Heat-treatment method and equipment for nickel-titanium shape memory alloy

A heat treatment method and technology of heat treatment equipment, applied in the direction of heat treatment equipment, heat treatment process control, process efficiency improvement, etc., can solve the problem that alloy wires cannot be heated by differential temperature gradients, heat preservation, nickel-titanium shape memory alloy wires with small diameters, high Frequency induction heating equipment can not be realized and other problems, to achieve the effect of short time, few process steps, low cost of equipment and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

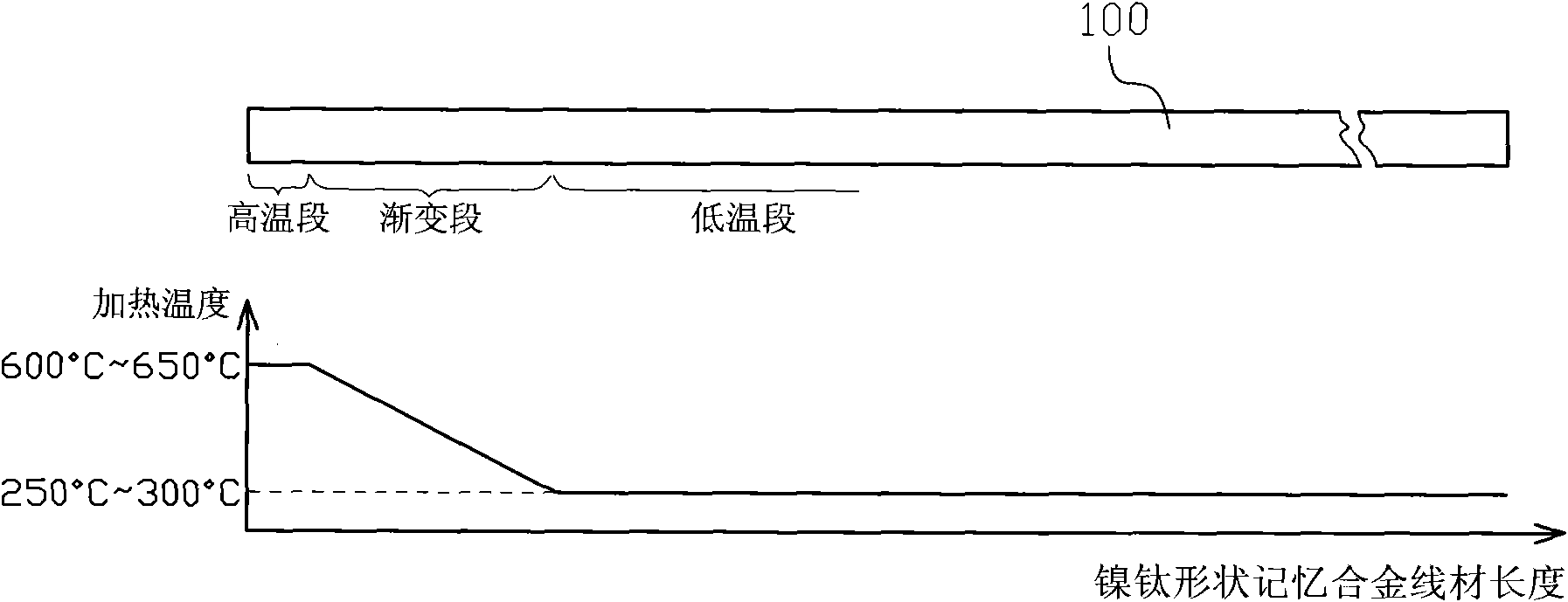

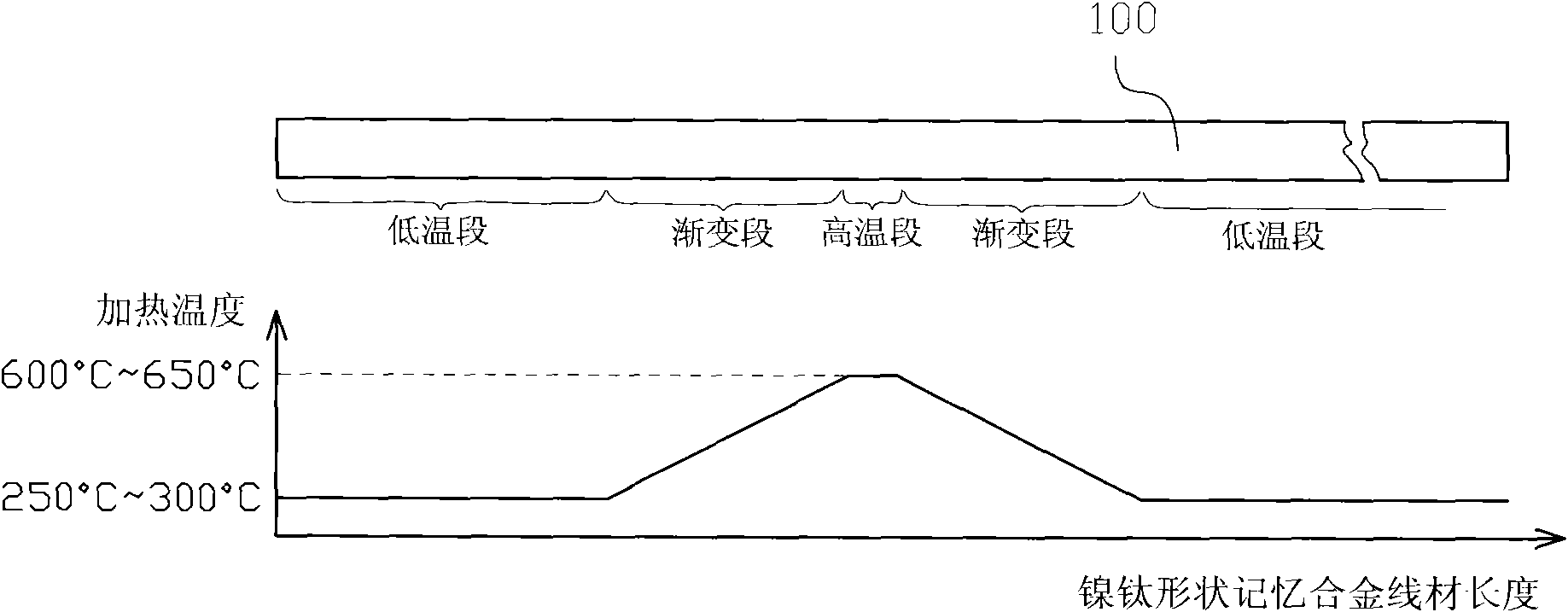

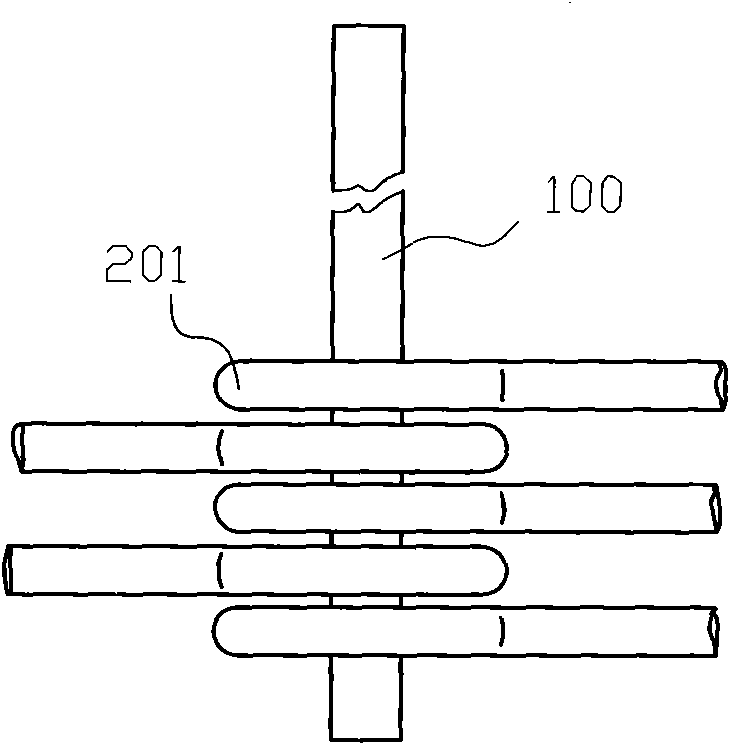

[0025] The heat treatment method of the present embodiment comprises the following steps and processing conditions: (1), the diameter is 0.6~ A nickel-titanium shape memory alloy wire rod with a thickness of 4.0 mm and an atomic ratio of 51.0 to 55.0% of Ni is uniformly preheated to a temperature of about 250° C. to 300° C. (2), if image 3As shown, each tuner coil 201 of 5 high-frequency induction heaters that can independently set the firepower is formed into a tuner coil group at a close distance with the coaxial center. The 5 high-frequency coils are set to the heating temperature of nickel-titanium shape memory alloy wire with continuous differential temperature gradient. ℃, and the heating temperature of the remaining coils is set in an orderly and step-by-step manner to form a continuous differential temperature gradient. For example, the lowermost high-temperature fire ring is set at 620°C, and the remaining four fire rings are set at a step-by-step temperature di...

Embodiment 2

[0031] Its steps and process conditions are different from embodiment one, and step (2) is: by a high-frequency induction heating machine, its high-frequency fire ring is wound into a spiral multi-circle, and the diameter of the fire ring 202 is from one end to the other end Gradually from small to large (such as Figure 5 shown), or the diameter of the fire ring 203 gradually changes from the small diameter of the middle ring portion to the large diameter of the two end ring portions (such as Figure 6 shown), it is measured from the sample of the nickel-titanium shape memory alloy wire to be treated that the heating temperature in the small diameter fire ring part, that is, the high temperature part, is 600 ° C ~ 650 ° C, while in the large diameter fire ring part That is, the heating temperature of the low-temperature part is 250°C to 300°C, and the gradual change of the coil diameter forms a continuous differential temperature gradient heating temperature for the alloy wir...

Embodiment 3

[0034] Its steps and process conditions are different from Embodiment 1 in that step (2) is: by a high-frequency induction heating machine, its high-frequency head fire ring is wound into a helical multi-circle of at least three circles, and the fire circle spiral 204 The pitch gradually increases from small to large from one end to the other (such as Figure 7 shown), or the pitch of the fire ring spiral 205 gradually changes from a small pitch in the middle circle to a large pitch in both ends (such as Figure 8 shown), the temperature measured from the sample of nickel-titanium shape memory alloy wire to be processed is 600°C to 650°C in the small-pitch fire ring part, that is, the high-temperature part, while in the large-pitch fire ring The heating temperature of the low temperature part is 250°C to 300°C, the gradual change of the pitch of the coiled coil forms a continuous differential temperature gradient heating temperature for the alloy wire, and the section of the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com