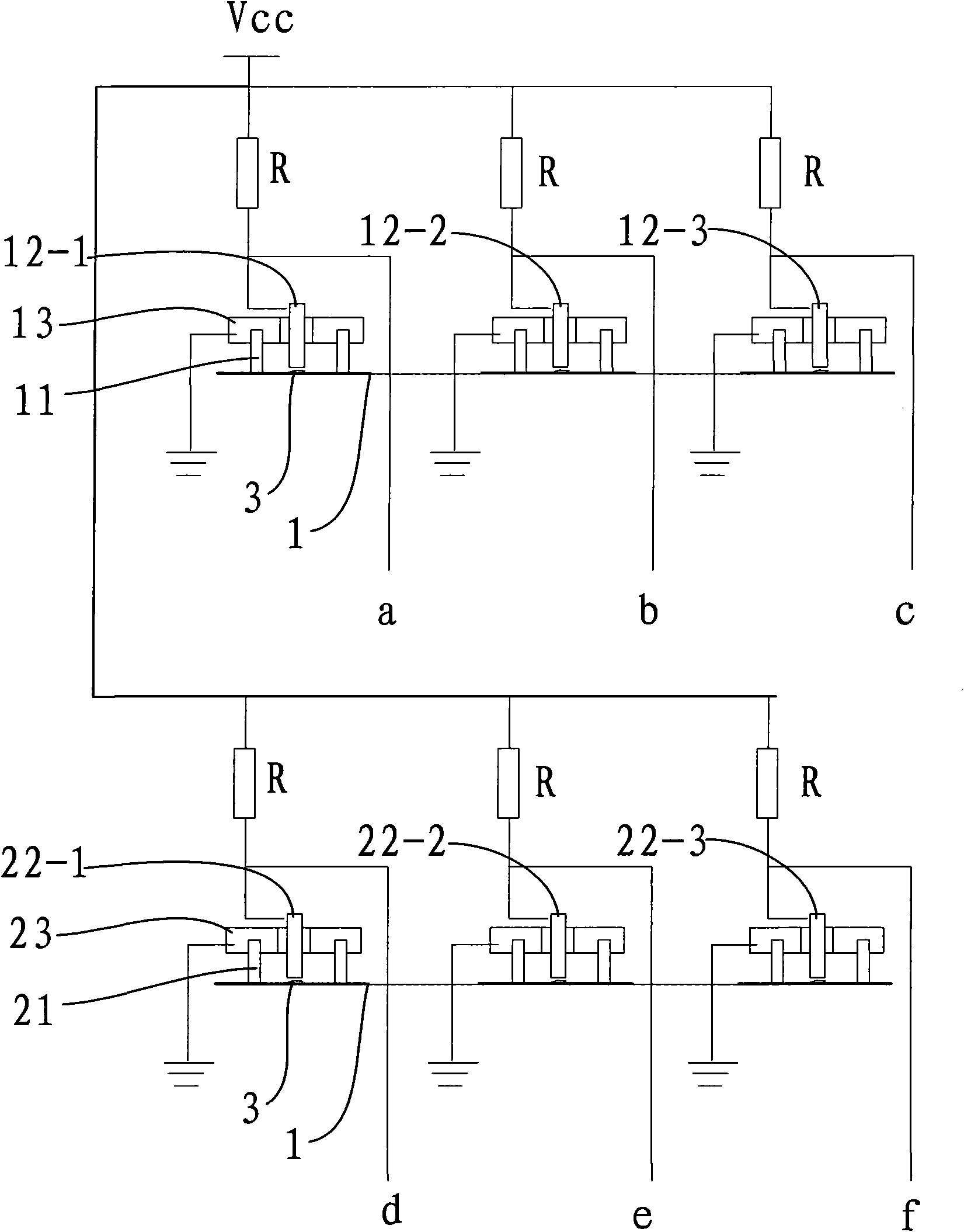

Method and device for detecting height of spring plates on slide cover plate on line and jigs

ActiveCN101986096AMeet testing needsReliable test resultsUsing electrical meansSortingProduction lineLower limit

The invention relates to a detection device, in particular to a method and device for detecting height of spring plates on a slide cover plate on line and a jigs. The invention has simple structure, is convenient and rapid in detection and is suitable for production lines. The method comprises the following steps: 1. arranging an upper limit height detection jig and a lower limit height detection jig which are provided with spring plate contact columns with quantity equal to that of the spring plates; 2. placing the slide cover plate welded with the spring plates on the upper limit height detection jig and the lower limit height detection jig respectively and carrying out energization to detect and record the level of each contact column; and 3. judging whether the level of all the contact columns on the upper limit height detection jig is high level and whether the level of all the contact columns on the lower limit height detection jig is lower level, if so, the product is qualified, and if not, the product is disqualified.

Owner:DONGMING XINGYE SCI TECH CO LTD

Water-soluble fertilizer and preparation method thereof

InactiveCN107793262AEasy to prepareMild operating conditionsAmmonium salt fertilisersOrganic fertilisersGluconic acidFertilizer

The invention provides water-soluble fertilizer and a preparation method thereof. The water-soluble fertilizer is mainly composed of titanium gluconate complex and alkaline substance, wherein the titanium gluconate complex is prepared from gluconic acid substance and titanium compound according to a coordination molar ratio of (2-5):1. The preparation method includes: (A), enabling the gluconic acid substance and the titanium compound to be in coordination, and allowing reaction at 25-60 DEG C for 1-3h to obtain the titanium gluconate complex; (B), aging for 1-3d, neutralizing, settling, filtering, and adding other substances to obtain the water-soluble fertilizer. Gluconic acid is used as a ligand to coordinate with titanium ions to form titanium gluconate complex functional fertilizer. The fertilizer is nontoxic, can be better absorbed and utilized by crops, is environment-friendly, more reasonable in element proportioning, capable of improving yield and quality of the crops and freeof causing soil caking and has the advantages of being capable of managing soil and environment-friendly.

Owner:RI ZHENG JIU AN SCI BEIJING TECH CO LTD

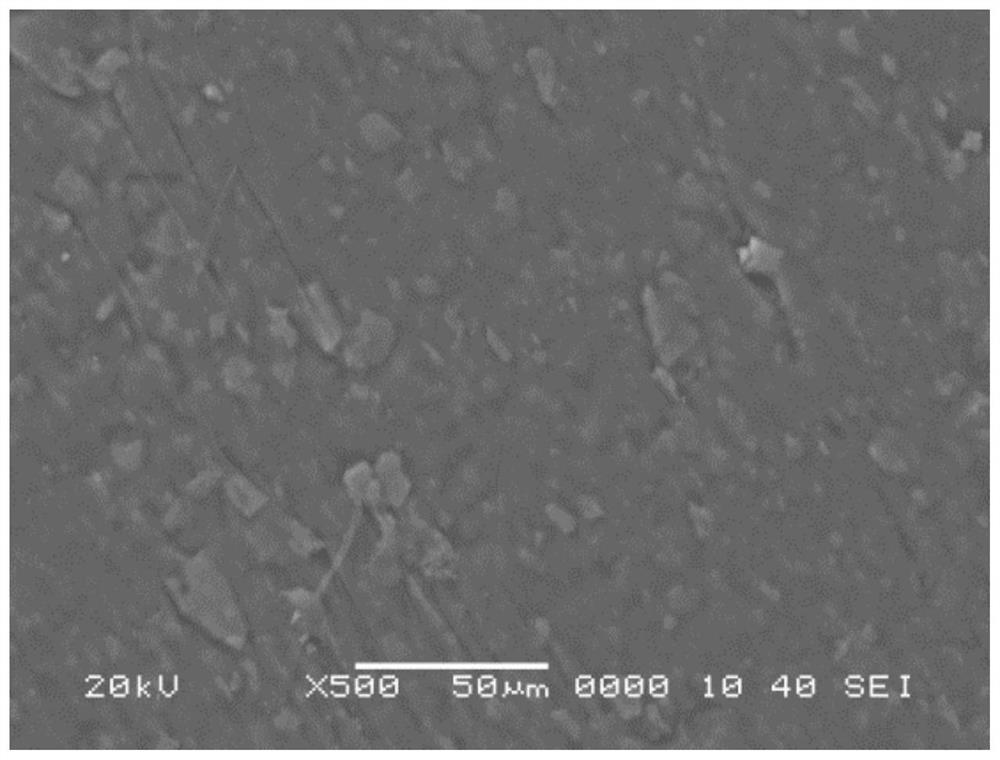

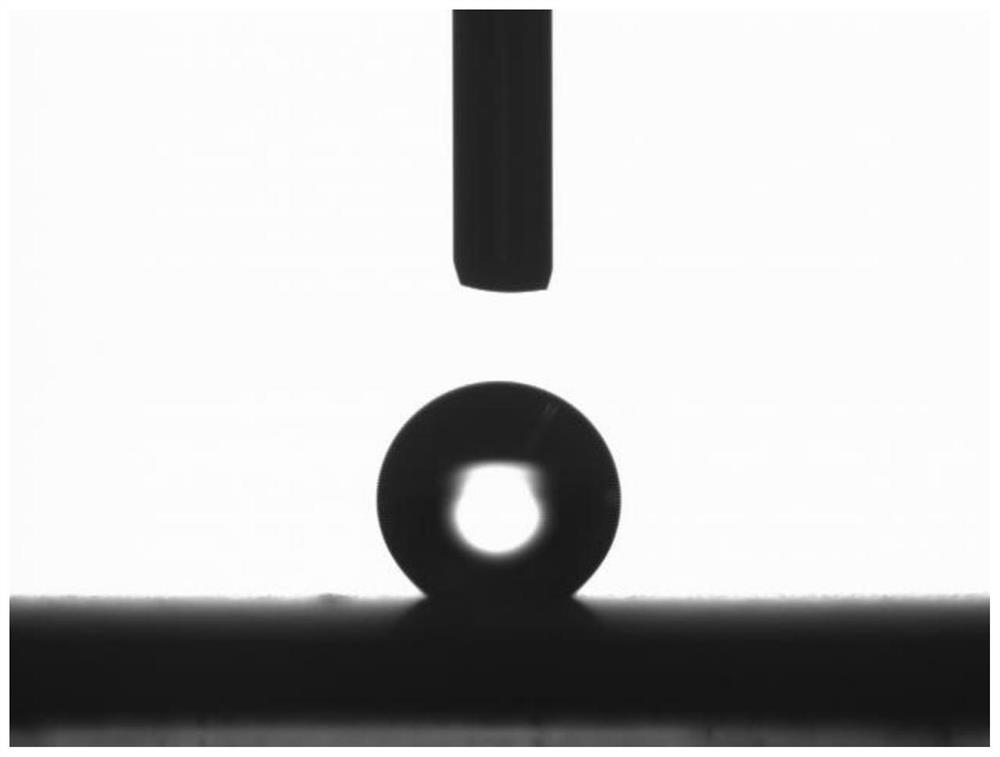

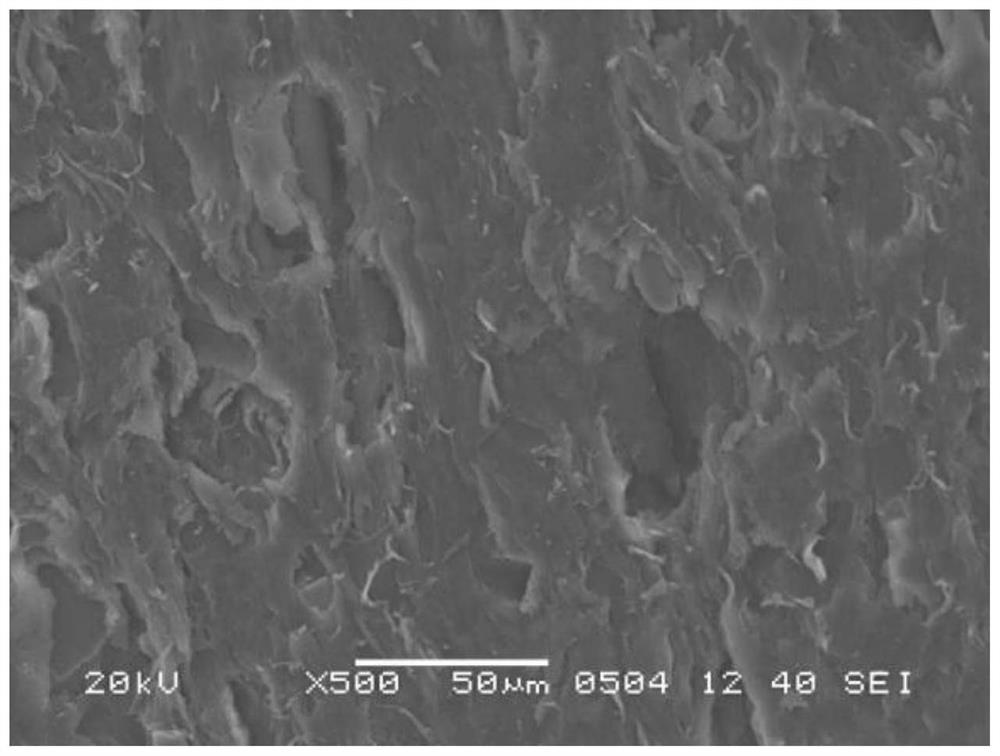

Environment-friendly method for conducting surface roughening on liquid crystal polymer devices before chemical plating

PendingCN112647065APost-processing is simpleSimplify operation stepsLiquid/solution decomposition chemical coatingChemical platingOxidizing agent

The invention discloses an environment-friendly method for conducting surface roughening on liquid crystal polymer devices before chemical plating. The environment-friendly method for conducting surface roughening on the liquid crystal polymer devices before chemical plating comprises the following steps: placing liquid crystal polymer (LCP) materials in potassium persulfate roughening liquid, introducing ozone, and conducting roughening treatment under the action of ultrasonic waves; and placing liquid crystal polymers subjected to roughening treatment in an oxidant-removing solution, and then taking out the liquid crystal polymers for cleaning to obtain roughened surfaces. According to the environment-friendly method for conducting surface roughening on the liquid crystal polymer devices before chemical plating, by using low-concentration potassium persulfate as the roughening liquid in combination with ring opening and oxidizing by the ozone and the cavitation and crushing action of the ultrasonic waves, the surfaces of the compound materials are subjected to roughening treatment, adopted technology methods and an adopted formula are environmentally friendly, no flammable, combustible or carcinogenic solvents are used, no high-temperature high-pressure operation is conducted, conventional equipment of an electroplate factory is adopted, the operation steps are simple, and the environment-friendly method for conducting surface roughening on the liquid crystal polymer devices before chemical plating has a good effect, and is especially suitable for large-scale surface roughening treatment of LCP devices of the fields of electronics, communication and micro-electronic machines.

Owner:JIANGSU UNIV OF SCI & TECH

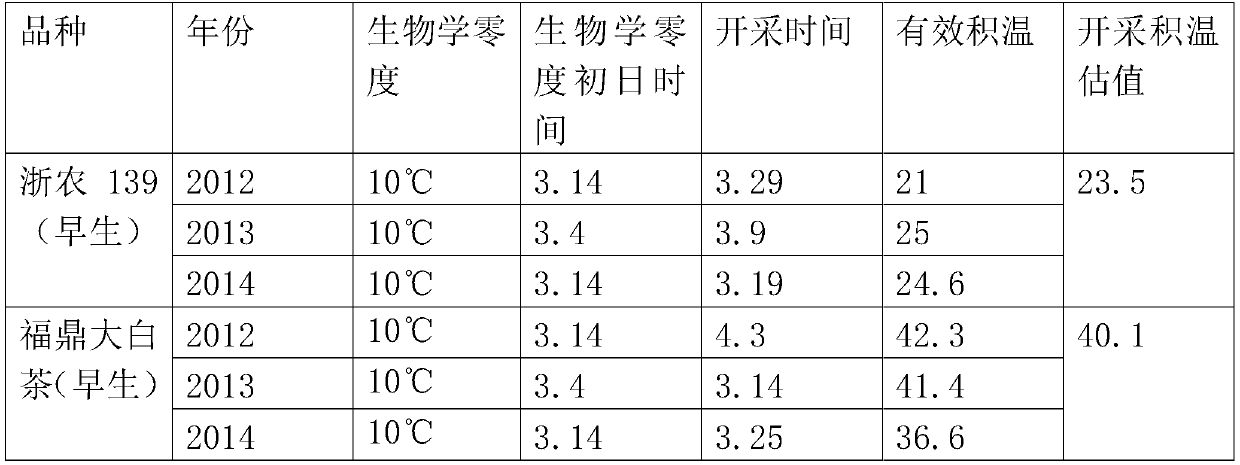

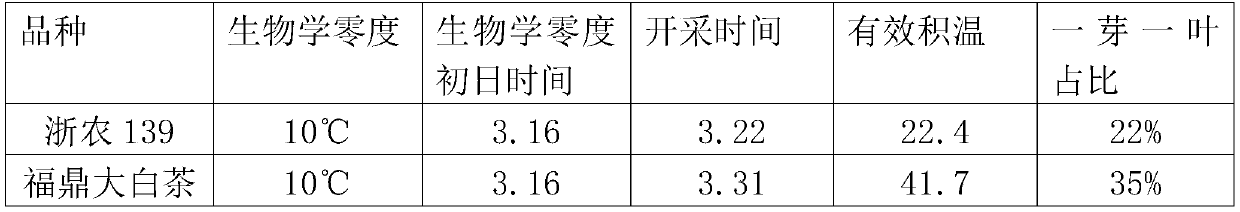

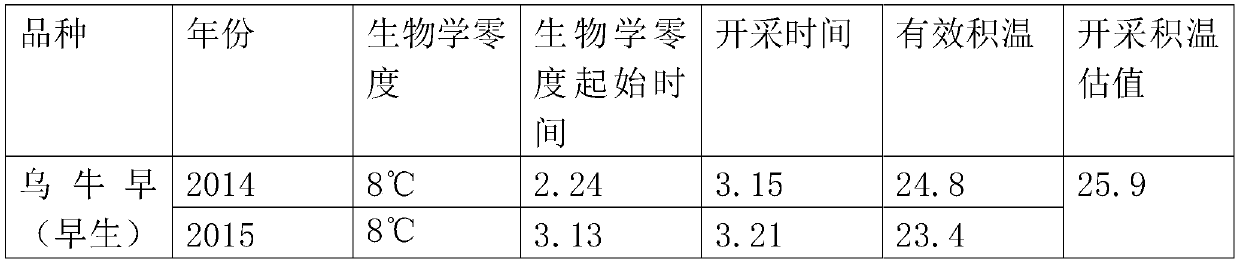

Tea tree picking period prediction method based on Internet of Things technology

ActiveCN110009149ASolve the inability to evaluate the temperature specificity of the tea garden environment caused by the microclimate environmentSuitable for production applicationsForecastingComplex mathematical operationsObservation pointMedicine

The invention belongs to the field of tea production and cultivation, and particularly relates to a tea tree mining period prediction method based on the Internet of Things technology. For a long timein spring tea production, when 20%-40% of tea trees have one bud and one leaf, the period is set as the picking period wherein the picking period is mainly determined by field observation. The investigation workload in the tea picking period is large, and production arrangement is not facilitated. Accorrding to the method, when 20%-40% of tea trees haveone bud and one leaf, corresponding tea treecanopy effective accumulated temperature is used as a mining period prediction index, agricultural meteorological parameters of observation points are collected in a tea garden in real time through the Internet of Things technology, the tea leaf picking period is predicted according to meteorological factor indexes of different types of varieties in the mining period, the investment is low, the operation is easy, the tea leaf production management level can be effectively improved, and economic benefits are improved. The method comprises the following steps: 1, calculating meteorological indexes and picking accumulated temperature estimation values in a tea picking period; 2, collecting agricultural meteorological parameters; and 3, predicting the tea picking period.

Owner:无锡市茶叶品种研究所有限公司 +1

Mushroom planting waste culture medium produced organic fertilizer and preparation method thereof

InactiveCN109574723AImprove structural performanceLow costCalcareous fertilisersBio-organic fraction processingCalcium hydroxideContinuous fermentation

The invention discloses a mushroom planting waste culture medium produced organic fertilizer. A preparation method of the mushroom planting waste culture medium produced organic fertilizer comprises the steps sequentially including, debagging, drying and then crushing mushroom planting waste culture mediums; adding in an appropriate amount of ammonium hydrogen carbonate or powder calcium hydroxideor a mixture of the ammonium hydrogen carbonate and the powder calcium hydroxide, and regulating the pH to 5.5-8.5; proportionally and uniformly mixing the crushed mushroom planting waste culture medium and straw decomposing agent to obtain a mixed material; stacking the mixed material into bars for decomposition, covering the stacked mixed material with plastic films, increasing the stacked mixed material to 60-70 DEG C for continuous fermentation for 7-15 days; uniformly mixing bentonite into the fermented materials, and then performing pelletizing to obtain fertilizer pellets; drying the fertilizer pellets into a drying cylinder to obtain dried fertilizer pellets; cooling the dried fertilizer pellets inside a cooling cylinder to obtain cooled fertilizer pellets; performing grain size screening on the cooled fertilizer pellets to obtain the finished organic fertilizer.

Owner:郧西县金穗肥业中心

Foaming agent comprising polyamine and alcohol amine salt and use in polyurethane continuous sheet foam material

ActiveCN109422907AImprove performanceStable storageOrganic compound preparationAmino compound preparationAlcoholFoaming agent

The invention discloses a foaming agent comprising a polyamine and an alcohol amine salt and use in a polyurethane continuous sheet foam material. The foaming agent is a polyurethane foaming agent comprising a polyamine salt and an alcohol amine salt. The foaming agent comprises: 1) a first compound mixture (M1) comprising organopolyamine salt compounds of a following general formula (I): A<->B<+>(I), wherein B<+> is a cation of an organic polyamine B, and A<-> is CO<3><2->, HCO<3><->, or a combination of CO<3><2-> and HCO<3><->; and 2) a second compound mixture (M2) containing N-monohydroxypropyl / monohydroxyethyl-ammonium carbonate compounds having a general formula (II) and N,N'-di(hydroxypropyl / hydroxyethyl)-ammonium carbonate compounds having a general formula (III): (RN<+>H<3>)(N<+>H<4>)CO<3><2-> (II), or (RN<+>H<3>)<2>CO<3><2->(III), wherein R is a combination of hydroxypropyl and hydroxyethyl, and the molar ratio of the monoolamine compound of the formula (II) to the diolaminecompound of the formula (III) is 1:0 to 1:2.5. The foaming agent is suitable for use in preparation of the polyurethane continuous sheet foam material.

Owner:BUTIAN NEW MATERIAL TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com